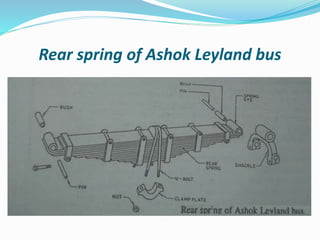

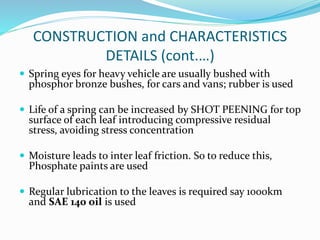

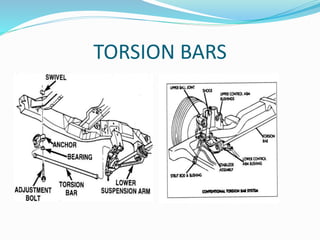

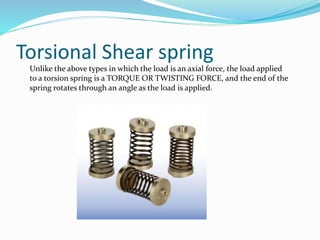

This document provides information on various automotive suspension systems. It discusses the need for suspension systems to provide vertical compliance over uneven roads and maintain proper wheel alignment. It describes different types of suspension springs including leaf springs, coil springs, and torsion bars. Details are given on the construction and characteristics of leaf springs and coil springs. Independent suspension, rubber suspension, and hydro-elastic suspension systems are also overviewed. Shock absorbers and their role in damping vibration are explained. Factors relating to vehicle comfort provided by suspension systems are discussed.