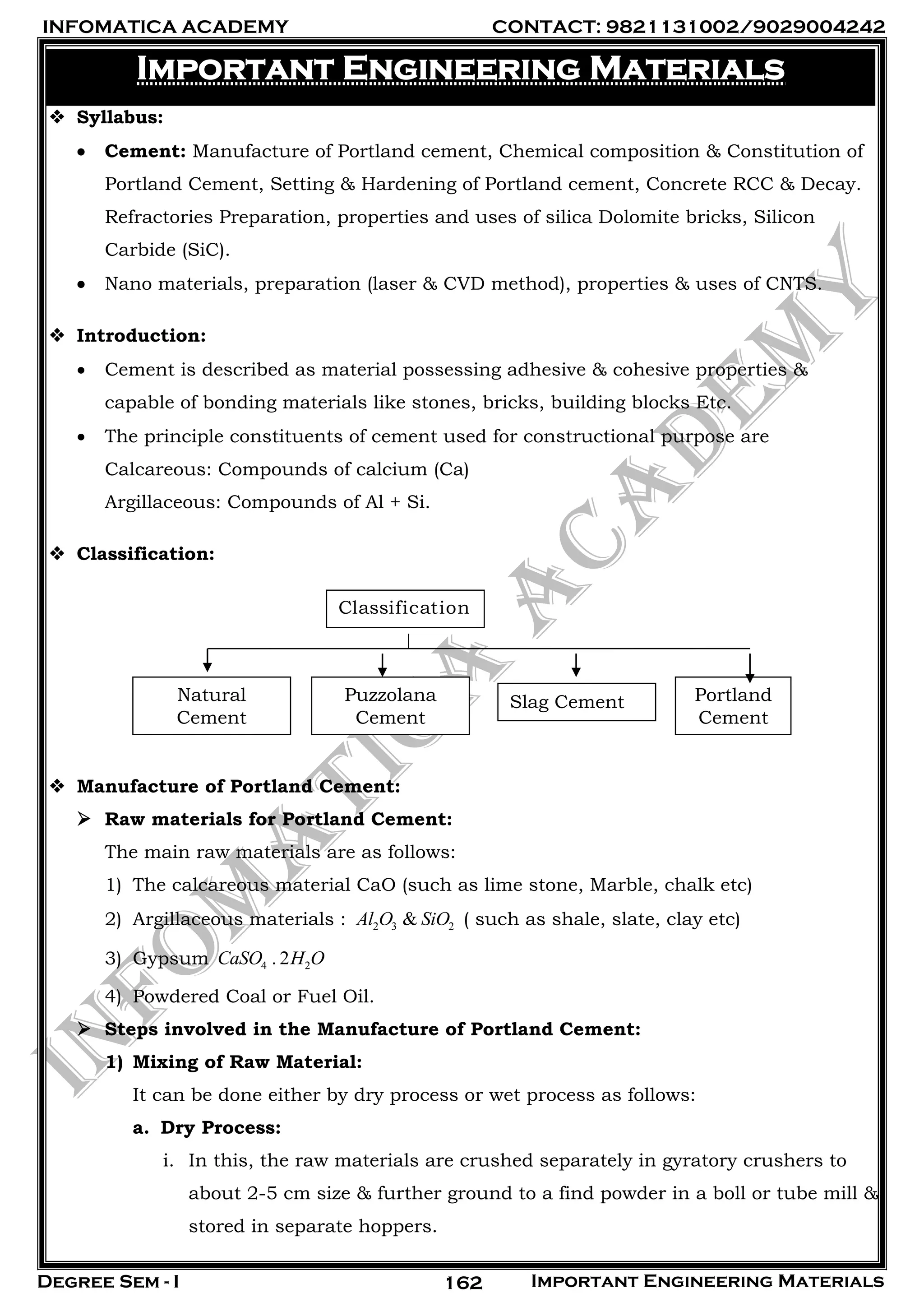

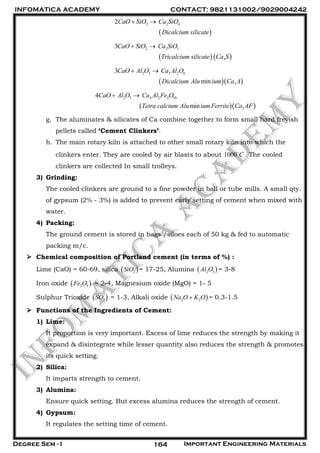

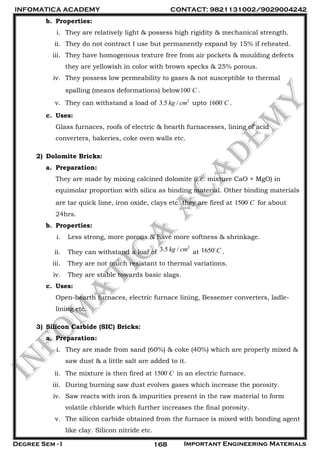

The document outlines the course syllabus for important engineering materials, focusing on cement, its manufacture, and properties. It details the processes involved in producing Portland cement, the chemical composition, functionalities of ingredients, and the setting and hardening processes. Additionally, it covers various materials such as concrete, reinforced concrete, refractories, and nano-materials, highlighting their applications and properties.