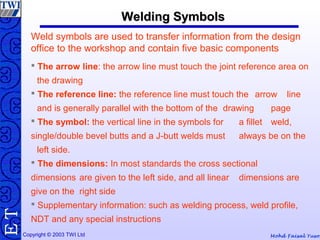

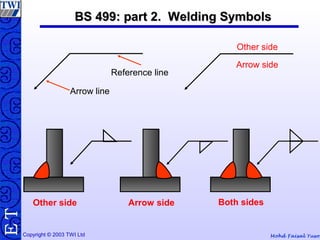

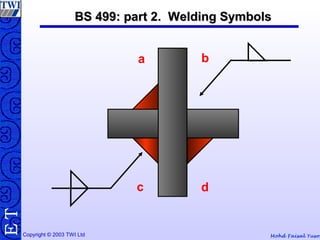

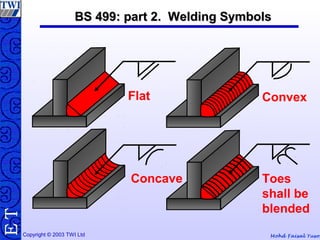

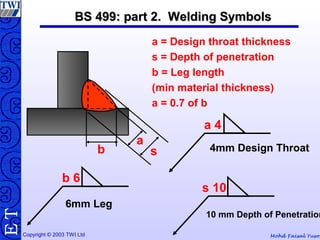

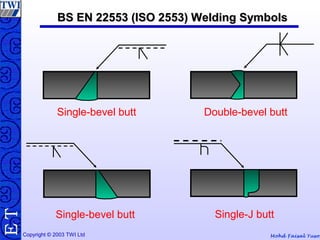

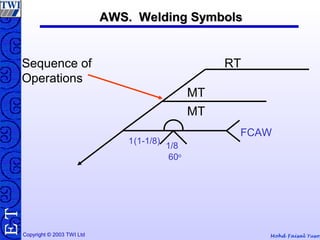

The document discusses welding symbols according to BS 499 part 2 and BS EN 22553 (ISO 2553) standards. It provides information on the components and rules for welding symbols, including arrow lines, reference lines, dimensions, and supplementary information. Examples of various weld types and symbols like fillet welds, butt welds, and flared flange welds are presented. Numerical codes for different welding processes are also listed. The document aims to explain the standards for welding symbols used on engineering drawings.