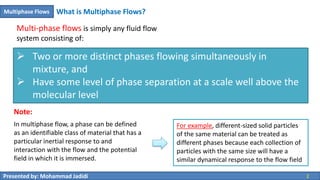

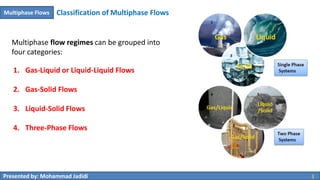

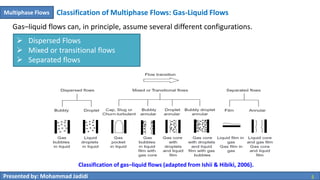

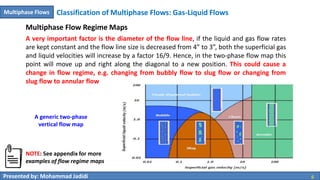

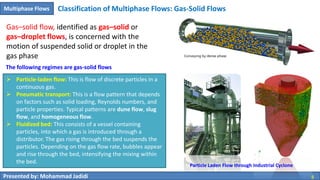

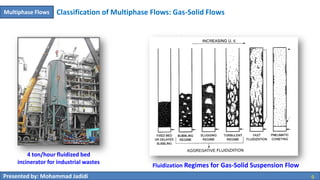

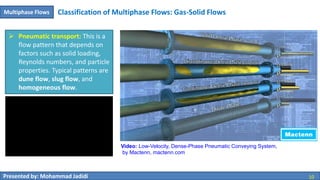

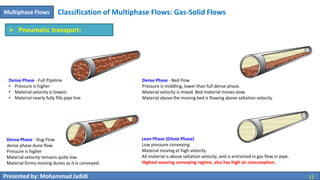

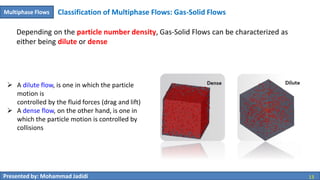

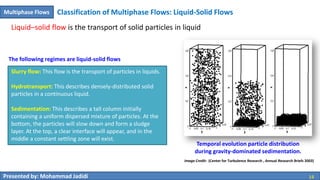

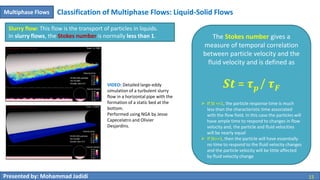

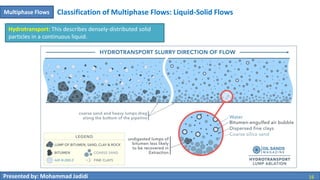

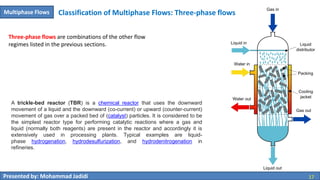

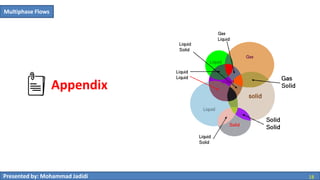

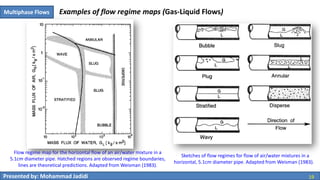

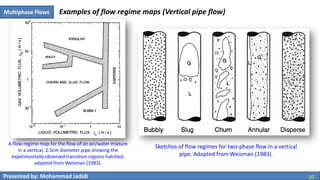

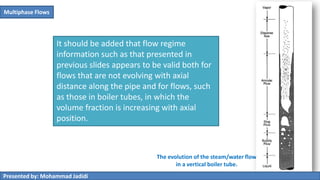

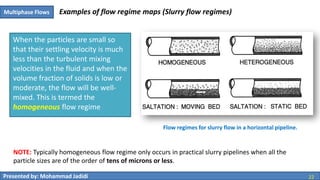

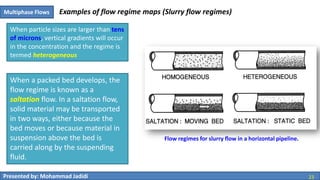

The document discusses different types of multiphase flows. It defines multiphase flow as any fluid system with two or more distinct phases flowing simultaneously in mixture. Multiphase flows are classified into four main categories: gas-liquid flows, gas-solid flows, liquid-solid flows, and three-phase flows. Each category contains different flow regimes depending on factors like particle size and flow rates. Flow maps are used to characterize different flow patterns that can occur for a given system.