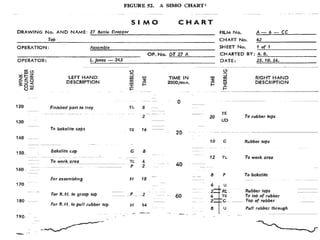

A Simo chart records the simultaneous motions of different body parts of a worker(s) on a common time scale, often based on analyzing filmed footage of an operation. It shows the therbligs or groups of therbligs performed by different parts of the body. Simo charts are used for short, rapid operations and are generally compiled from slow motion or paused film footage. They provide a micromotion-level view of an operation analogous to a man-type flow process chart. Movements are recorded against time measured in "winks" from a counter visible in filmed footage.