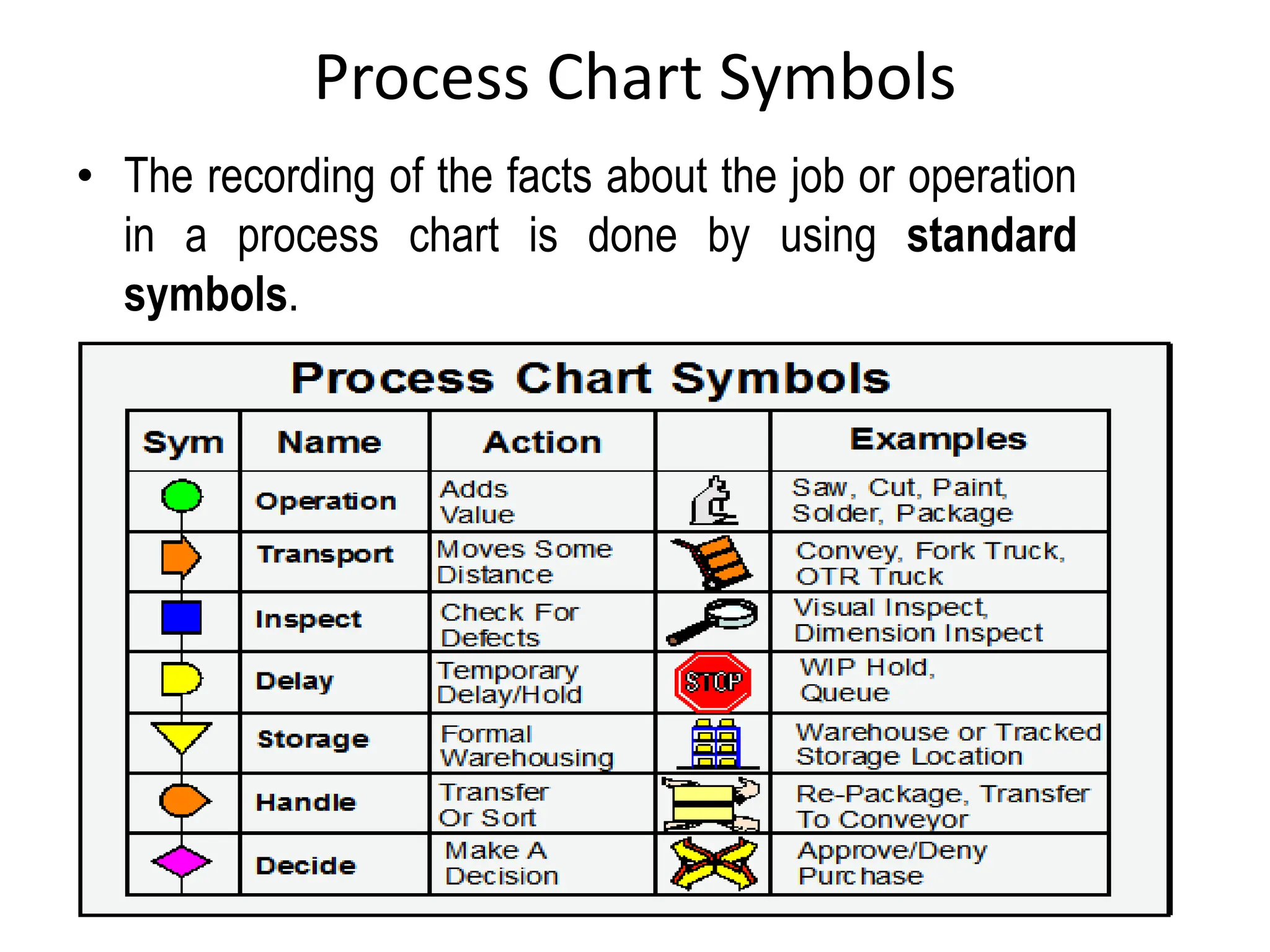

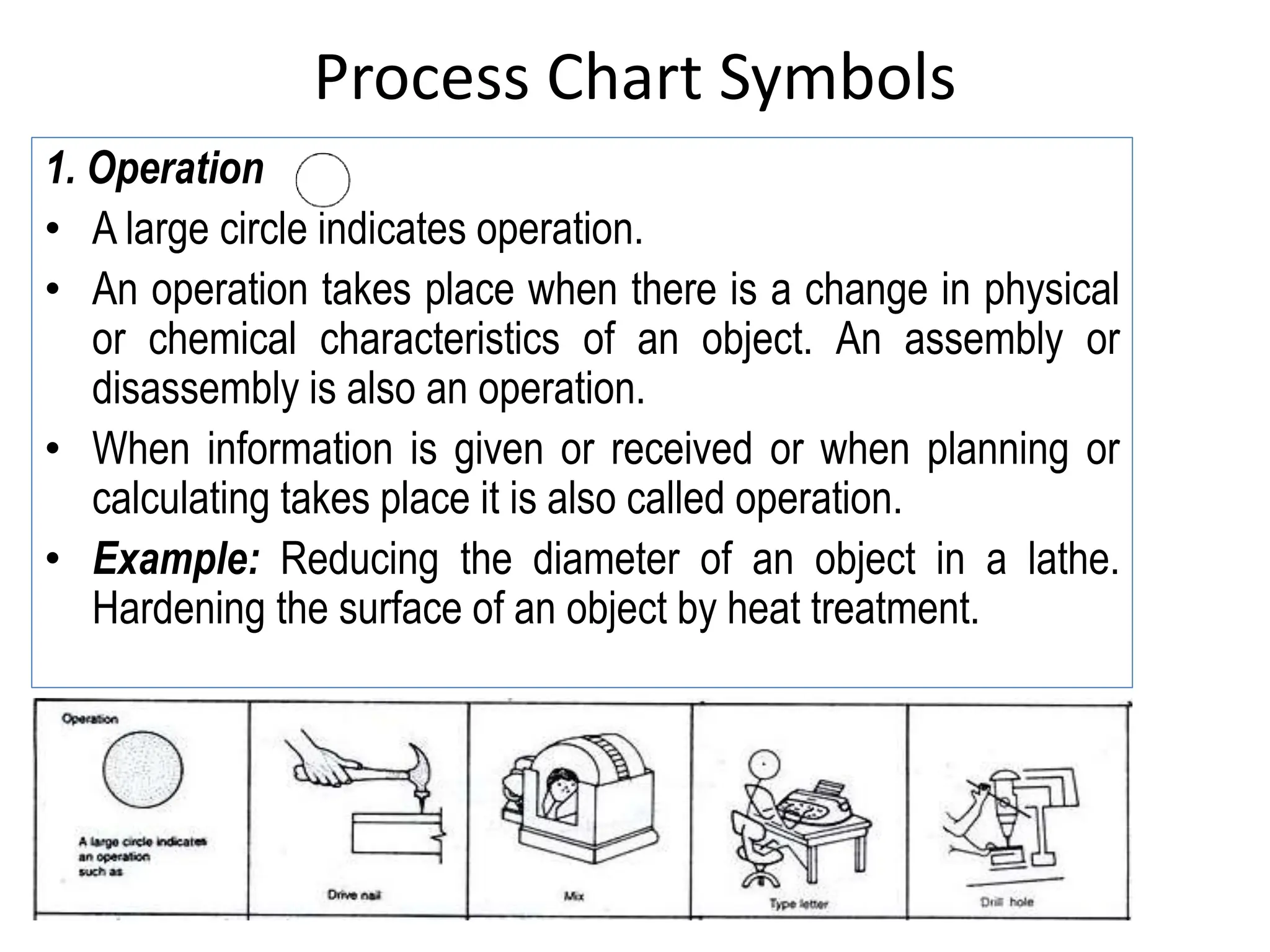

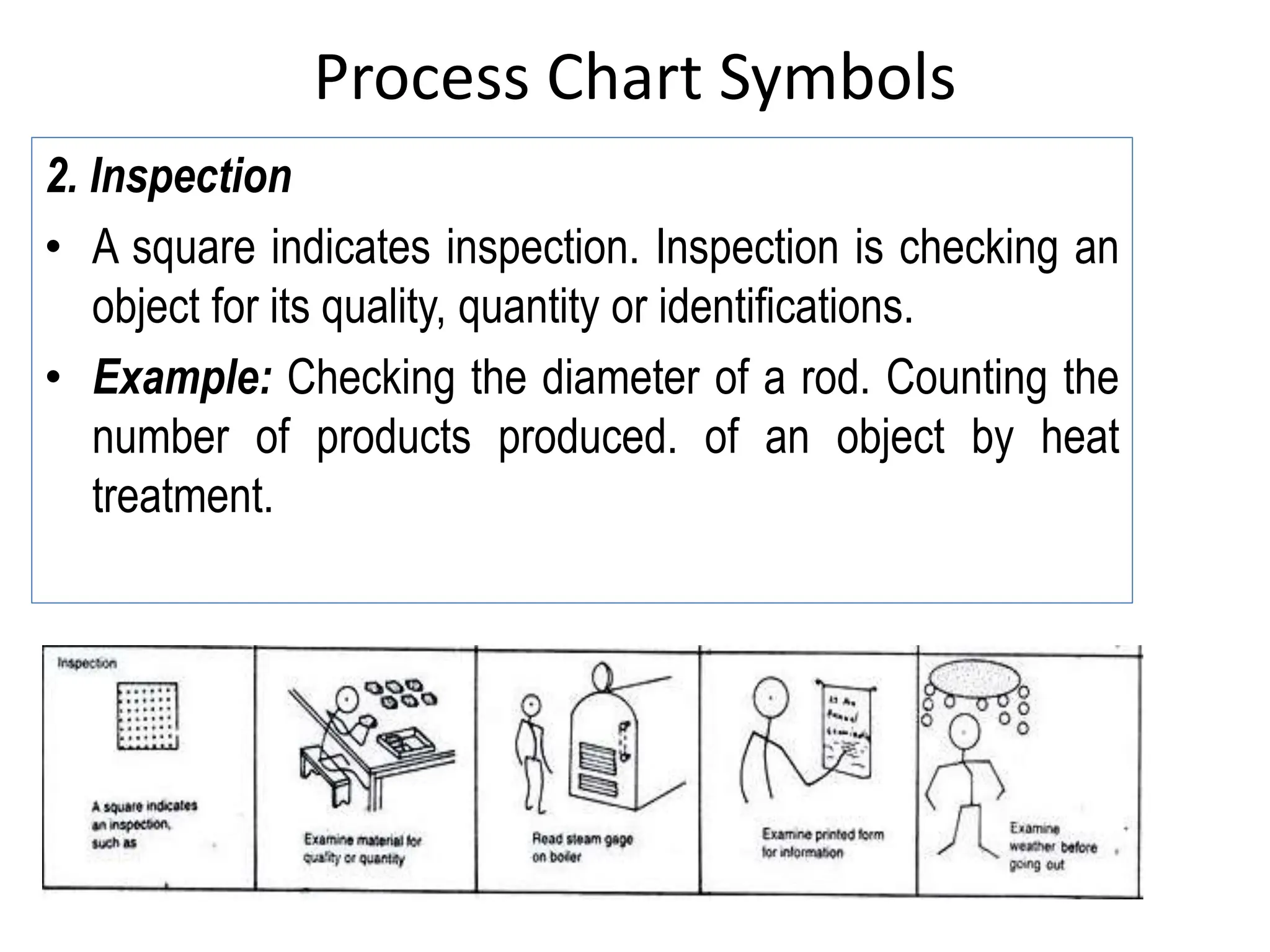

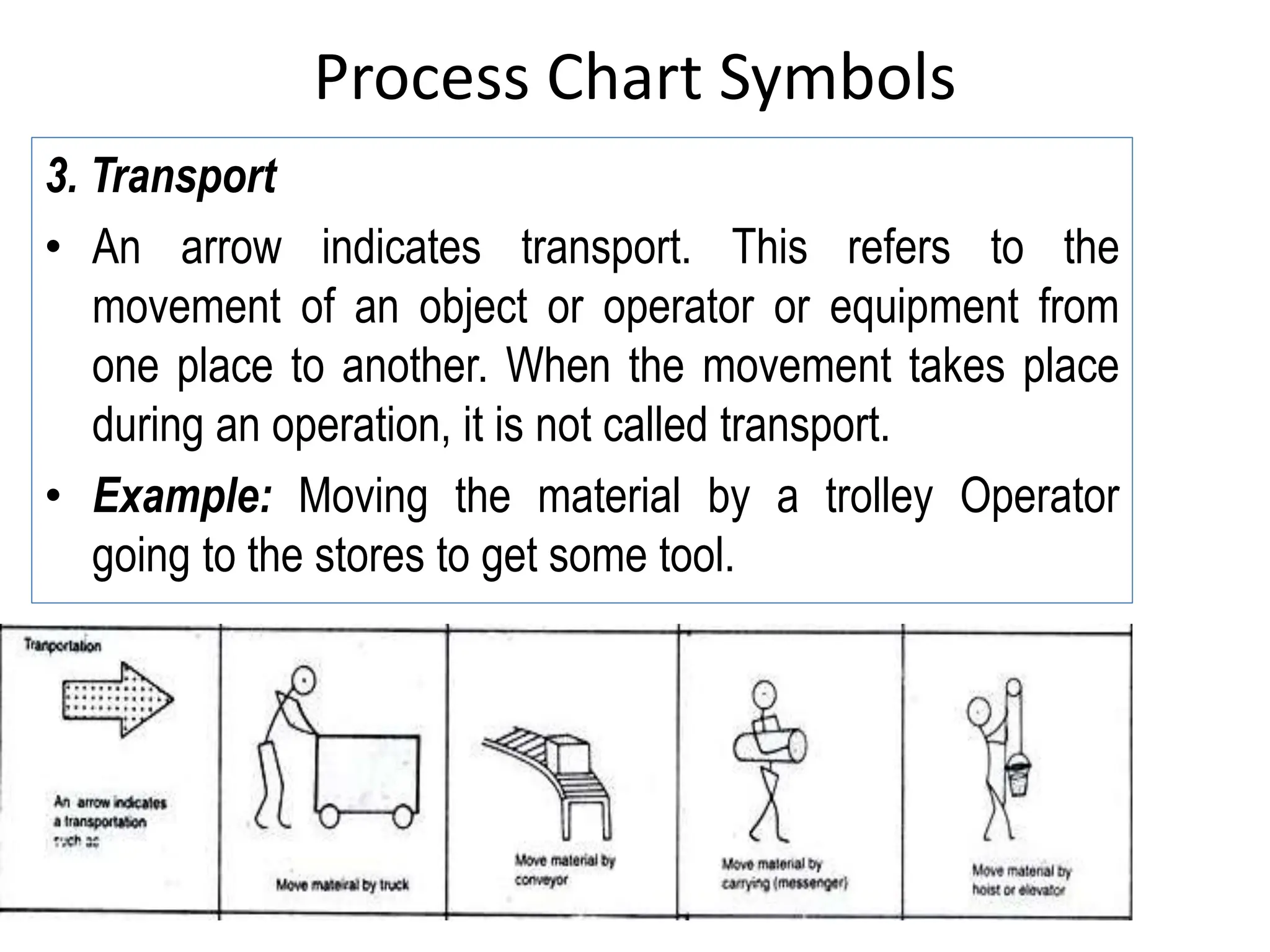

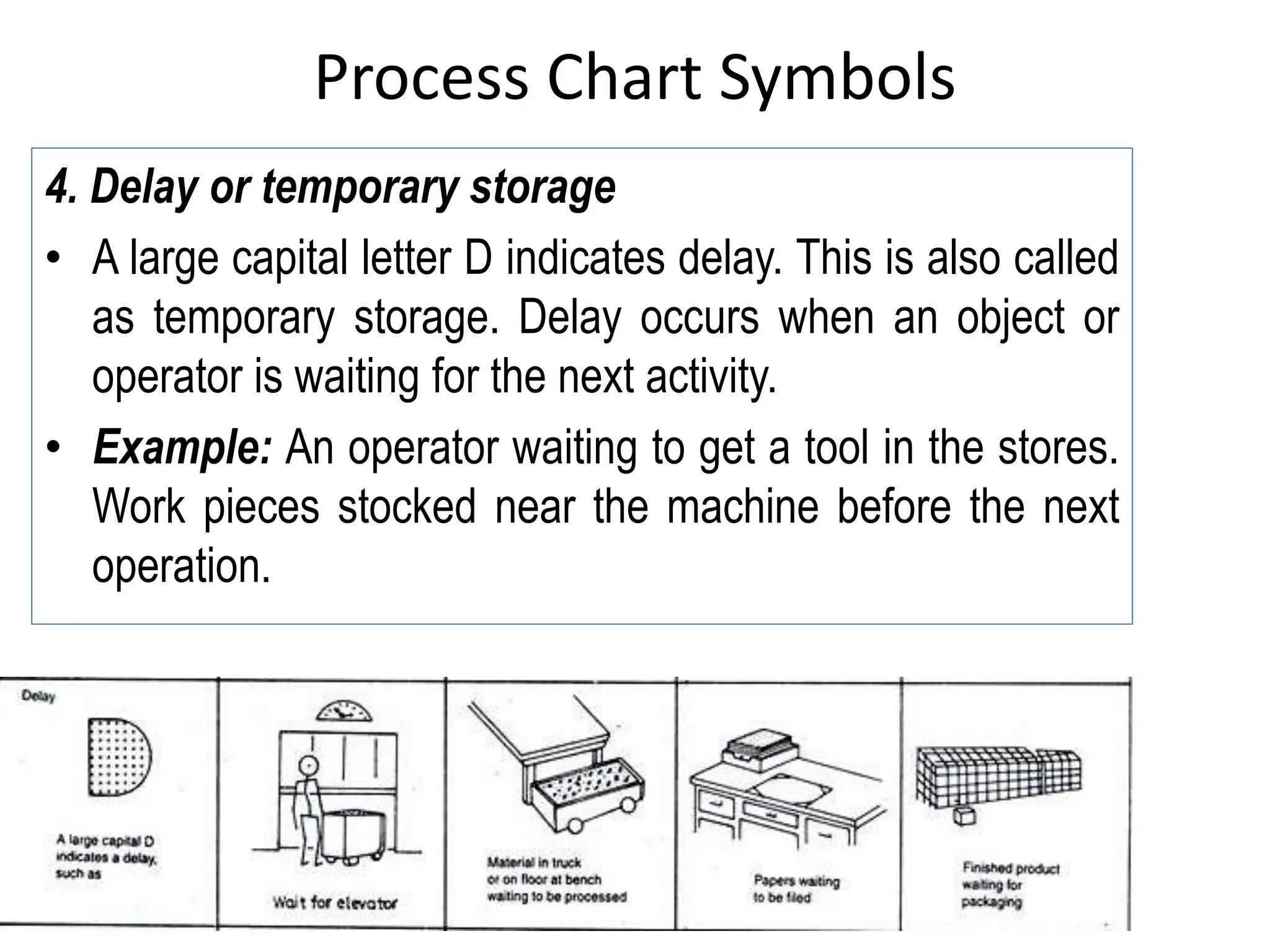

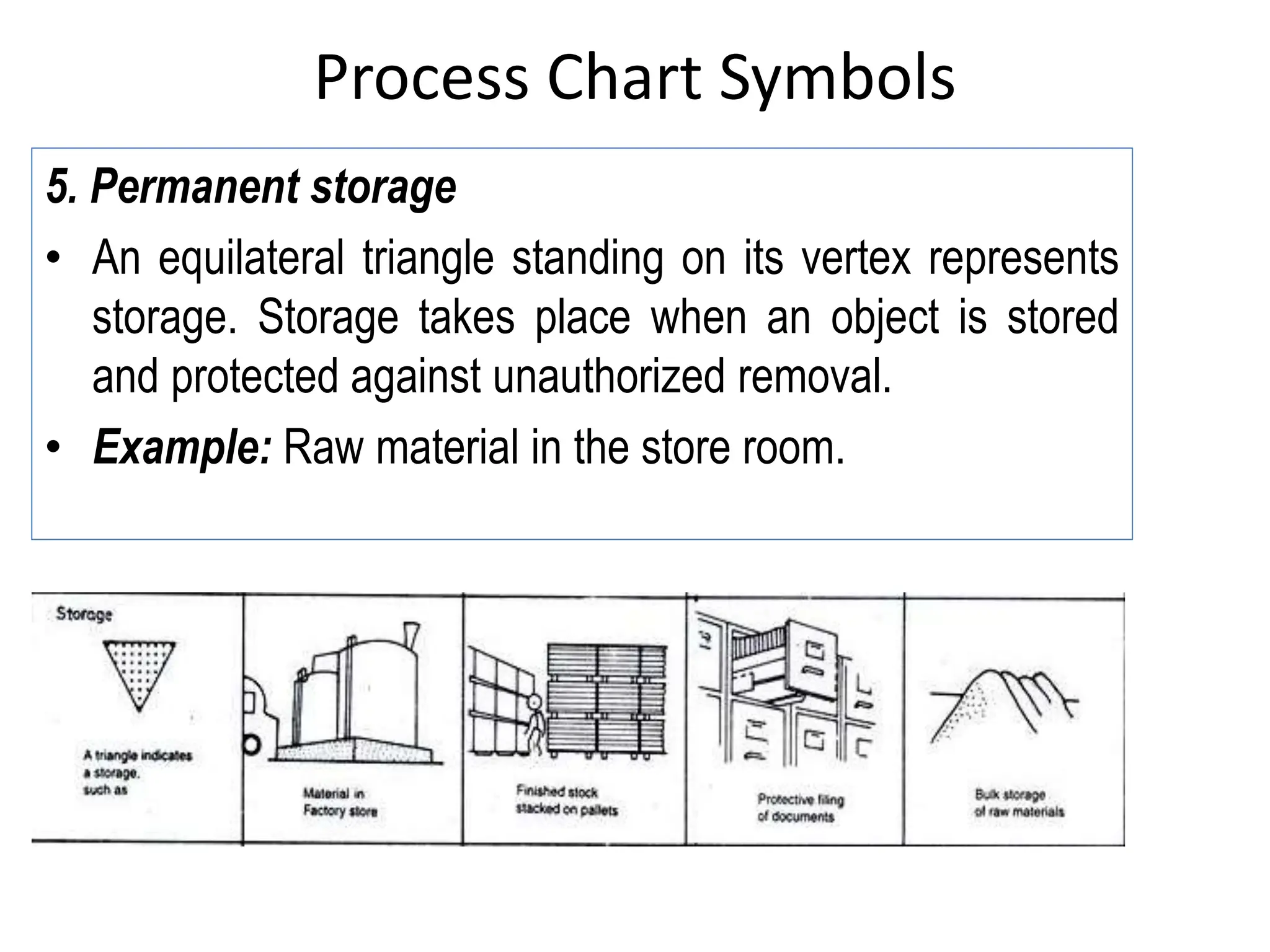

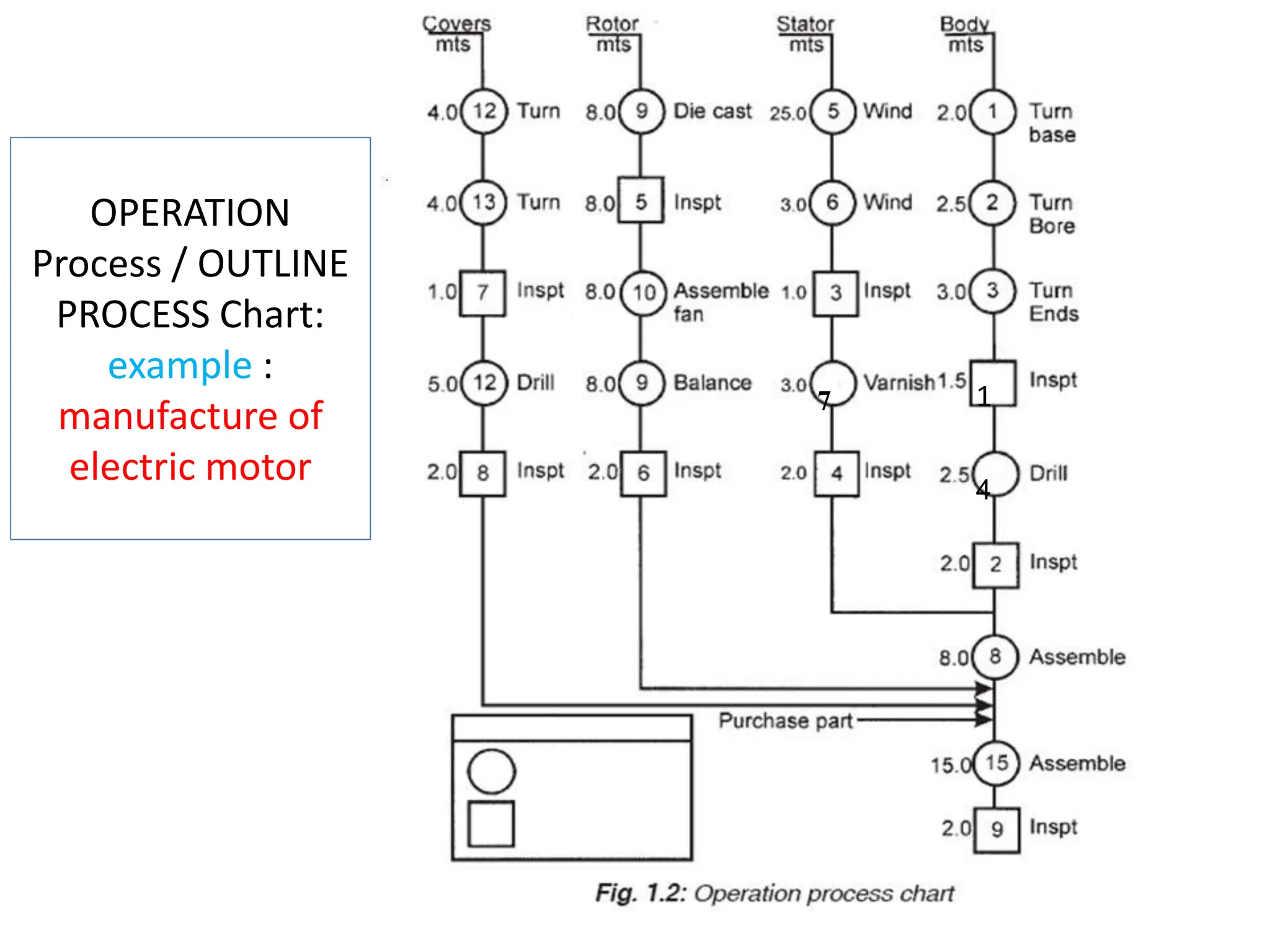

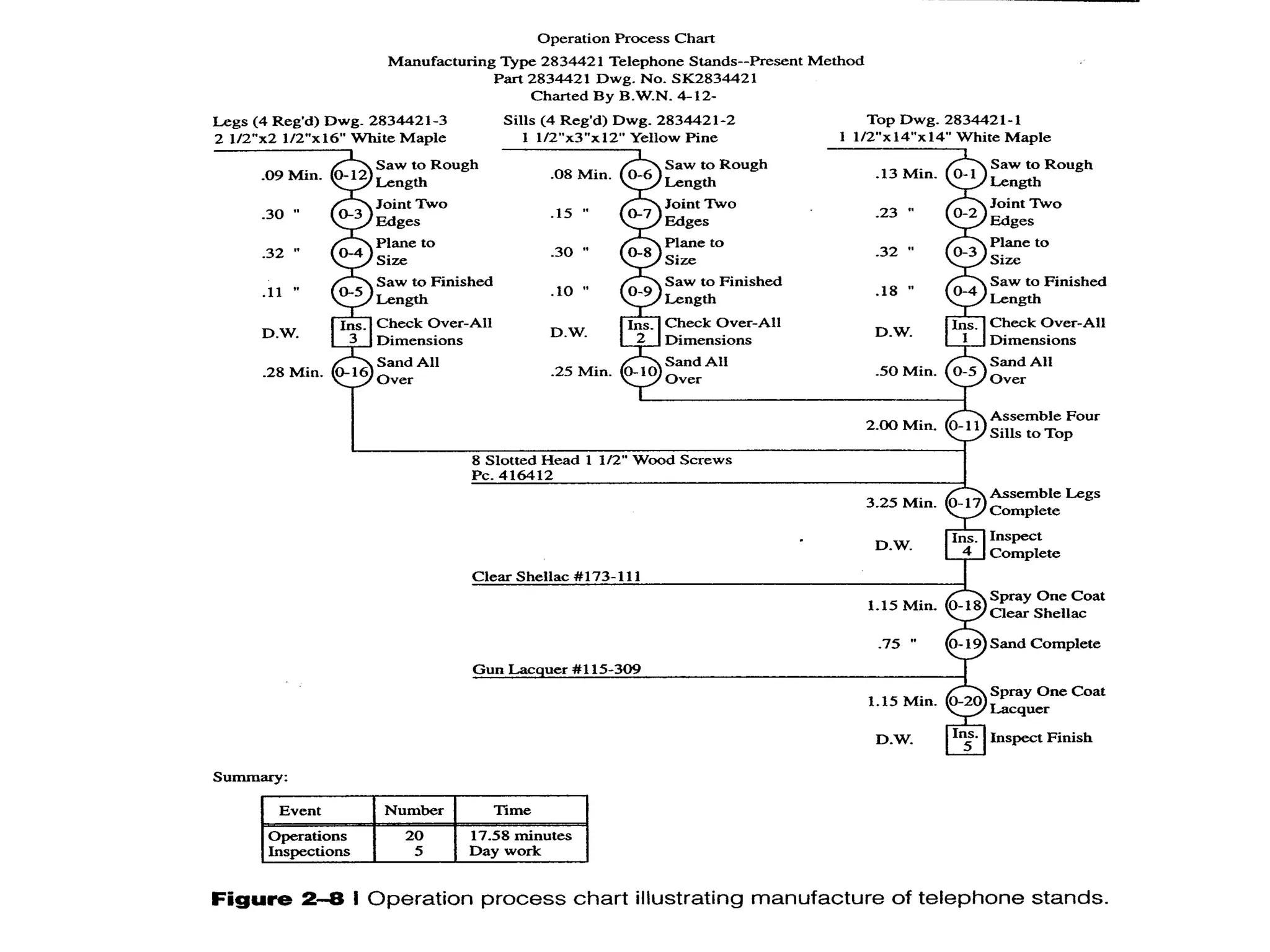

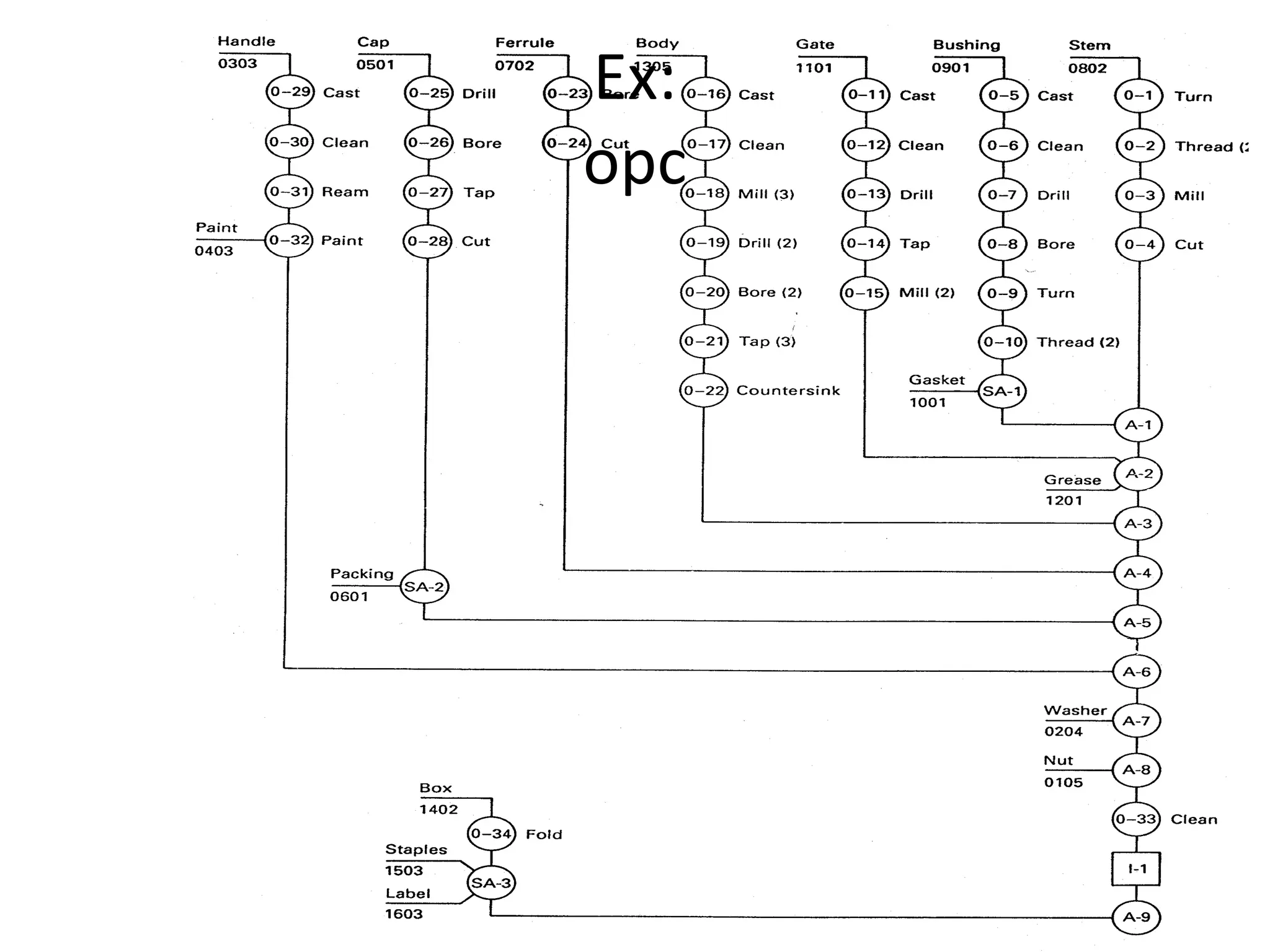

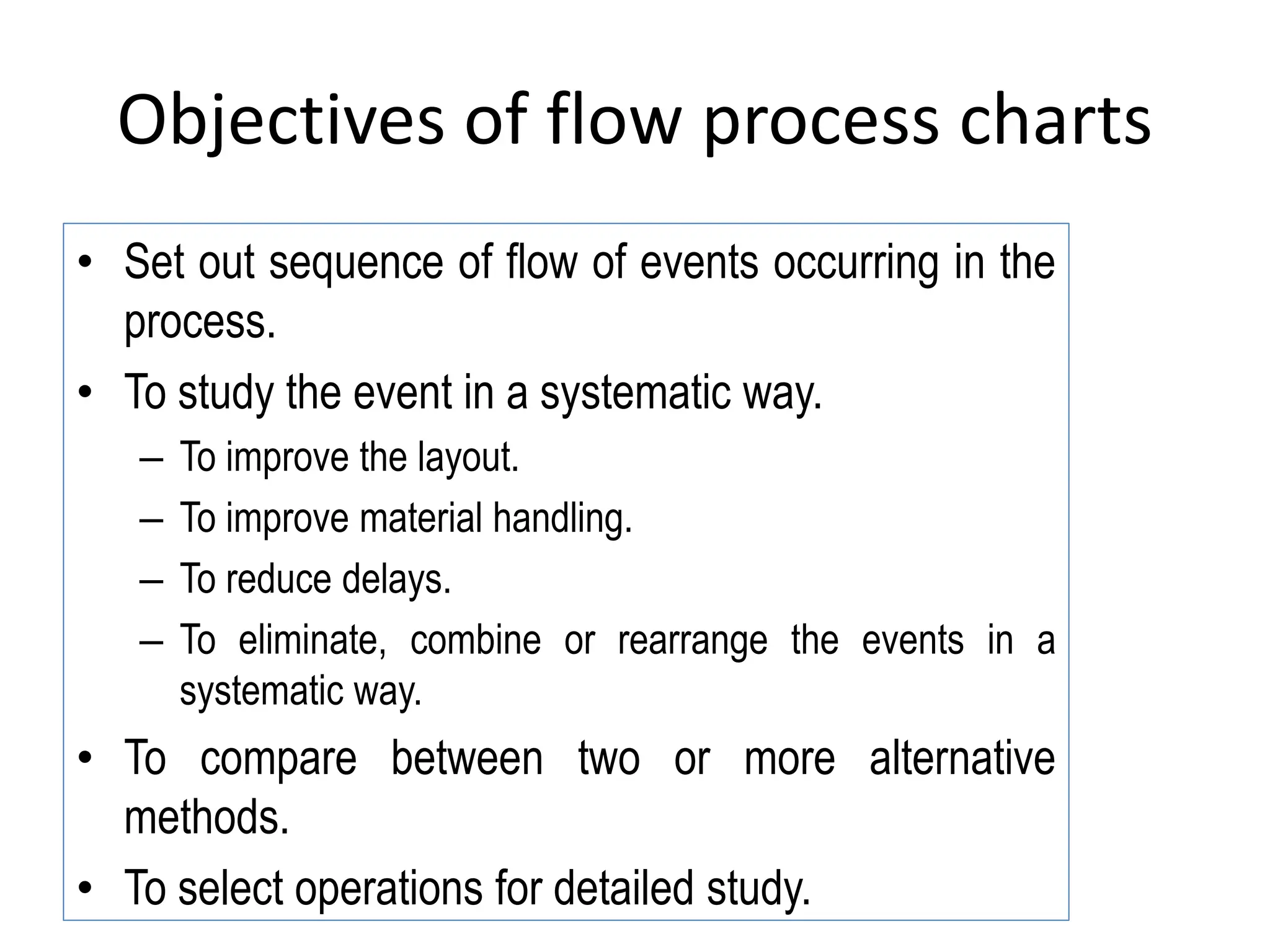

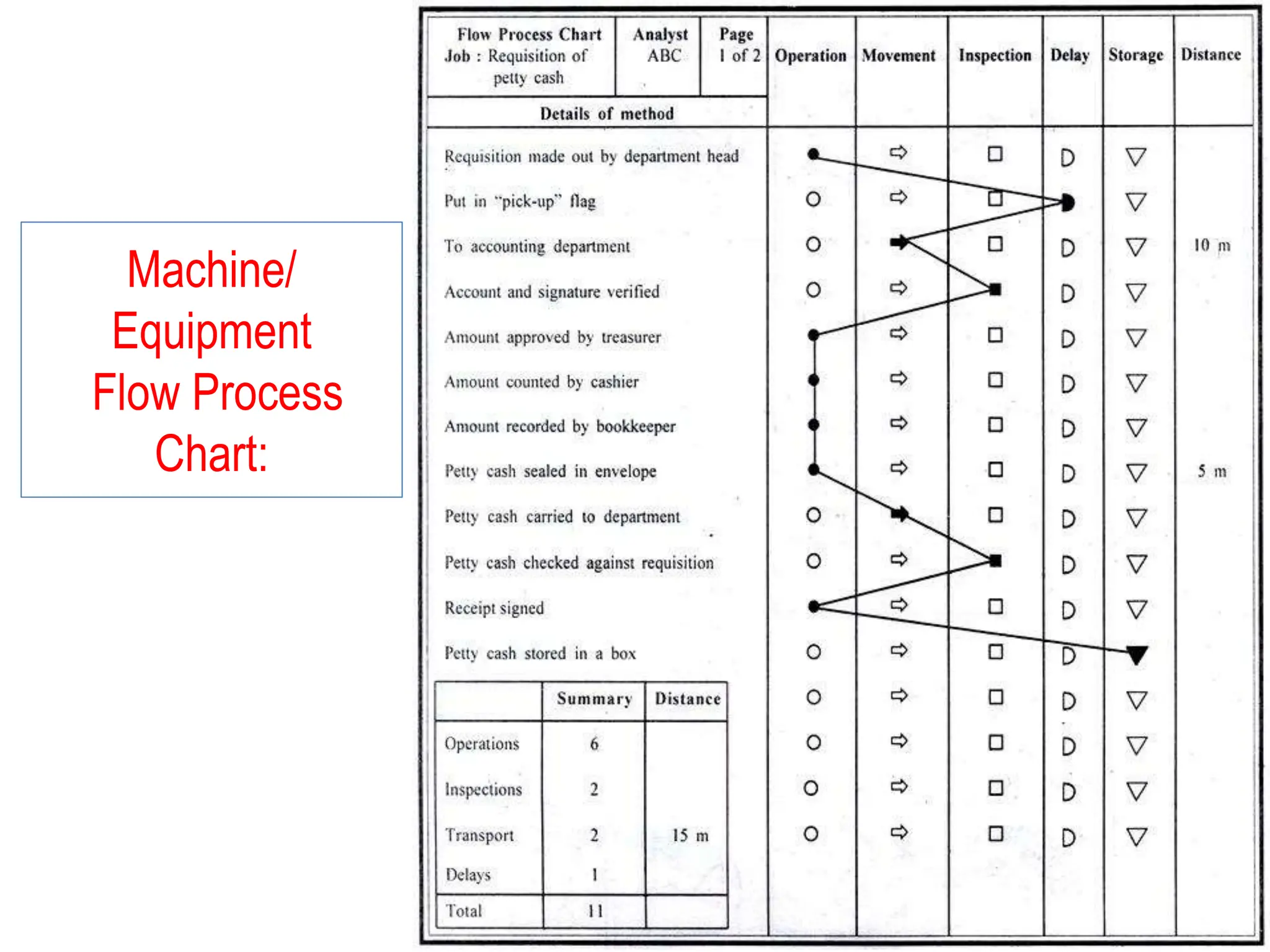

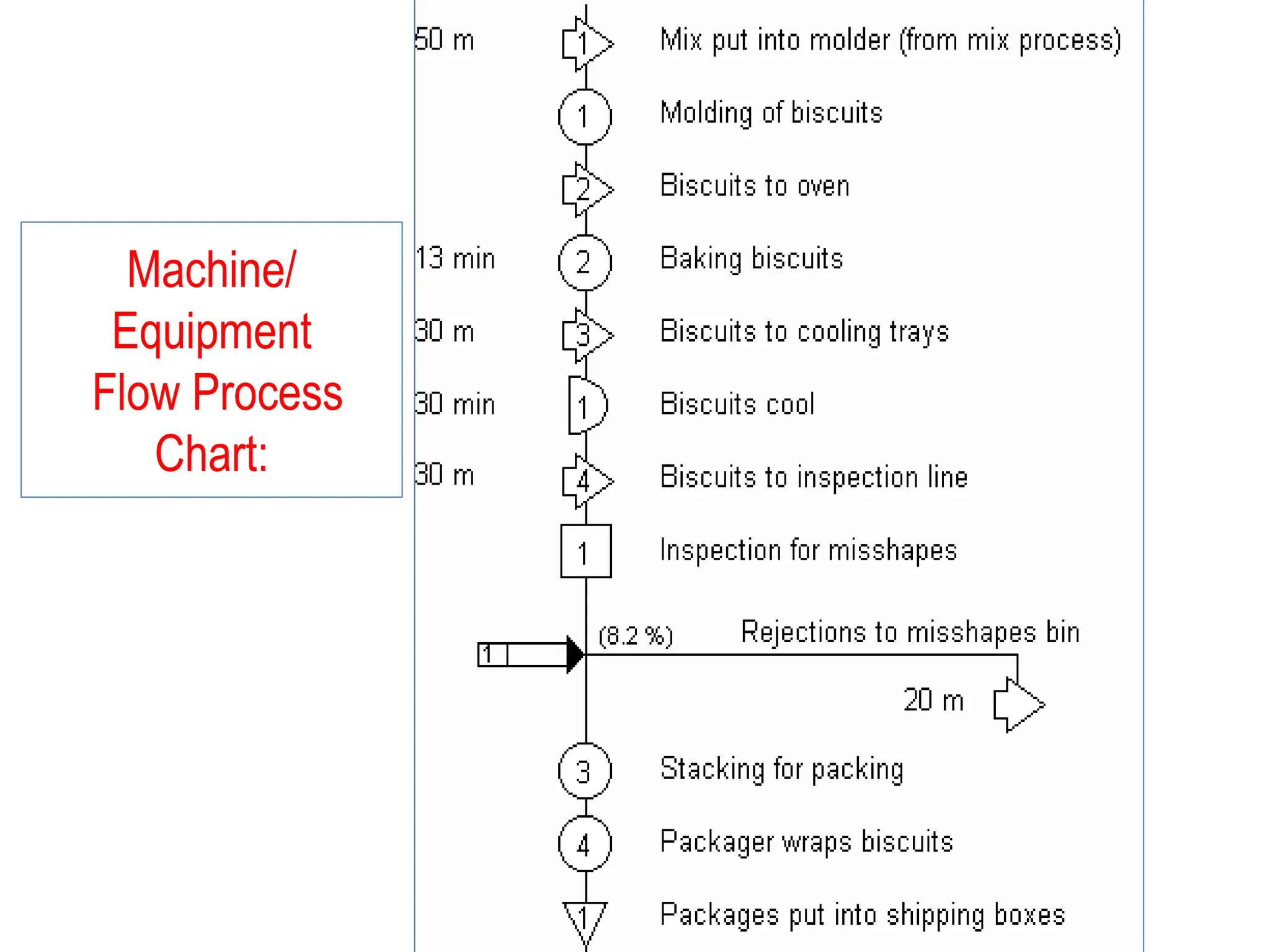

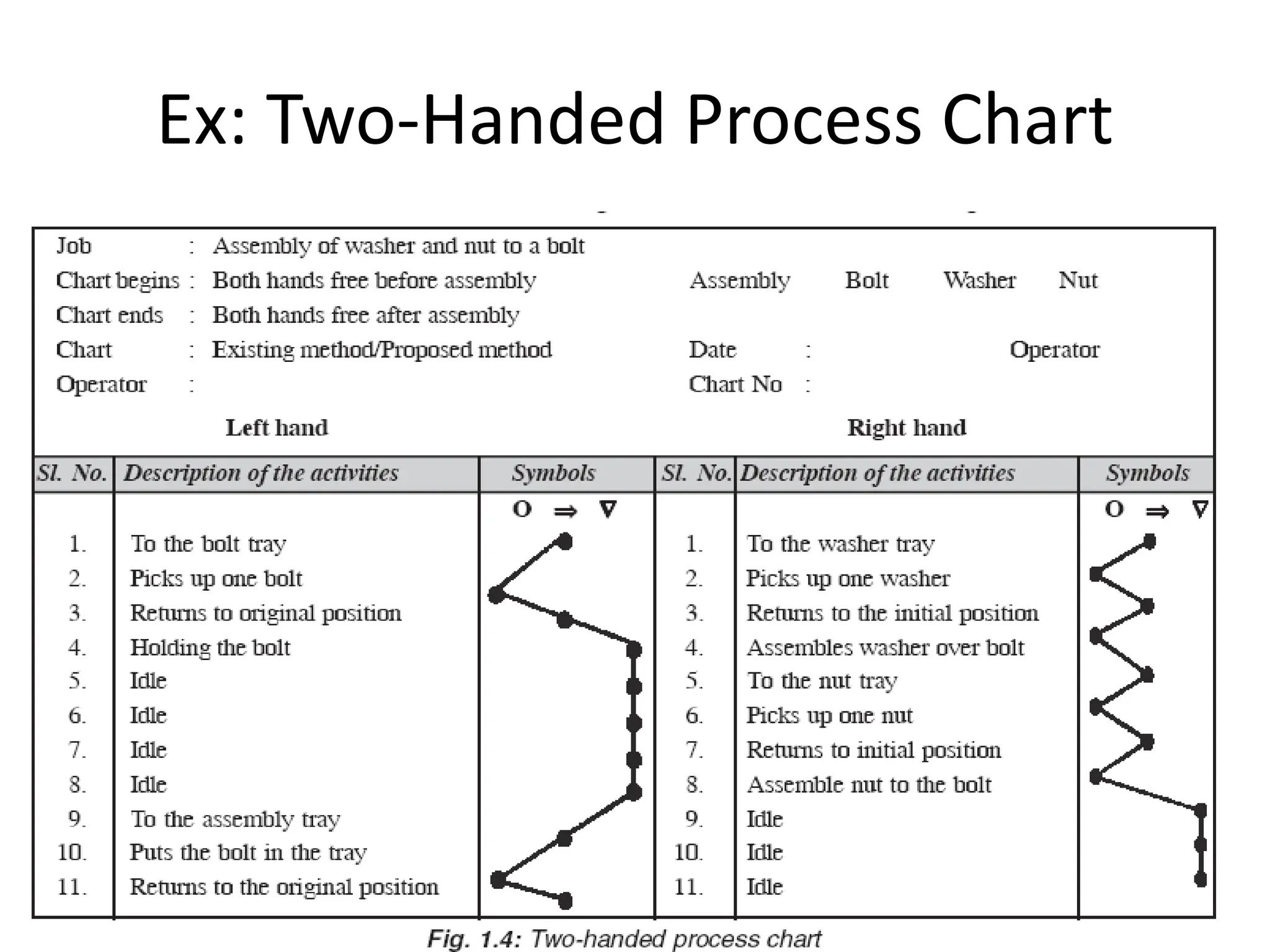

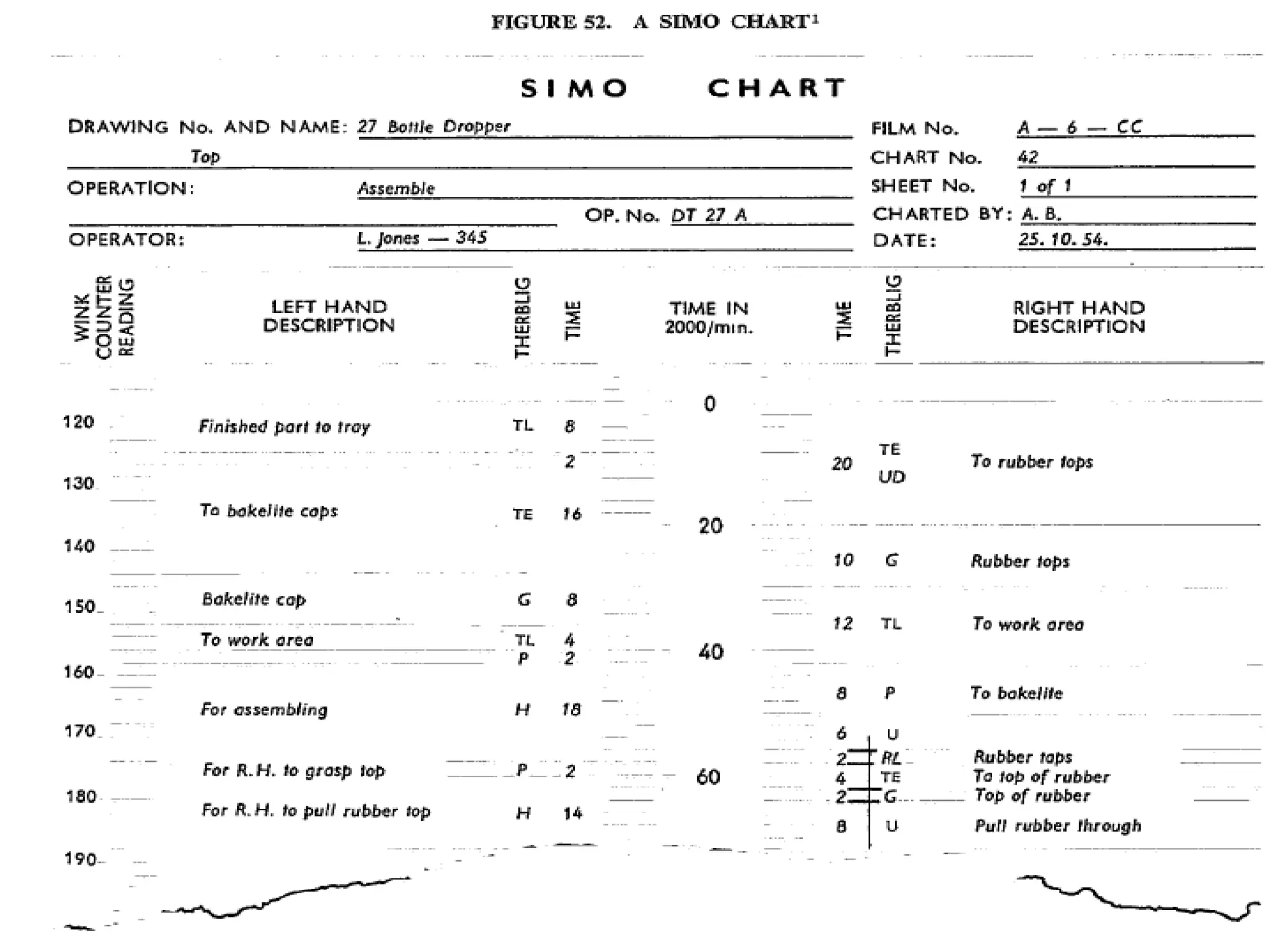

The document outlines various types of process charts used to represent operations, inspections, transport, delays, and storage in manufacturing processes. It includes descriptions of standard symbols used to denote different activities, as well as guidelines for creating detailed flow process charts and two-handed process charts. The objective is to improve efficiency, analyze workflows, and optimize operations within industrial settings.