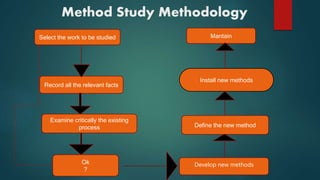

The document discusses method study, which is a technique for observing and analyzing work processes to identify opportunities for improvement. It aims to develop more efficient methods that enhance productivity and reduce costs. The methodology involves selecting a work process, recording details, critically examining the current process, developing new methods, defining the new method, installing it, and maintaining it. Common charts used in method study include outline process charts, flow process charts, two-handed process charts, and multiple activity charts. Flow process charts specifically map the sequence of operations, movements, inspections and delays for a process.