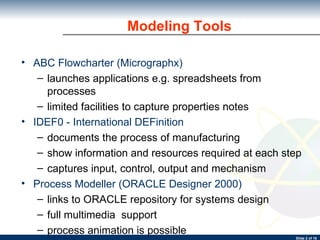

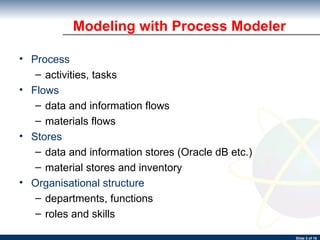

The document discusses various tools and techniques for business process re-engineering and analysis. It describes process modeling tools like ABC Flowcharter and IDEF0 that can be used to map and design processes. It also explains techniques for analyzing processes such as workflow tracing, activity-based costing, cycle time analysis, problem analysis using tools like structured brainstorming and Ishikawa diagrams.