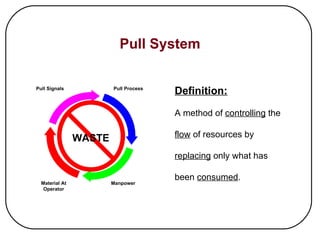

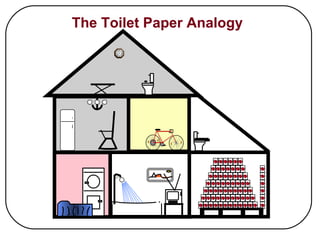

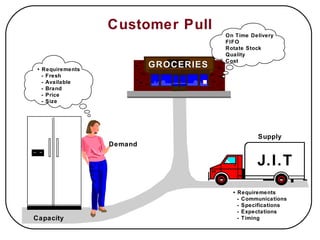

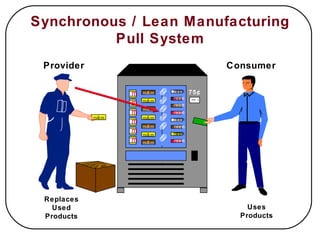

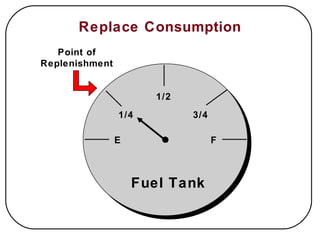

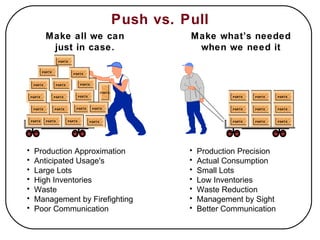

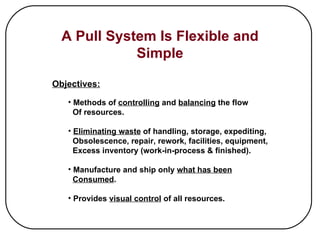

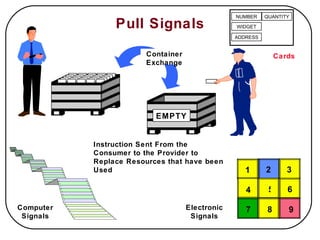

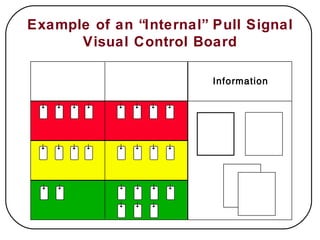

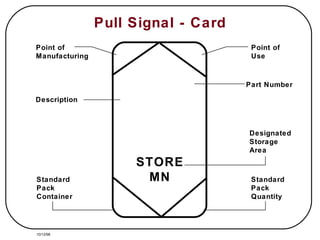

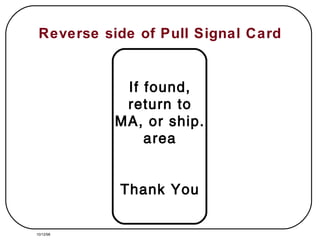

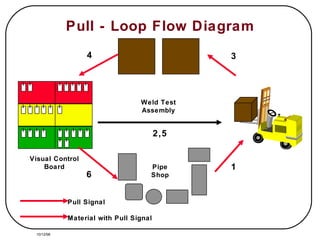

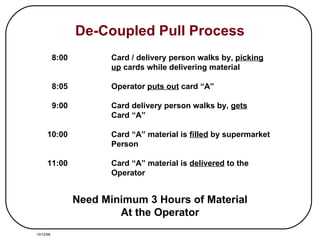

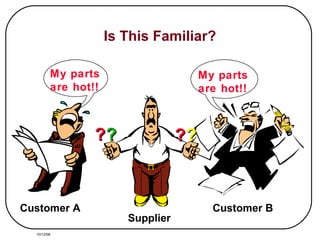

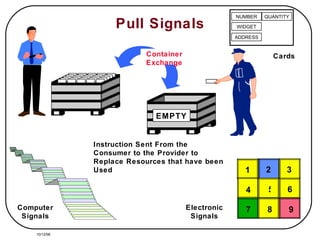

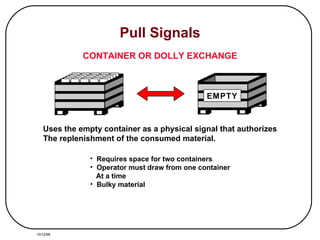

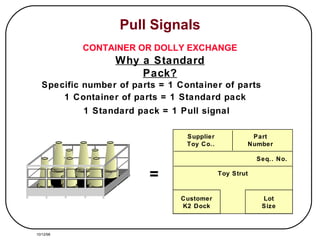

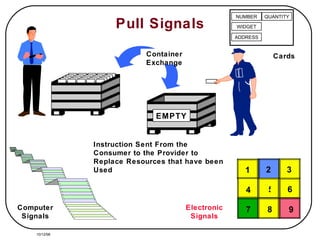

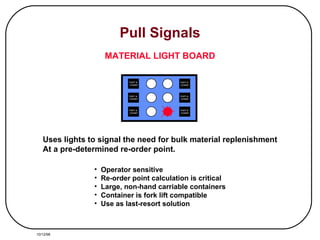

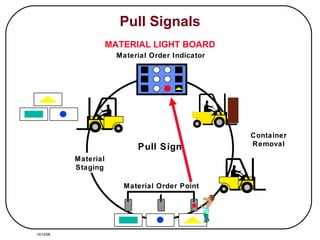

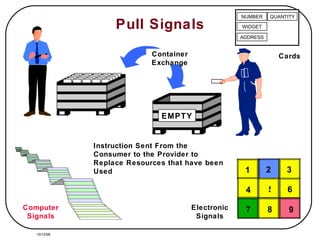

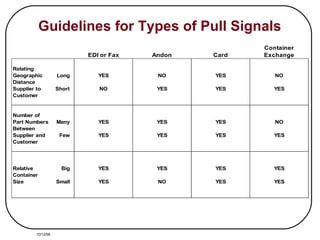

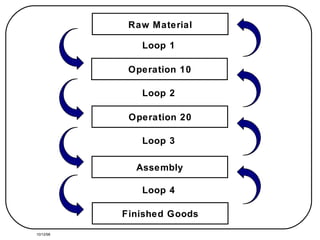

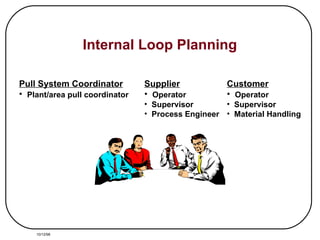

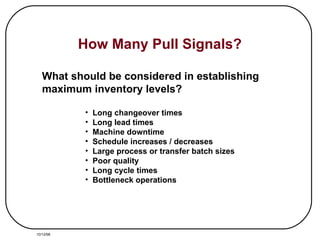

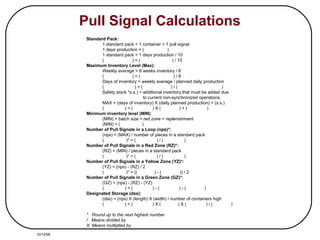

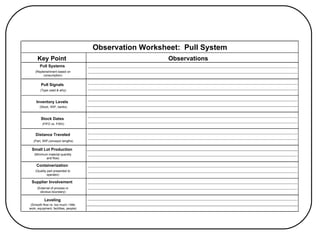

The document discusses pull systems and how they work. It defines pull systems as methods for controlling the flow of resources by replacing only what has been consumed. It contrasts this with push systems, which provide resources based on forecasts. It provides examples of how pull signals like cards or containers can be used to trigger the replenishment of consumed materials.