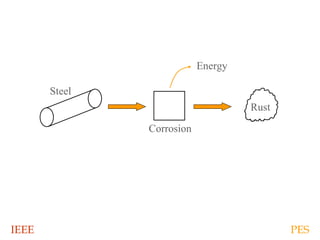

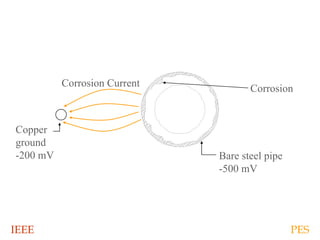

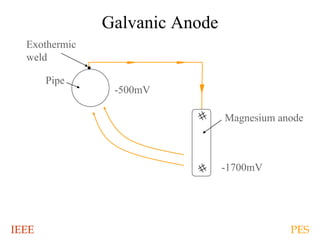

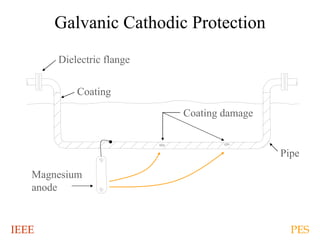

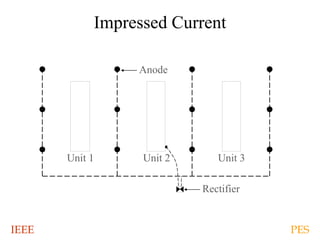

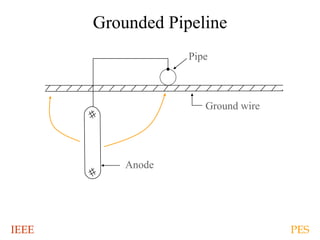

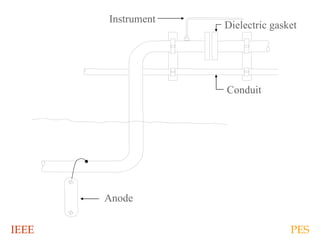

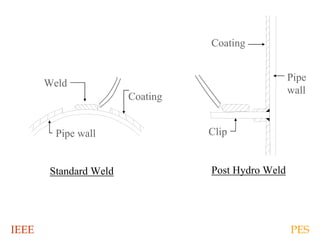

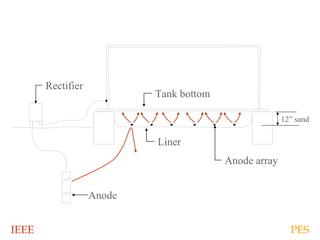

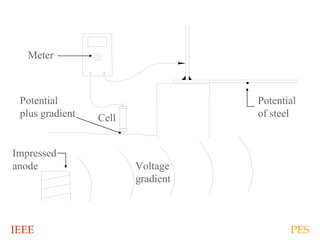

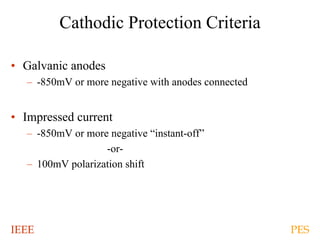

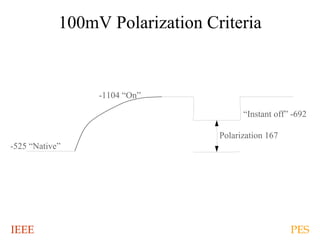

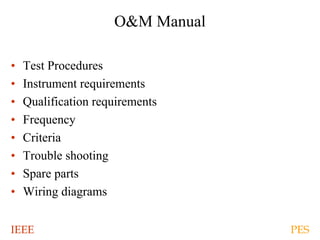

The document discusses cathodic protection for tanks and underground piping in power generation plants. It covers corrosion processes and principles of cathodic protection, design requirements for galvanic and impressed current systems, construction and testing procedures, and ongoing monitoring and maintenance. Proper planning, installation, and maintenance of cathodic protection can significantly extend the service life of steel structures at a plant for over 30 years.