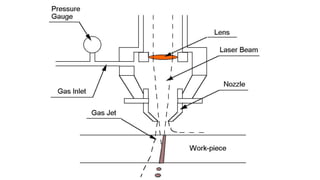

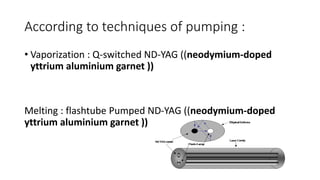

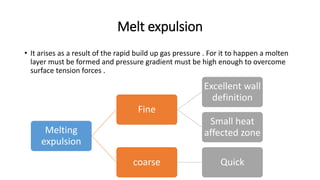

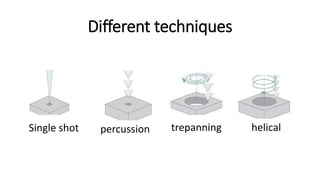

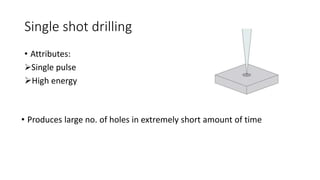

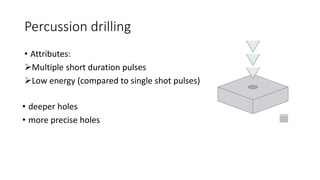

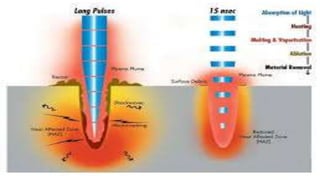

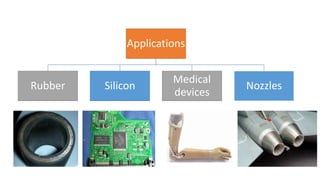

Laser drilling, welding, and cutting are important industrial applications of lasers. There are several advantages to laser processing including ease of programming with CNC, high accuracy and precision, and being a non-contact process. Lasers can remove material either through melting or vaporization, with melting requiring around 25% of the energy of vaporization. The type of laser used depends on the pumping technique, with Q-switched ND-YAG lasers used for vaporization and flashlamp pumped ND-YAG lasers used for melting. Different laser drilling techniques like single shot, percussion, and trepanning can produce holes with varying attributes in terms of size, depth, and precision for applications in industries like rubber, silicon