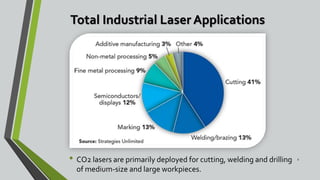

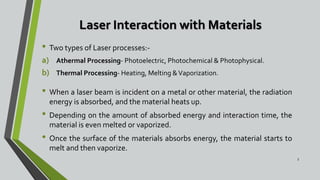

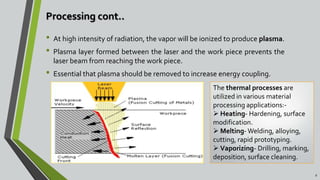

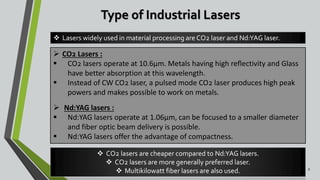

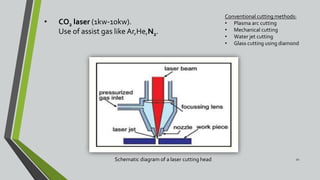

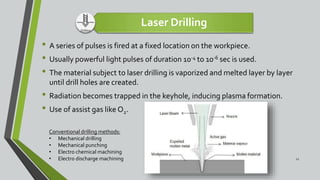

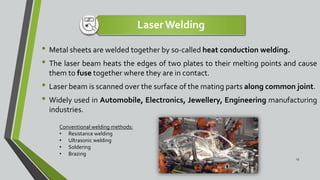

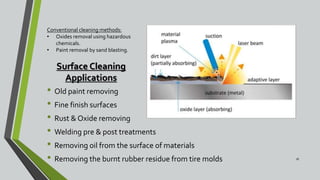

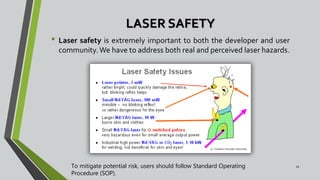

The document discusses various industrial applications of lasers, including laser cutting, drilling, welding, surface cleaning, and safety considerations. It describes how laser processing works by absorbing laser energy, heating and melting materials. CO2 and Nd:YAG lasers are commonly used for cutting, welding, and drilling of metals. Laser cleaning removes contaminants from surfaces through ablation. Lasers provide precision, speed, and flexibility over traditional fabrication methods.