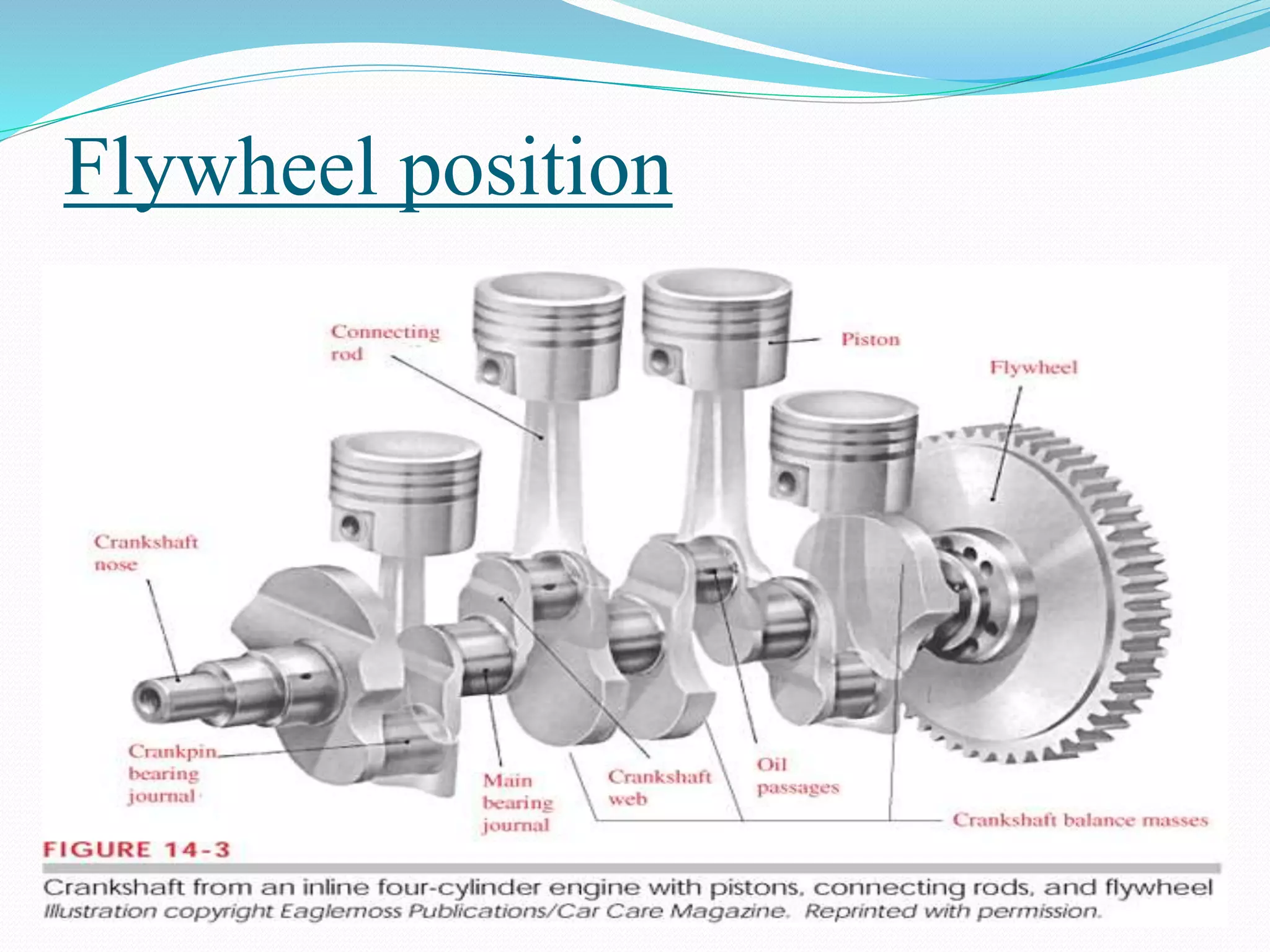

A flywheel is a rotating mechanical device that is used to store rotational energy. It serves as an energy reservoir, storing energy during periods where energy production exceeds energy demand, and releasing stored energy by applying torque when demand is higher than production. Flywheels reduce fluctuations in rotational speed by absorbing and releasing energy. They are commonly used in engines and machines to maintain a constant angular velocity of rotating components. Modern high-energy flywheels use composite materials to achieve very high rotational speeds while storing significant amounts of energy.