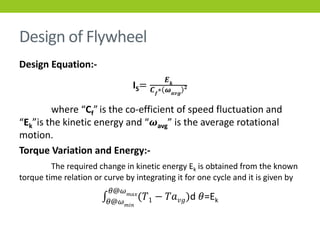

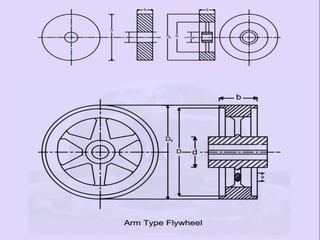

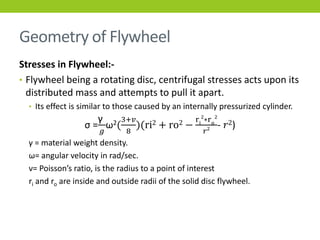

This document discusses the design of flywheels for storing rotational energy. Flywheels smooth out fluctuations in shaft speed caused by torque variations and provide continuous energy. The key design parameters are the degree of energy required and the flywheel's moment of inertia. The design process involves determining the acceptable speed fluctuation and calculating the required kinetic energy. Common geometries are solid disks or hollow wheels with multiple arms. Modern flywheels use high-strength composite materials and can rotate at speeds over 100,000 rpm to achieve high power densities. Flywheels are beneficial for aerospace applications due to their high energy density, low mass, long life, and peak load capability.