fdocuments.us_turning-moment-diagram-flywheel.ppt

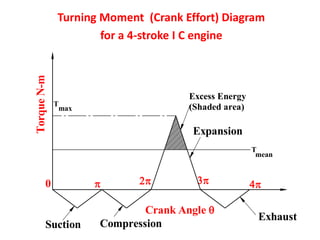

- 1. Turning Moment (Crank Effort) Diagram for a 4-stroke I C engine Crank Angle Torque N-m 0 Suction Compression Expansion Exhaust T T max mean Excess Energy (Shaded area)

- 2. Turning Moment (Or Crank Effort) Diagram (TMD) Turning moment diagram is a graphical representation of turning moment or torque (along Y-axis) versus crank angle (X-axis) for various positions of crank. Uses of TMD 1. The area under the TMD gives the work done per cycle. 2. The work done per cycle when divided by the crank angle per cycle gives the mean torque Tm.

- 3. Uses of TMD 3. The mean torque Tm multiplied by the angular velocity of the crank gives the power consumed by the machine or developed by an engine. 4. The area of the TMD above the mean torque line represents the excess energy that may be stored by the flywheel, which helps to design the dimensions & mass of the flywheel.

- 4. FLYWHEEL Flywheel is a device used to store energy when available in excess & release the same when there is a shortage. Flywheels are used in IC engines, Pumps, Compressors & in machines performing intermittent operations such as punching, shearing, riveting, etc. A Flywheel may be of Disk type or Rim Type Flywheels help in smoothening out the fluctuations of the torque on the crankshaft & maintain the speed within the prescribed limits.

- 5. DISK TYPE FLYWHEEL DISK TYPE FLYWHEEL D

- 6. RIM TYPE FLYWHEEL Section X-X X X b t D

- 7. 2 , where m=Mass of the flywheel. k=Radius of gyratio Flywheels posess inertia due to its heavy mass. Mass moment of inertia of a flywheel is given by I = mk Comparision between Disk Type & Rim Type Flywheel : 2 2 n of the flywheel. For rim type, k= where D=Mean diameter of the flyheel 2 For Disk type, k= where D=Outer diameter of the flywheel 2 2 Hence I=m and I=m 4 8 Rim Disk D D D D Hence for a given diameter & inertia,the mass of the rim type flywheel is half the mass of a disk type flywheel

- 8. 1 2 It is the difference between the maximum & minimum speeds in a cycle. (= ) n n Important Definitions (a) Maximum fluctuation of speed : (b)Coefficient of fluctuation of 1 2 1 2 ) It is the ratio of maximum fluctuation of speed to the mean speed. It is often expressed as a % of mean speed. (or K ) 2 where =Angular velocity= 60 s s s s or K n n C n n speed :(C

- 9. 1 2 ) It is the ratio of maximum fluctuation of energy to the mean kinetc energy. (or K ) e e e e or K E E C Important Definitions (c)Coefficient of fluctuation of energy :(C It is the reciprocal of coeffi E e E E E (d)Coefficient of steadiness : e e ** It is often expressed as the ratio of excess energy e to the work done per cycle.C ( or K ) = W.D / cycle 1 2 cent of fluctuation of speed. Coefficient of steadiness=

- 10. 1 2 Let be the mass moment of inertia of the flywheel & be the max & min speeds of the flywheel Mean speed of the flywheel m=Mass of the flywheel, k=Rad I EXPRESSION FOR ENERGY STORED BY A FLYWHEEL s 2 2 2 2 1 2 1 2 1 2 1 2 1 2 ius of gyration of the flywheel C =Coefficient of fluctuation of speed The max fluctuation of energy (to be stored by the flywheel) 1 1 1 2 2 2 1 ( ) 2 e E E I I I e I

- 11. 1 2 2 1 Putting the mean agular speed = , 2 We get Multiplying & dividing by , Also ,the coefficient of fluctuation o s C EXPRESSION FOR ENERGY STORED BY A FLYWHEEL 1 2 1 2 1 2 e = Iω(ω - ω ) (ω - ω ) e = Iω (ω - ω ) 2 2 2 2 2 2 f speed Hence Putting I=mk ,we get 1 Alternatively, if Mean kinetic energy E= , 2 2 , e=2EC Note: 1 2 But O . R s s e I I E e e C C E E s s e = mk ω C e = Iω C e s C = 2 C

- 12. 2 2 1 e= I , Putting mean Kinetic energy E= 2 and expressing C as a percentage, 2EC 100 1 Alternatively, if Mean kinetic 0.02 energy E Note: = . 2 2 s s s s e E e k C C I m EXPRESSION FOR ENERGY STORED BY A FLYWHEEL 2 2 2 2 2 2 , 1 ( ) , E= 2 s k v mv e mv c

- 13. 2 We know that mass m=Density Volume For Disk type flywheel, Volume = t 4 For Rim type flywheel, Volume= D( ) where A= Cross section of t D A MASS OF FLYWHEEL IN TERMS OF DENSITY & CROSSECTION AREA 2 he rim =b t b= width of rim & t= thickness of the rim (i)Velocity of the flywheel (ii) Hoop Stress (Centrifugal stress) in the flywheel where = density of flywheel mate Note: v= ri / sec 60 = v al Dn m

- 14. Problem 1 A single cylinder 4 stroke gas engine develops 18.4 KW at 300 rpm with work done by the gases during the expansion being 3 times the work done on the gases during compression. The work done during the suction & exhaust strokes is negligible. The total fluctuation of speed is 2% of the mean. The TMD may be assumed to be triangular in shape. Find the mass moment of inertia of the flywheel.

- 15. Crank Angle Torque N-m 0 Suction Compression Expansion Exhaust T T max mean x Excess Energy TURNING MOMENT DIAGRAM

- 16. 3 Power P=18.4 KW=18.4 10 W, Mean speed n=300 rpm Work done during expansion W 3 Work done during compression 2% 0.02 Given 4-stroke cycle engine Crank angle per cycle= E s C Data : 4π radians( 2 rev of cra 3 3 31.416 rad 2 Angular Velocity of flywheel = 60 2 300 . . 60 Also power P=T 18.4 10 T 31.416 /sec Mean tor 18.4 10 31.41 que T 585. N-m 6 7 m m m n i e Solution : nk shaft)

- 17. W.D/C Work done per cycle=T Crank angle per cycle i.e. W.D/Cycle =T 4 585.7 31.416 W.D/Cycle W.D during expansio y n cl W.D during compression (As the W.D during suction & e 7360 N-m co m m Work done per cycle max mpression are neglected) 7360=(W W ) Given W 3 Or W , we can write 3 2 7360= W 3 3 1 . . 11040 2 11040 N-m Max E C E E C C E E E E W W W W W i e T This work represents the area under triangle for expansion stroke max 7 tor 028. qu 3 - e m N T

- 18. max max The shaded area represents the excess energy. 1 . .excess energy stored by flywheel e= ( ) 2 where is the base of shaded triangle, given by ( ) mean mean i e x T T x T T x Excess energy stored by the flywheel max max max ( ) (7028.3 585.7) 2.88 7028.3 1 Hence e= 2.88 (7 9276.67 N- 028.3 585.7) 2 m mean T T T x rad T

- 19. 2 2 2 We know that excess energy is given by e=I 9276.64 (31.416) 0.02 Hence mass moment of inertia of flywheel I=470 Kg-m s C I

- 20. Problem 2 A single cylinder internal combustion engine working on 4-stroke cycle develops 75 KW at 360 rpm. The fluctuation of energy can be assumed to be 0.9 times the energy developed per cycle. If the fluctuation of speed is not to exceed 1% and the maximum centrifugal stress in the flywheel is to be 5.5 MN/m2, estimate the diameter and the cross sectional area of the rim. The material of the rim has a density 7.2 Mg/m3.

- 21. 3 3 3 Power P=75 KW=75 10 W, Mean speed n=360 rpm Fluctuation of energy =0.9 W.D/cycle 4 stroke cycle Crank angle per cycle= Density =7.2 Mg/m 7200 Kg/m ,Hoop stress =5.5 MPa Angu Data : Solution : e 4π radians 3 3 2 lar Velocity of flywheel = 60 2 360 . . 60 Also 37.7 rad/sec Mean torque T 1989.4 power P=T 75 10 T 37.7 75 10 37.7 N-m m m m n i e

- 22. 2 W.D/Cycle Work done per cycle=T Crank angle per cycle i.e. W.D/Cycle =T 4 1989.4 4 Also given Hoop s 25000 tress N-m = v 5.5 1 m m Work done per cycle : Diameter of the flywheel : e = 0.9 ×W.D / cycle = 22500 N - m 6 2 0 =7200 (v ) Hence, 360 60 60 Dn D velocityof flywheel v = 27.64m / sec Also Diameter of the flywheel = v = 2 1.4 7.64 = 66 m

- 23. 2 2 2 2 The energy stored by the flywheel is given by . 1.466 For rim type, radius of gyration k= 0.733 2 2 37.7) 0.01 But , for rim type, m s D m Hence, Mass of the flywheel m = 2946.4 Kg e = mk C 22500 = m ( 0.733) ( ass m= DA (where A=cross section area of the rim) 1.466 7200 A 2946.4 2 A= 0.09m

- 24. 2 2 If it is given that the rectangular cross section of the rim has width (b)=3 thickness ( t), Then A=b t=3t t=3t t=0.1732m 173 mm b=3t= 0.09 3 520 mm t Note :

- 25. Problem 3 The crank effort diagram for a 4-stroke cycle gas engine may be assumed to for simplicity of four rectangles, areas of which from line of zero pressure are power stroke =6000 mm2, exhaust stroke =500 mm2, Suction stroke=300 mm2, compression stroke = 1500 mm2. Each Sq mm represents 10 Nm. Assuming the resisting torque to be uniform, find a) Power of the engine b) Energy to be stored by the flywheel c) Mass of a flywheel rim of 1m radius to limit the total fluctuation of speed to ±2% of the mean speed of 150 rpm.

- 26. Crank Angle Torque N-m 0 Suction Compression Expansion Exhaust T mean T max Excess energy (Shaded area)

- 27. 4 stroke cycle Crank angle per cycle= Radius of gyration k 1 meter, Mean speed n=150 rpm C 2% 4% 0.04 ( Total fluctuation=2 Fluctuation on either side) Angular Velocity of fl s Data : Solution : 4π radians 2 15.71 rad/sec WD/cycle=W.D during Expansion-(W.D during other strok 2 ywheel = 60 2 150 . . 60 W.D/cycle= 6000-(300 1500 500) 3700mm W.D/cycle 3700 scale of diagram=3700 10=37000 N-m Mean Torque es) n i e W.D/cycle 37000 T 2944.4 N-m Crank angle/cycle 4 m

- 28. max max max 2944.4 15.71 But W.D during expansion =T 6000 10 T Substituting for T 46.256 m W P T K (i) Power developed by engine : (ii) Energy stored by flywheel : max T = 19098.6N - m max m e = Shaded area = π( T -T ) max , ( ) (19098.6 2944.6) m e T T e = 50749.27 N - m Crank Angle Torque N-m 0 Suction Compression Expansion Exhaust T mean T max Excess energy (Shaded area)

- 29. 2 2 2 2 We know that energy stored by flywheel 50749.27 (1) (15.71) 0.04 s e mk C m (iii) Mass of flywheel Mass of flywheel m = 5140.64 Kg

- 30. Problem 4 A multi cylinder engine is to run at a speed of 600 rpm. On drawing the TMD to a scale of 1mm=250 Nm & 1mm=30, the areas above & below the mean torque line are +160, -172, +168, -191, +197, -162 mm2 respectively. The speed is to be kept within ±1% of the mean speed. Density of Cast iron flywheel=7250 kg/mm3 and hoop stress is 6 MPa. Assuming that the rim contributes to 92% of the flywheel effect, determine the dimensions of the rectangular cross section of the rim assuming width to be twice the thickness.

- 31. 1 2 3 4 5 6 160 172 191 197 162 168 Turning Moment Crank angle Mean Torque line Let the energy at 1=E Energy at 2=(E+160) Energy at 3=(E+160)-172=(E-12) Energy at 4=(E-12)+168=(E+156) Energy at 5=(E+156)-191=(E-35) 7 Energy at 6=(E-35)+197=(E+162) Energy at 7=(E+162)-162=E= Energy at 1 Hence, Maximum fluctuation of energy (in terms of area) = (E+162)-(E-35)=197 Sq mm

- 32. 2 2 2 600 Angular velocity = 62.84 / sec, 60 60 1% 2% 0.02 3 1mm 250 13.1 180 Max Fluctuation of s N rad C Nm Scale of t Energy stored by the fl he dia ywhee gra l : m is 2 2 2 energy (Max.K.E-Min K.E) e=(E+162)-(E-35)=197 mm . .2581=I I (62.84) 0.02 Mass moment of inertia s e i e C 2 e =197 ×13.1 = 2581Nm I = 32.7Kg - m

- 33. 2 6 2 Using = v ; 6 10 7250 Velocity 600 Also v= 28.8= 60 60 Mean dia of flywheel D=0.92 m v=28.8 m ec /s v DN D Dia G meter of the flywhee iven 92%of the l : flywh 2 2 2 2 2 0.92 2581 2375 ( ) 2375 (28.8) 0.02 rim rim s s s Nm mk c m k c mv c m eel effect is provi Mass of rim m = ded by 143 kg. the rim, e e

- 34. 2 We know that mass of the flywheel rim m=Volume of rim density=( DA) 143 ( 0.92 A) 7250 A=0.00682 As cross section of rim is rectangular with b=2t, A ( 4m = b t Dimensions of the crossection of the rim : 2 2 )=2t 0.006824 2t Hence t = 58.4 mm,b = 2t = 116.8 mm.

- 35. Problem 5 Torque –output diagram shown in fig is a single cylinder engine at 3000 rpm. Determine the weight of a steel disk type flywheel required to limit the crank speed to 10 rpm above and 10 rpm below the average speed of 3000 rpm. The outside diameter of the flywheel is 250 mm. Determine also the weight of a rim type flywheel of 250 mm mean diameter for the same allowable fluctuation of speed.

- 36. 0 90 180 360 450 540 630 720 25 50 75 100 -25 -50 -75 -100 T N-m (Degrees)

- 37. 0 Crank angle per cycle=720 Mean speed n=3000 rpm, 250 Radius of gyration k= =125 mm =0.125 m 2 0.25 Radius of gyration k= =0.0884 m 2 2 10 20 C 0.00 3000 3000 s (For rim type) (For disk type) Data : = 4π radians 667 2 Angular Velocity of flywheel = 60 2 3000 . . 314.16 rad/ e 0 c 6 s n i e Solution :

- 38. =75 50 100 75 50 100 75 2 2 2 2 2 2 W.D per c WD/c ycle 87.5 Mean torque T Crank angl ycle=Net are e per c a under TM ycle 4 D m m W.D / cycle = 87.5π N - m T = 21.875N - m

- 39. 0 90 180 360 450 540 630 720 25 50 75 100 -25 -50 -75 -100 T N-m (Degrees) Tmean 1 2 3 4 5 6 7 8

- 40. Let the energy at 1=E Energy at 2=E+(75-21.875) 26.5625 2 Energy at 3=( 26.5625 ) -(71.875) 9.735 2 Energy at 4=( 9.735 )+(1 68.75 00-21.875) Energy E E E E E Excess energy stored by flywheel at 5=( 68.75 )-(96.875) 20.3125 2 Energy at 6=( 20.3125 ) (50-21.875) 34.375 2 Energy at 7=( 34.375 )-(121.875) 2 Energy at 8=( 26.5625 )+(75-21.875) 2 2 6.5625 E E E E E E E E

- 41. 2 2 2 2 = Max Energy-Min energy e=(E+68.75 ) (E-26.5625 ) We know that energy stored by flywheel 299.43 (0.125) (314.16) 0.00667 s e mk C m Mass of flywheel Excess energy e Rim type Mass of flywheel m 299.43Nm = 29.11 Kg Fordisk type,k = 0.0884 m Mass of flywheel m = 58.221 Kg

- 42. Problem 6 The torque required for a machine is shown in fig. The motor driving the machine has a mean speed of 1500 rpm and develop constant torque. The flywheel on the motor shaft is of rim type with mean diameter of 40 cm and mass 25 kg. Determine; (i) Power of motor (ii) % variation in motor speed per cycle.

- 43. 400 N-m 2000 N-m Torque Crank angle

- 44. Crank angle per cycle= Mean speed n=1500 rpm, 40 Radius of gyration k= =20 cm =0.2 m 2 m=25 kg 2 Angular Velocity of flywheel 1 = 60 2 1500 . . 6 57.08 e 0 rad/s (For rim type) n i e Data : Solution : 2π radians c

- 45. W.D/cycle area 1+area 2+area 3 1 =400 2 (2000 400) (2000 400) 4 2 2 W.D per cycle 1600 Mean torque T Crank angle per cycle 2 m (i) Power developed by the engine : m W.D / cycle =1600π N - m T P=T 800 157.08 m Power developed by the en 125.664 KW gine = 800 N - m

- 46. 400 N-m 800 N-m 2000 N-m Crank angle mean Excess energy e (shaded area) 1 2 3 Torque x

- 47. 1200 From the similar triangles, 1.178 1600 2 Energy stored by flywheel = Shaded area 1 = 2000 800 1.178 2000 800 4 2 We know that energy st s x x rad e (ii) Coefficent of fluctuation of speed e C e =1649.28Nm 2 2 2 2 ored by the flywheel 1649.28 25 (0.2) (157.08) s s e mk C C Coefficient of fluctuation of speed = 0.0668 = 6.68%

- 48. Problem 7 A 3 cylinder single acting engine has cranks set equally at 1200 and it runs at 600 rpm. The TMD for each cylinder is a triangle, for the power stroke with a maximum torque of 80 N-m at 600 after dead center of the corresponding crank. The torque on the return stroke is zero. Sketch the TMD & determine the following; (i) Power developed (ii) Coefficient of fluctuation of speed if mass of flywheel is 10 kg and radius of gyration is 8 cm. (iii)Maximum angular acceleration of flywheel.

- 49. T (N-m) 0 60 120 180 240 300 360 80N-m degrees

- 50. Crank angle per cycle= Mean speed n=600 rpm, Radius of gyration k=8 =0.08 m m=10 kg 2 Angular Velocity of flywheel = 60 2 600 . . 6 62.83 r e 0 ad/s c cm n i e Data : Solution : 2π radians

- 51. W.D/cycle area of 3 triangles 1 =3 80 2 W.D per cycle 377 Mean torque T Crank angle per cycle 2 m m m T = 60 N - m max mean 377 N - m As the maxim (i) Mean to um torque (T ) is 80 Nm, and rque T T : = 60 min Nm,the minimum torque (T ) will be = 40 N - m. Hence the modified TMD may be drawn as shown in fig.

- 52. T (N-m) 0 60 120 180 240 300 360 80 N-m degrees 60 Nm 40 Nm Modified TMD for 3 Cylinder engine

- 53. 60 62.83 20 From the similar triangles, 3 2 40 3 Due to symmetry,the energy stored by flywheel =Area of (Shaded portion) 1 = 80 60 3 2 mean P T x x rad e (i) Power developed : any one traingle 3.77 Kw e =10.47 N - m

- 54. 2 2 2 2 We know that energy stored by the flywheel 10.47 10 (0.08) (62.83) s s e mk C C Coefficient of fluctuation of speed = 0.04 (ii) Coefficeint of fluctuation of speed : (iii) Maximum angular 14 = 4.1 acce 4% lera max 2 2 2 We know that T=I ,where T=Max fluctuation of torque=(T ) I=mk ,the mass moment of inertia of flywheel = Max angular acceleration, rad/sec 20 10(0.08) mean T ∴ α= 312.5 2 tion of flywheel rad / sec

- 55. Problem 8 A torque delivered by a two stroke is represented by T=(1000+300 sin 25 cos 2 Nm where is the angle turned by crank from IDC. The engine speed is 250 rpm. The mass of the flywheel is 400 kg and the radius of gyration is 400 mm. Determine (i) The power developed (ii) Total percentage fluctuation of speed (iii) The angular acceleration and retardation of flywheel when the crank has rotated through an angle of 600 from the IDC (iv) Max & Min angular acceleration & retardation of flywheel.

- 56. 0 0 As the torque is a function of 2 , equate 2 360 180 Mean speed n=250 rpm, Radius of gyration k=400 =0.4 m m=400 kg Angular Velocity of fl mm Data : Solution : 0 The crank angle per cycle = 180 π radians 2 ywheel = 60 2 250 . . 6 26.18 rad/se 0 c n i e

- 57. 0 0 W.D per cycle Mean torque T Crank angle per cycle 1 1 (1000 300sin 2 500cos2 ) 1000 26.18 m Td d P Mean torque Power developed by eng (i) Power developed by ine P engine : = m m T =1000 N - m T 26.18 KW

- 58. Sl No Angle Torque T N-m 1 0 500 2 30 1010 3 60 1510 4 90 1500 5 120 990 6 150 490 7 180 500 0 180 Tmean =1000 N-m 500 Nm T (N-m) Crank Angle Excess Energy mean )

- 59. 1 2 1 2 The excess energy stored by the flywheel is given by integrating between the limits & where & correspond to points where T=T Or (T-T mean mean (ii)Coefficient of fluctuation of speed : ΔT ) = = 0 i.e. (300sin 2 500cos2 ) 0 500 Hence tan2 = 1.667 300 (As the torque curve intercepts the mean torque line at these points) 0 0 0 0 1 0 0 1 2 2 2θ = 59 ΔT Hence θ = 29. & 5 & 2θ = ( 180 +5 θ =119 9 ) = 2 .5 39

- 60. 2 1 119.5 29.5 . (300sin 2 500cos2 ) T d d Excess energy e = e = (The above integration may be perf (ii)Coefficient ormed using calcul of fluctuation of ator by keeping in speed (contd.. radian mode ...) and 2 2 2 2 Also e=mk 583.1 400 (0.4) C 0.0 ( 133 1.33 2 8) % 6.1 s s s C C sub e = 583.1 N - m Coefficient of fluctua sti tio tuting the limits of integration in radia n of speed ns)

- 61. 0 0 Acceleration (or retardation) is caused by excess (or deficit) torque measured from mean torque at any instant. At = i.e T 60 , 300sin(2 60) 50 . (iii) Angular acceleration at 60 crank position ΔT 2 0 0cos(2 60) Now, 509.8 400 (0.4) Hence Angular acceleration at 60 crank positi 50 n 9 8 o . N m I 0 2 60 ΔT ΔT α =7.965 rad / sec

- 62. max Maximum acceleration (or retardation) is caused by maximum fluctuation of torque from mean, i.e max (To find ΔT first find the crank positions at which ΔT is ma (iv) Maximum angular acceleration : ΔT 0 0 0 0 For max value of T, ( T) 0 (300sin 2 500cos2 ) 0 . 600 co tan2 =-0.6 2 =-31 & 2 (180 ( 31 s 2 +1000 sin2 0 H ) 149 ence ximum &then substitute those values in the equation of ΔT.) d d d d i e

- 63. 0 0 max max 2 At 2 =-31 , 583.1N-m (causes retardation) At 2 =149 , 583.1 (Causes acceleration) Max angular acceleration of flywheel 583.1 400(0.4) T T T I (iv) Maximum angular acceleration (contd) : 9.11 min min 2 Max angular retardation of flywheel 583.1 400(0.4) (-ve sign indicates retardation) T I 2 2 rad / sec -9.11 rad / sec

- 64. Problem 9 A machine is coupled to a two stroke engine which produces a torque of (800+180 Sin 3 N-m where is the crank angle. The mean engine speed is 400 rpm. The flywheel and the rotating parts attached to the engine have a mass of 350 kg at a radius of gyration of 220 mm. Calculate; (i) The power developed by the engine (ii) Total percentage fluctuation of speed when, (a) The resisting torque is constant (b) The resisting torque is (800+80 Sin

- 65. Sl No Angle Torque T N-m 1 0 800 2 30 980 3 60 800 4 90 620 5 120 800 (a)When the resisting torque is Constant 0 120 T (N-m) Crank Angle 0 0 300 600 90 0 Excess Energy T E T E = Engine torque =mean Torque Tm Tm Nm

- 66. 0 0 As the torque is a function of 3 , equate 3 360 120 Mean speed n=400 rpm, m=350 kg Radius of gyration k=220 =0.22 m Angular Velocity o mm Data : Solution : 0 2 The crank angle per cycle = 120 3 π radians 41.89 r 2 f flywheel = 60 2 400 . . ad/s 60 ec n i e

- 67. 2 2 3 3 0 0 W.D per cycle Mean torque T Crank angle per cycle 1 1 (800 180sin3 ) 2 2 3 3 800 41.89 m Td d P Mean torque Power developed by engine (i) Power developed by engi P ne : = m m T = 800 N 33. - m T 51 KW

- 68. 1 2 1 2 The excess energy stored by the flywheel is given by integrating between the limits & ,where To find & (ii)Coefficient of fluctuation of speed (a)When the resisting torque is constant : ΔT 0 0 are crank positions at which T=T (T-T i.e. (800 180sin3 800) 0 180sin3 0 3 0 & 3 1 0 0 8 mean mean (As the torque curve intercepts the mean torque line at these points) Or 0 1 2 ΔT = θ = 0 & ) θ = = 600

- 69. 2 1 60 0 . (180sin3 ) T d d Excess energy e = e = (The above integration may be performed using calc (ii)Co ulator efficient of fluctuation of sp by keeping in radian mode and eed (contd.. substitutin ...) g the 2 2 2 2 Also e=mk 120 350 (0.22) (41.89) C 0.00404 0.404% s s s C C e = 120 N - m Coefficient of fluctuation of speed limits of integration in radians)

- 70. (b)When the resisting torque is (800 + 80sin ) 0 120 T (N-m) Crank Angle 0 0 300 600 900 Excess Energy 180 0 T E T M T E TM = Engine torque =Machine Torque

- 71. 1 2 1 The excess energy stored by the flywheel is given by integrating between the limits & ,where To find & (ii)Coefficient of fluctuatio (b)When the resisting torque is (80 n of speed : 0 + 80sin ) ΔT 2 3 are crank positions at which T =T (T -T i.e. (800 180sin3 ) (800 80sin ) 0 180(3sin 4sin ) 0 i 0 8 s E M E M (As the engine torque curve intercepts the machine torque curve at these points) Or Δ ) = T = 2 n =0 (460-720sin 0 sin 0.799 0 0 1 2 θ = 53 &θ = ( 180 -53) =127

- 72. 2 1 127 53 . (180sin3 80sin ) T d d Excess energy e = e = (The above integration may be performed (ii)Coeff using calcu icient of f lator by ke luctuation of sp eping in radian e m ed (contd.....) ode and substi 2 2 2 2 Also e=mk 208.3 350 (0.22) (41 C 0.007 .89) 0.7% s s s C C tuting the limits of integration e = -208.3 N - m Coefficient of fluctuation of sp in radians) (Take absolute valu eed e)

- 73. Problem 10 A certain machine requires a torque of (500+50sin N-m to drive it, where is the angle of rotation of the shaft. The machine is directly coupled to an engine which produces a torque of (500+60 sin2 Nm. The flywheel and the other rotating parts attached to the engine have a mass of 500 kg at a radius of 400 mm. If the mean speed is 150 rpm. Find; (a) The maximum fluctuation of energy (b)Total % fluctuation of speed (c) Max & Min angular acceleration of the flywheel & the corresponding shaft positions.

- 74. 0 T (N-m) Crank Angle 0 Excess Energy 180 0 TE T M TE T M = Engine torque =Machine Torque

- 75. 0 0 As the torque is a function of 2 , equate 2 360 180 Mean speed n=150 rpm, Radius of gyration k=400 =0.4 m m=500 kg Angular Velocity of fl mm Data : Solution : 0 The crank angle per cycle = 180 π radians 2 ywheel = 60 2 150 . . 6 15.71 rad/se 0 c n i e

- 76. 1 2 1 2 The excess energy stored by the flywheel is given by integrating between the limits & ,where To find & are crank positions at which T =T (T -T E M E M (i) Excess energy stored by flywheel : Or ΔT ) 0 0 0 i.e. (500 60sin 2 ) (500 50sin ) 0 (60sin 2 50sin )=0 sin 12cos 5 0. 0 0 ,18 Either sin 0 5 or 12cos 5 0 cos 12 Considering max difference between consecutive 0 65.37 = Put sin2θ = 2sinθ Δ cosθ T = crank positions, 0 0 1 2 θ = 65.37 &θ = 180

- 77. 2 1 180 65.37 . (60sin 2 50sin ) T d d Excess energy e = e = (The above integration may be performed using calculator by keeping in radian mode and substituting the limits of integration in radian e = - s) 120. 2 2 2 2 Also e=mk 120.42 500 (0.4) (15.71) C 0.0061 s s s C C (Take absolute value) Coefficient o 42 N - m (i f fluctuat i)Coefficient of fluctuation of speed : ion of speed 0.61%

- 78. max Maximum acceleration (or retardation) is caused by maximum fluctuation of torque from mean, i.e max (To find ΔT first find the crank positions at wh (iii) Maximum & Minimum angular acceleration : ΔT For max value of T, ( T) 0 (60sin 2 50sin ) 0 . .12 cos 2 - 5cos 0 ich ΔT is maximum &then substitute those values in the equation of ΔT.) d d d d i e

- 79. 2 0 0 2 0 & . .12 cos 2 - 5cos 0 Put cos 2 (2cos 1), we get 12(2cos 1) - 5cos 0 At : T=60 sin(2 35)-50sin(35)= 27.7 0.3 8 6 0 4 max i e 27.7 N Maximum - m ra acce d / leration sec = 2 = 35 =12 24cos θ -5cosθ -12 = 0 5 7.6 = 3 0 At : T=60 sin(2 127.6)-50sin(127.6)=-9 1 97. . 0 6 22 2 8 max 2 2 7.62 Maximum retardation N - m rad / se = c =127.6

- 80. Flywheel for Punch press Crank Plate Die Punching tool Flywheel Flywheel for Punch Press Crank shaft connecting rod d t

- 81. Flywheel for Punch press • If ‘d’ is the diameter of the hole to be punched in a metal plate of thickness ‘t’ , the shearing area A=d t mm2 • If the energy or work done /sheared area is given, the work done per hole =W.D/mm2 x Sheared area per hole. • As one hole is punched in every revolution, WD/min=WD/hole x No of holes punched /min • Power of motor required P=WD per min/60

- 82. 1 2 1 2 ) 2 (E = Energy supplied per sec× Actual time of punching) e = ( E E where; E = Energy required per hole E = Energy Excess energy Stored by Flywheel : supplied during actual punching

- 83. Problem 11 A punching machine carries out 6 holes per min. Each hole of 40 mm diameter in 35 mm thick plate requires 8 N-m of energy/mm2 of the sheared area. The punch has a stroke of 95 mm. Find the power of the motor required if the mean speed of the flywheel is 20 m/sec. If the total fluctuation of speed is not to exceed 3% of the mean speed, determine the mass of the flywheel.

- 84. 2 Mean speed of flywheel v=20m/sec 3% 0.03, Diameter of hole d=40 mm Thickness of plate t=35 mm, Energy/mm =8 N-m Stroke length =95 mm, No of holes/min=6 Speed of crank=6rpm Time required to pu s C Data : 3 3 nch one hole= W.D/hole= W.D/hole holes/min Power of motor= KW 60 10 35185.4 6 60 10 P Solution : 2 10 secs Sheared area per hole = πdt = π×40× 35 = 4398.23 mm 4398.23 8 = 35186 N 3.51 - m 86KW

- 85. Thickness of plate Time taken per cycle 2×stroke length 35 10= 1 0 9 actual actual 1.842 Secs Excess energy supplied by flyw As the punch travels 95 ×2 =190 mm in10 secs ⇒actual time taken to punch one hole T = T = 2 e=Energy required/hole Energy supplied during actual punching = ( e heel 2 s 35186 3518.6 1.842) = 28705 N - m Also e = mv C 28705 m ( 20) 0.0 m = 239 3 2 Kg

- 86. Problem 12 A constant torque 2.5 KW motor drives a riveting machine. The mass of the moving parts including the flywheel is 125 kg at 700 mm radius. One riveting operation absorbs 10000 J of energy and takes one second. Speed of the flywheel is 240 rpm before riveting. Determine; (i) The number of rivets closed per hour (ii) The reduction in speed after riveting operation.

- 87. 1 1 2 240 Maximum speed of flywheel n =240 rpm 60 Energy required per rivet =10000 J Time taken to close one rivet =1 sec Energy supplied by motor=Power of motor =2.5KW=2500 J/sec Ma Data : 25.133 rad / sec 2 2 ss of flywheel m=125 kg, Rad. of gyration k=700 mm Mass M.O.I of flywheel I=125 (0.7) 61.25 Energy supplied by motor =2.5KW=2500 J/sec Energy supplied per ho Kg m (i) : Number of rivets closed per hour ur =2500 3600 J Energy required per rivet =10000 J 2500 3600 J Number of rivets closed per hour will be= 10000 900 rivets / hr

- 88. 2 2 1 2 2 2 2 2 2 =Energy required/rivet-Energy supplied by motor =(10000 2500) 1 2 1 7500 61.25 (25.13) 2 19.66 60 19.66 / sec 188 2 7500 e e I rad n rpm J Excess energy supplied by flywheel : Also e = ( ii) 1 2 . Reduction in speed after riveting=( ) n n (240 - 188) = 52 rpm