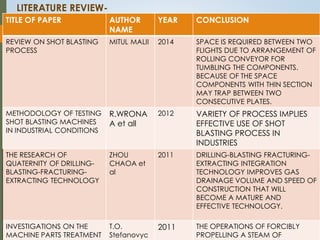

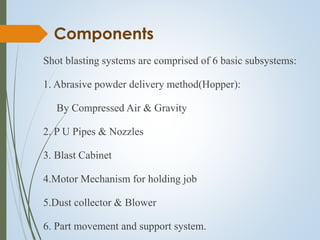

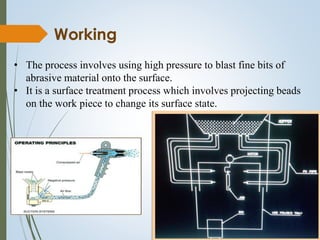

The document summarizes a student project on removing impure layers through abrasive shot blasting. It discusses the shot blasting process which uses compressed air or gravity to propel abrasive materials like sand or glass beads to clean surfaces. Key components of shot blasting systems and factors affecting the process are outlined. Applications include cleaning metals and producing decorative finishes. The document also covers safety precautions for the process.