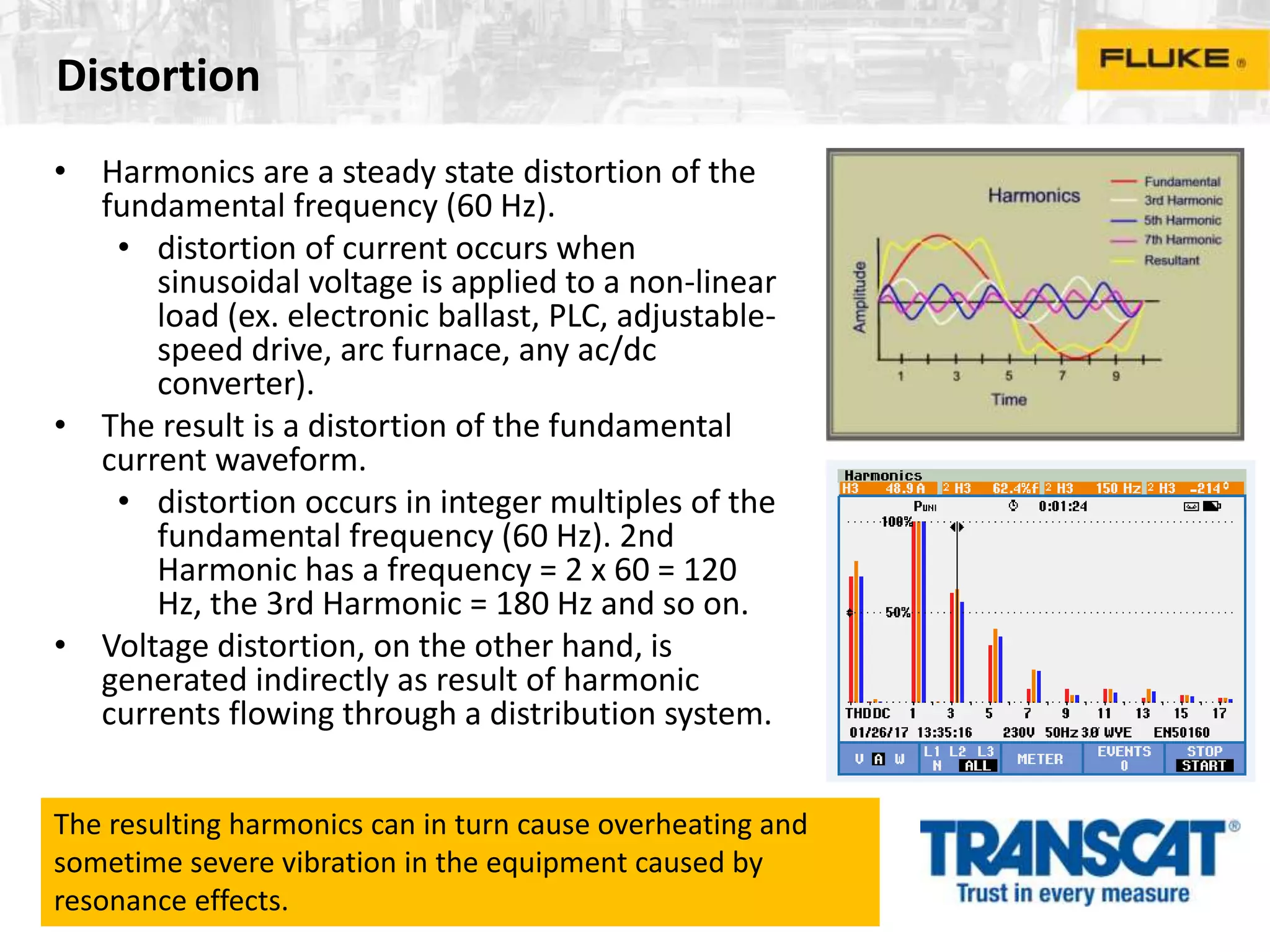

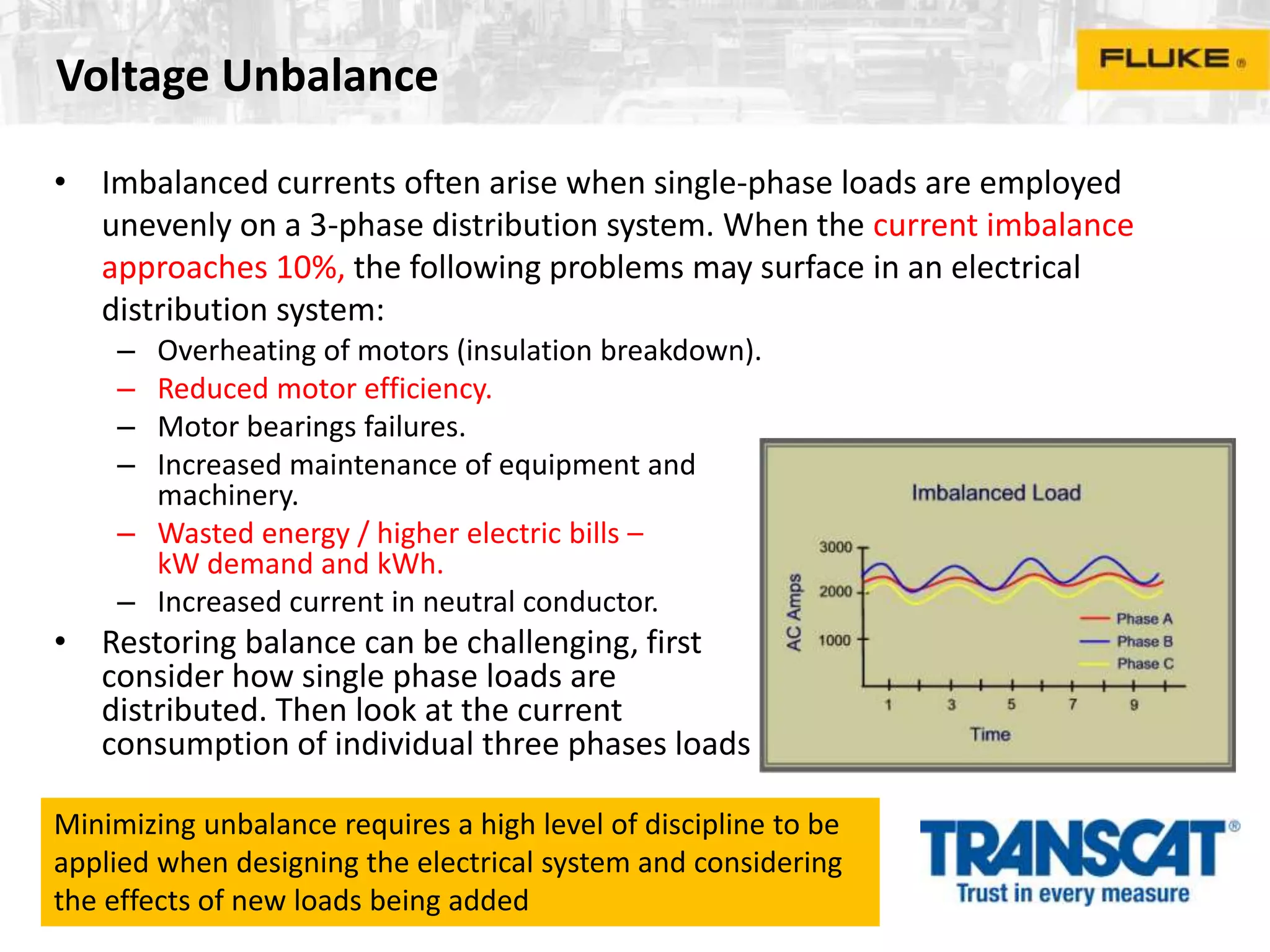

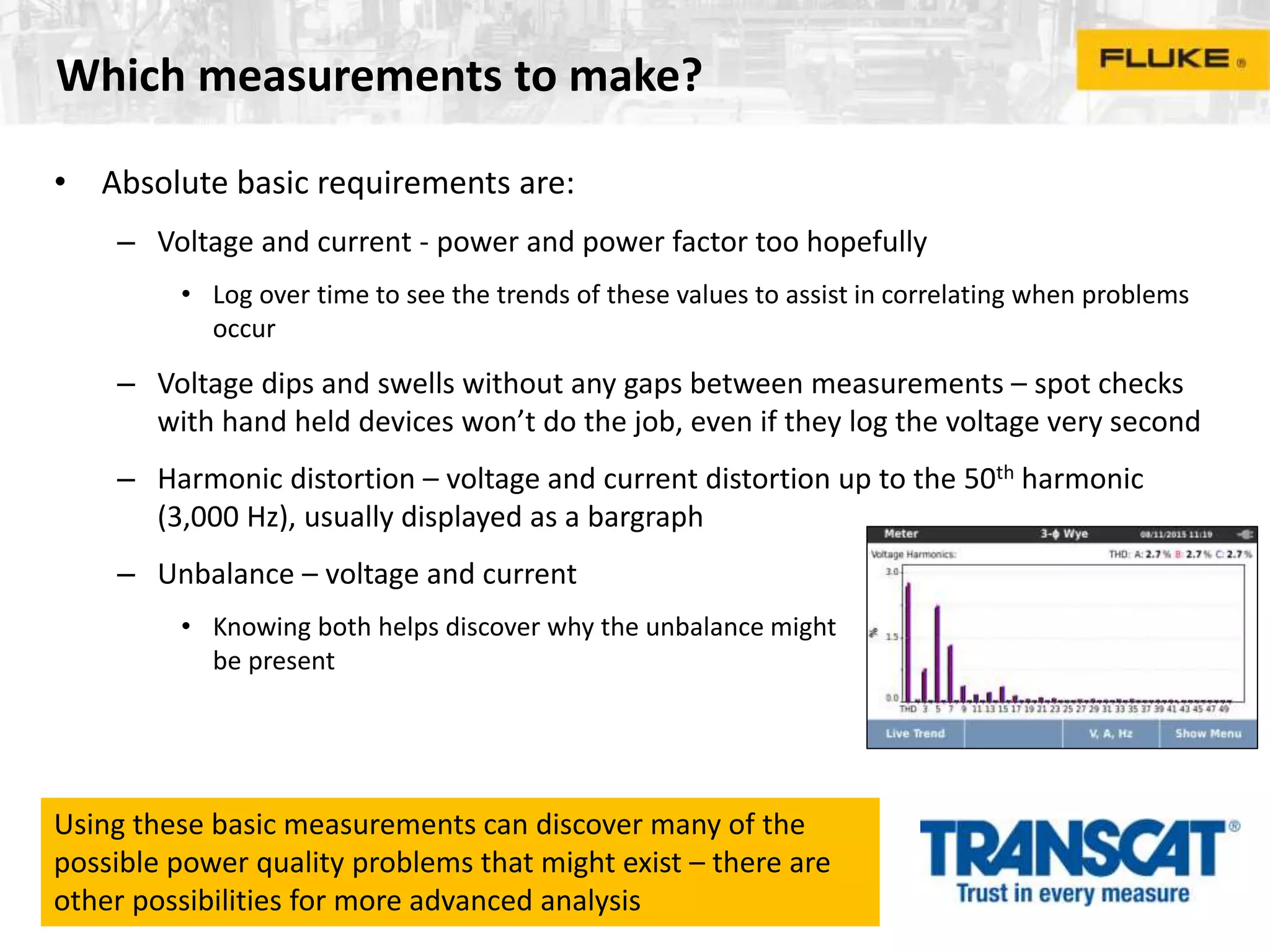

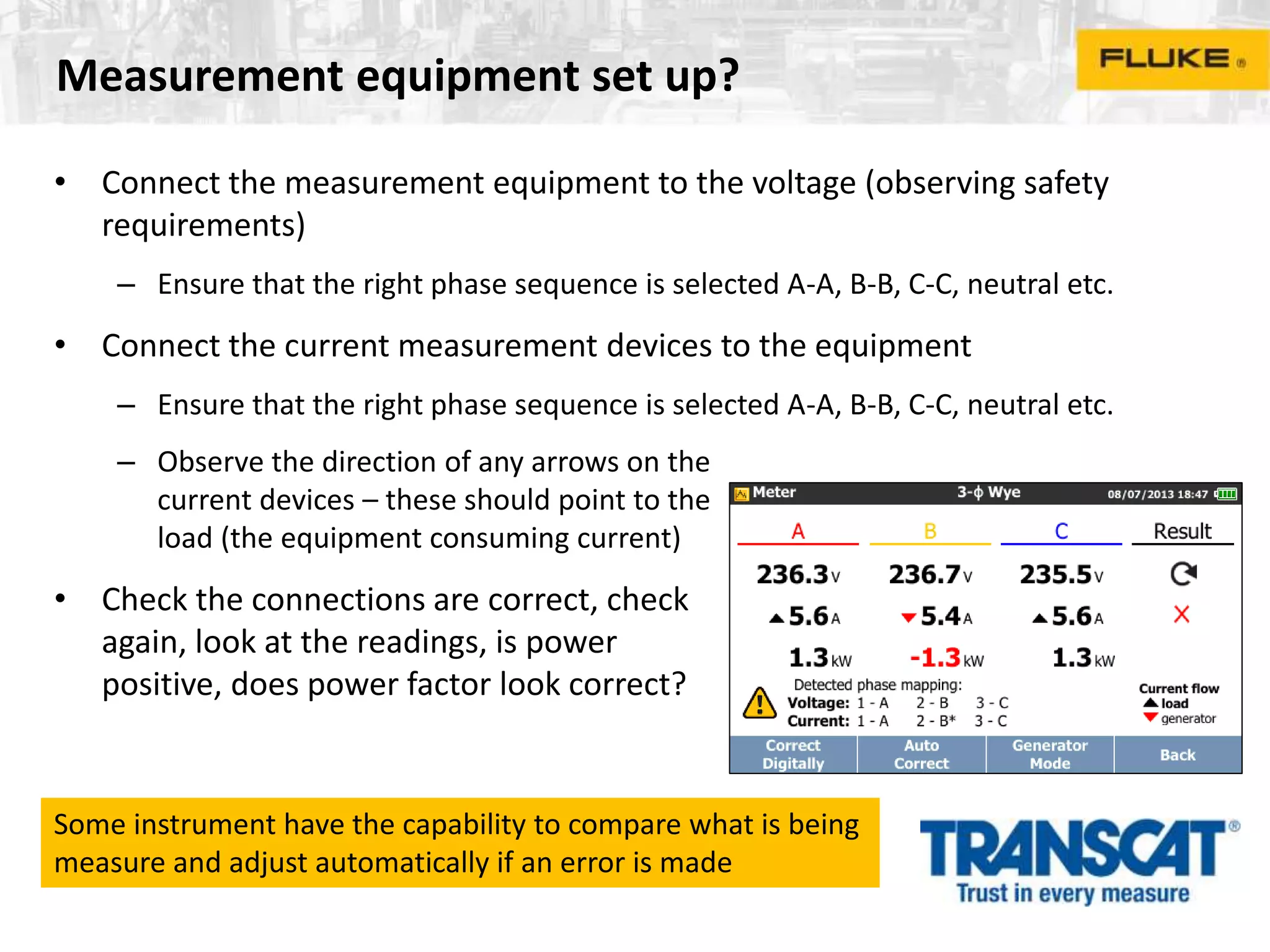

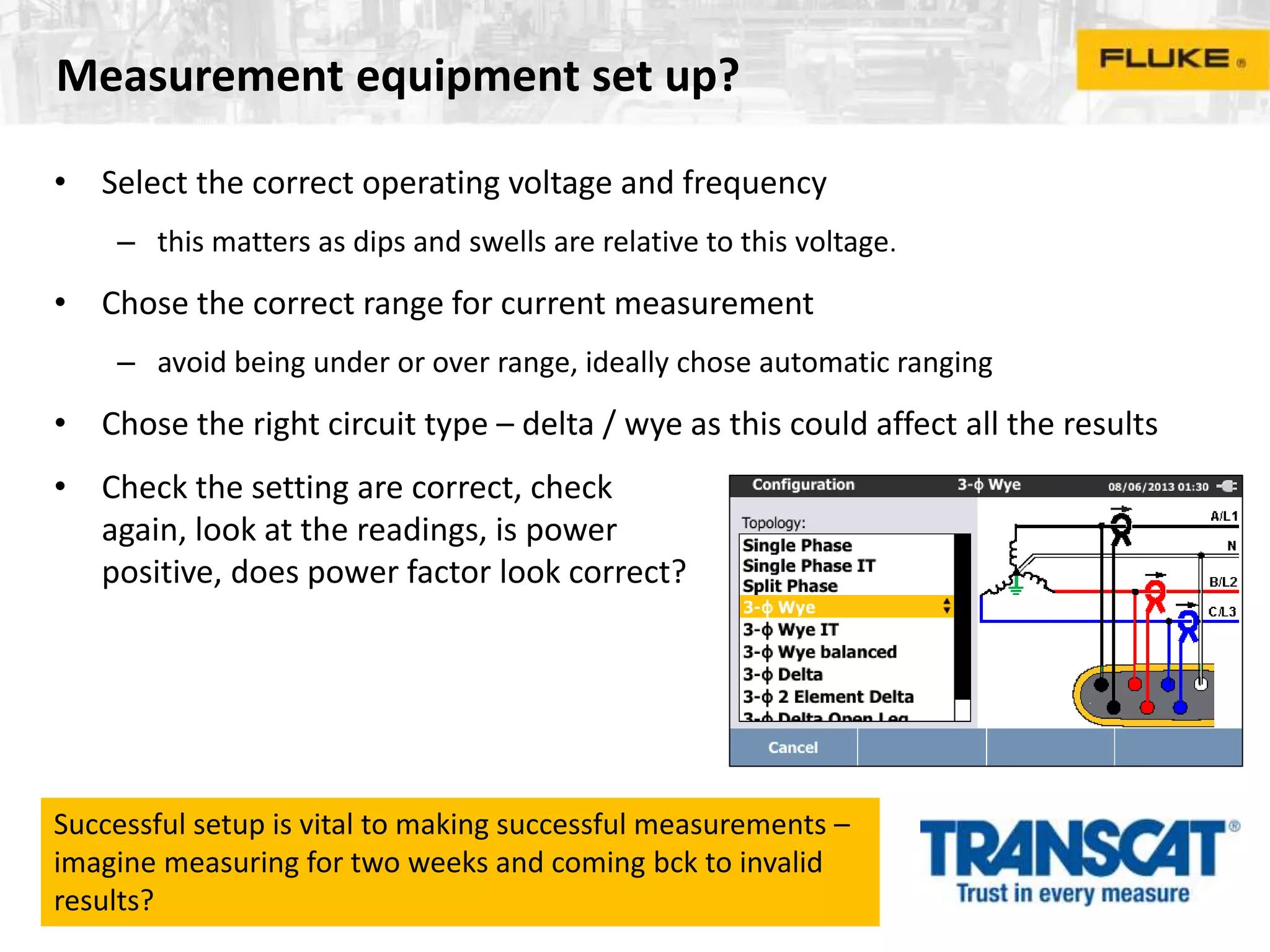

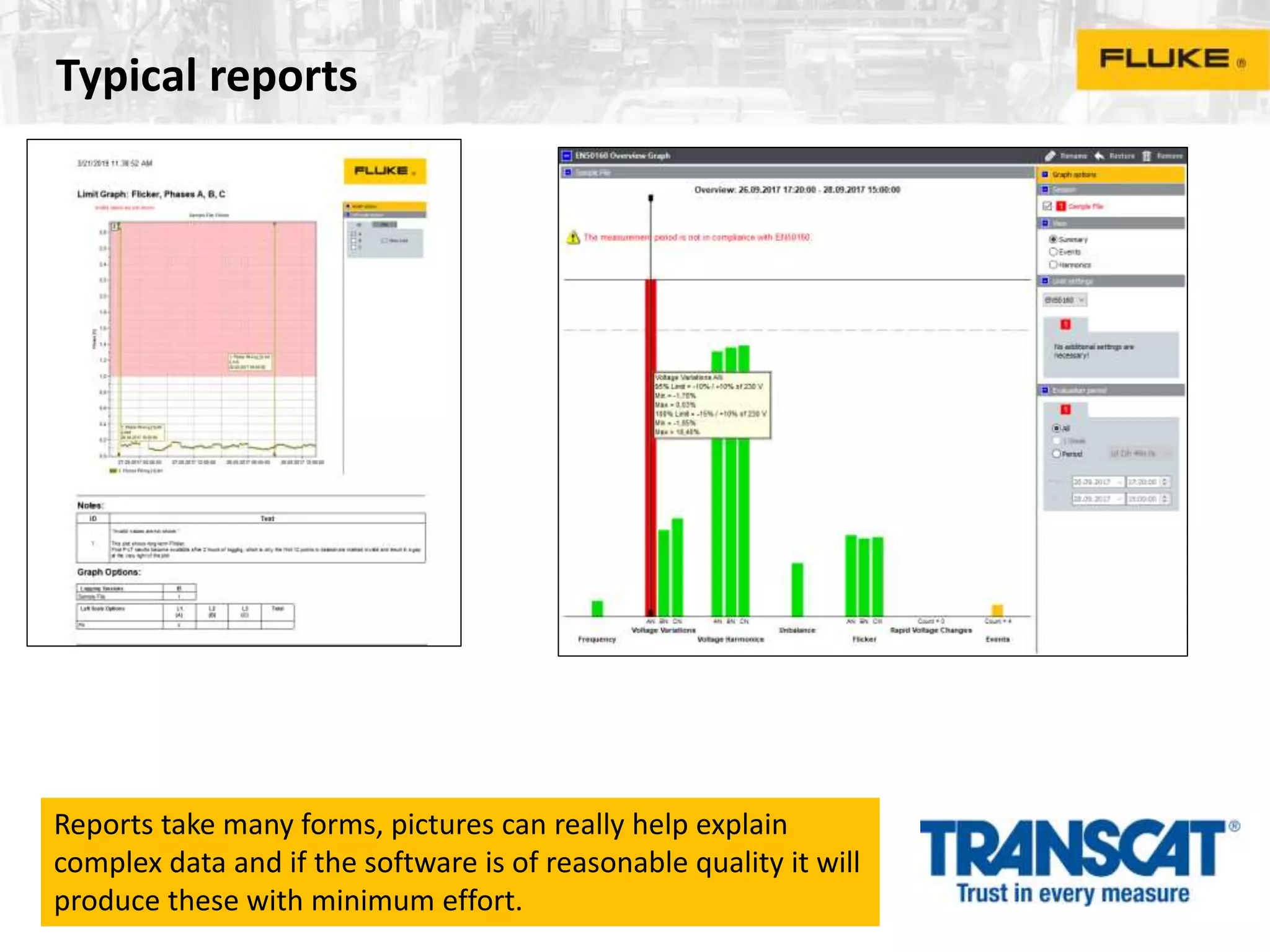

The document outlines practical power quality measurements and solutions to common issues such as unexpected energy bill increases, equipment tripping, overheating, and premature failures. It emphasizes the importance of methodical measurements and data analysis to identify power quality problems and suggests corrective actions like tightening connections, balancing loads, and utilizing filters for harmonics. A systematic approach, continual monitoring, and historical data tracking are recommended for maintaining good power quality and reducing costs.