1) The document discusses integrating basic power quality measurements into existing predictive maintenance procedures to monitor the health of critical equipment and identify potential failures.

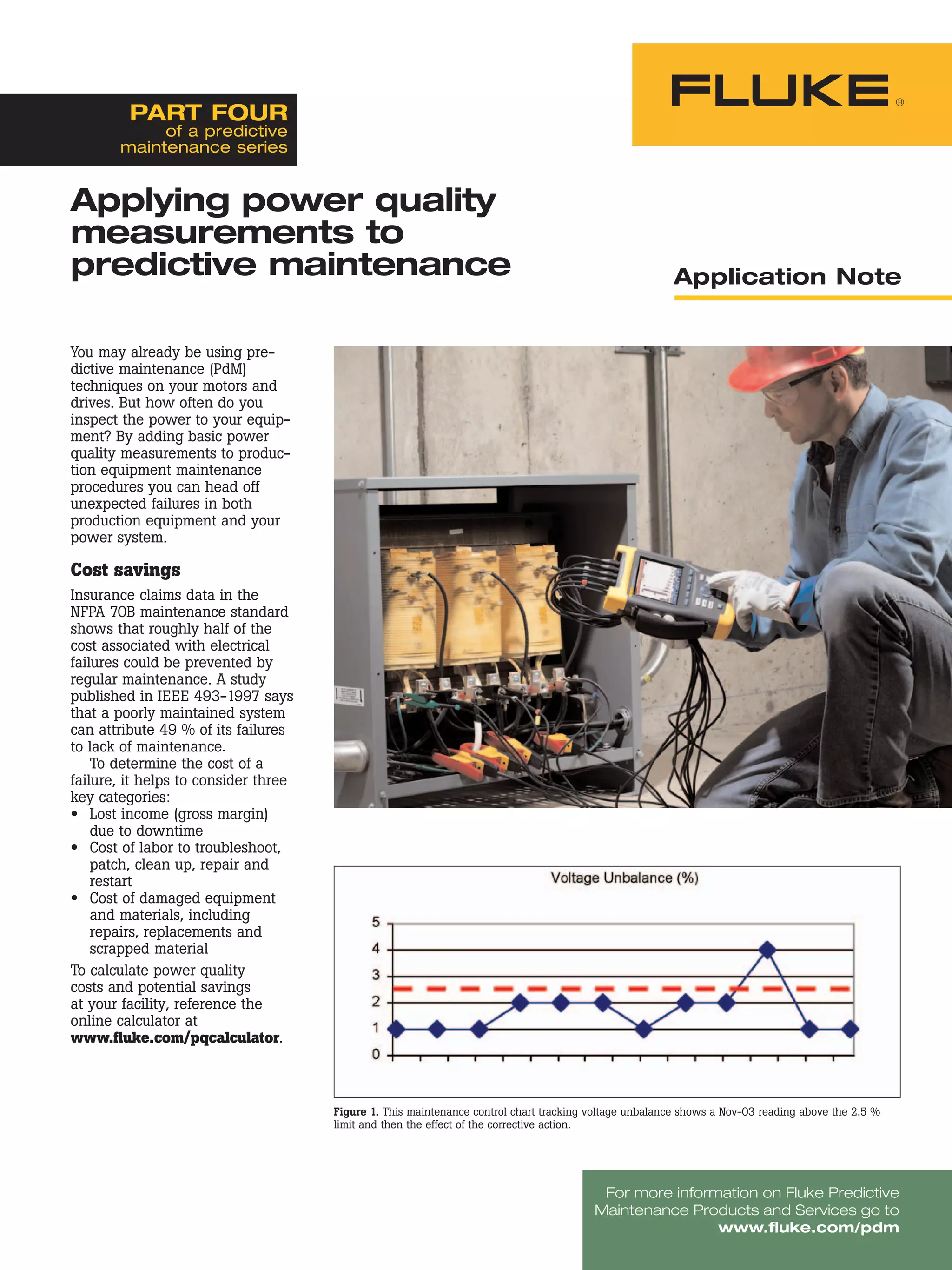

2) It recommends measuring voltage levels, sags, harmonics, unbalance, and currents over time at key points to track trends that may indicate degradation.

3) Catching issues early through low-cost power quality monitoring can help prevent nearly half of electrical failures according to industry studies and save on costs of downtime, repairs and replacement equipment.