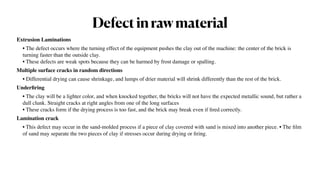

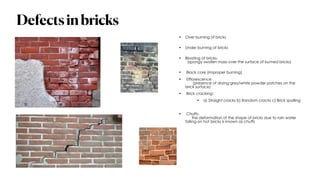

The document discusses various types of defects in brick masonry construction, highlighting factors such as material quality, environmental impacts, and construction errors that can lead to issues like cracks and weakening. It identifies specific defects including sulphate attacks, under or over burning of bricks, and various types of cracks arising from temperature changes and differential loading. Additionally, it emphasizes the importance of proper curing and aging of bricks for enhancing structural strength.