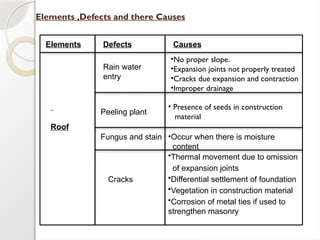

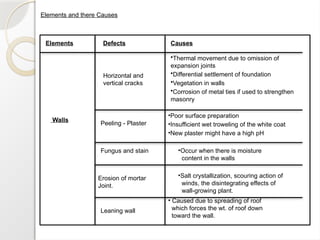

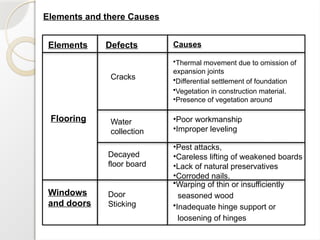

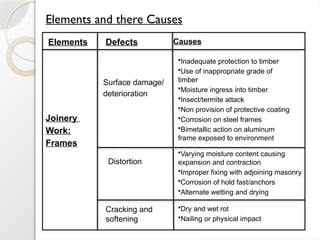

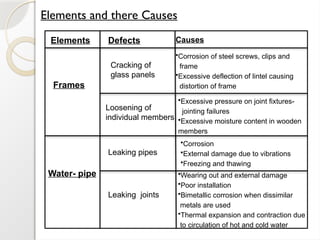

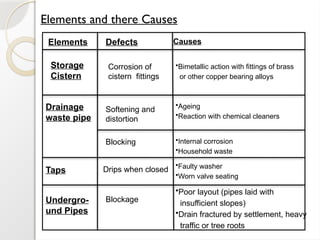

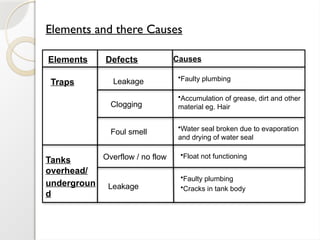

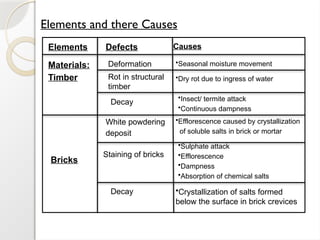

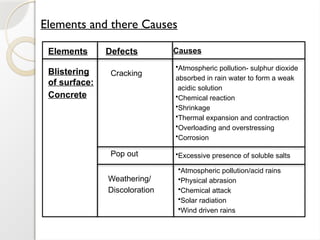

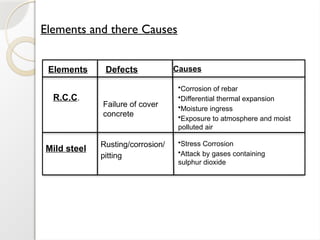

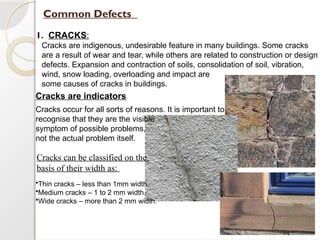

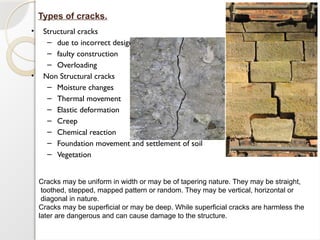

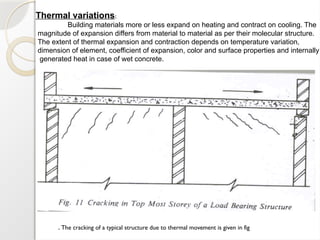

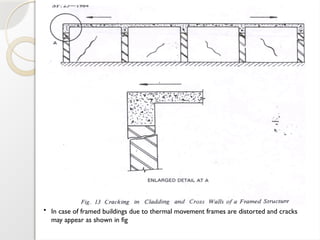

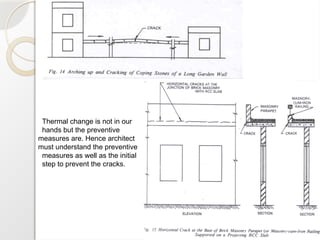

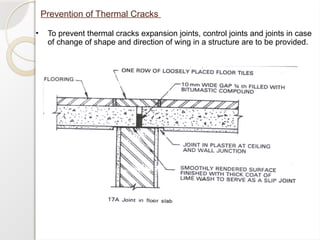

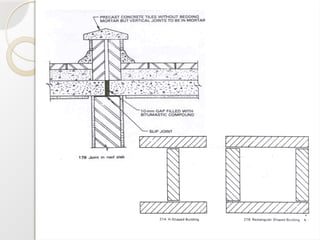

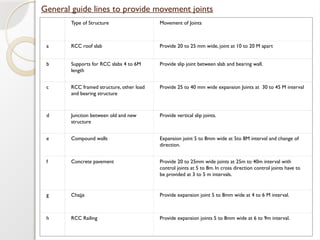

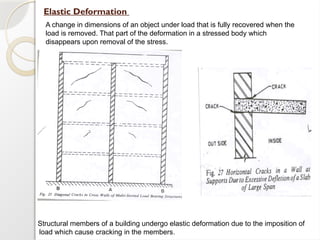

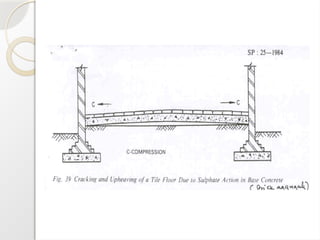

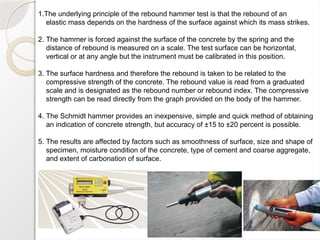

The document outlines various defects in buildings, their causes, types, and remedies. It emphasizes the importance of identifying and addressing defects to prevent safety hazards and significant repair costs, detailing common issues like cracks, water seepage, and corrosion. Additionally, it discusses preventive measures, rehabilitation methods, and non-destructive testing techniques to enhance building integrity and longevity.