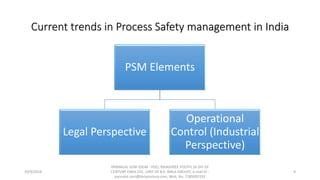

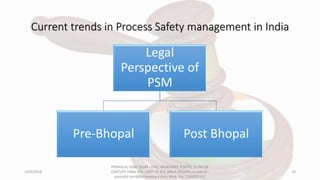

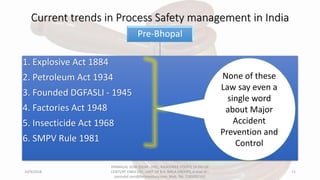

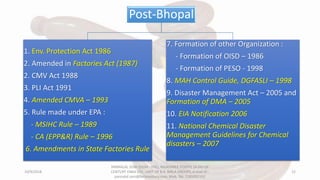

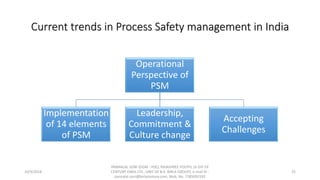

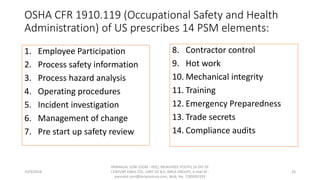

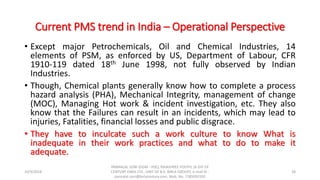

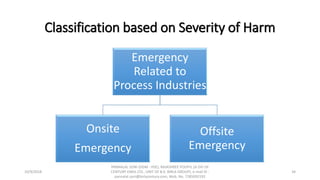

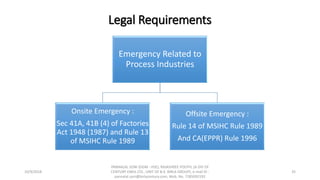

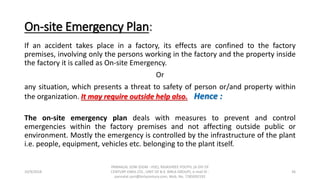

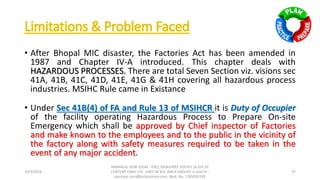

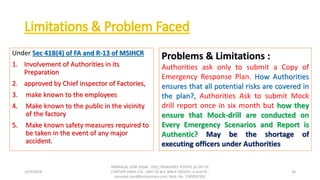

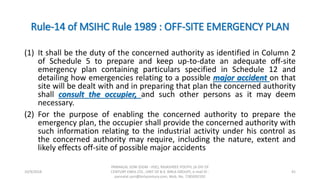

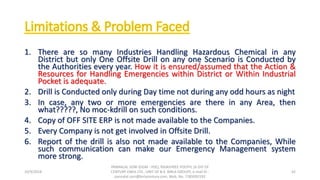

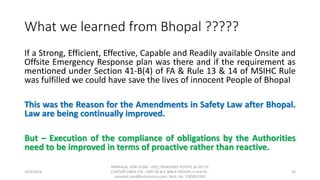

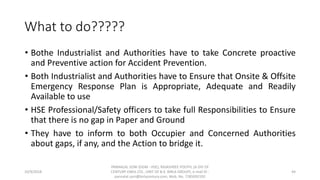

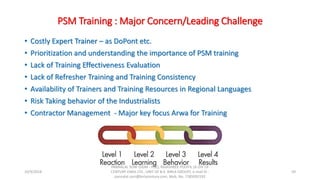

The document discusses current trends in process safety management in India from both a legal and operational perspective. It notes that while laws were strengthened after Bhopal to address major accidents, incidents still occur due to lack of awareness, competent professionals, monitoring, and information sharing. The discussion focuses on ensuring proper assessment of process safety systems, mandatory audits, compliance beyond paperwork, and public disclosure of emergency information as required by law.