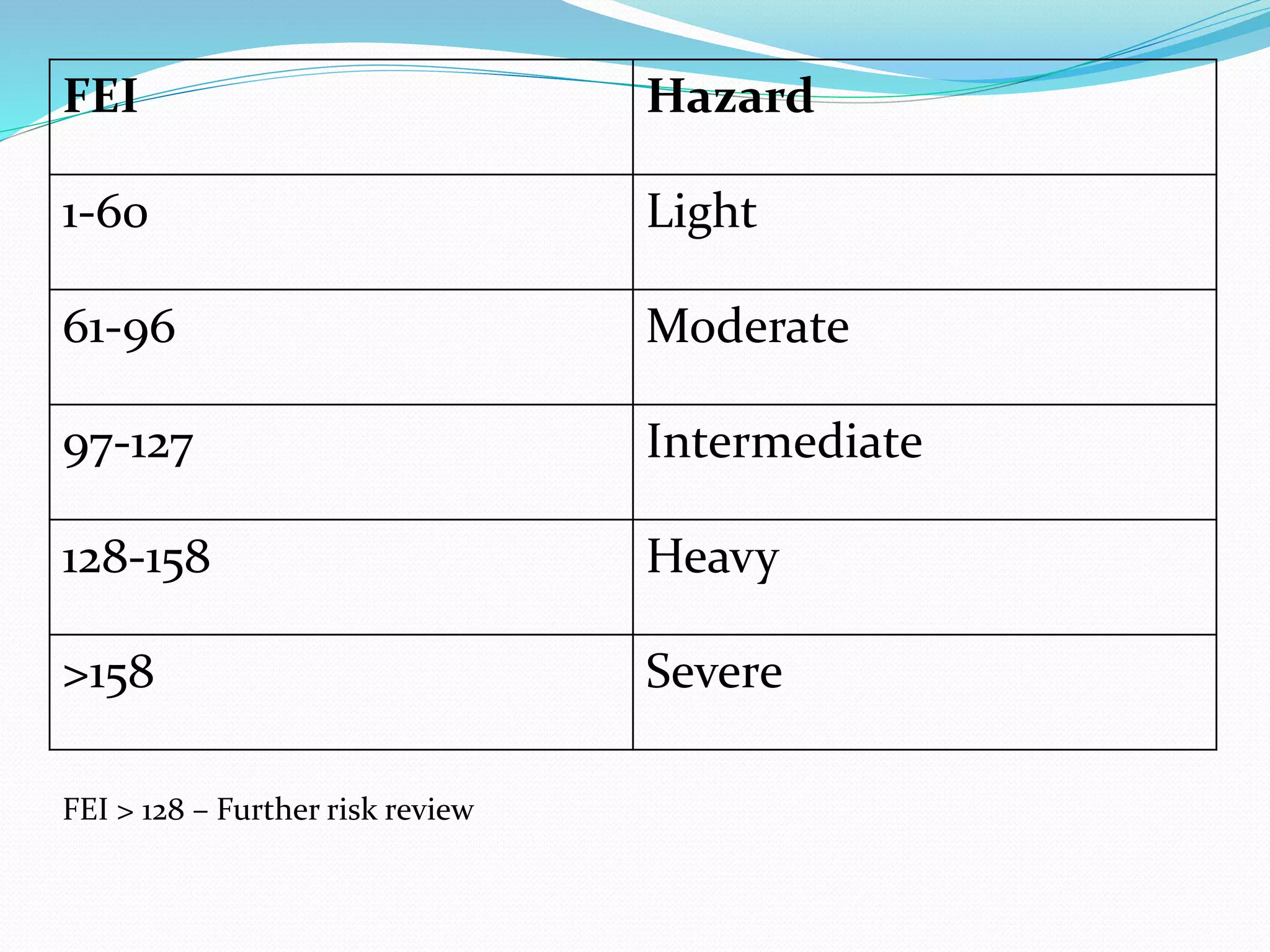

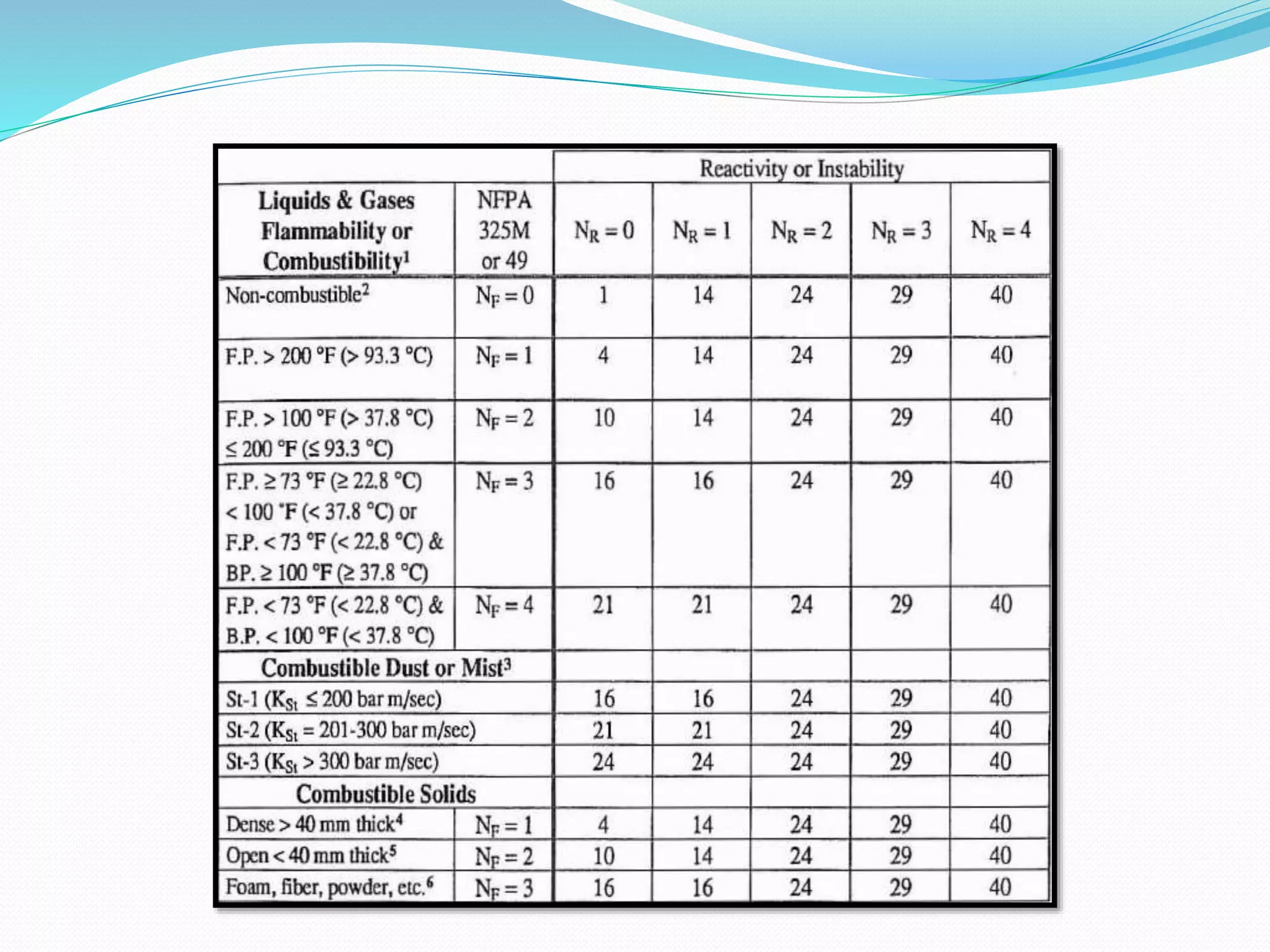

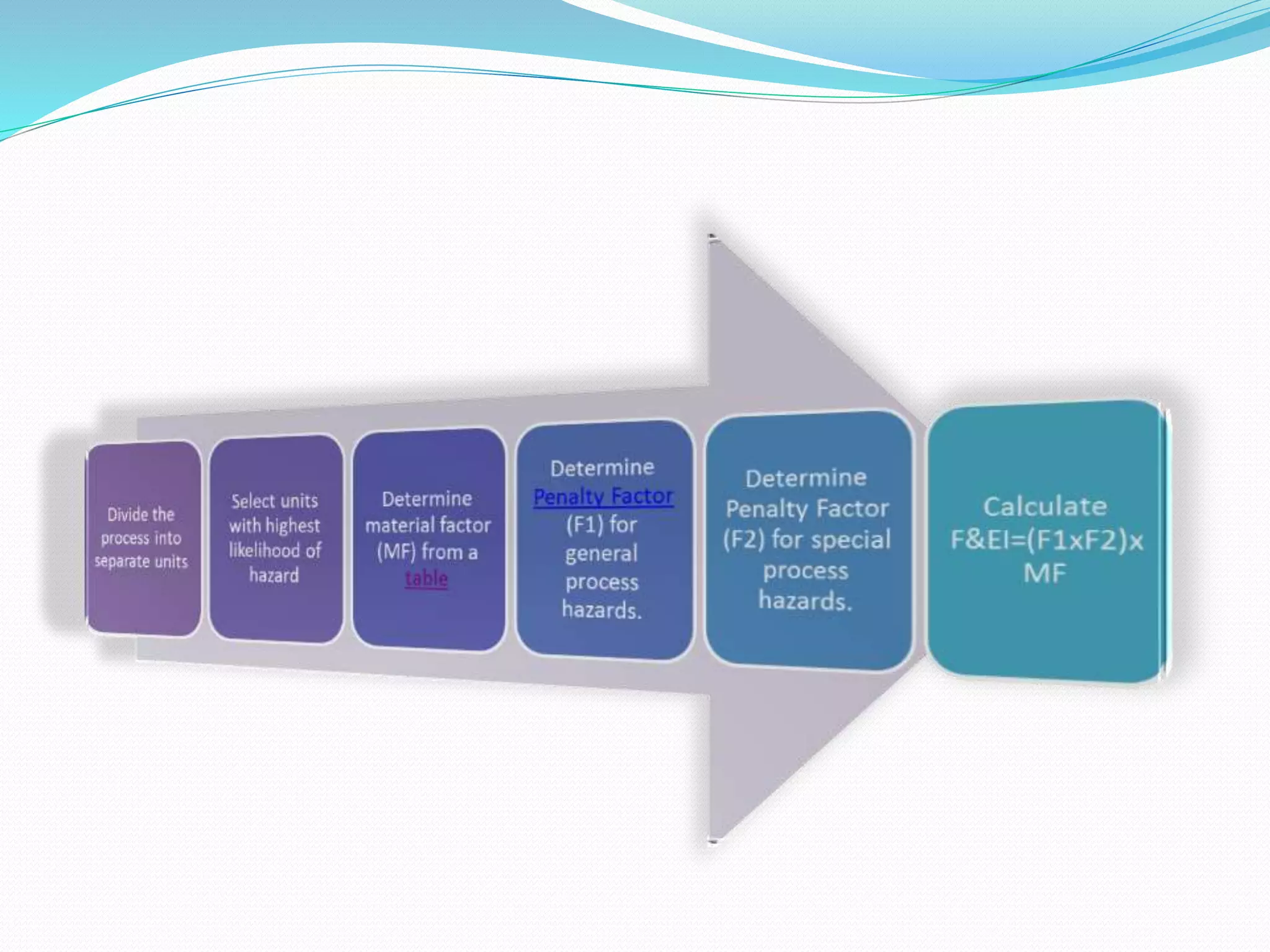

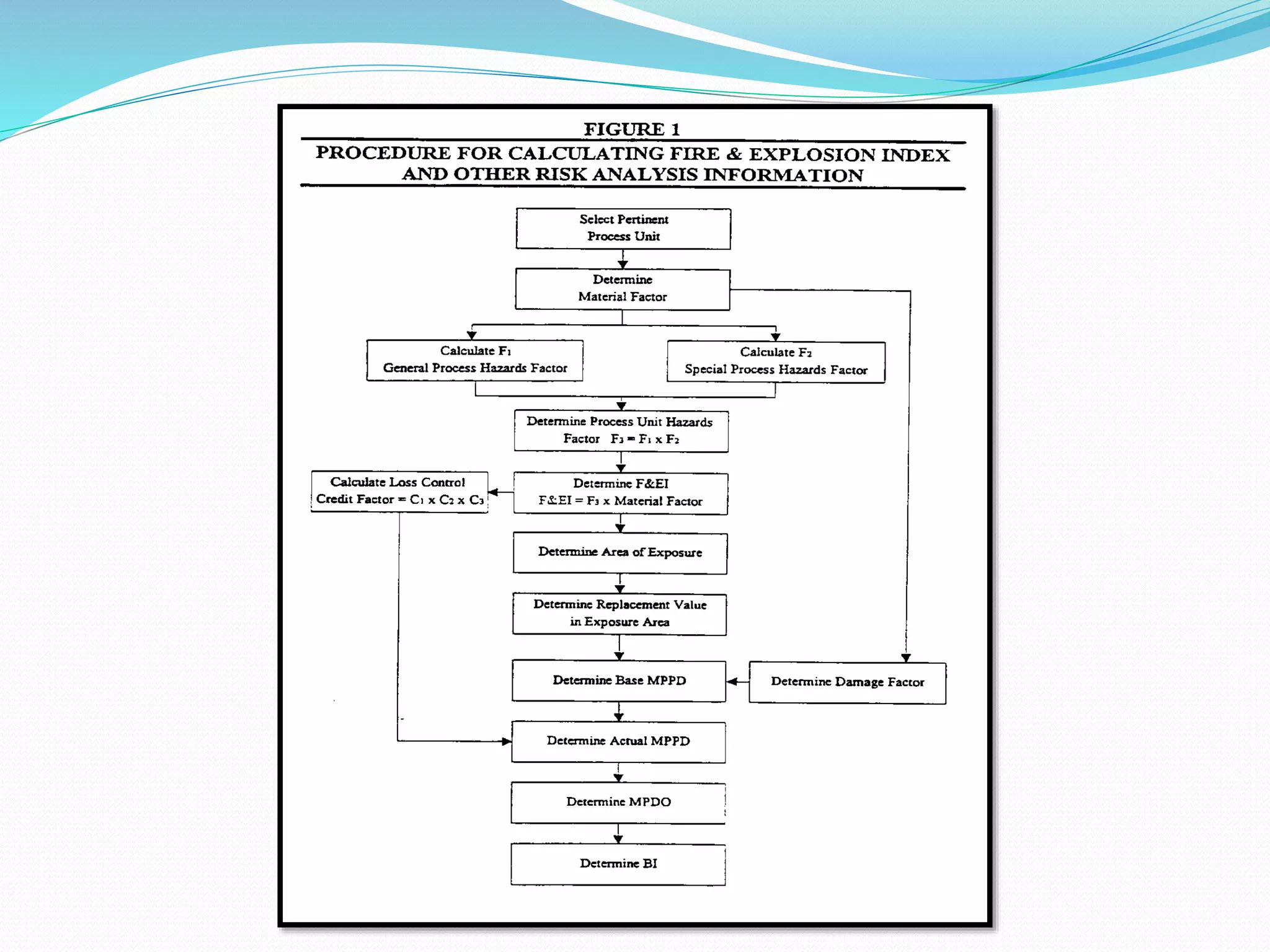

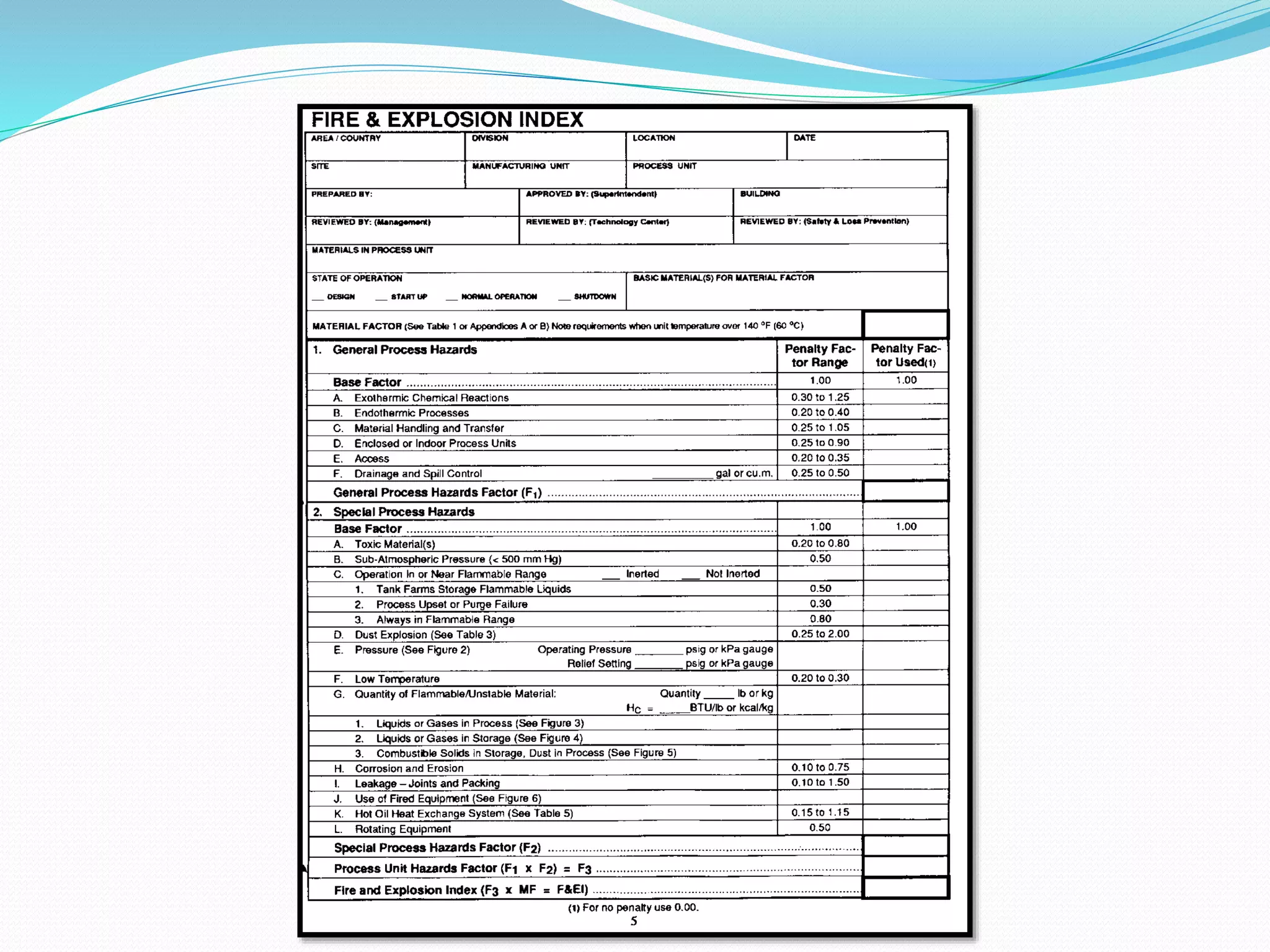

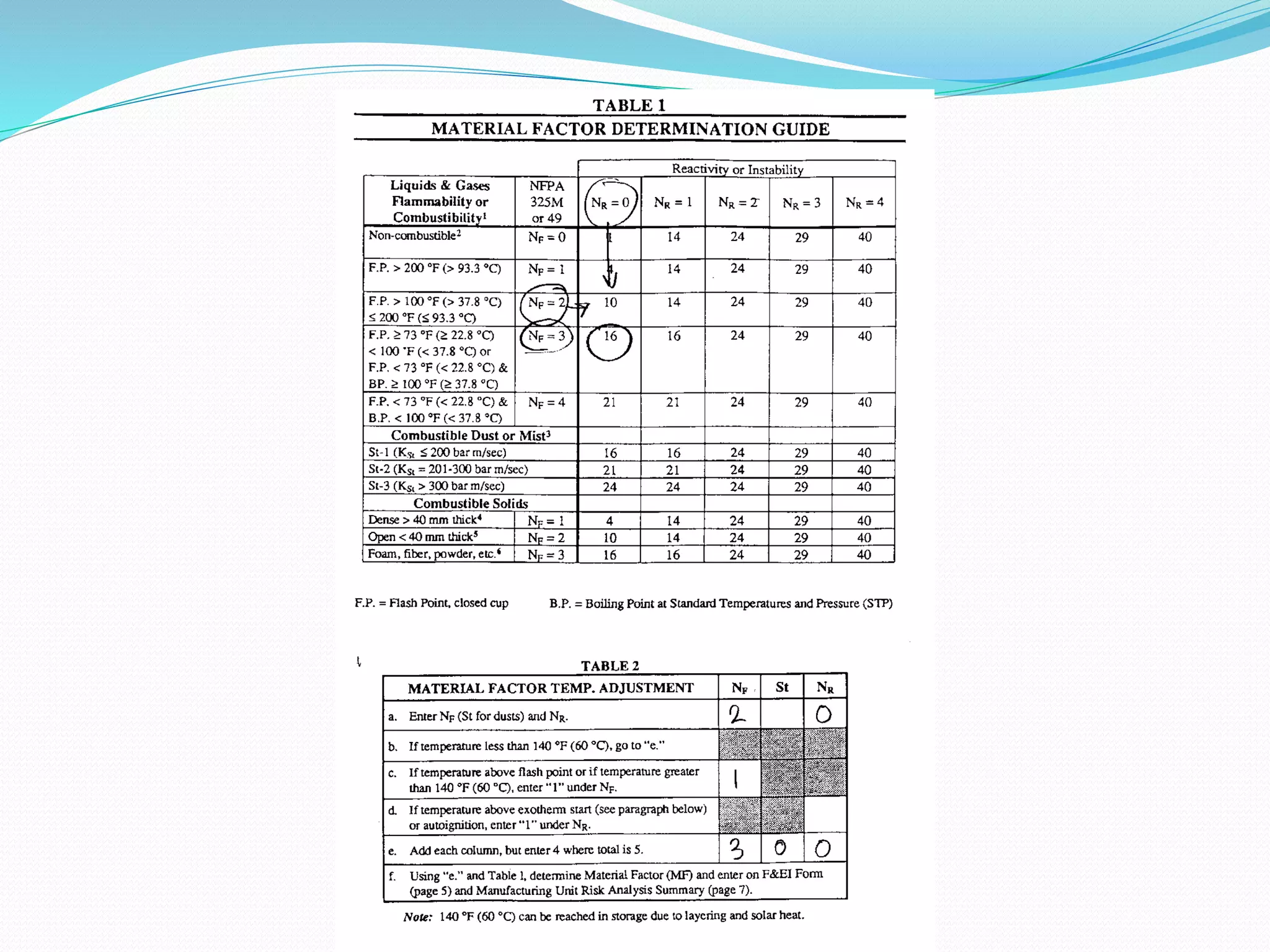

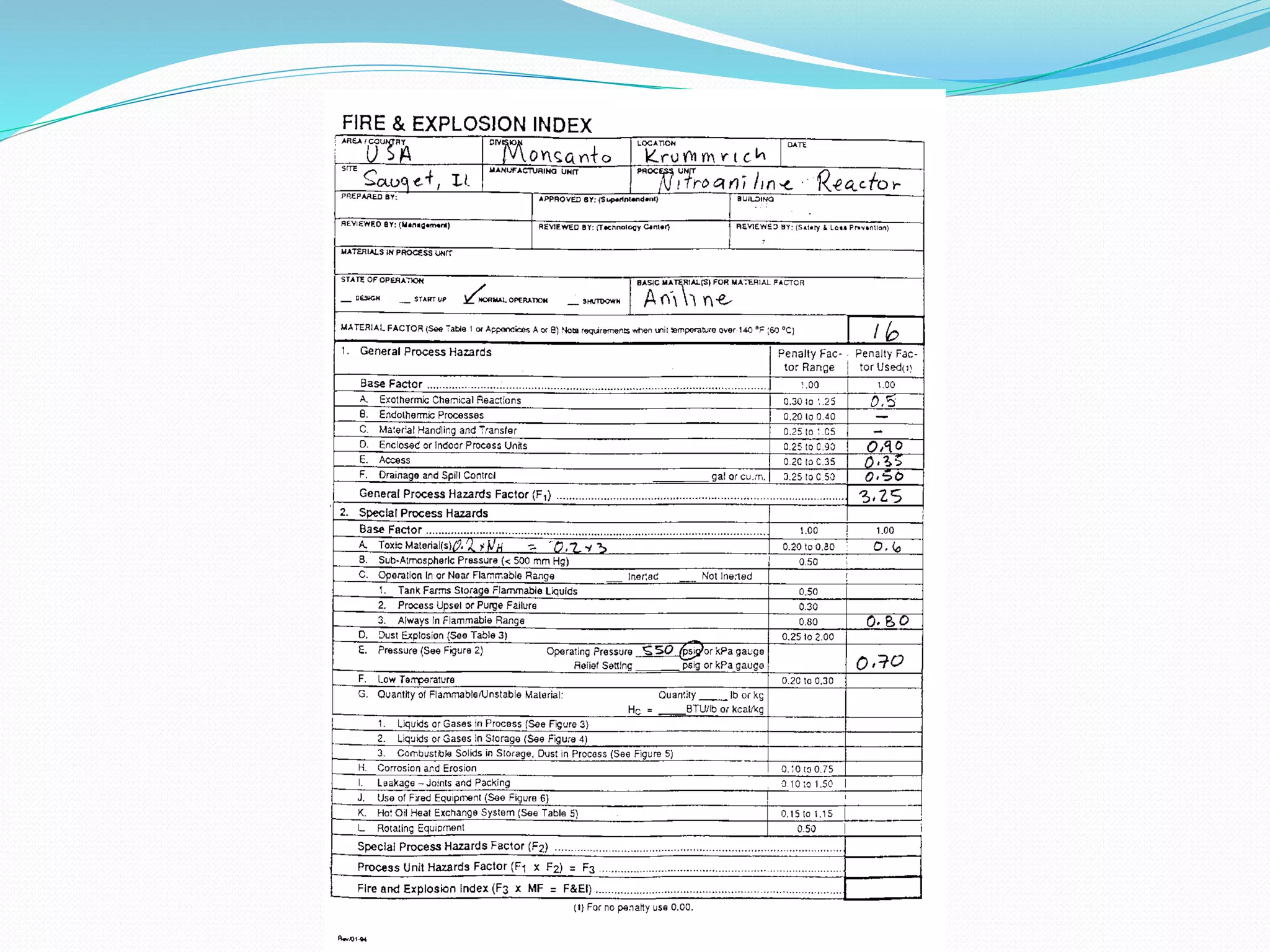

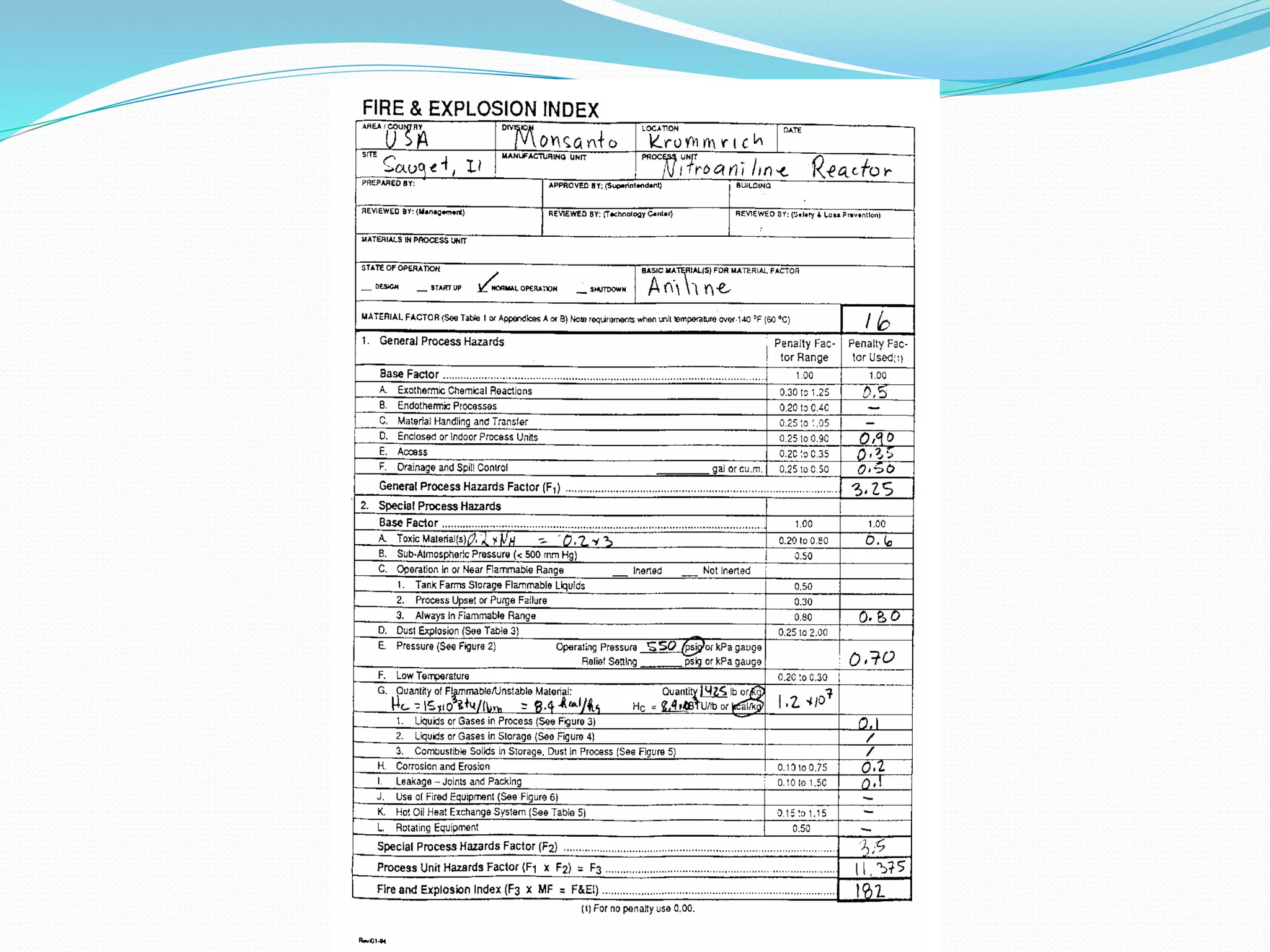

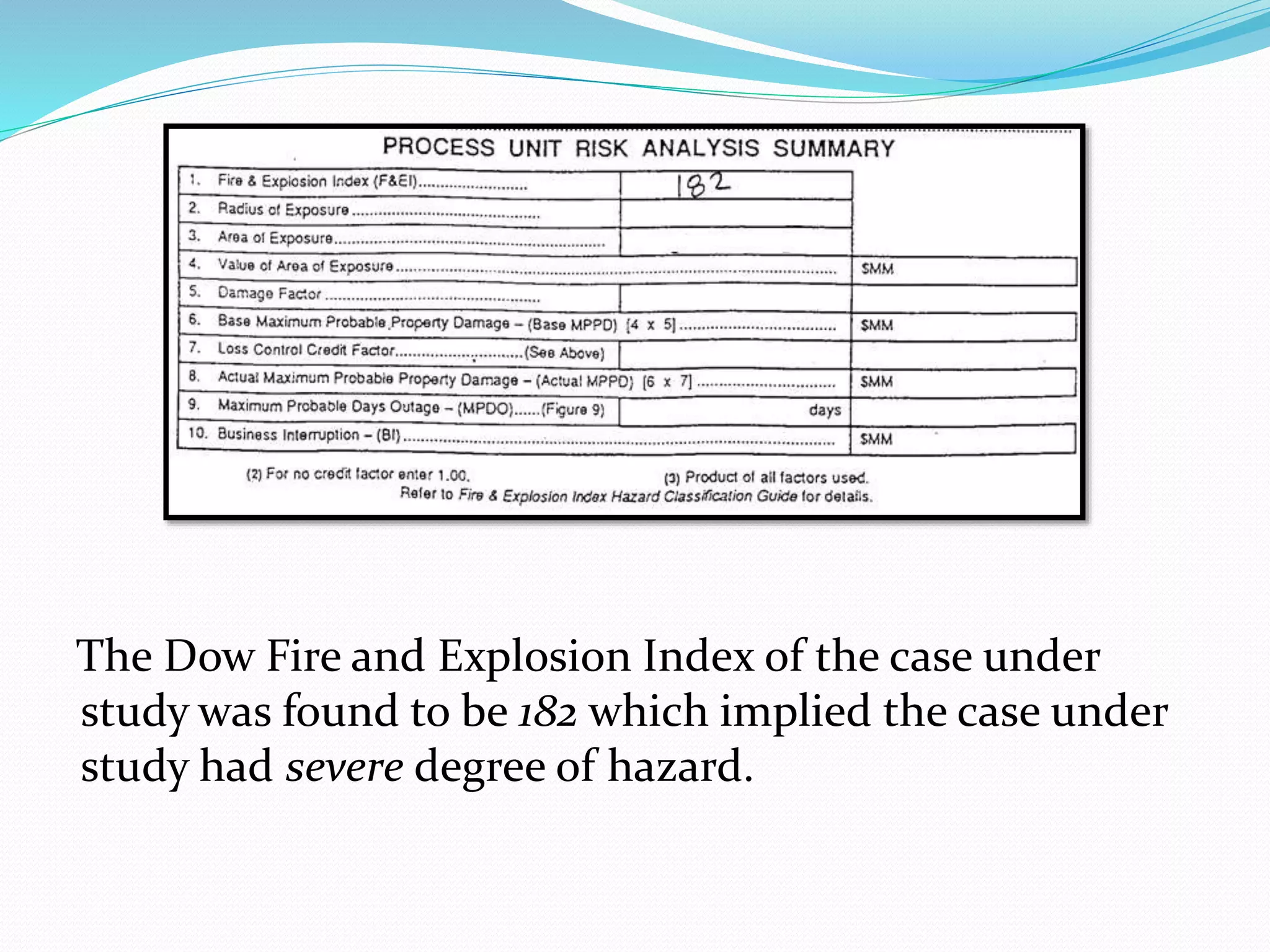

The Dow Fire and Explosion Index (F&EI) is a hazard classification guide that assesses the potential fire and explosion risks in chemical processes. It provides a systematic approach for evaluating risks based on various factors like material properties and process conditions, and is meant for early project stages as well as auditing existing plants. A case study of a nitroaniline reactor revealed a severe hazard level with a F&EI score of 182 due to critical process failures and conditions.