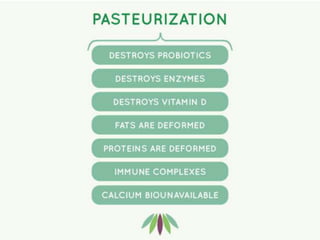

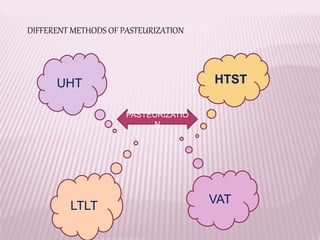

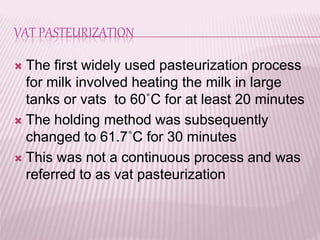

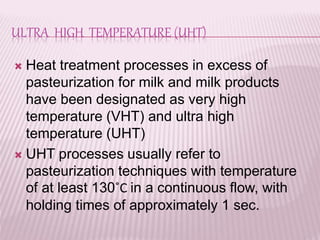

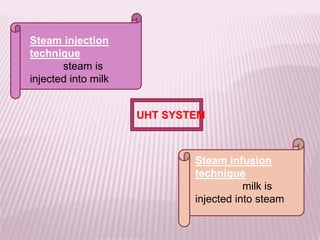

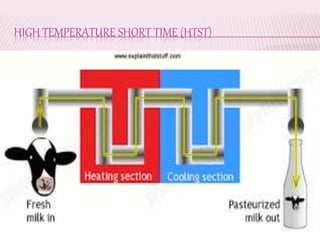

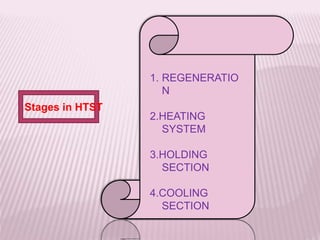

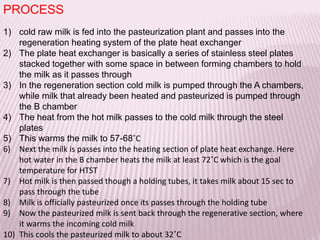

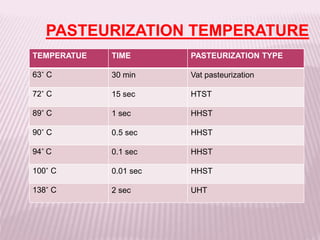

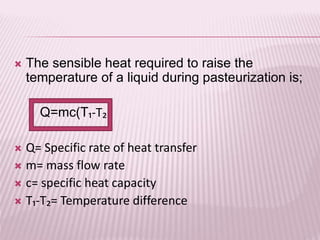

The document discusses pasteurization, which involves heating food to temperatures that kill pathogens and reduce spoilage organisms without completely sterilizing the food. Pasteurization was invented by Louis Pasteur to prevent wine and beer from souring, and later applied to milk. Common pasteurized foods include milk, cream, eggs, and fruit juices. Common pasteurization methods are vat pasteurization at 63°C for 30 minutes, high-temperature short-time (HTST) at 72°C for 15 seconds, and ultra-high temperature (UHT) processing above 130°C for 1 second or less. Pasteurization aims to reduce pathogens and extend the shelf life of foods.