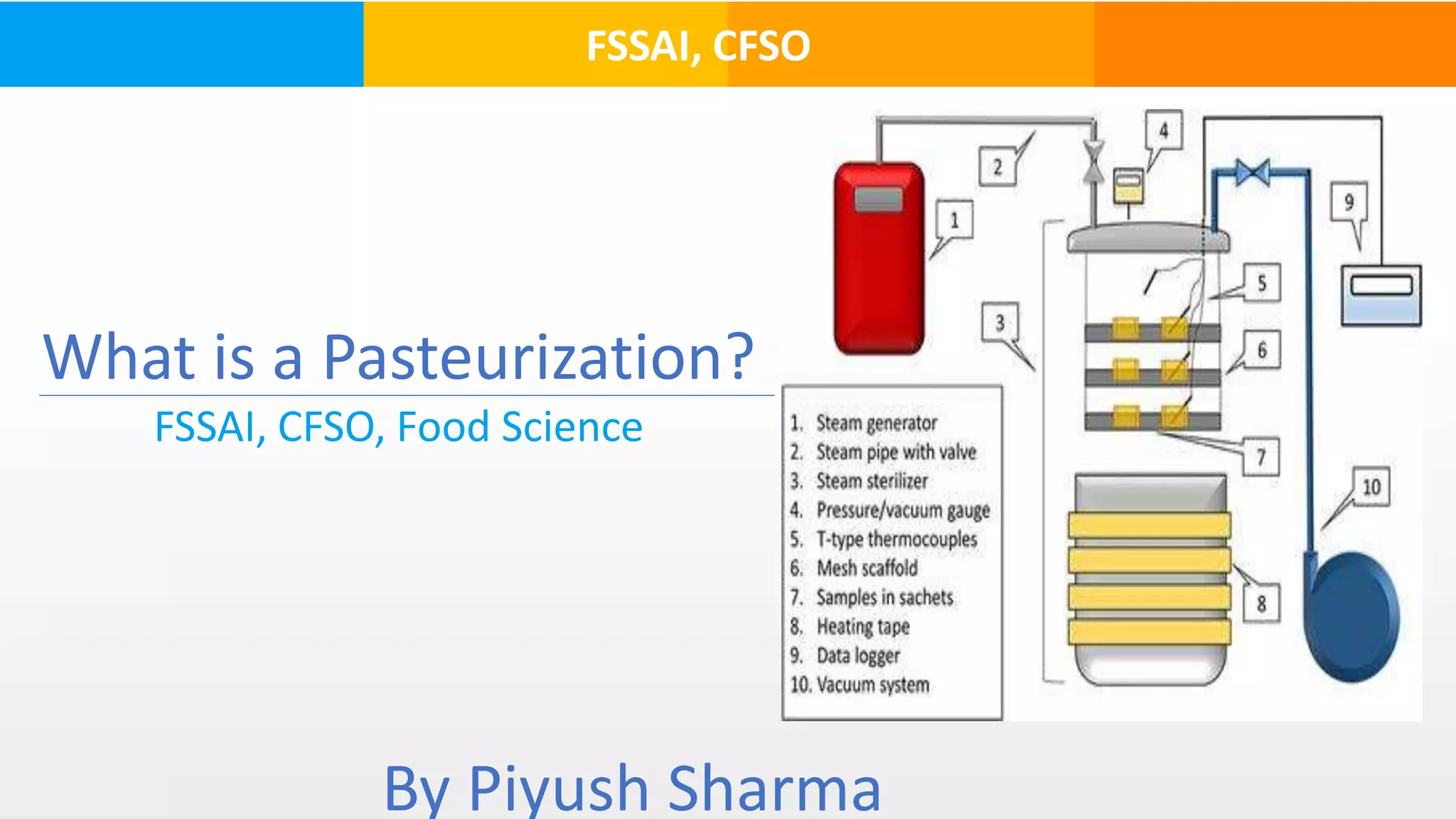

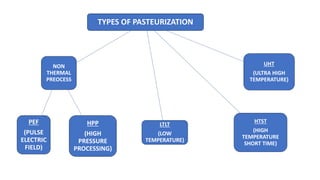

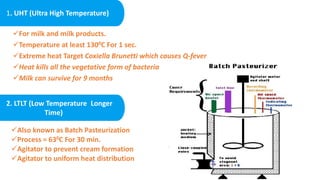

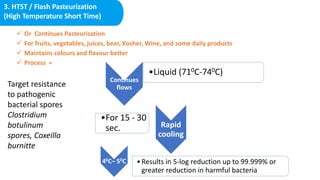

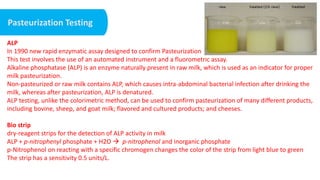

The document provides an overview of pasteurization, a process that involves heating food to eliminate pathogens and prolong shelf life. It discusses various pasteurization methods, including UHT, LTLT, and HTST, as well as the significance of alkaline phosphatase as an indicator for proper milk pasteurization. The document also details the history of pasteurization and testing methods to ensure the effectiveness of the process.