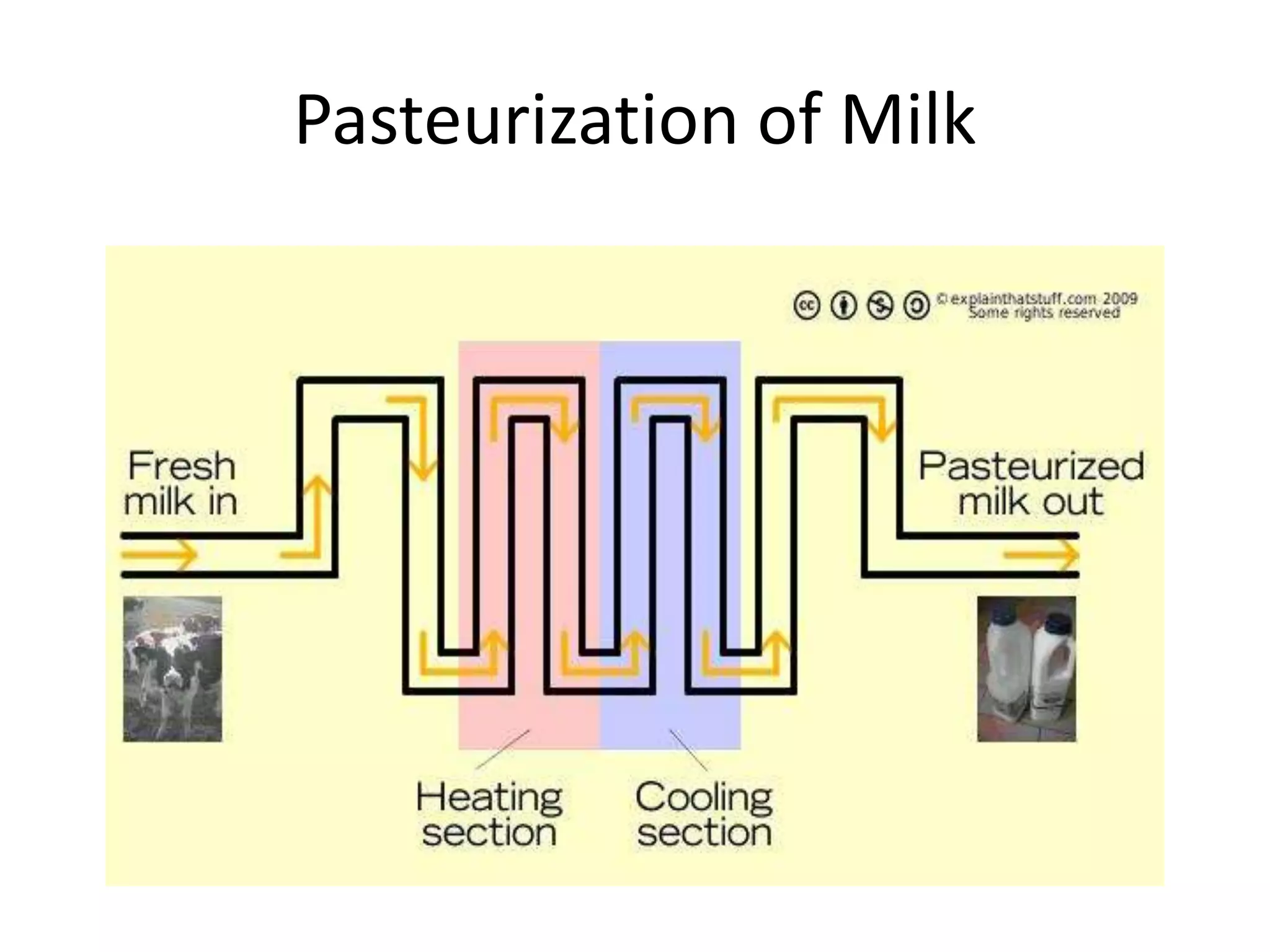

Pasteurization is a sterilization process that eliminates harmful microorganisms in food products, invented by Louis Pasteur in the 19th century, primarily used in the dairy industry. The document discusses various methods of pasteurization, including HTST (High Temperature Short Time) and UHT (Ultra High Temperature), detailing their processes and applications. It also covers the types of foods that can be pasteurized, consumer perceptions regarding unpasteurized products, and mentions FDA guidelines for pasteurization.