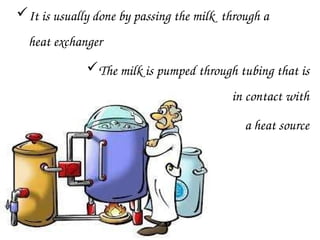

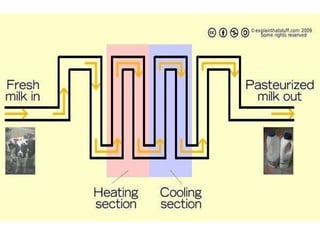

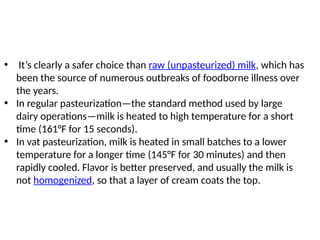

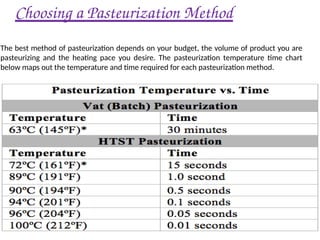

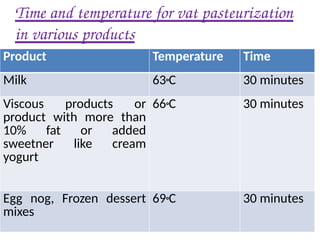

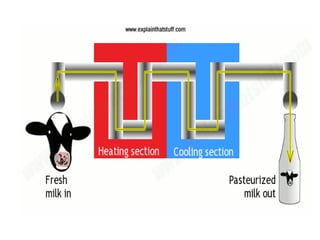

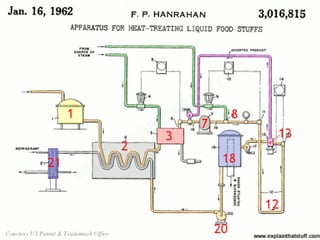

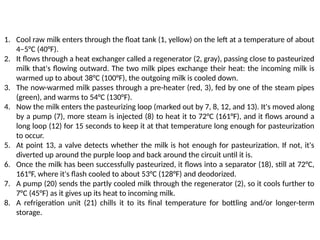

The document discusses the process of pasteurization, a heat treatment that eliminates pathogenic microorganisms in food and beverages, notably milk, to enhance food safety and shelf life. It details various pasteurization methods, including low-temperature long-time (LTLT) pasteurization and high-temperature short-time (HTST) pasteurization, describing their processes and benefits. Additionally, it emphasizes the importance of controlling microbial growth in food products and outlines the microbial analysis standards for raw and pasteurized milk.