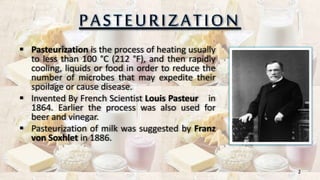

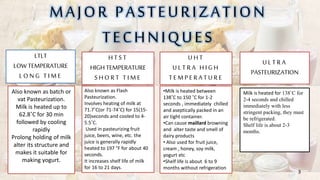

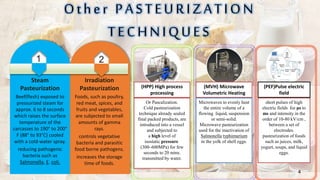

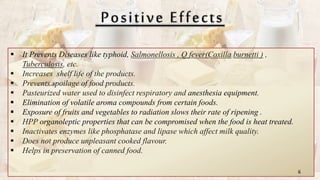

The document discusses pasteurization, which involves heating food or liquids to reduce microbes and extend shelf life. It describes various pasteurization techniques like low-temperature long-time (LTLT), high-temperature short-time (HTST), and ultra-high temperature (UHT) processing. Pasteurization has benefits like preventing disease and spoilage but also has negatives like loss of vitamins and changes to taste. The document concludes that pasteurization protects health while meeting demands, though some nutrients are reduced.