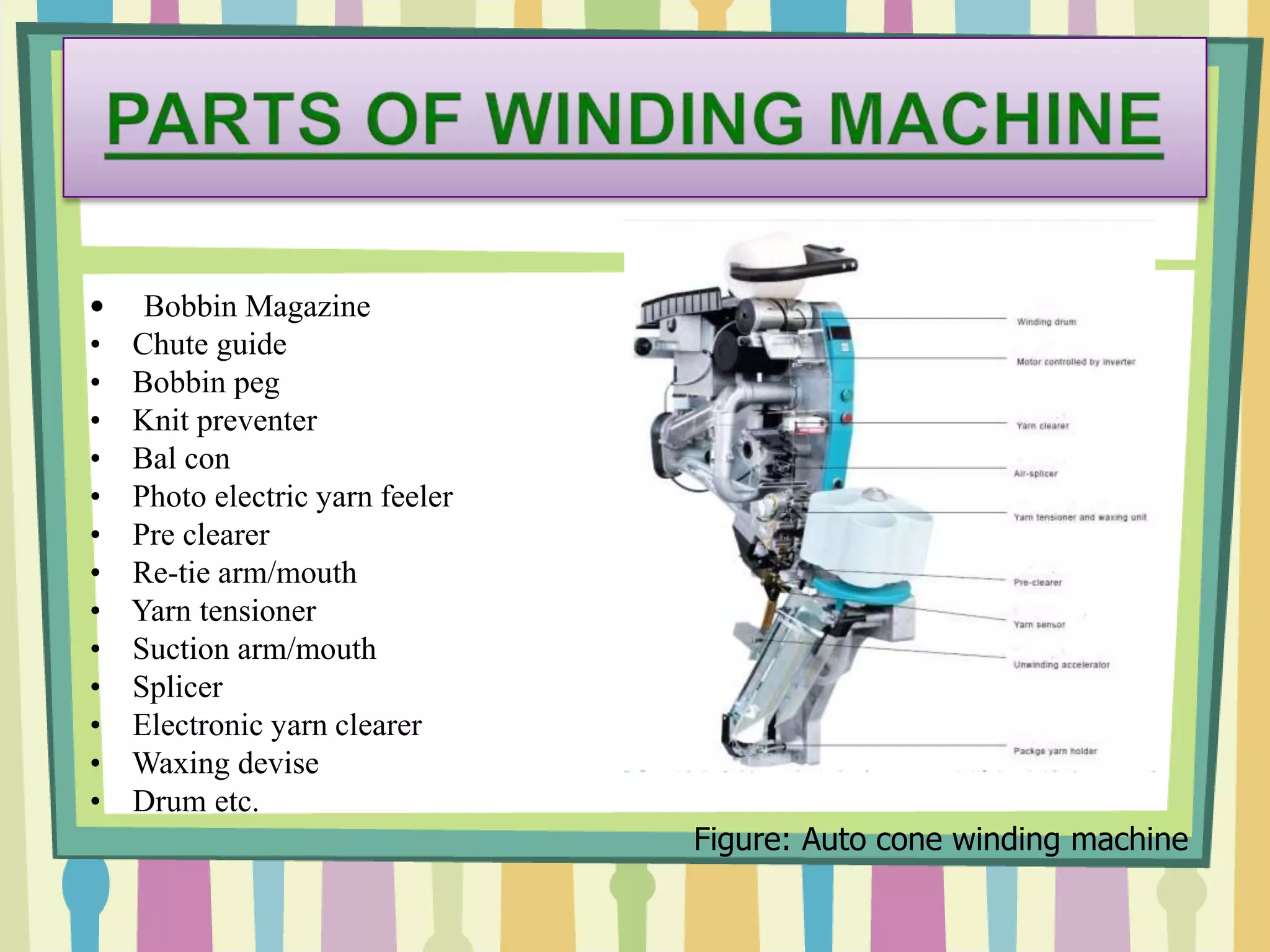

The document discusses an industrial visit presentation on an Autoconer Winding Machine. It provides definitions of winding types and auto cone winding machines. The auto cone winding machine transfers yarn from smaller packages to larger cones, removes faults like neps and slubs, and improves yarn quality. It features automatic splicing without knots and pneumatic tensioning. The machine functions to remove yarn faults and minimize imperfections. Atmospheric conditions for auto cone winding typically require 55-80% humidity and 22-39.5°C temperature.