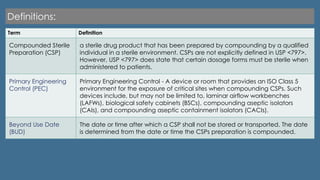

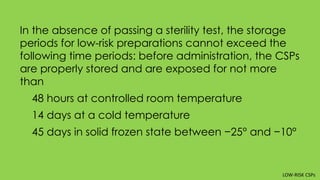

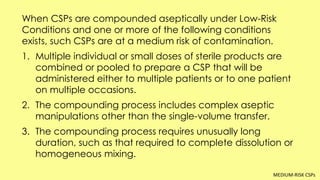

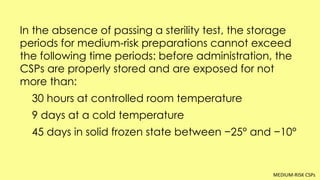

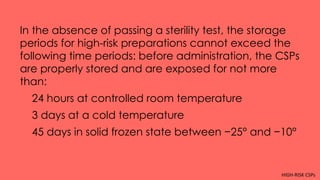

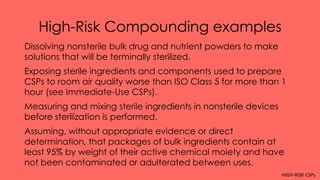

The document outlines three contamination risk categories for compounded sterile preparations (CSPs): low-risk, medium-risk, and high-risk. It defines each risk category based on factors like the complexity of compounding and potential for contamination. For each risk category, it provides examples and establishes maximum storage times in the absence of passing a sterility test. It also describes an immediate-use provision for emergency situations. Low-risk CSPs allow for the longest storage times of up to 48 hours at room temperature, while high-risk CSPs allow for the shortest storage of 24 hours. Medium-risk CSPs fall between the other two categories.