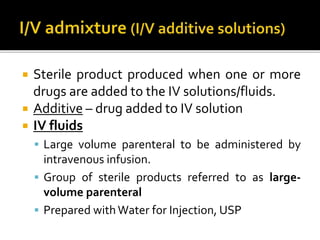

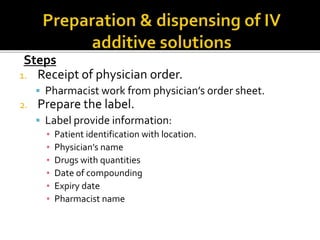

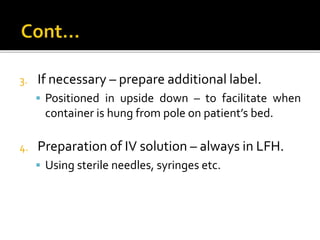

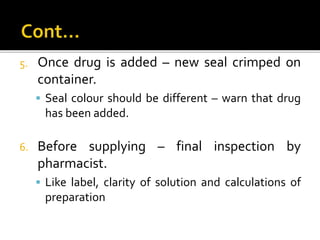

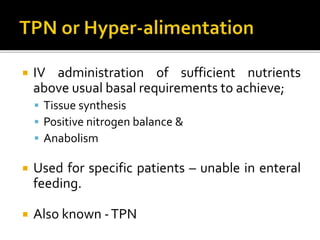

The document outlines procedures for the aseptic dispensing of intravenous admixtures, TPN, and cytotoxic drugs, detailing the preparation steps, necessary equipment, and personnel training required to ensure the safety and efficacy of these sterile products. It emphasizes the importance of labeling, documentation, inspection, and proper storage conditions to maintain product integrity and mitigate risks during handling. Additionally, it discusses the potential hazards of cytotoxic agents and the precautions necessary for safe preparation and administration.