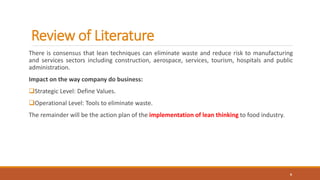

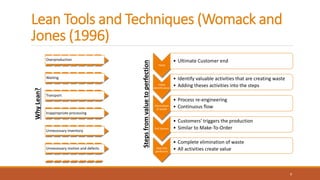

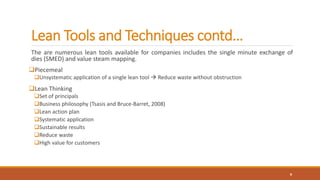

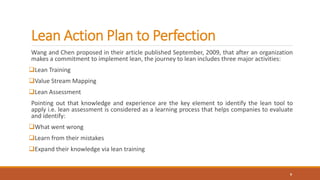

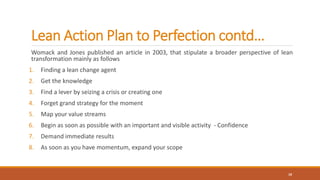

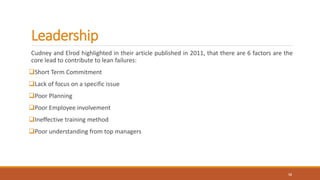

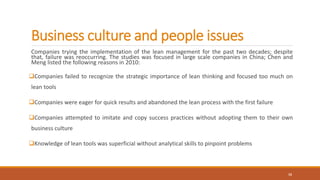

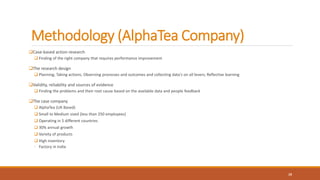

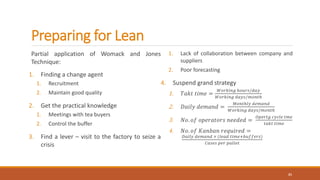

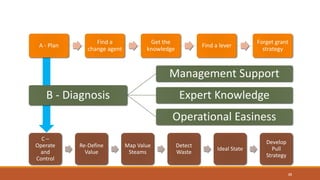

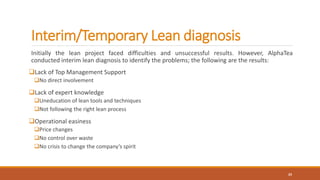

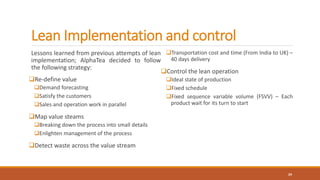

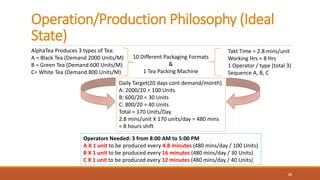

This document discusses the implementation of lean thinking in food supply chains, particularly focusing on the UK tea industry. It outlines a lean action plan using various lean tools to eliminate waste and improve customer satisfaction, while also addressing common challenges and failures in adopting lean practices. The study emphasizes the importance of leadership, training, and strategic approach for successful lean transformation in small and medium enterprises.