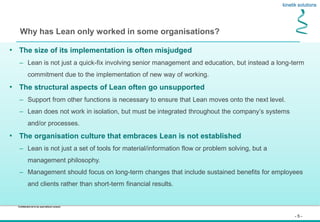

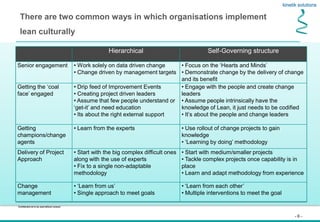

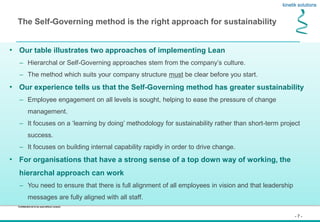

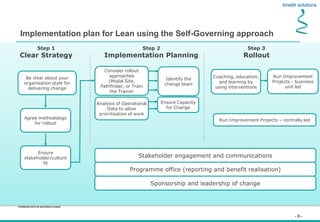

This document discusses implementing Lean in service industries and ensuring sustainability. It compares hierarchical and self-governing models of Lean rollout. The self-governing model, which focuses on employee engagement, learning by doing, and building internal capability, leads to the best opportunity for sustainability compared to the hierarchical, top-down approach.