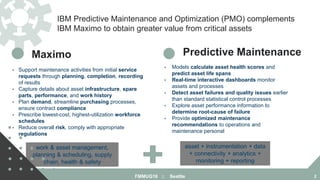

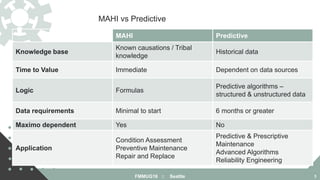

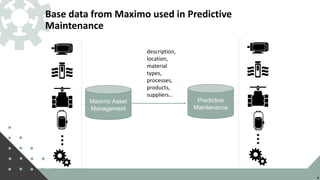

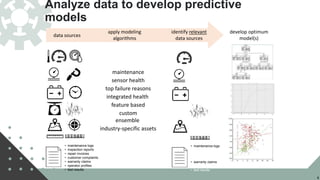

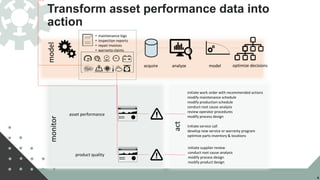

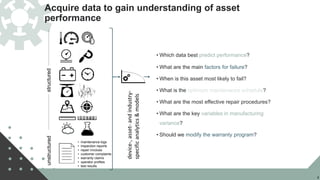

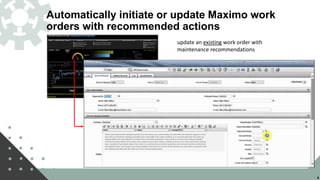

IBM's predictive maintenance and optimization (PMO) enhances the value of Maximo asset management by improving productivity, assessing asset health, and mitigating risks. The system utilizes models to calculate asset health scores, monitor assets in real-time, and provide data-driven maintenance recommendations. By leveraging historical data and analytics, organizations can optimize maintenance schedules, improve asset performance, and effectively manage supply chain operations.