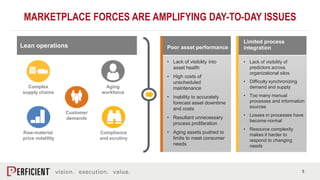

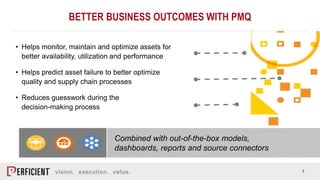

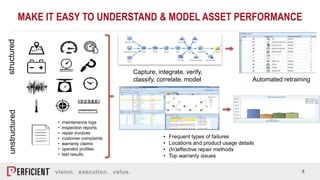

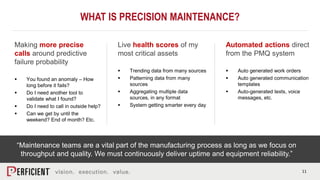

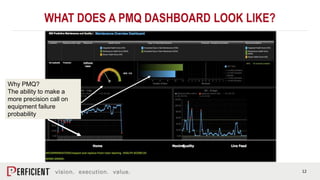

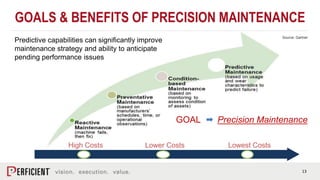

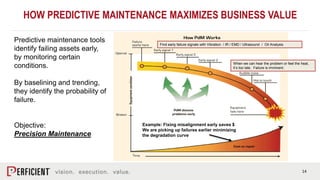

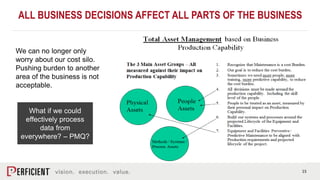

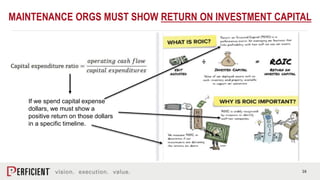

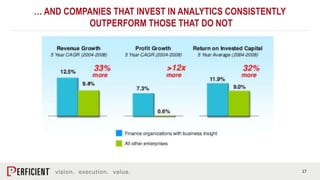

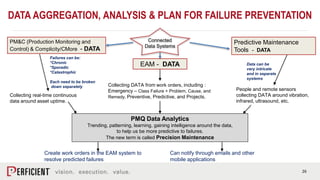

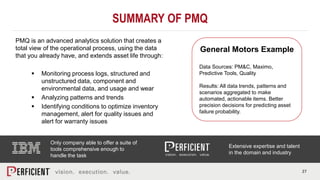

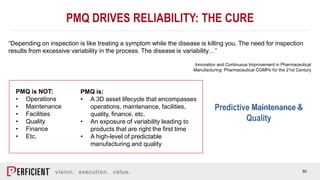

The document discusses Perficient, a consulting firm specializing in digital experience and asset management solutions, highlighting its leadership and expertise in predictive maintenance and quality solutions provided by IBM. It emphasizes the importance of advanced analytics for optimizing asset performance, addressing issues like asset health visibility, maintenance costs, and process integration. The content also outlines the features of IBM's predictive maintenance & quality solutions, their benefits for various industries, and the importance of innovation and continuous improvement in asset management.

![31

PMQ IN THE REGULATED INDUSTRIES: LIFE SCIENCES

Janet Woodcock, Director, FDA CDER (Center for Drug Evaluation and Research):

“…to shift [the FDA’s] focus to performance and away from compliance.”

• By its own admission, the heavy focus on compliance by the FDA and industry

has caused quality to suffer

• Performance (quality, throughput) drives compliance

• Quality metrics (analytics) and innovative technology/processes (predictability) are the future

PMQ is tipping the scales by exposing, eliminating or mitigating the risk

of failure and creating a culture of “knowns”](https://image.slidesharecdn.com/advancedanalyticsforassetmanagementwithibm-150806195508-lva1-app6892/85/Advanced-Analytics-for-Asset-Management-with-IBM-31-320.jpg)