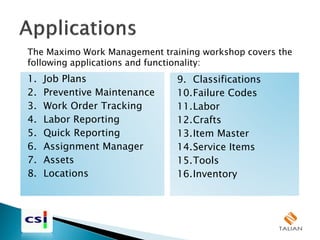

The document outlines a training program for maintenance and asset management professionals using the Maximo 7.5 system, highlighting its applications in managing work orders, asset location, and planning. It emphasizes the importance of user education and consistent data entry for achieving success in maintenance management and includes an overview of key functionalities such as job plans and preventive maintenance. After completion of the training, participants will be equipped to effectively navigate Maximo and execute various work management processes.