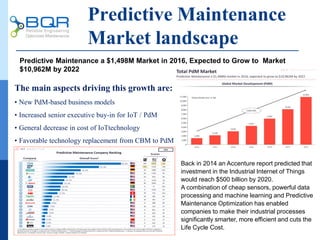

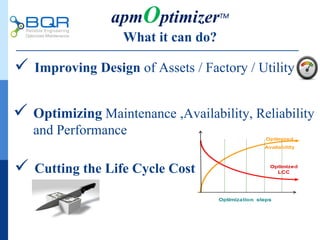

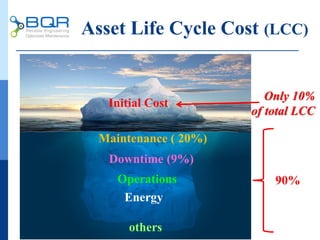

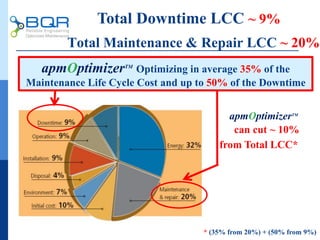

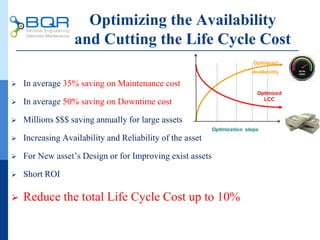

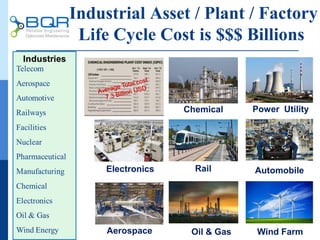

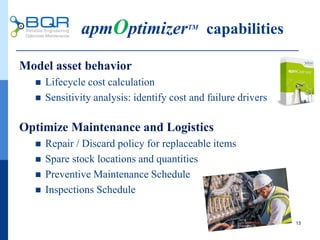

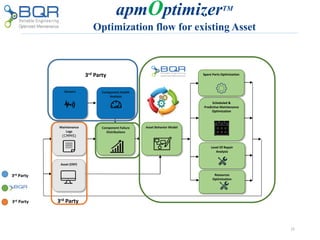

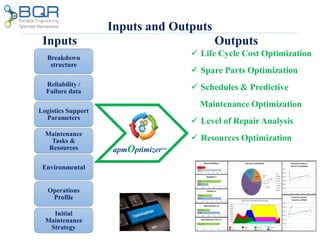

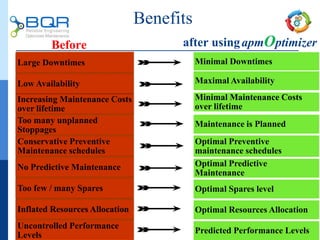

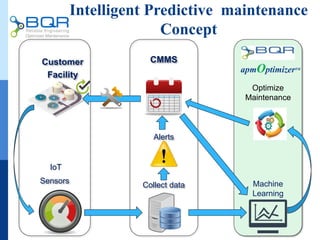

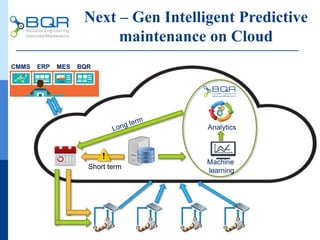

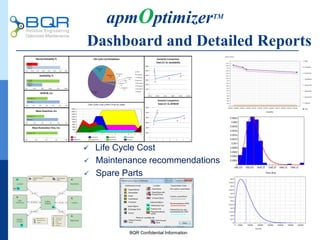

The document discusses the growth and benefits of predictive maintenance solutions, highlighting a market expectation of over $10 billion by 2022. It emphasizes the cost-saving potential of optimizing maintenance and reducing downtime, which can cut overall life cycle costs by up to 10%. APMOptimizerTM is presented as a tool for enhancing reliability and efficiency in industrial operations through data analysis and predictive maintenance strategies.