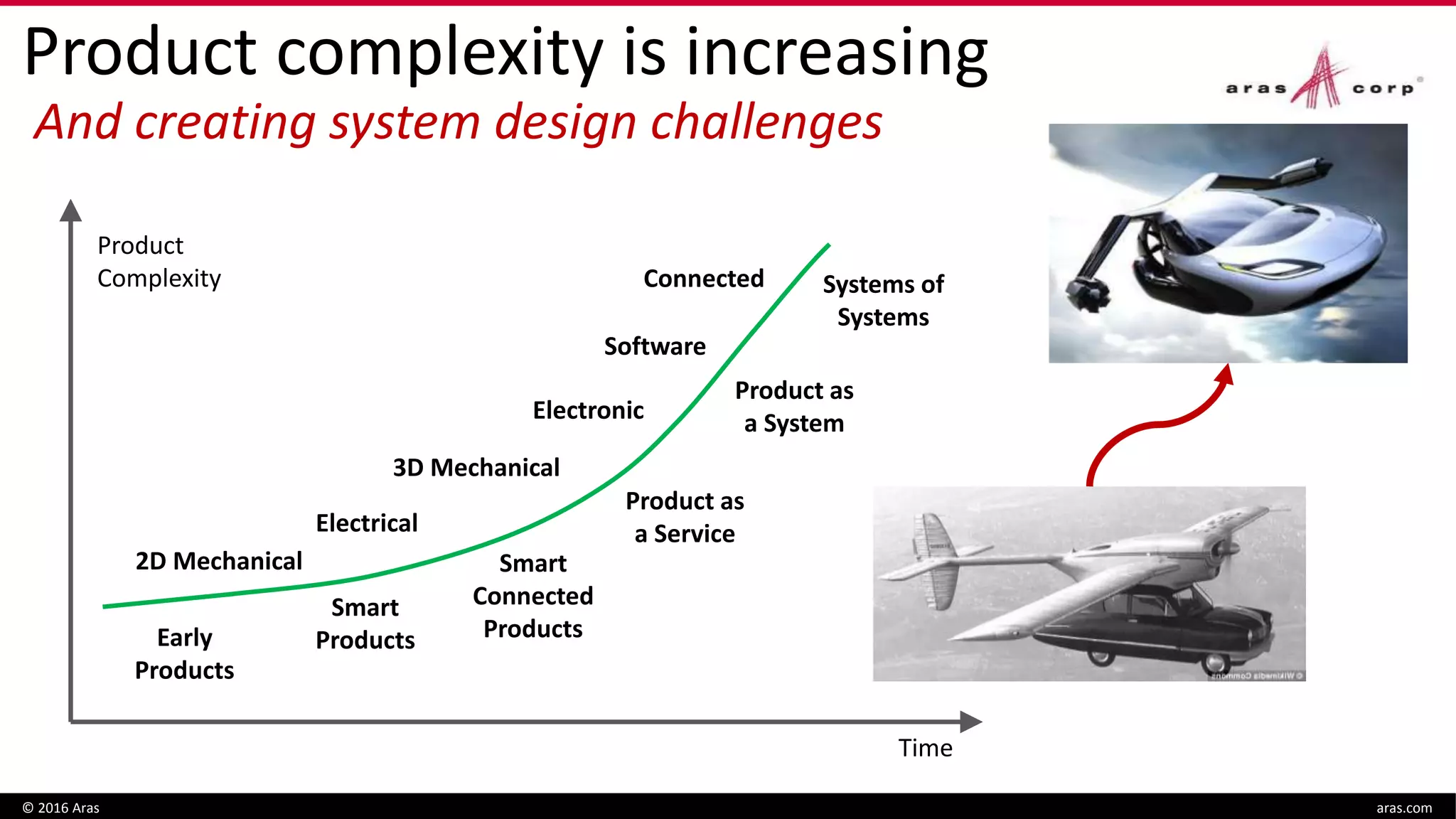

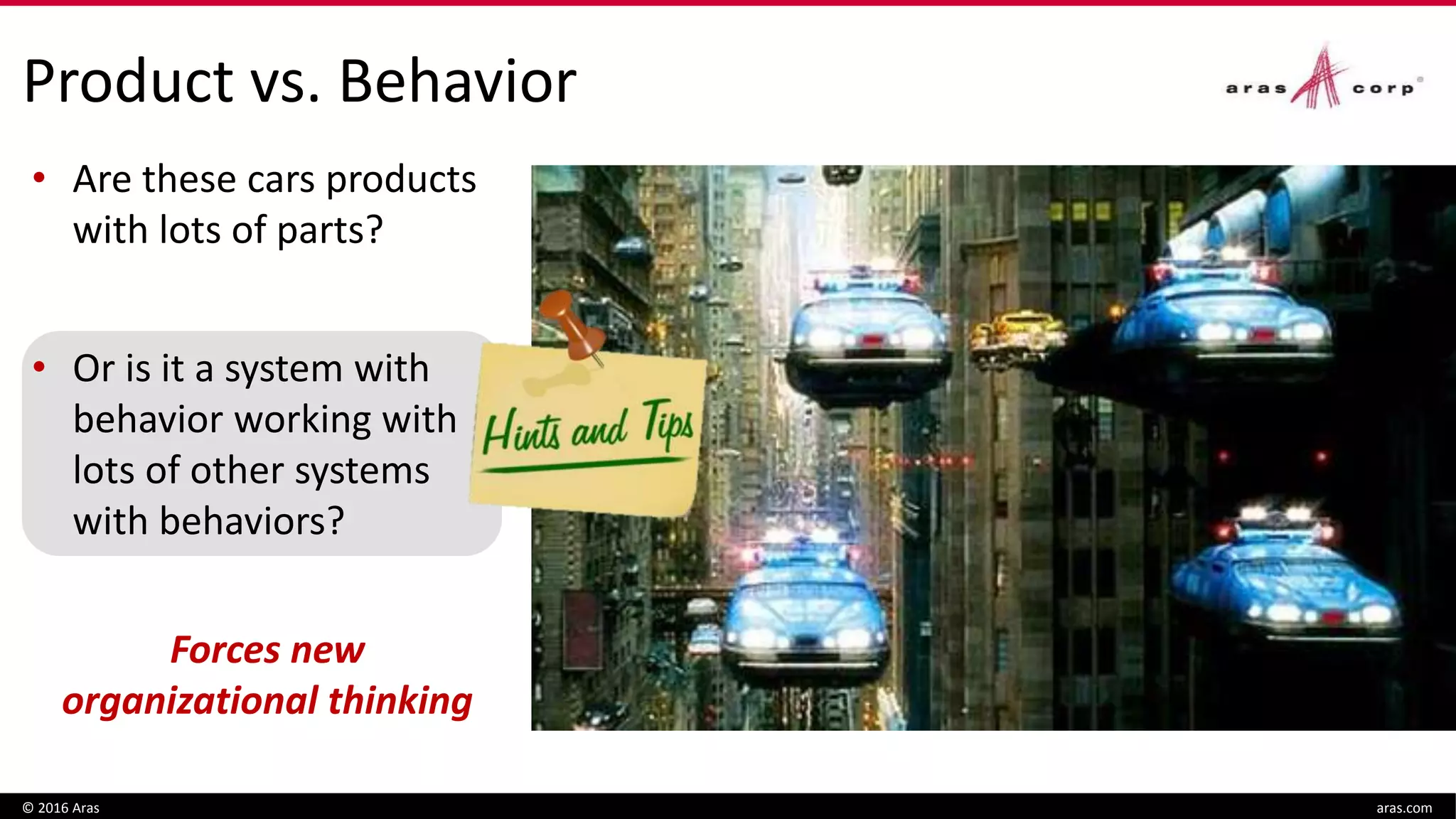

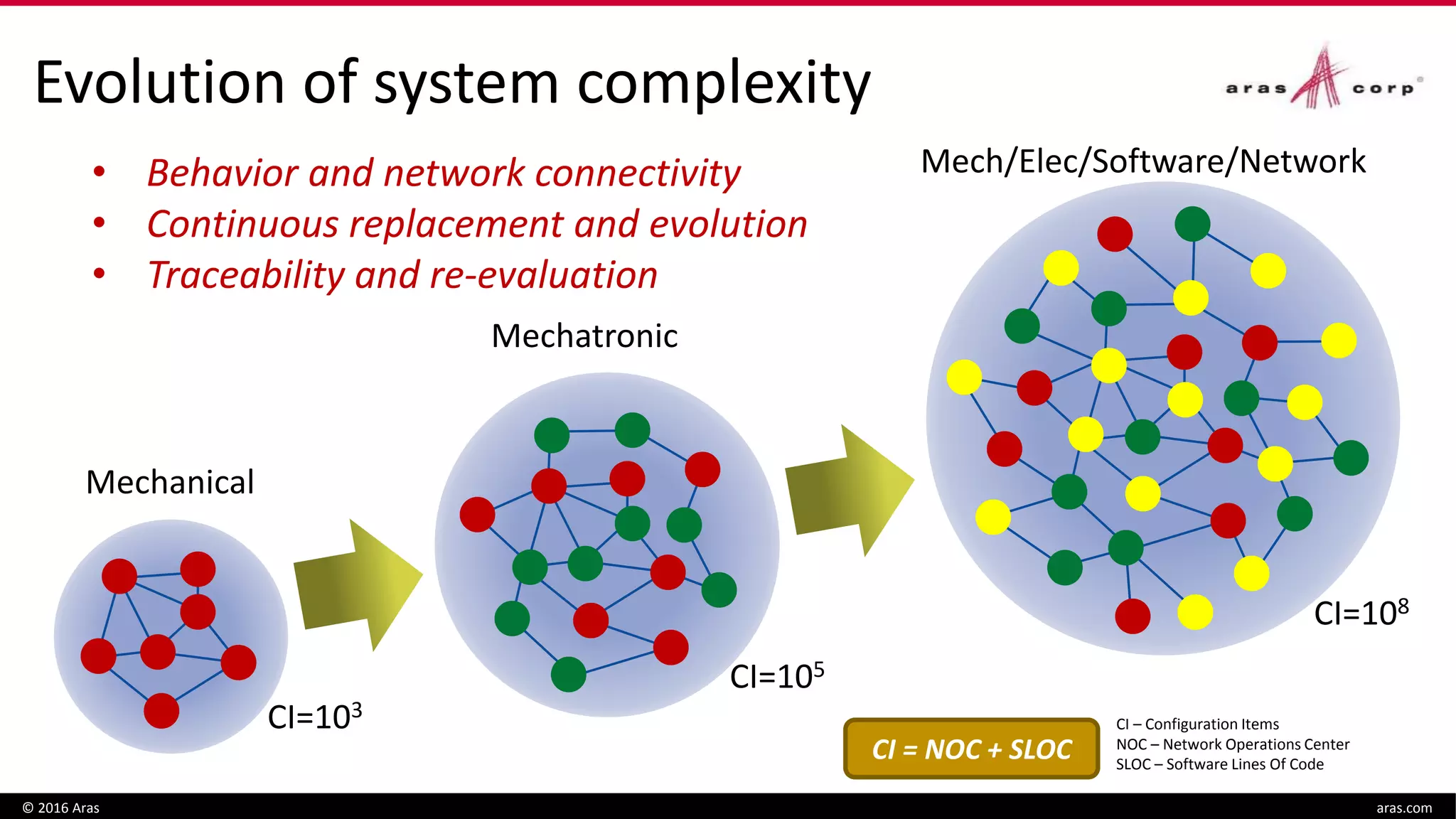

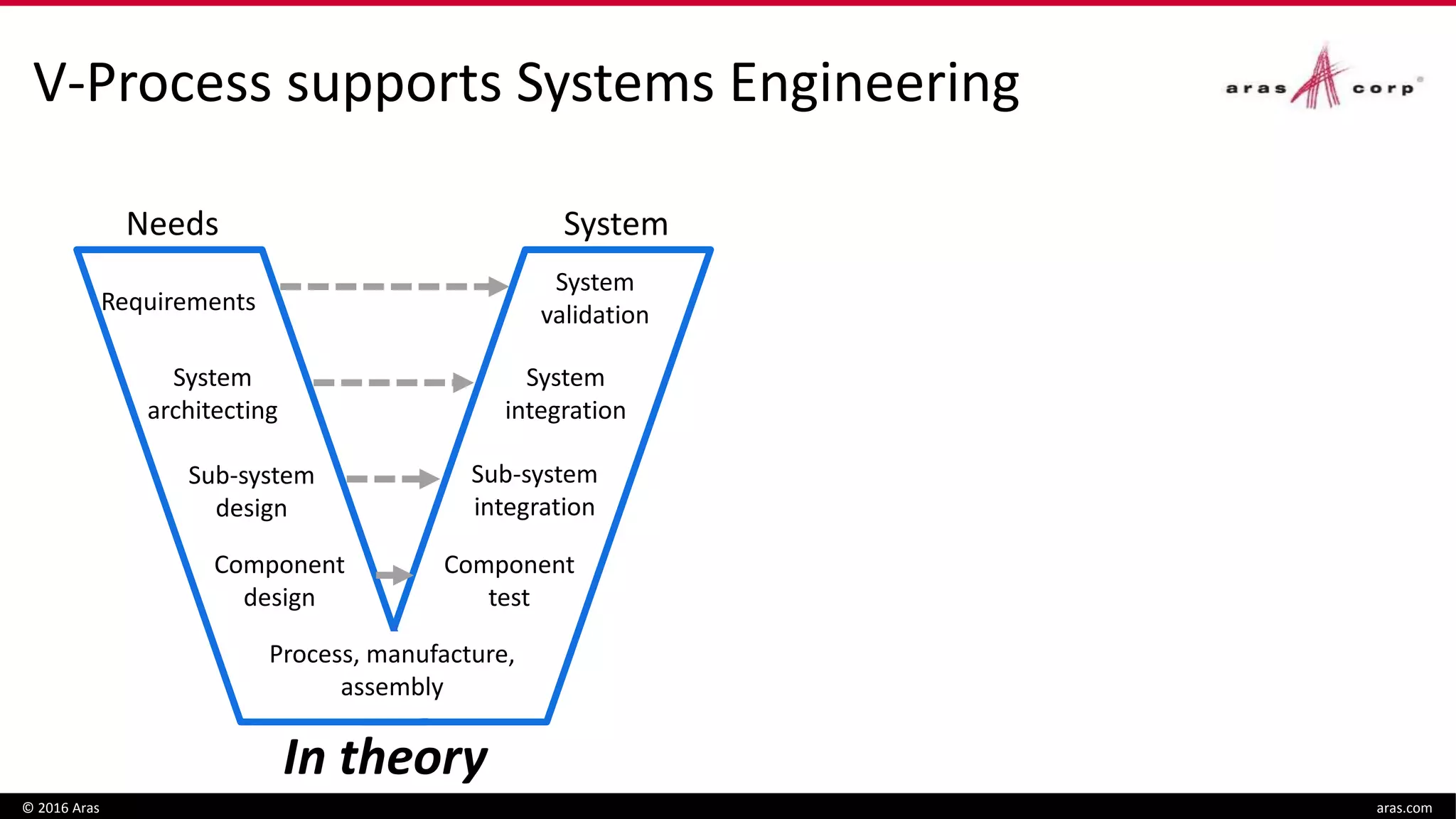

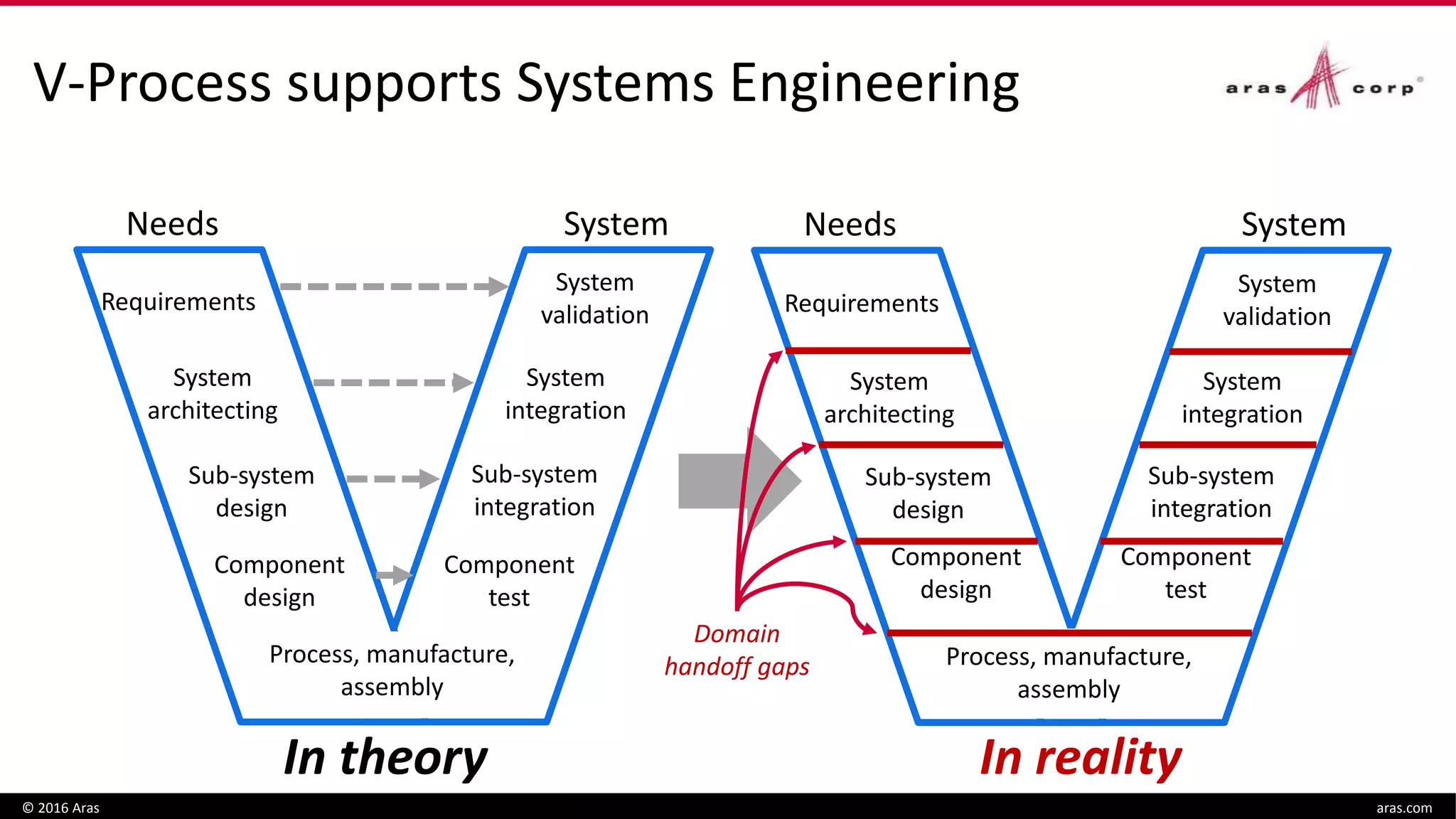

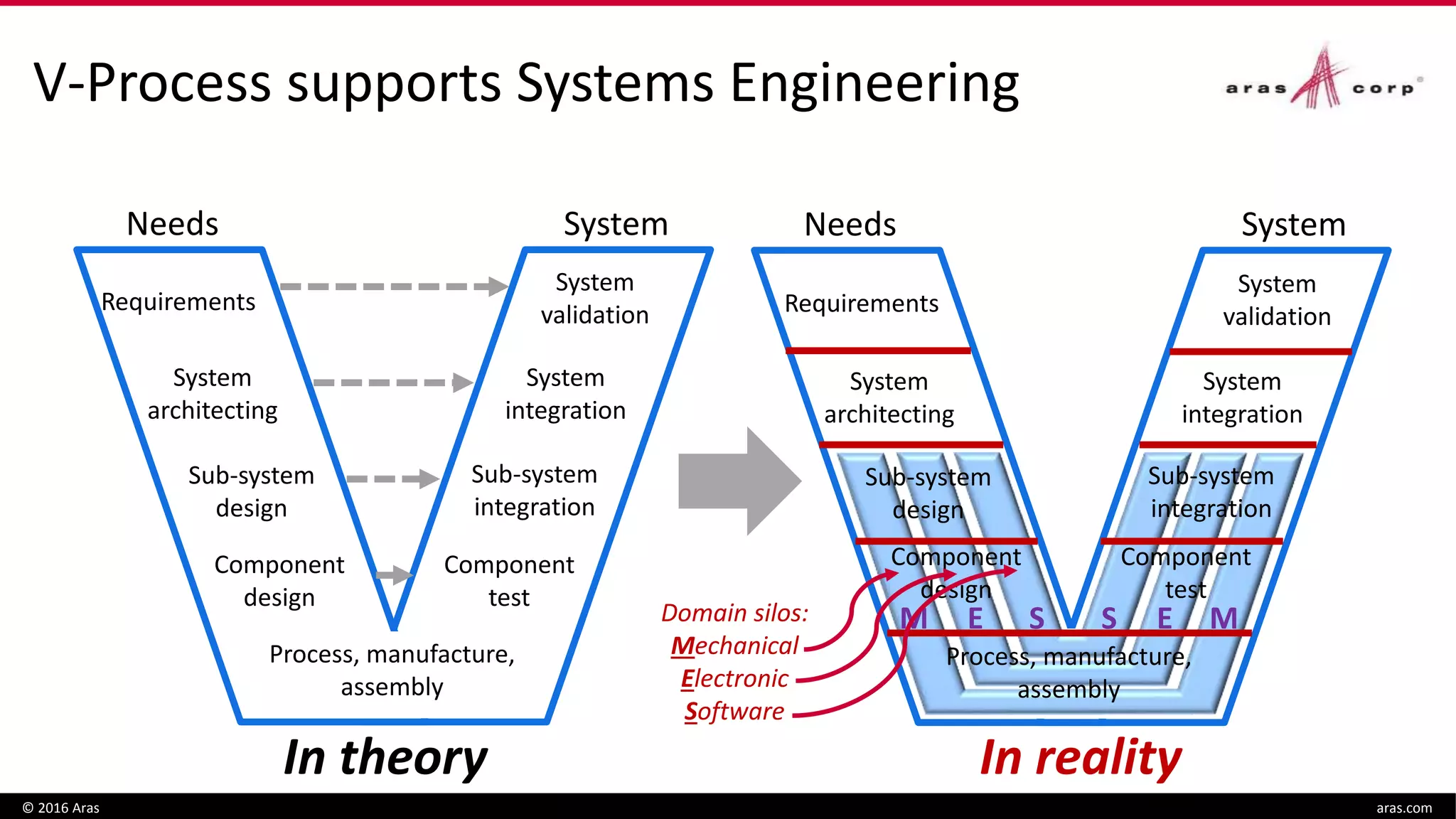

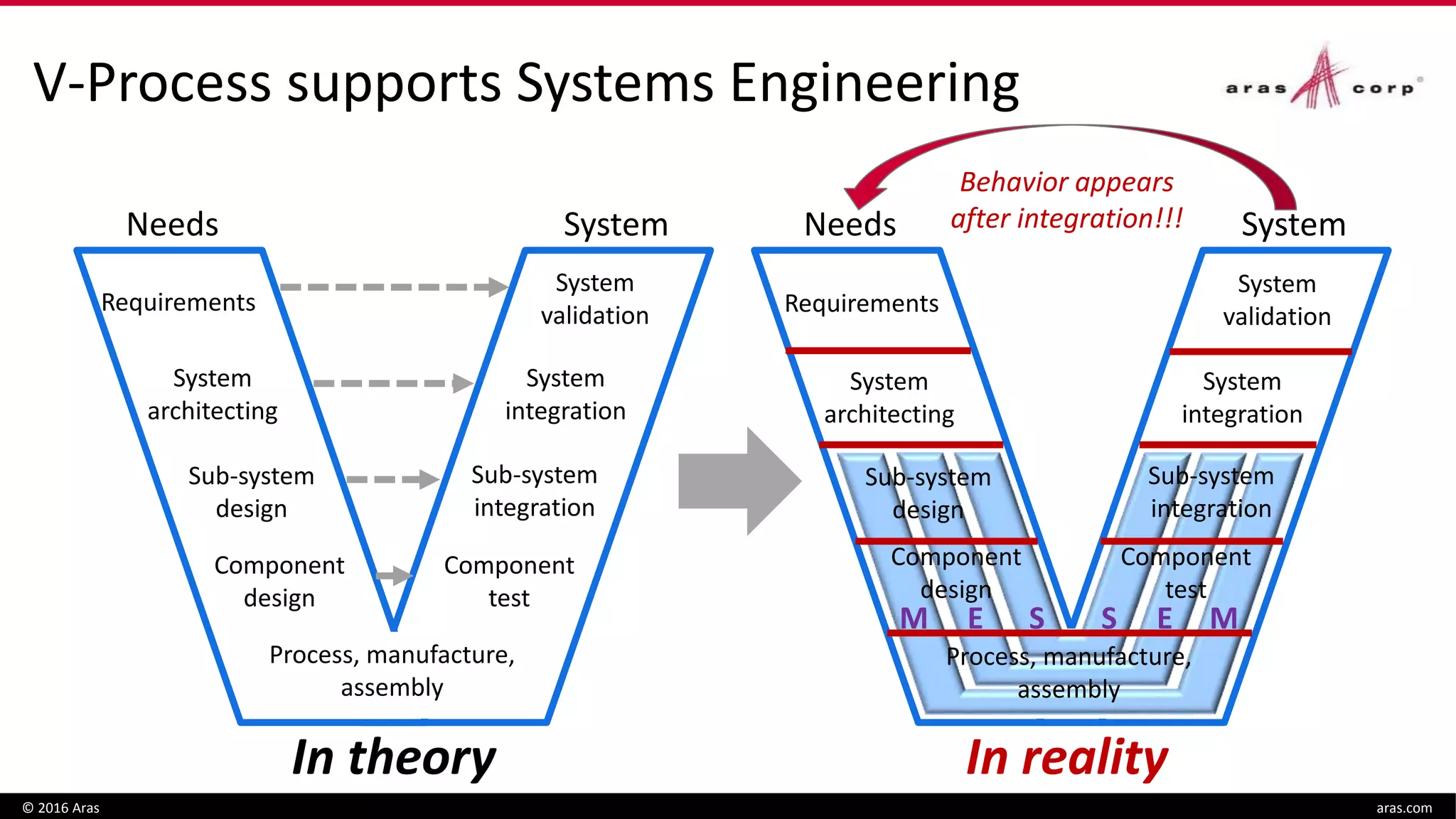

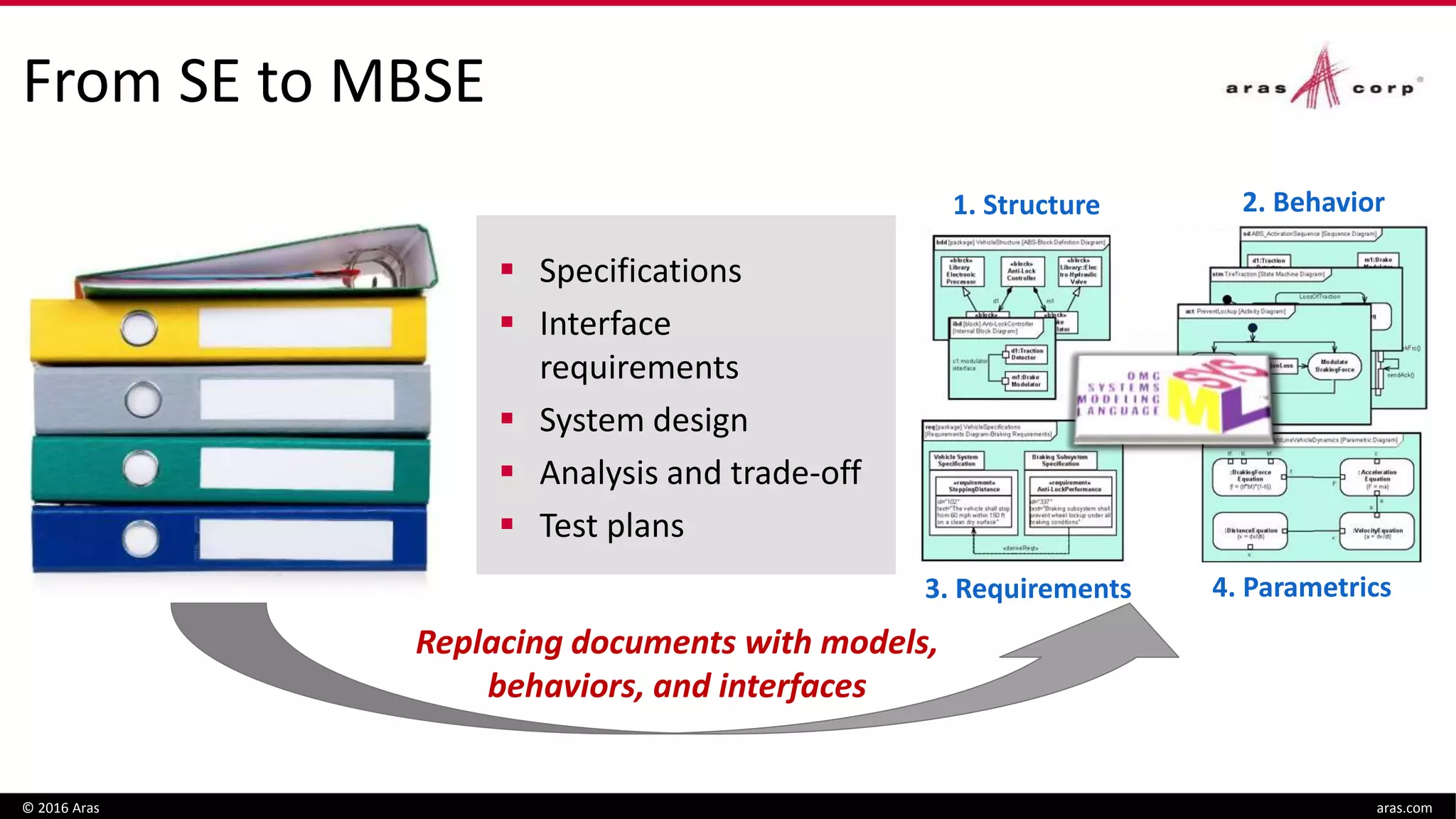

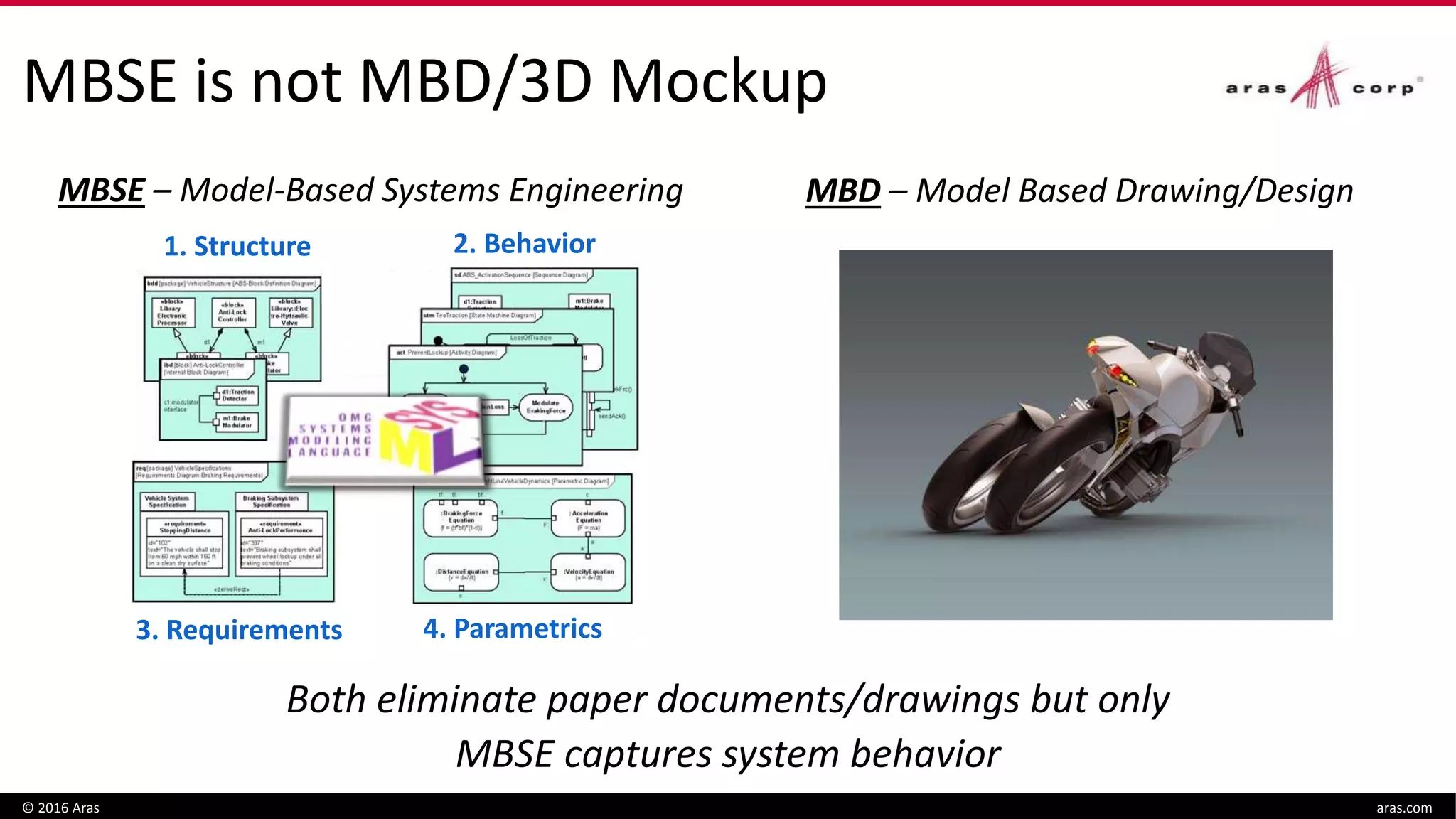

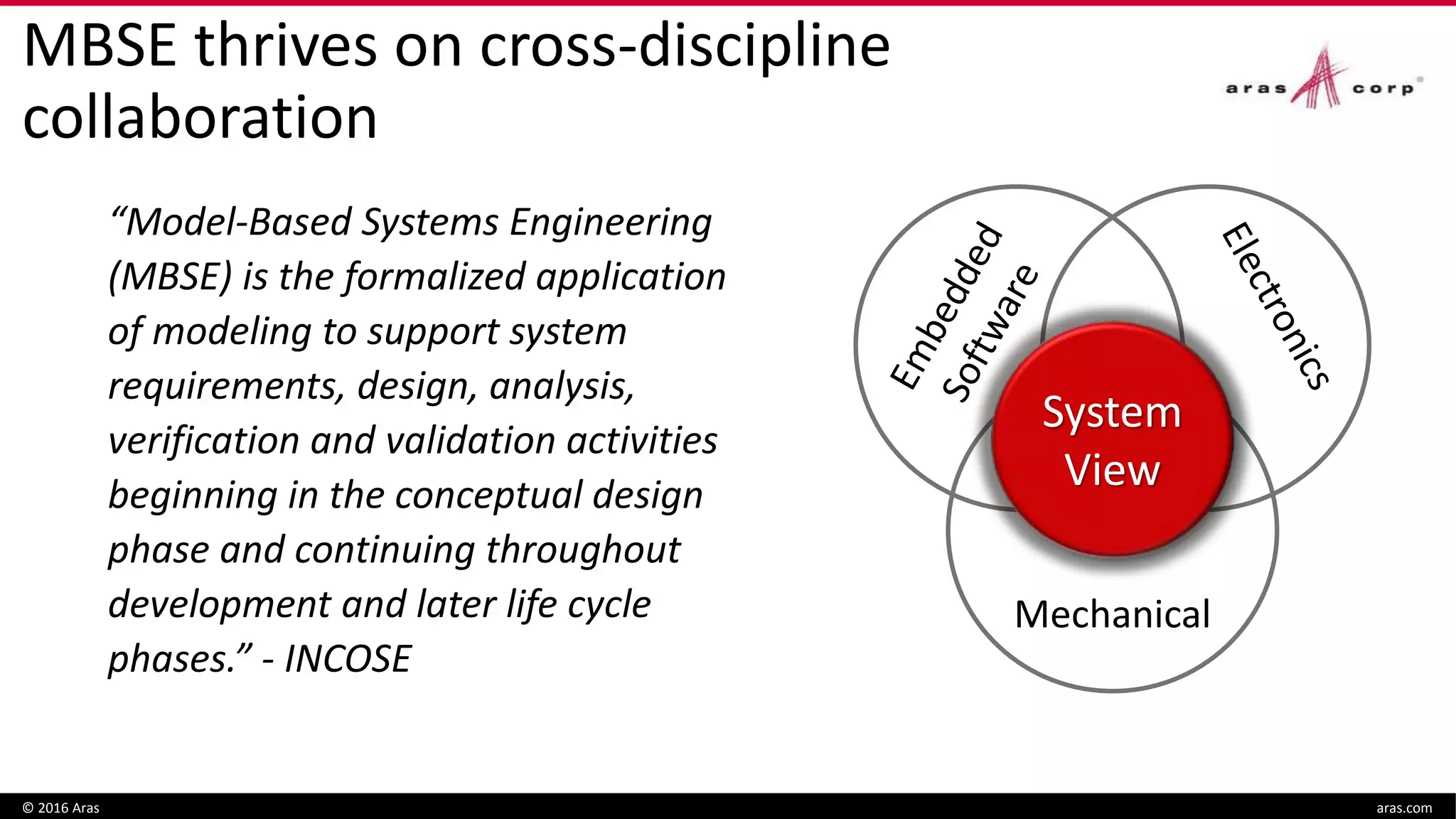

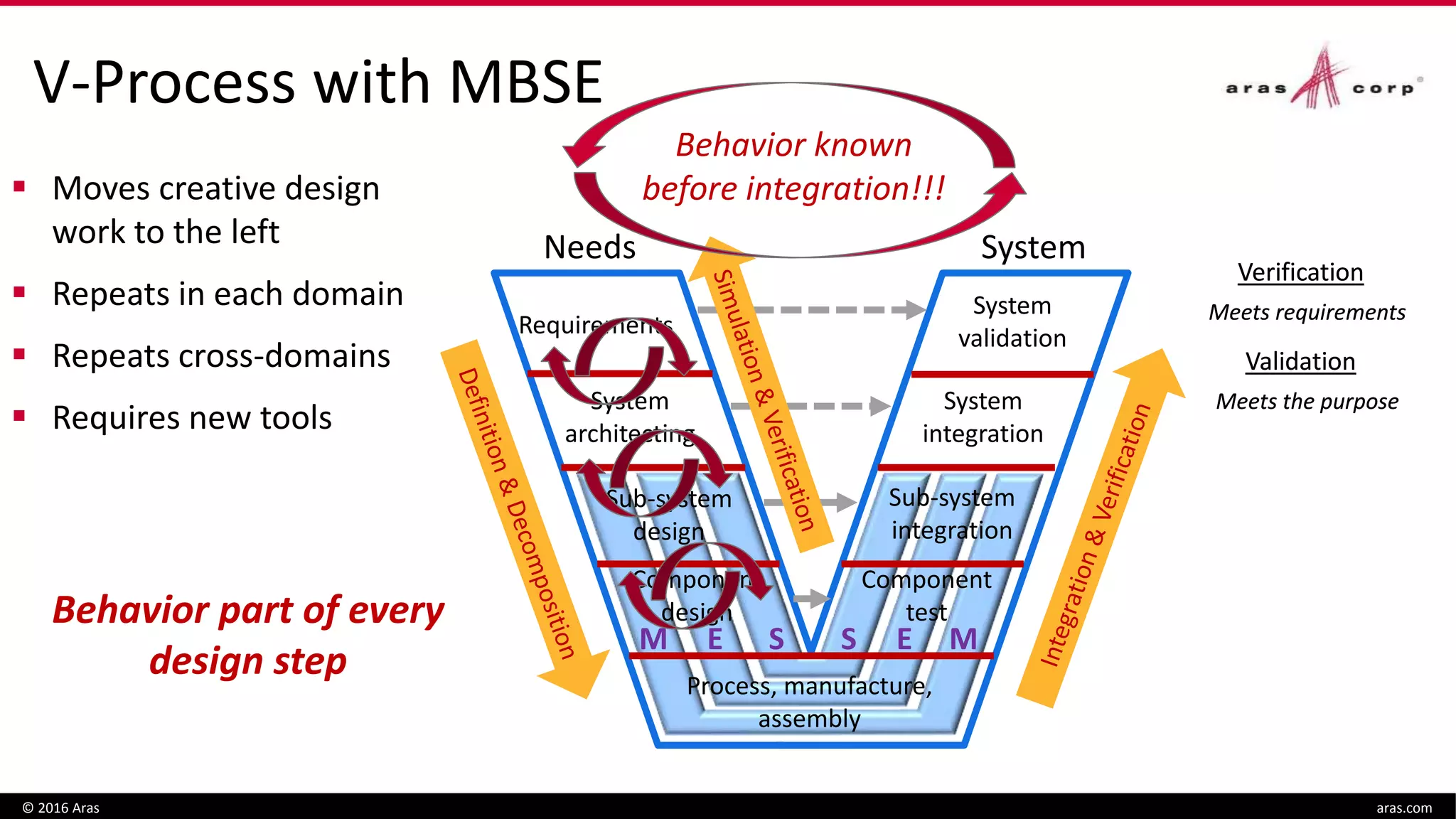

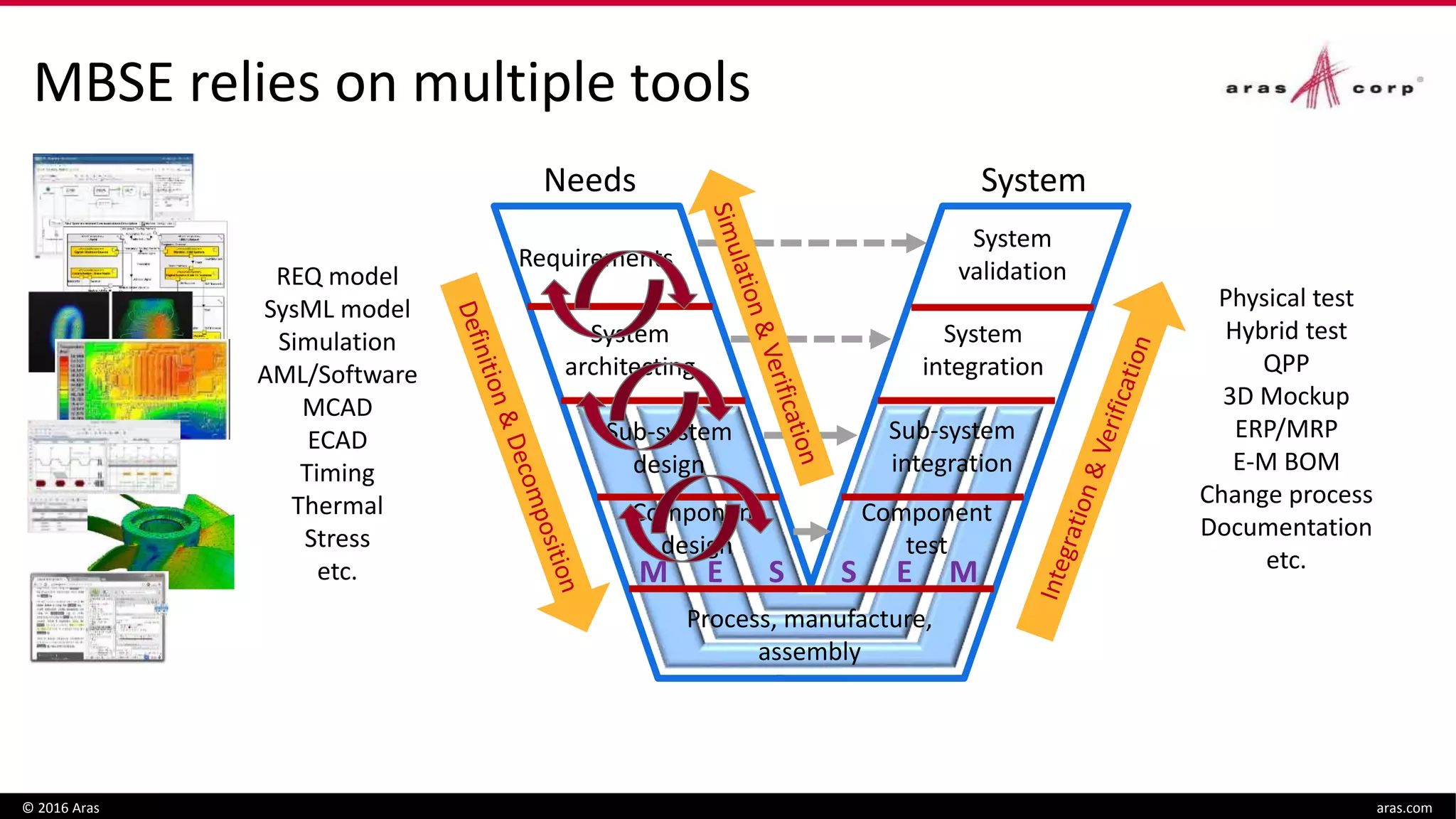

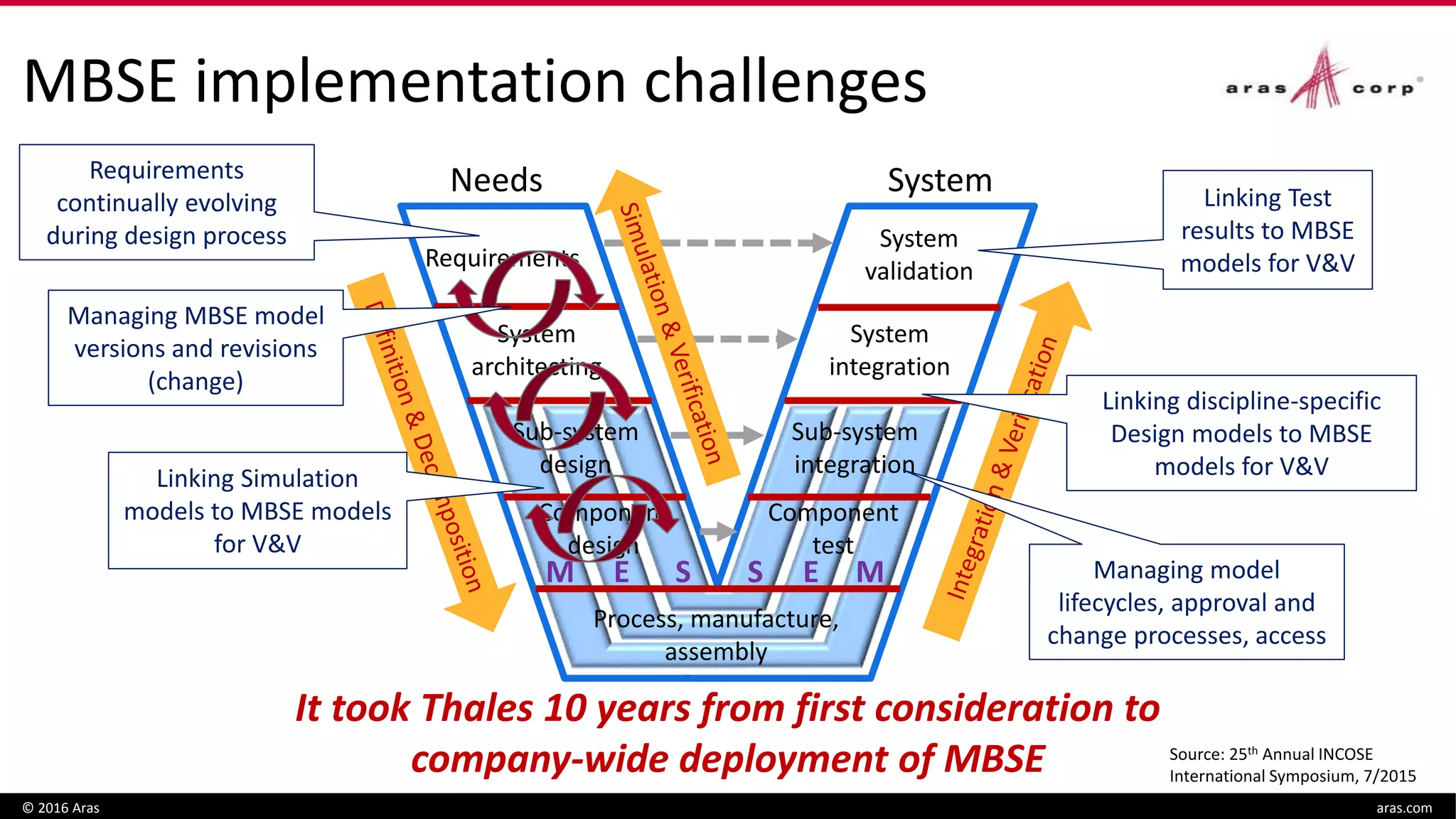

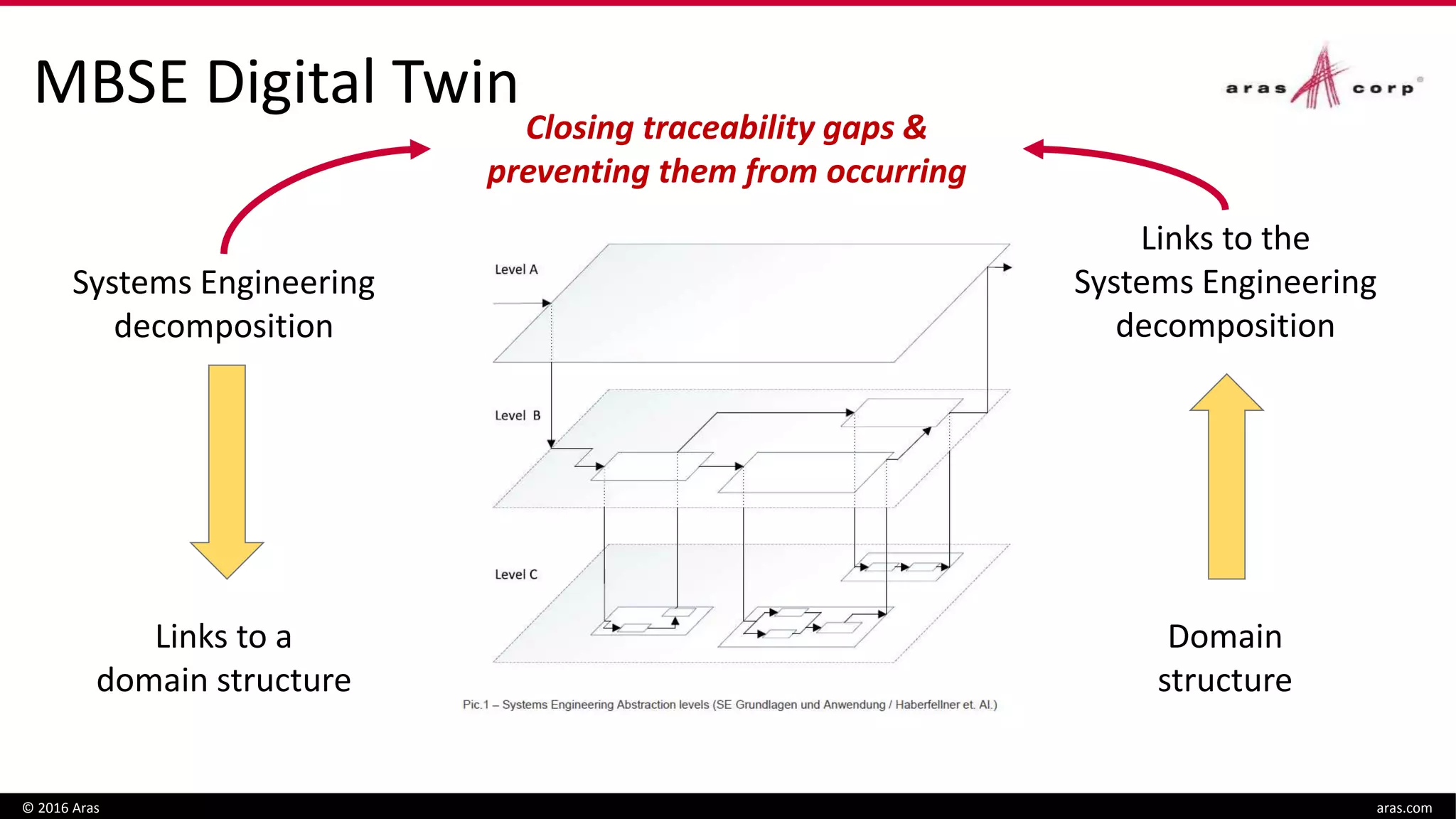

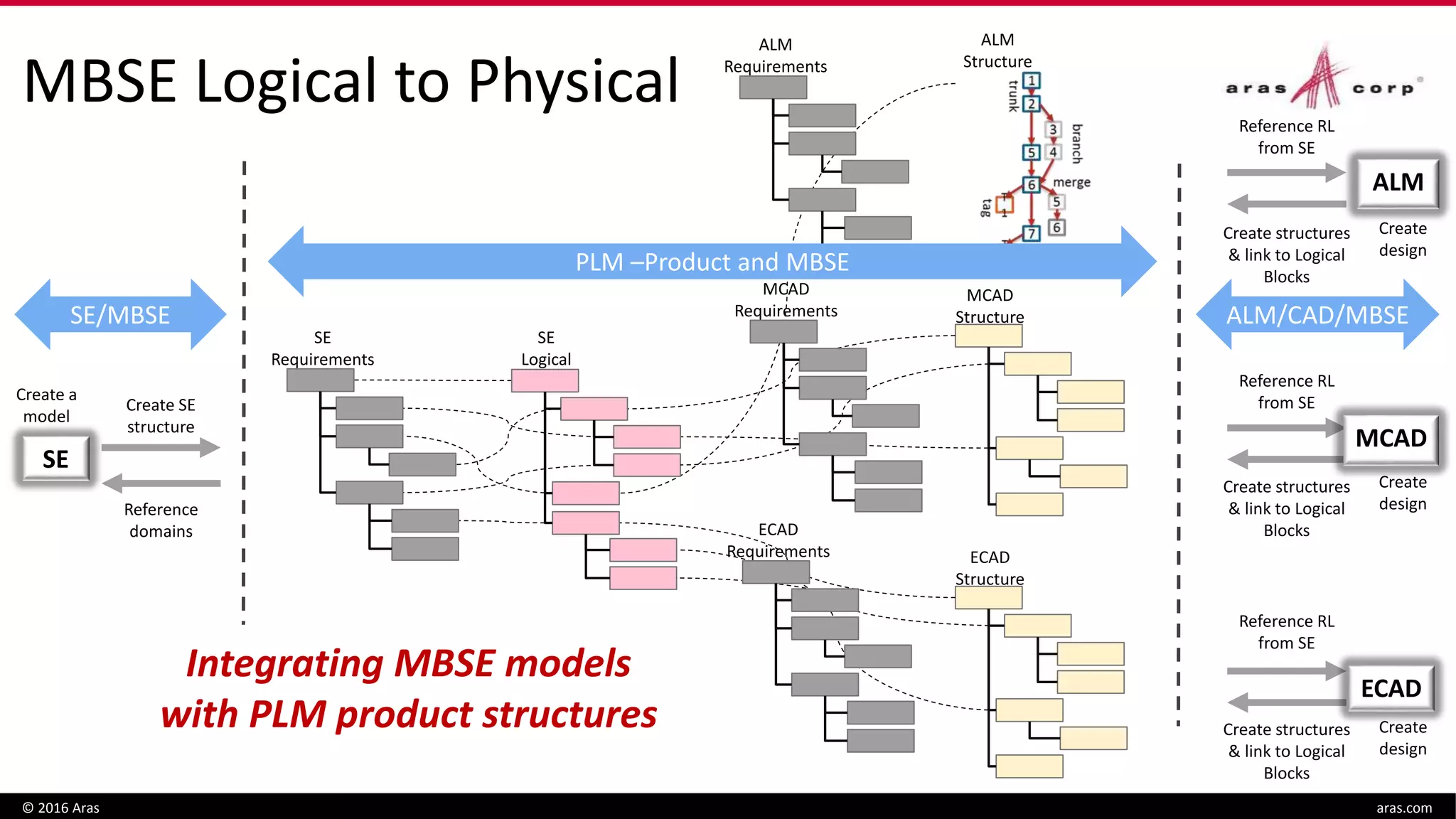

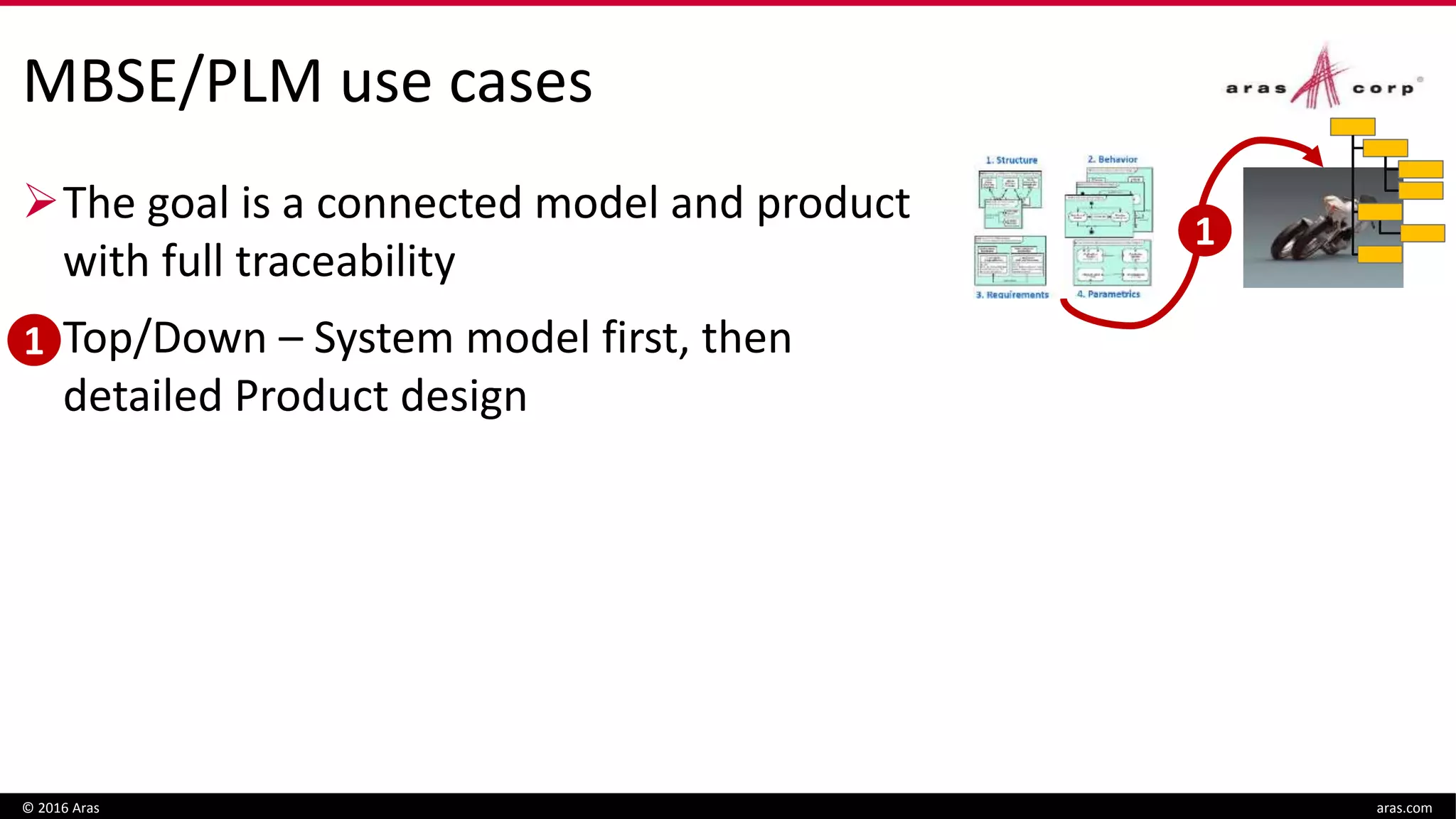

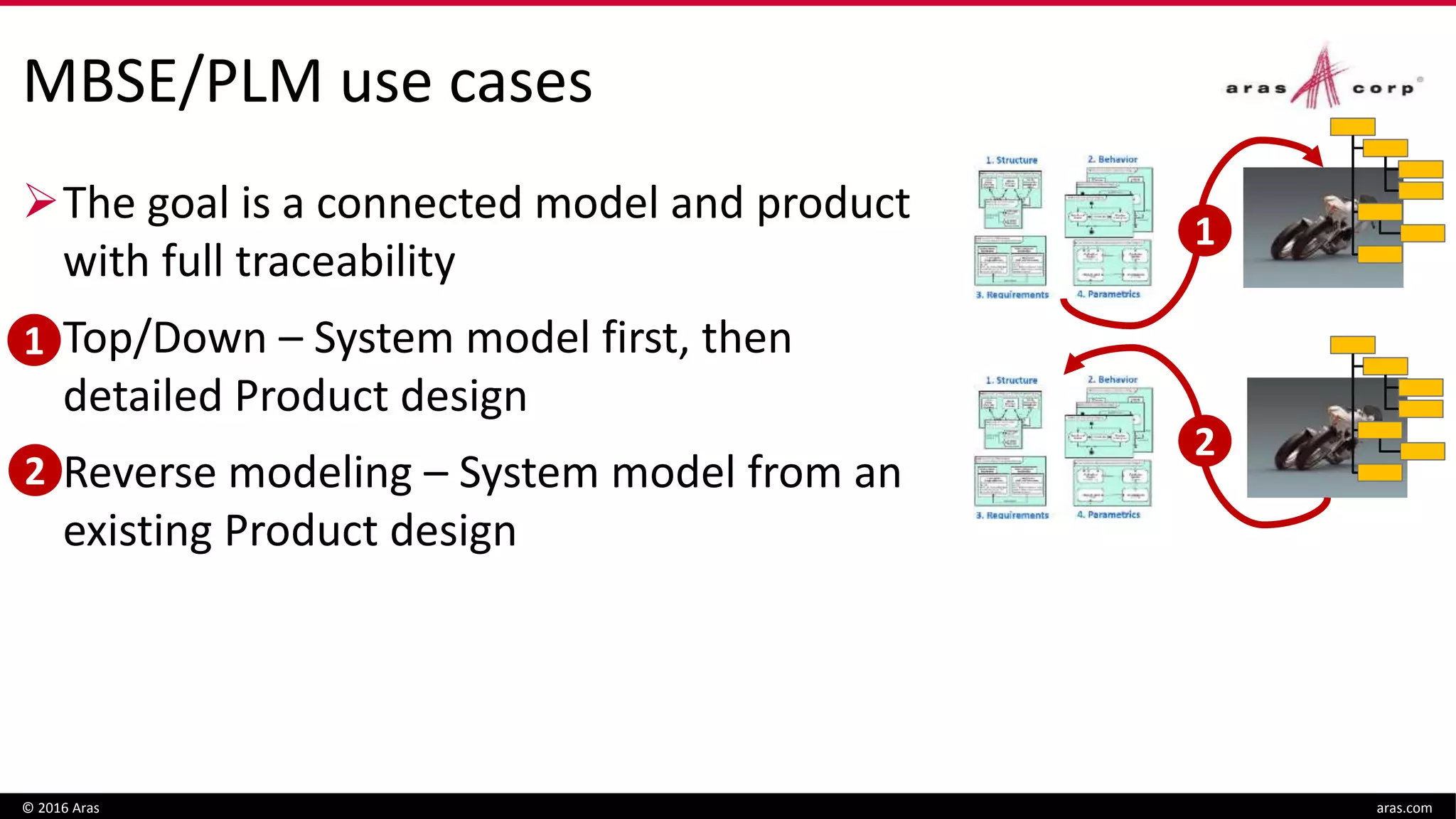

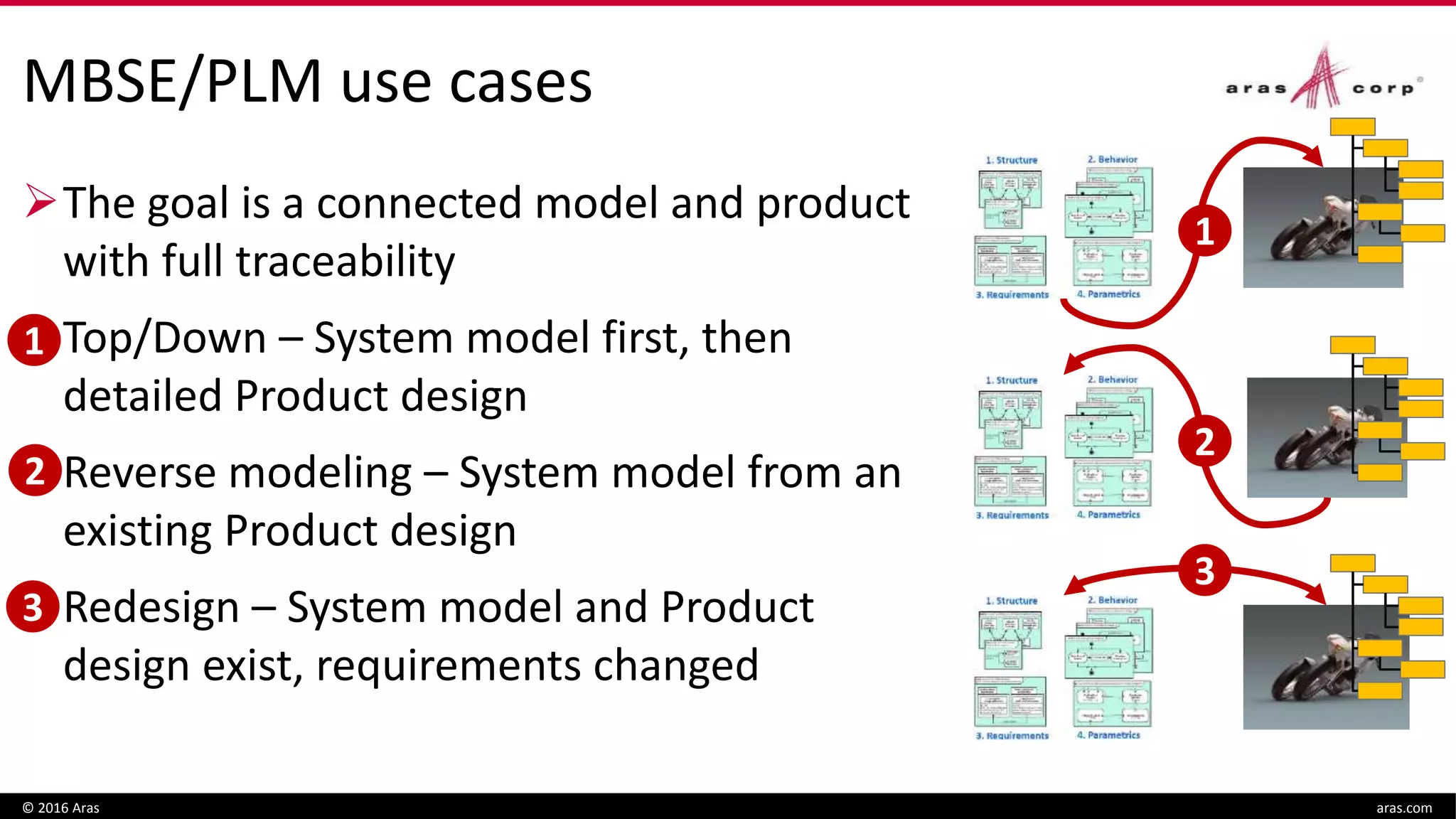

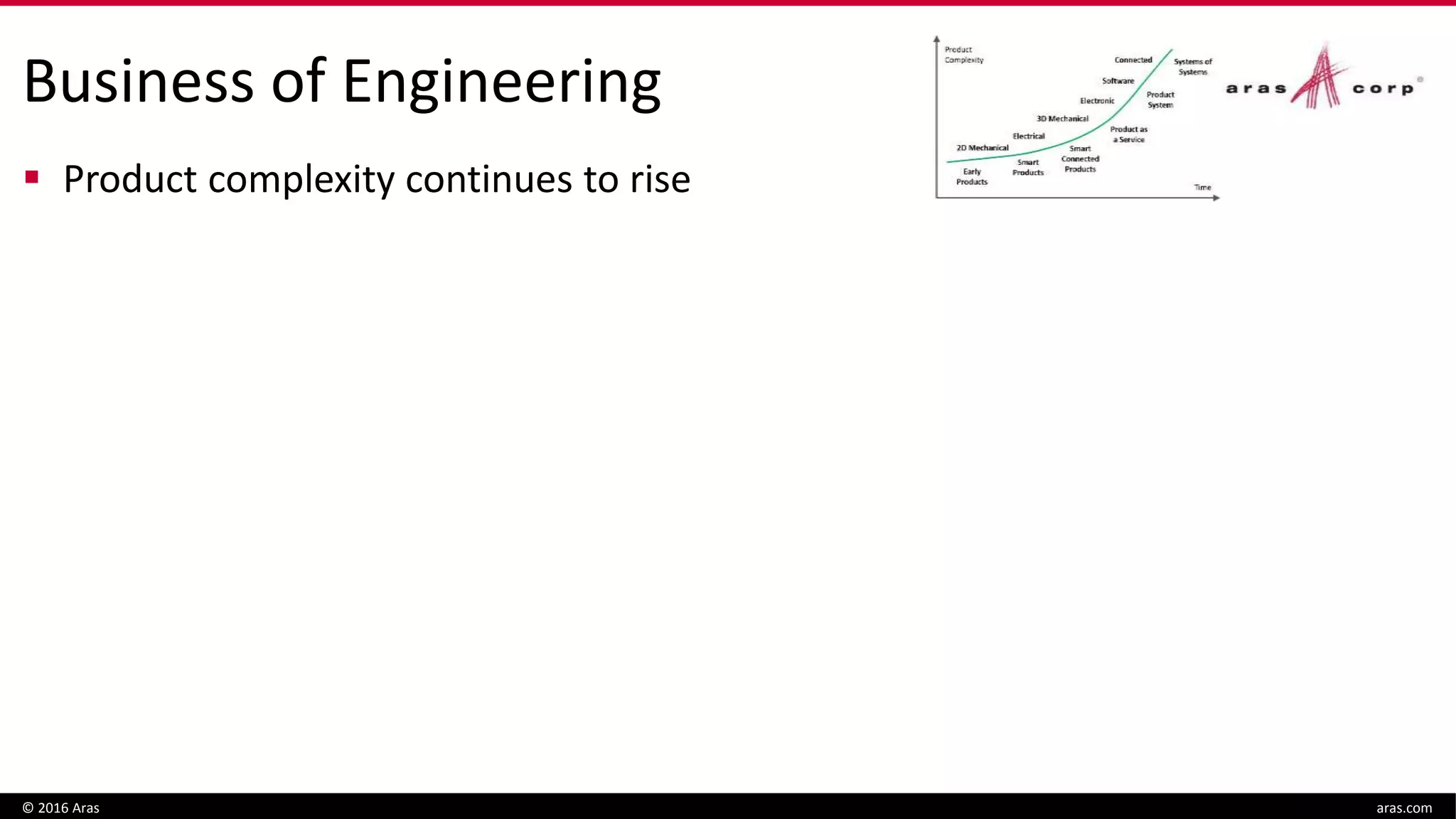

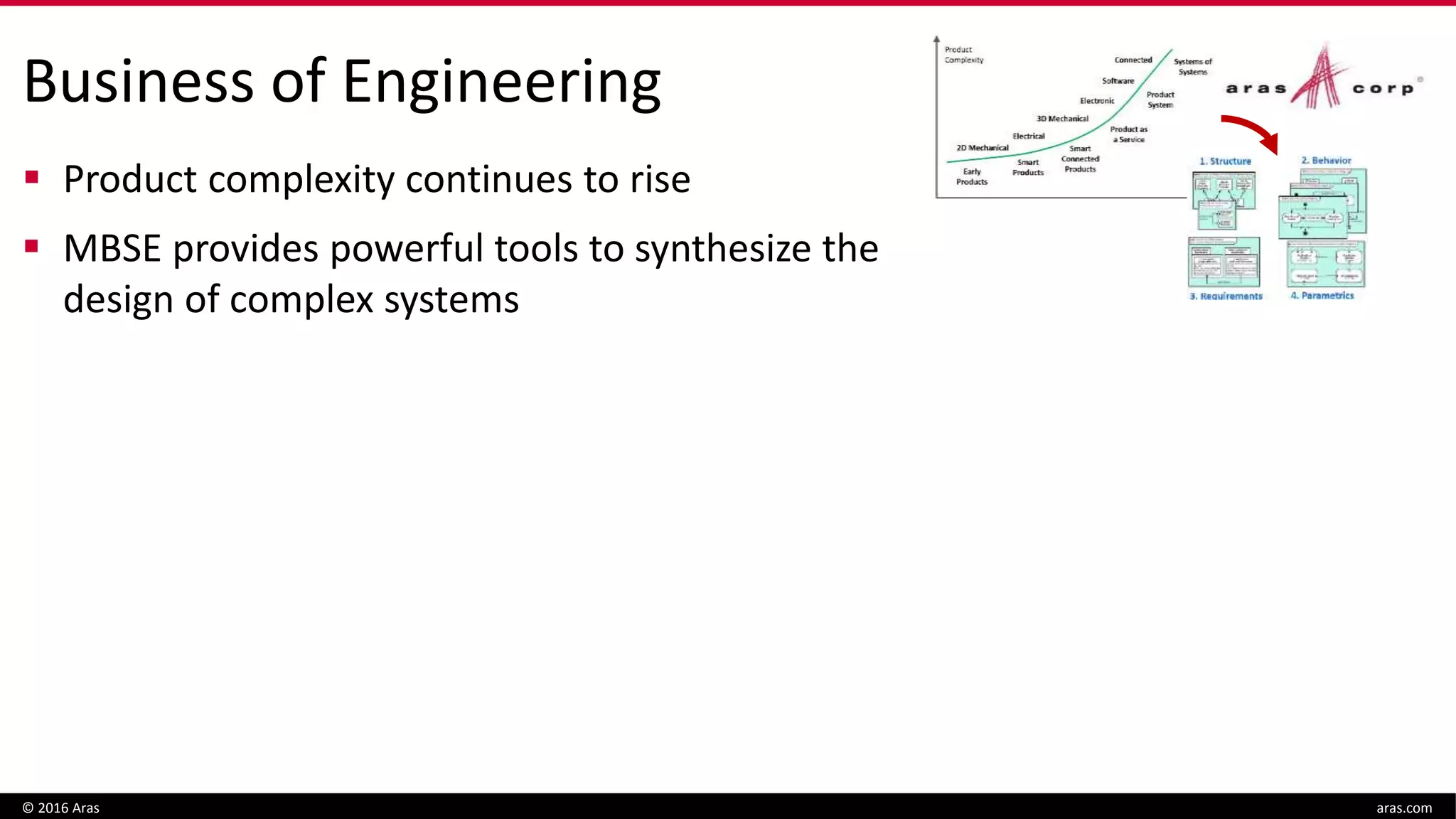

El ingeniero Pawel Chadzynski destaca el creciente desafío de la complejidad de los productos y la necesidad de un enfoque basado en modelos de ingeniería de sistemas (MBSE) para gestionar el diseño y la integración de sistemas complejos. MBSE permite una colaboración transversal entre disciplinas y proporciona herramientas para capturar el comportamiento de los sistemas desde las fases iniciales del diseño, mejorando así la trazabilidad y la gestión de cambios a lo largo del ciclo de vida del producto. Además, enfatiza la importancia de integrar MBSE con prácticas de gestión de configuración y trazabilidad para obtener los beneficios óptimos en el desarrollo de productos.