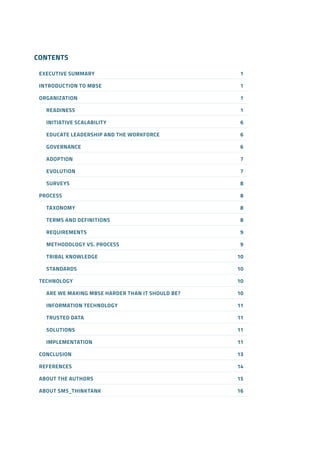

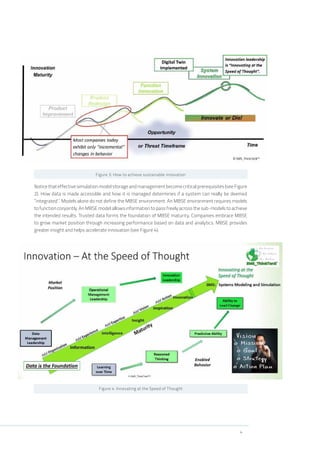

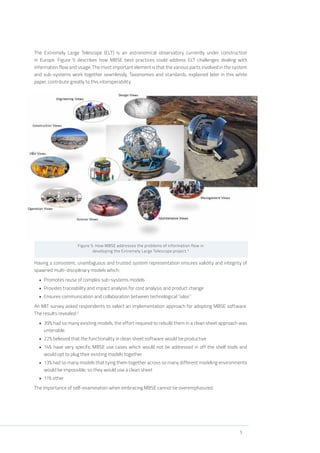

This white paper discusses the implementation of model-based systems engineering (MBSE) and highlights its importance in managing increasing product complexity across industries. It addresses the critical areas of organization, process, and technology necessary for successful MBSE adoption while emphasizing the need for proper planning, governance, and education within organizations. The document aims to guide companies through the MBSE journey by offering insights into best practices, common pitfalls, and strategies for achieving sustainable innovation.