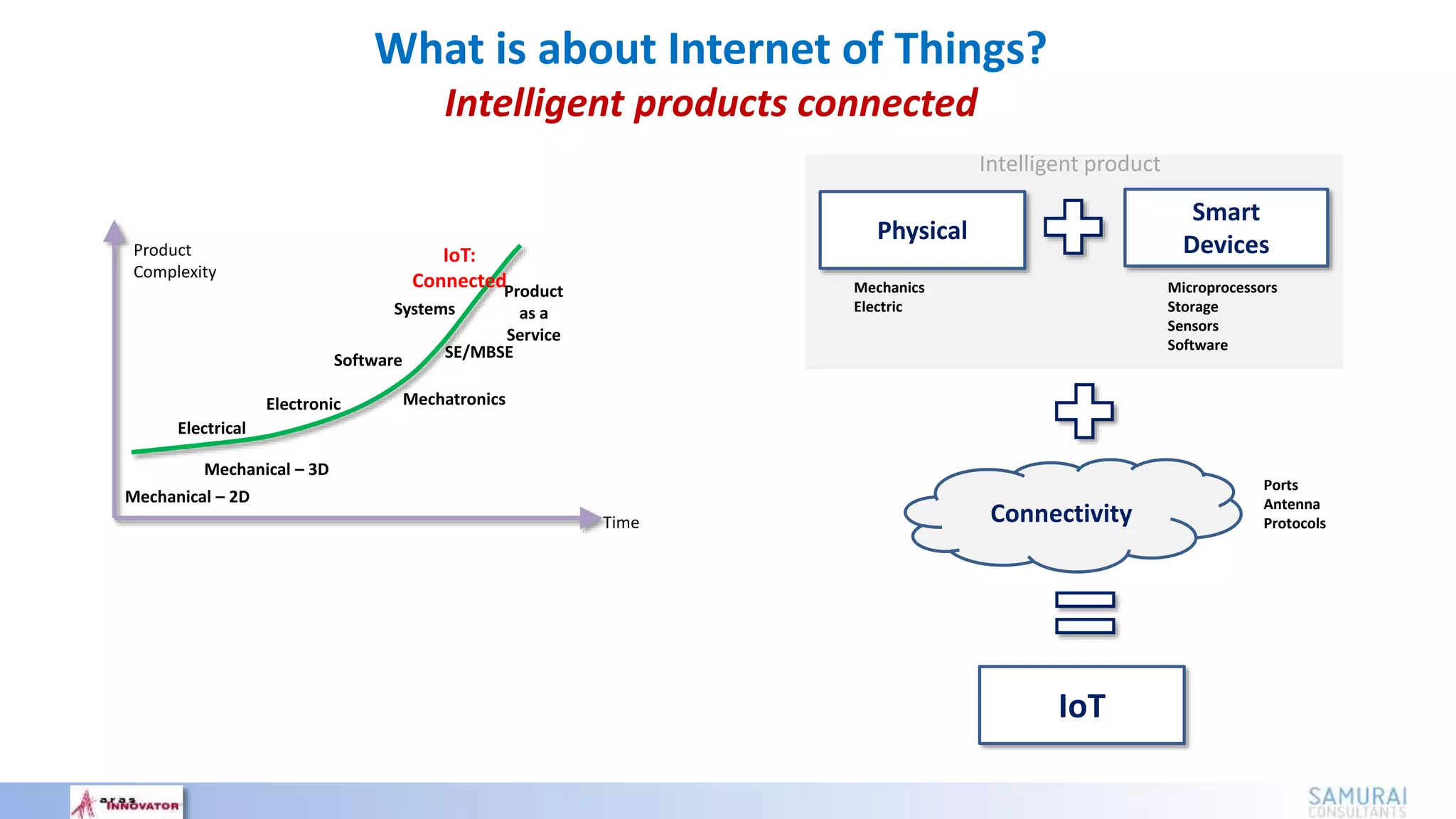

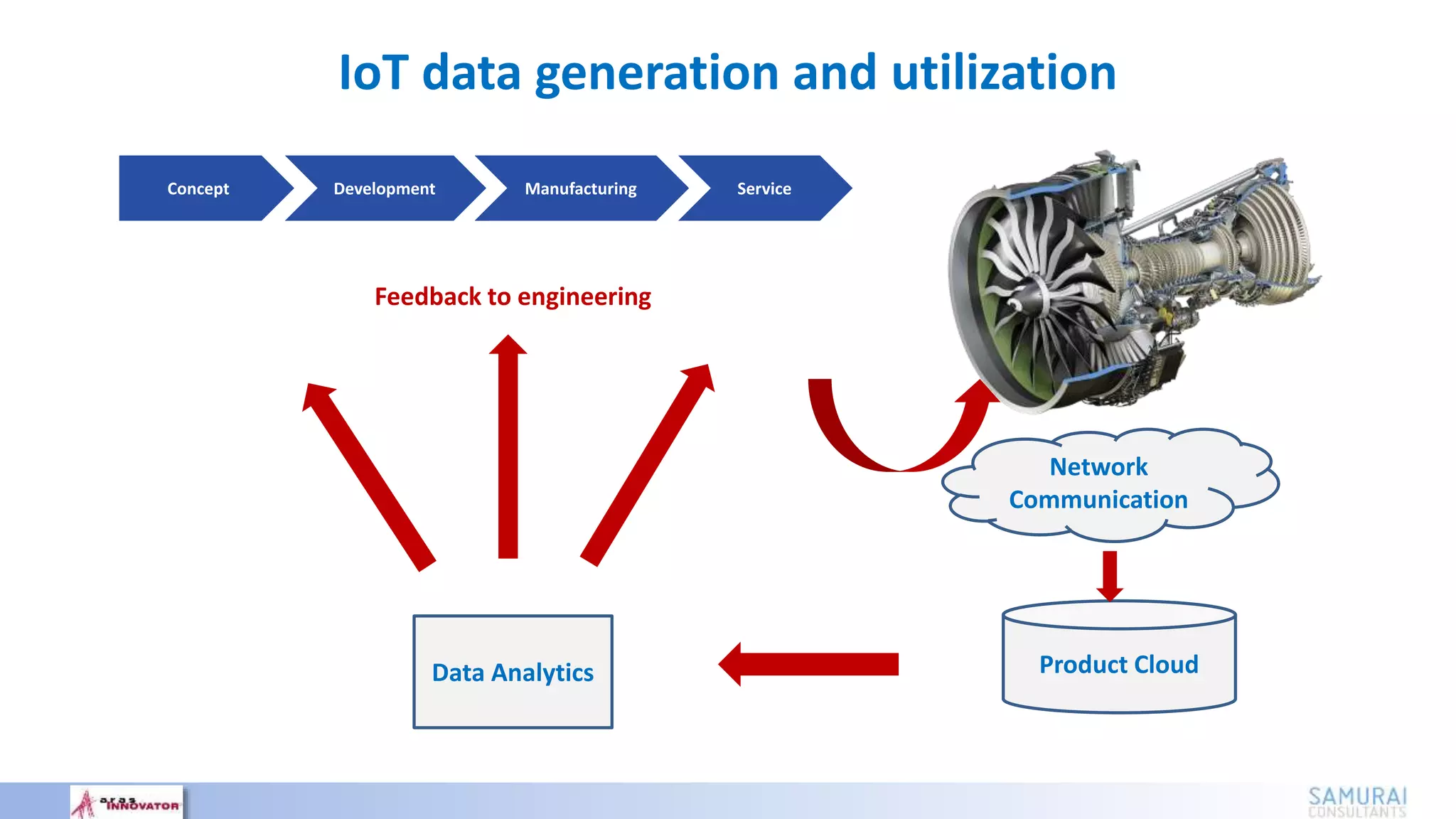

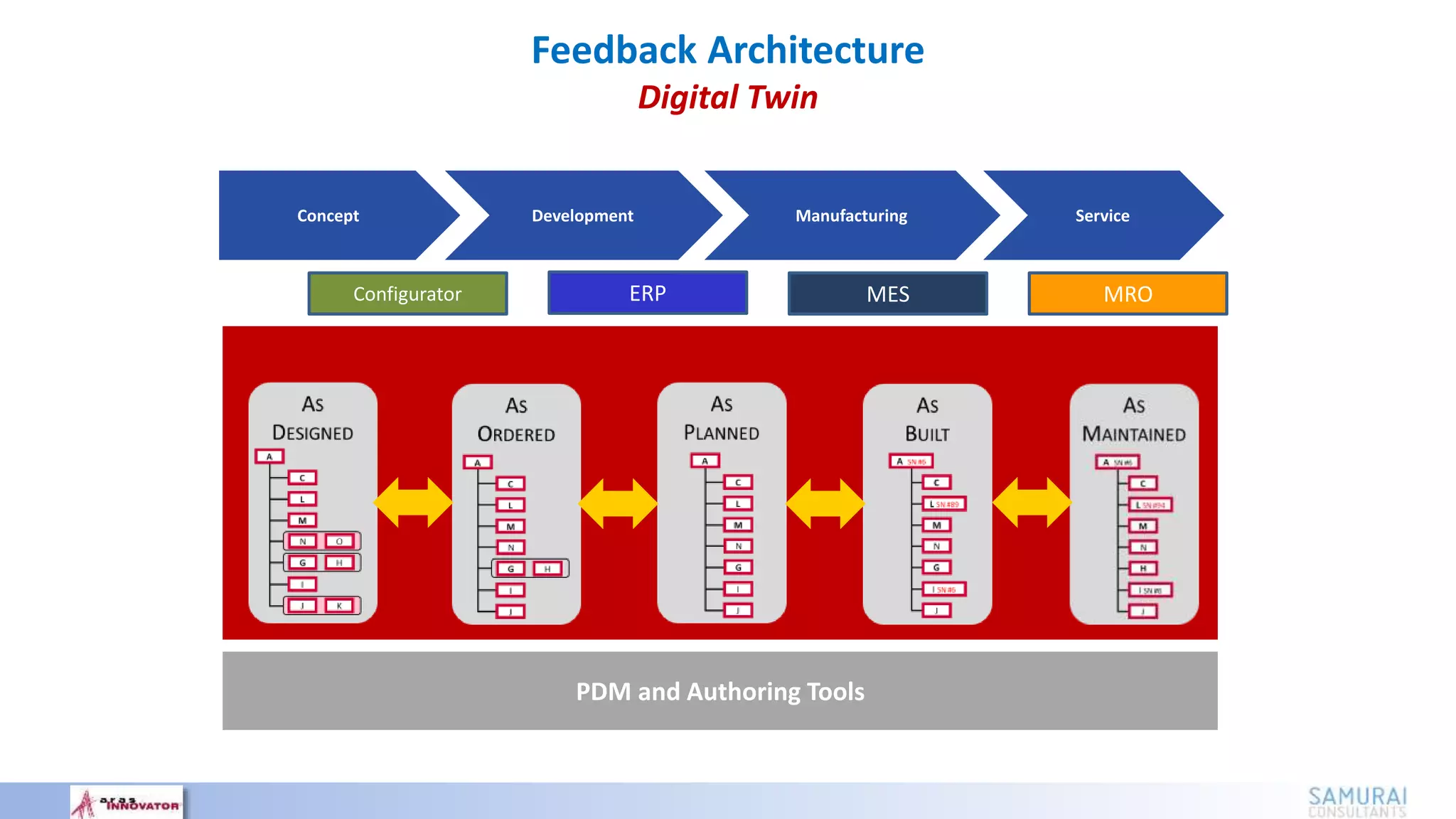

IoT will impact product design and development in several ways:

1) It will enable new product functionalities and greater reliability as products become connected and intelligent.

2) It presents new challenges around how to utilize and manage the large amount of new data generated from connected products.

3) Managing increasing product complexity as the role of software increases will be critical to maintain design integrity and coordination across outsourced activities.