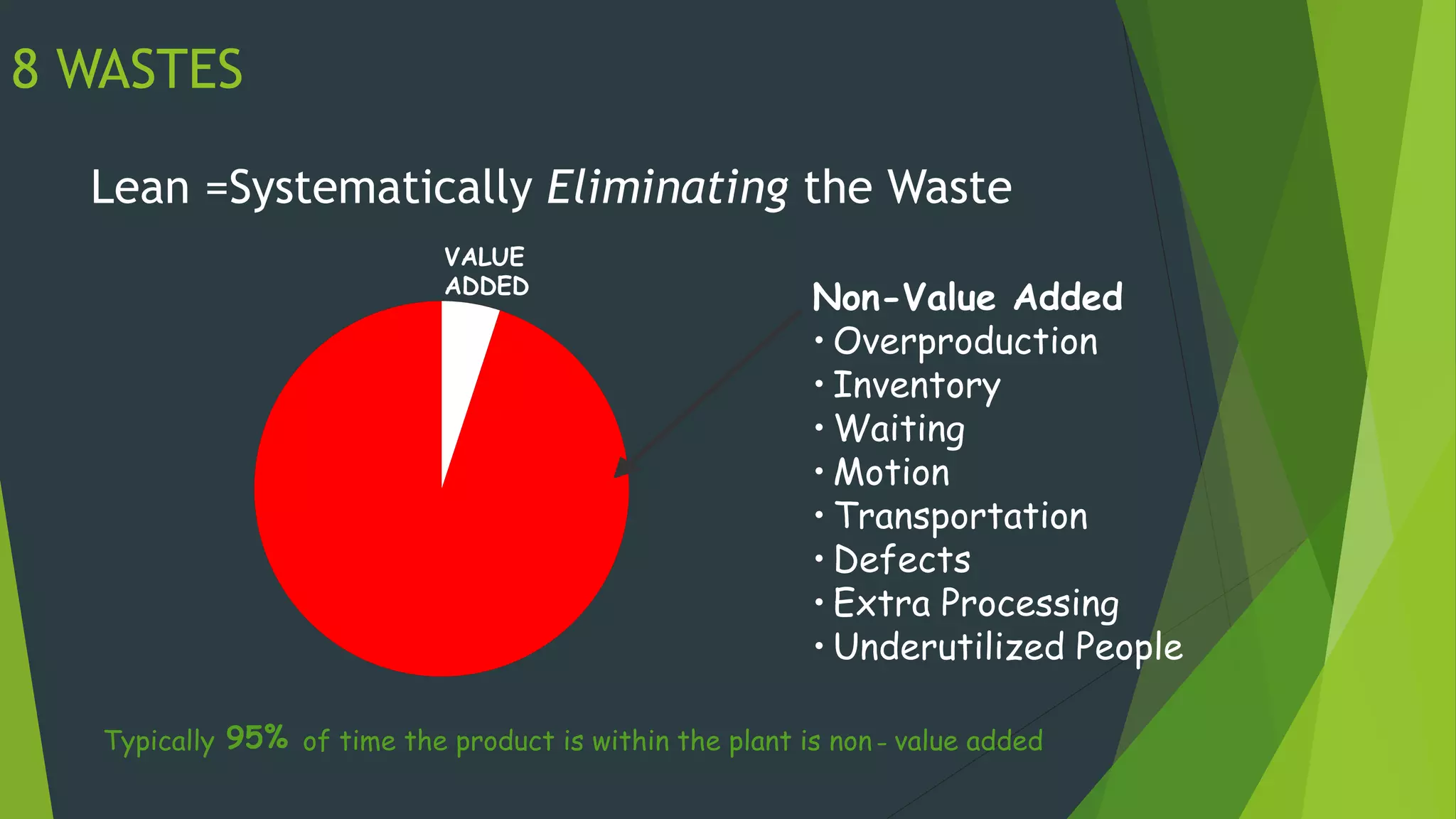

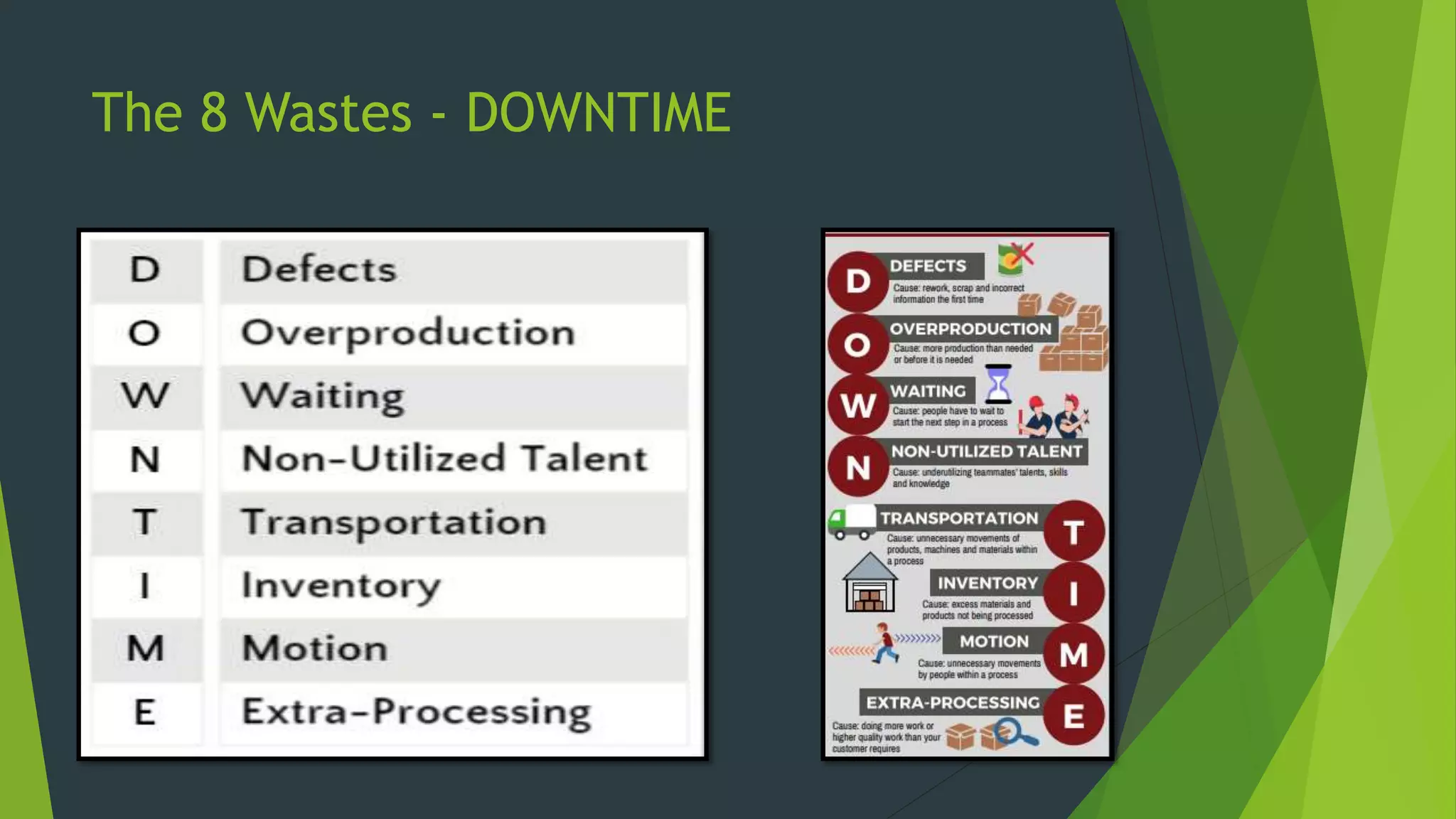

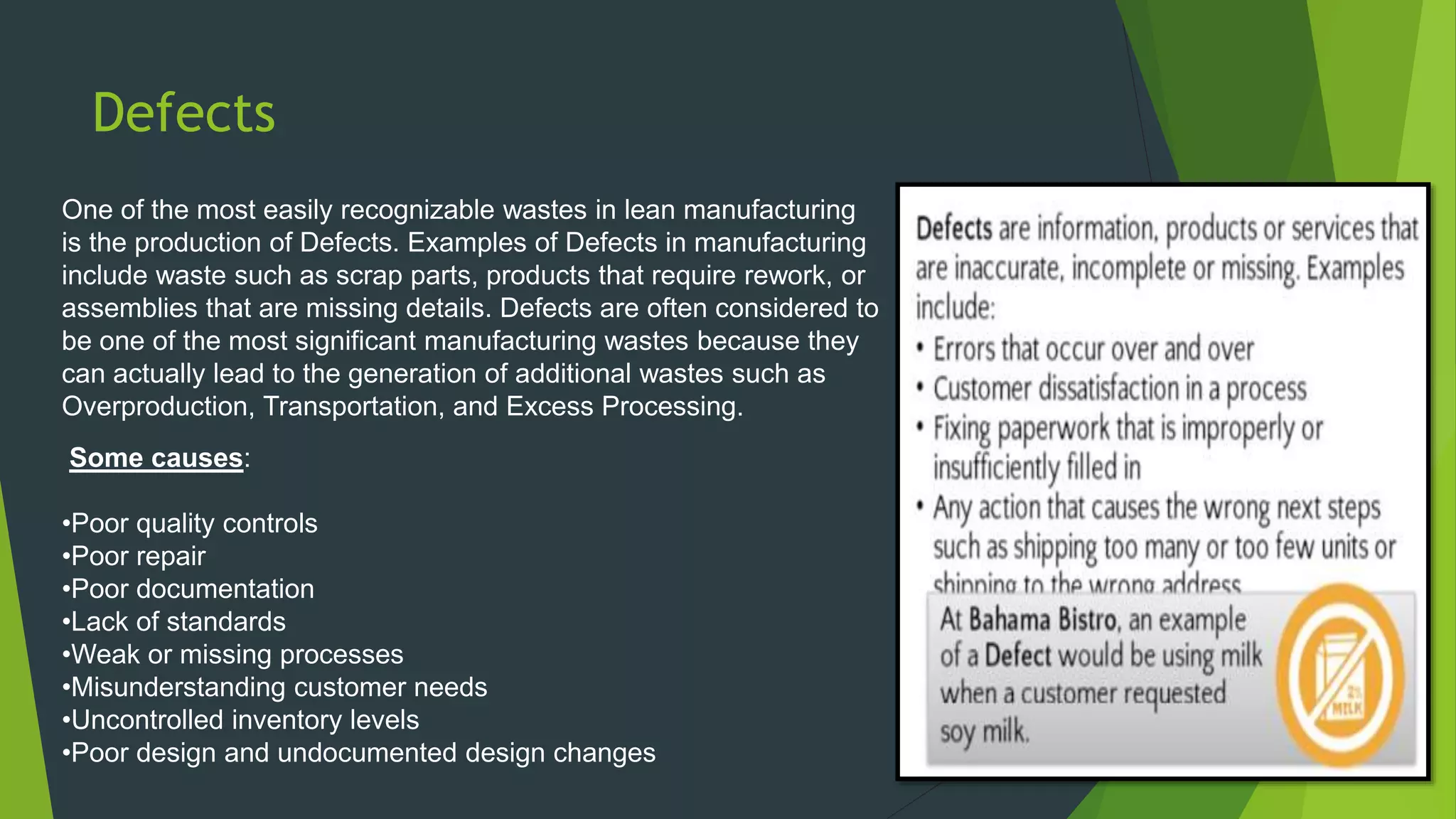

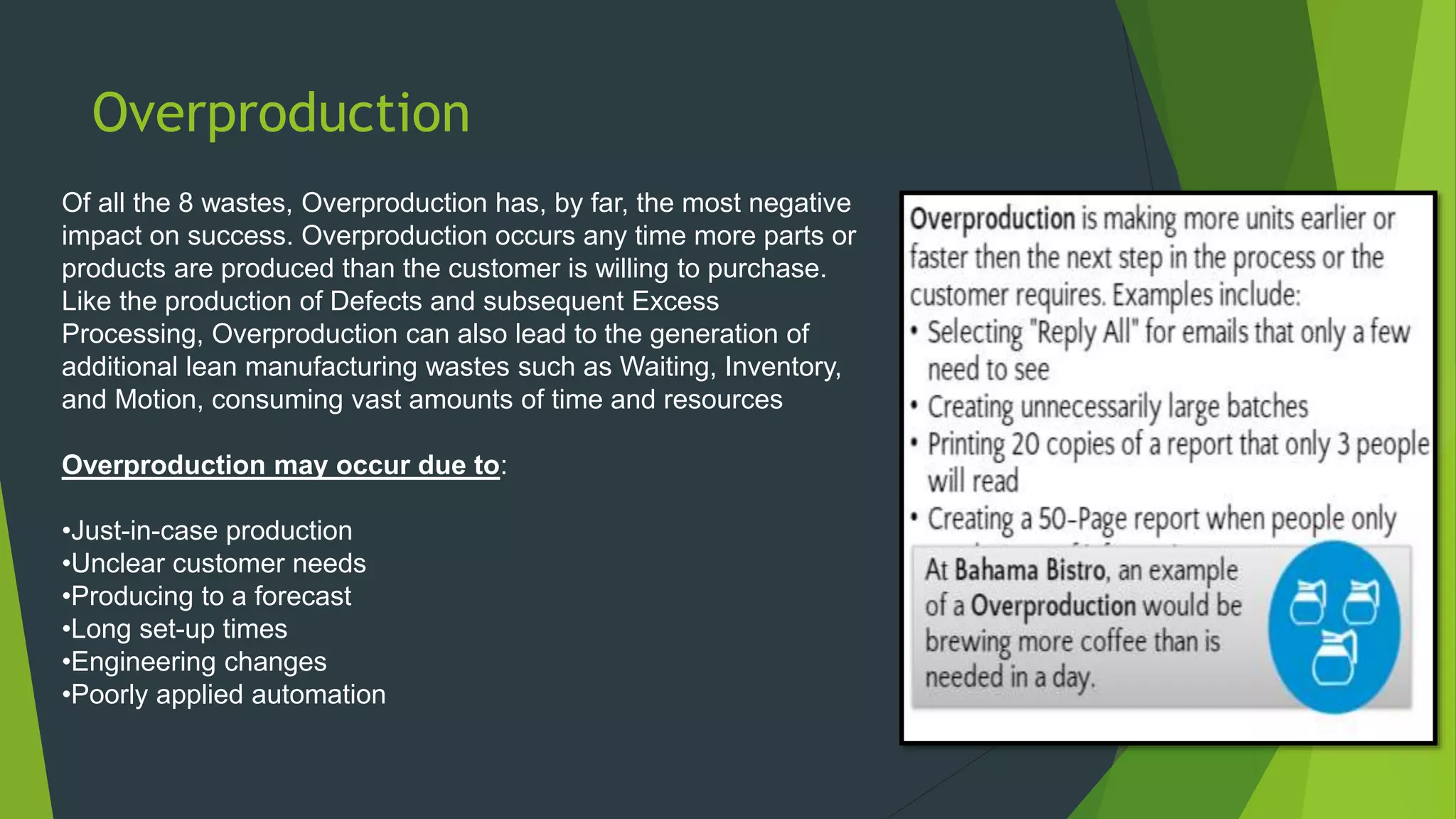

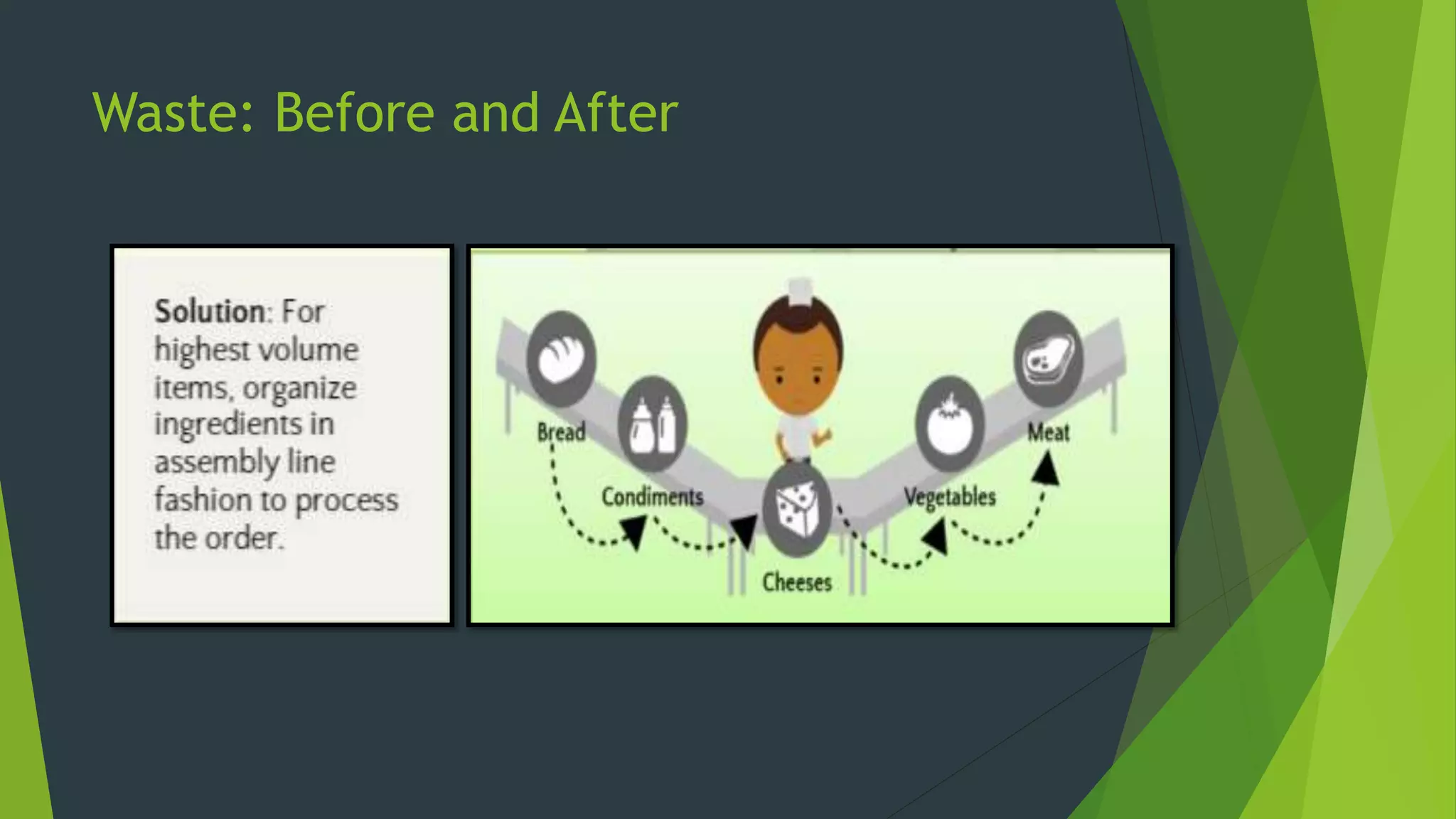

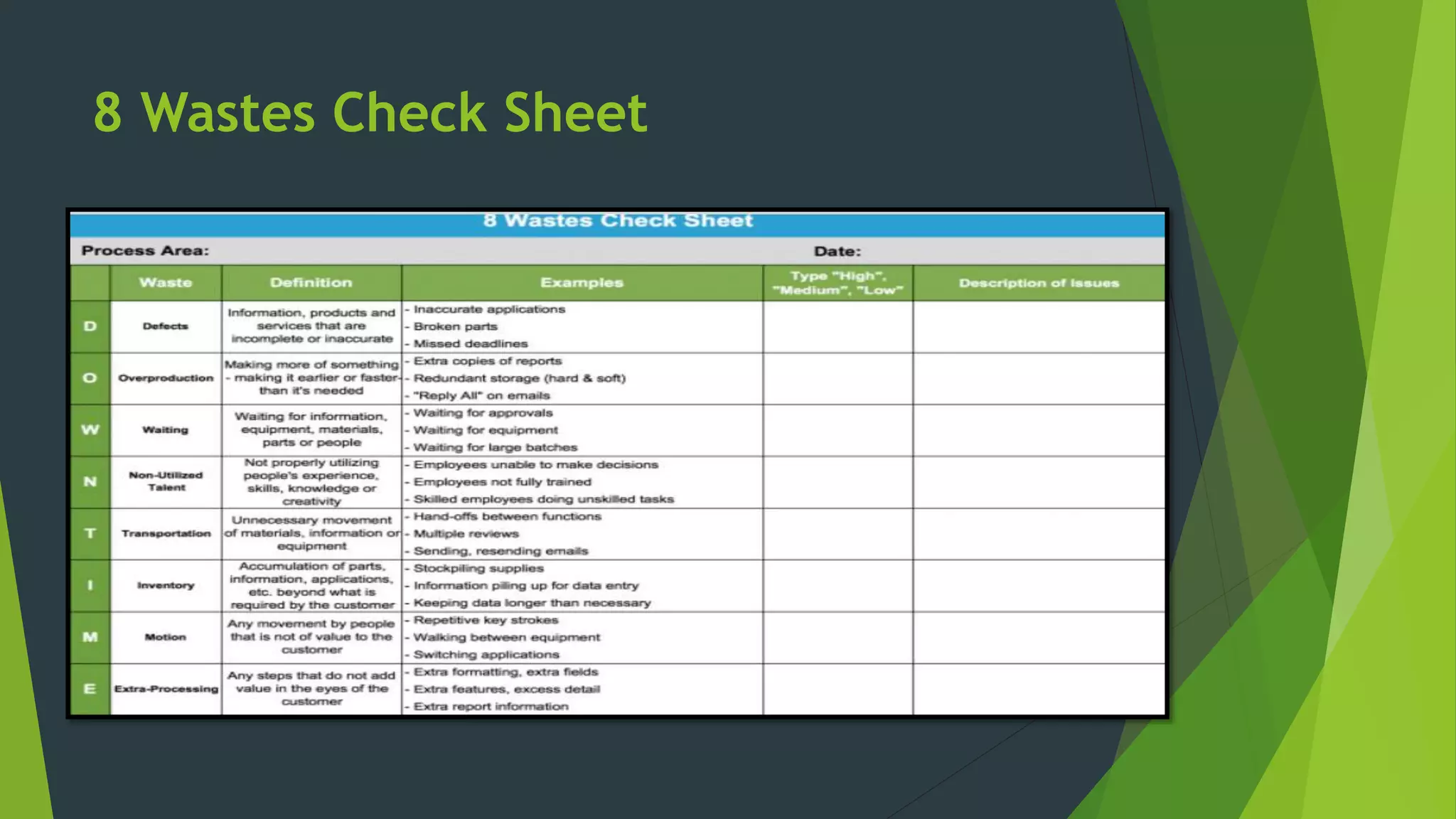

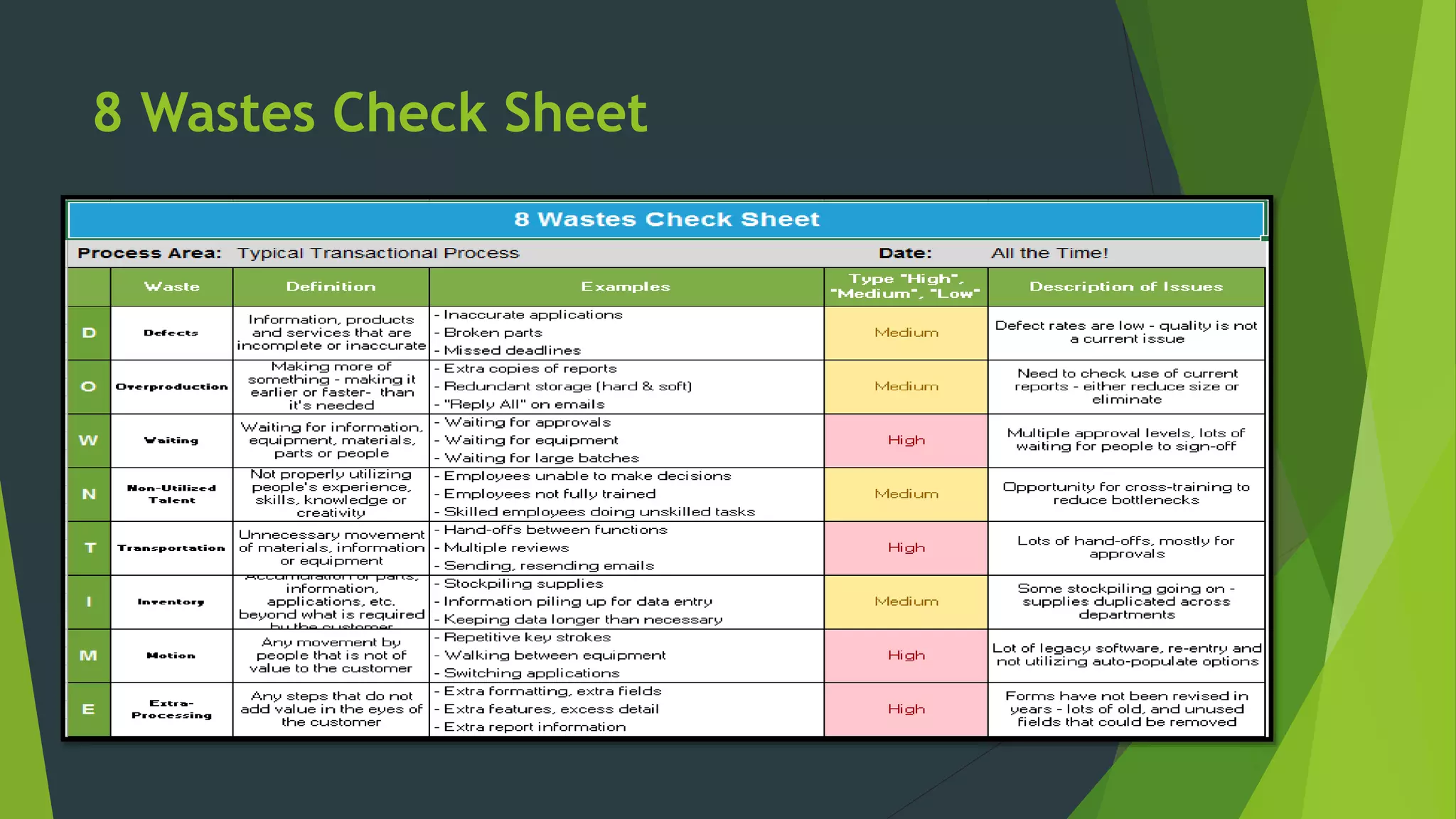

The document discusses the concept of waste in lean manufacturing, outlining the eight types of waste: defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and excess processing. It emphasizes the importance of identifying and eliminating these wastes to enhance efficiency and value for customers, citing strategies such as simplification and streamlining processes. Historical context is provided, highlighting the origins of lean practices from Toyota's manufacturing environment in the 1940s.