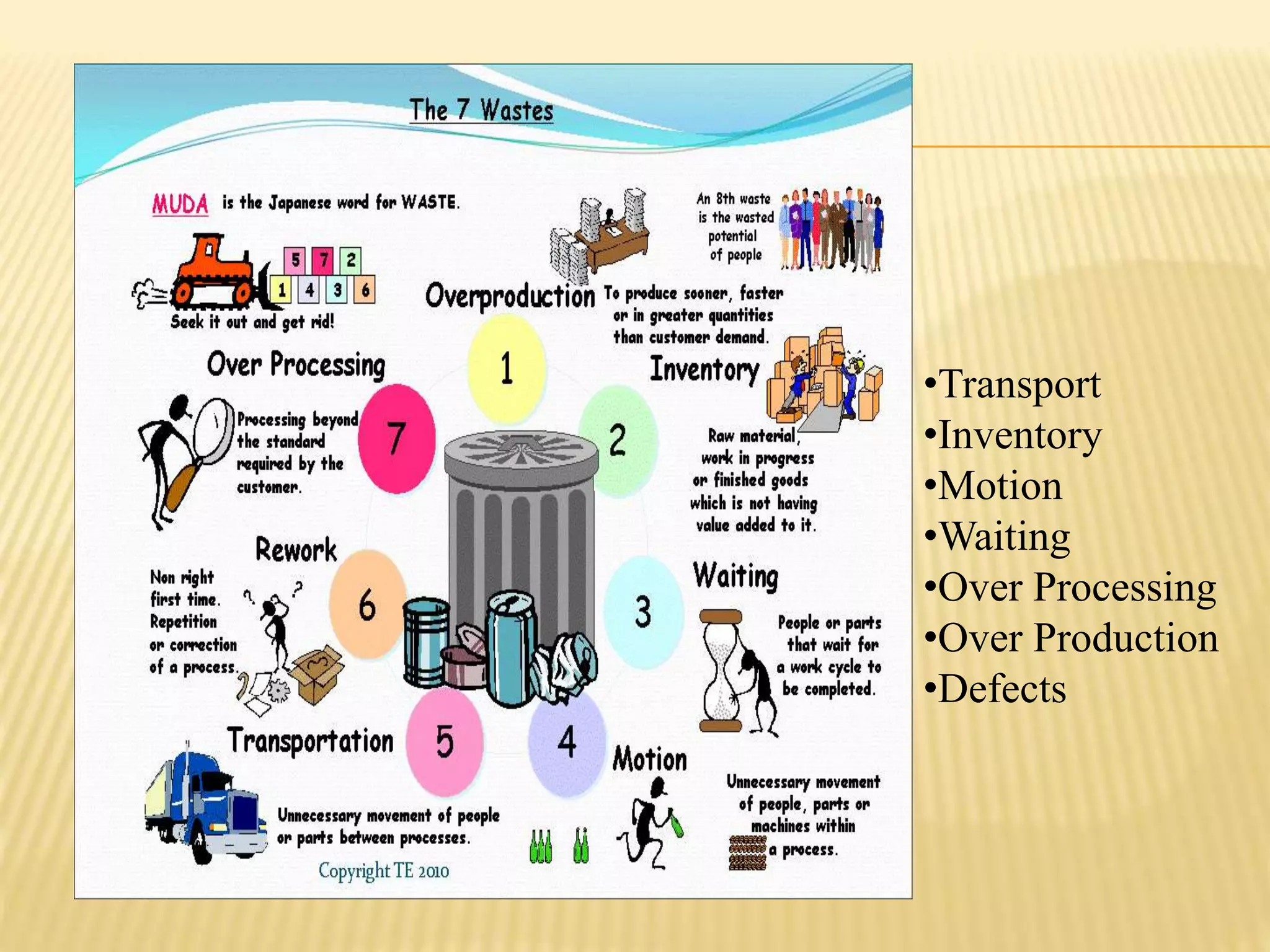

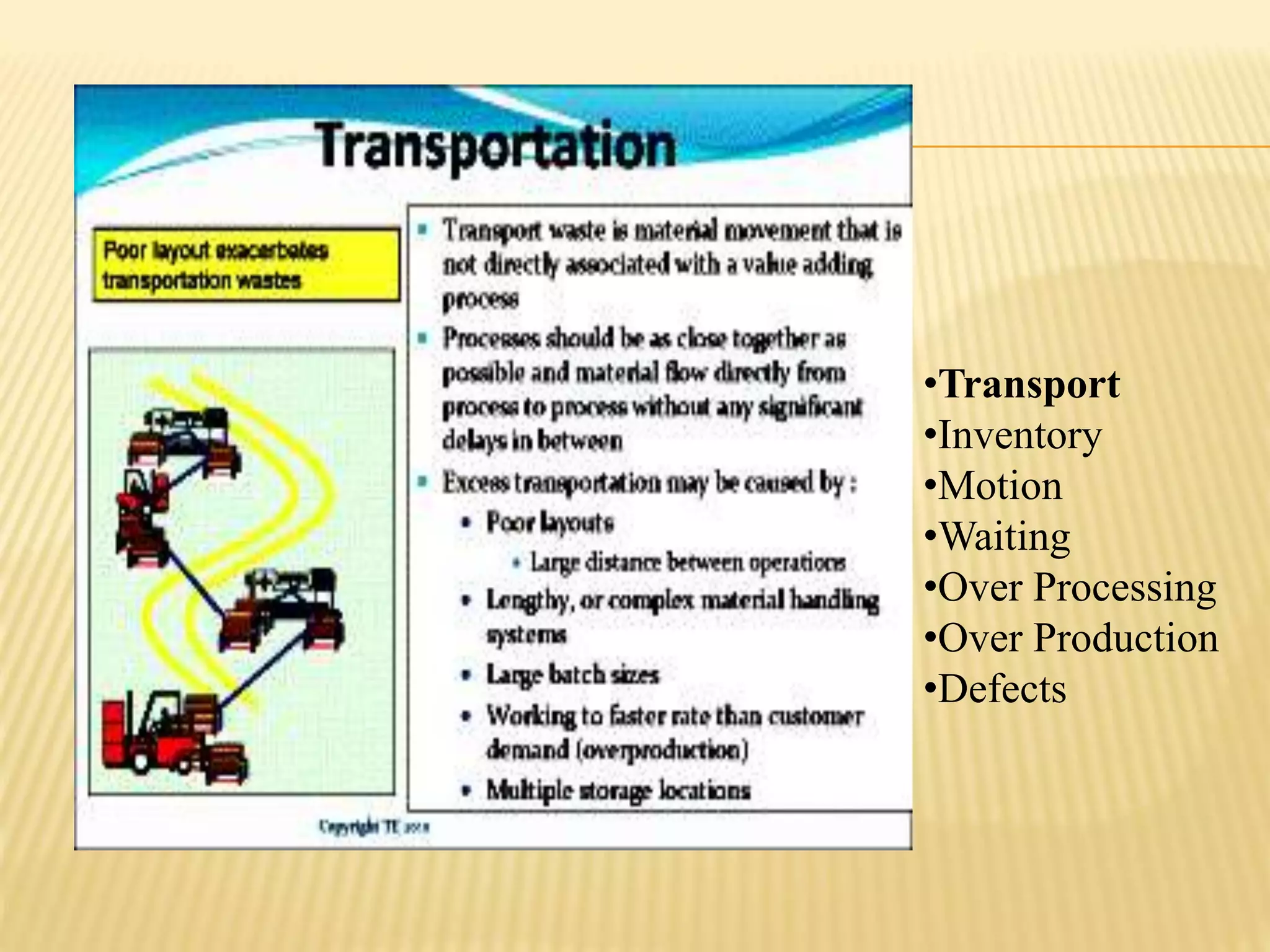

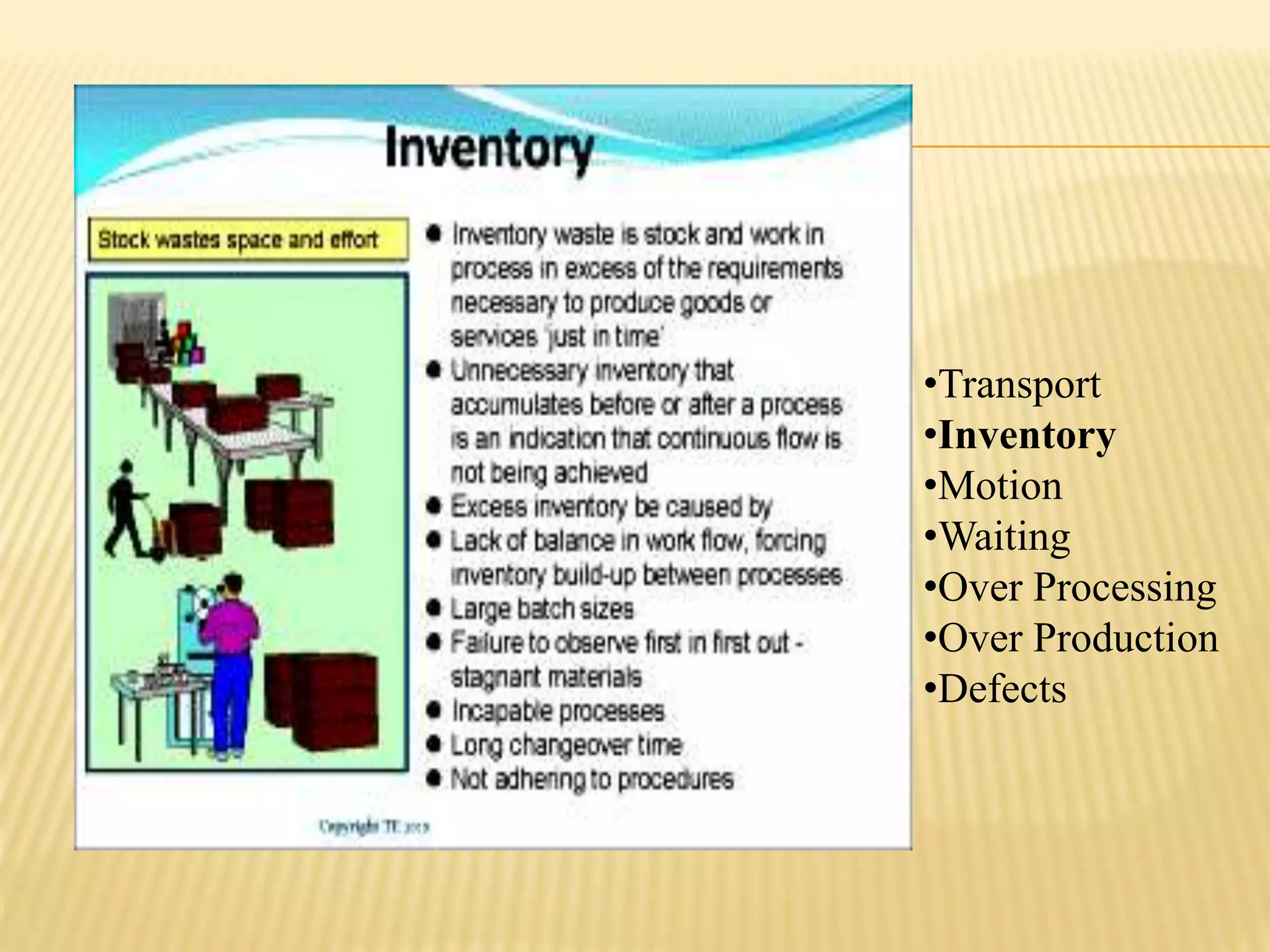

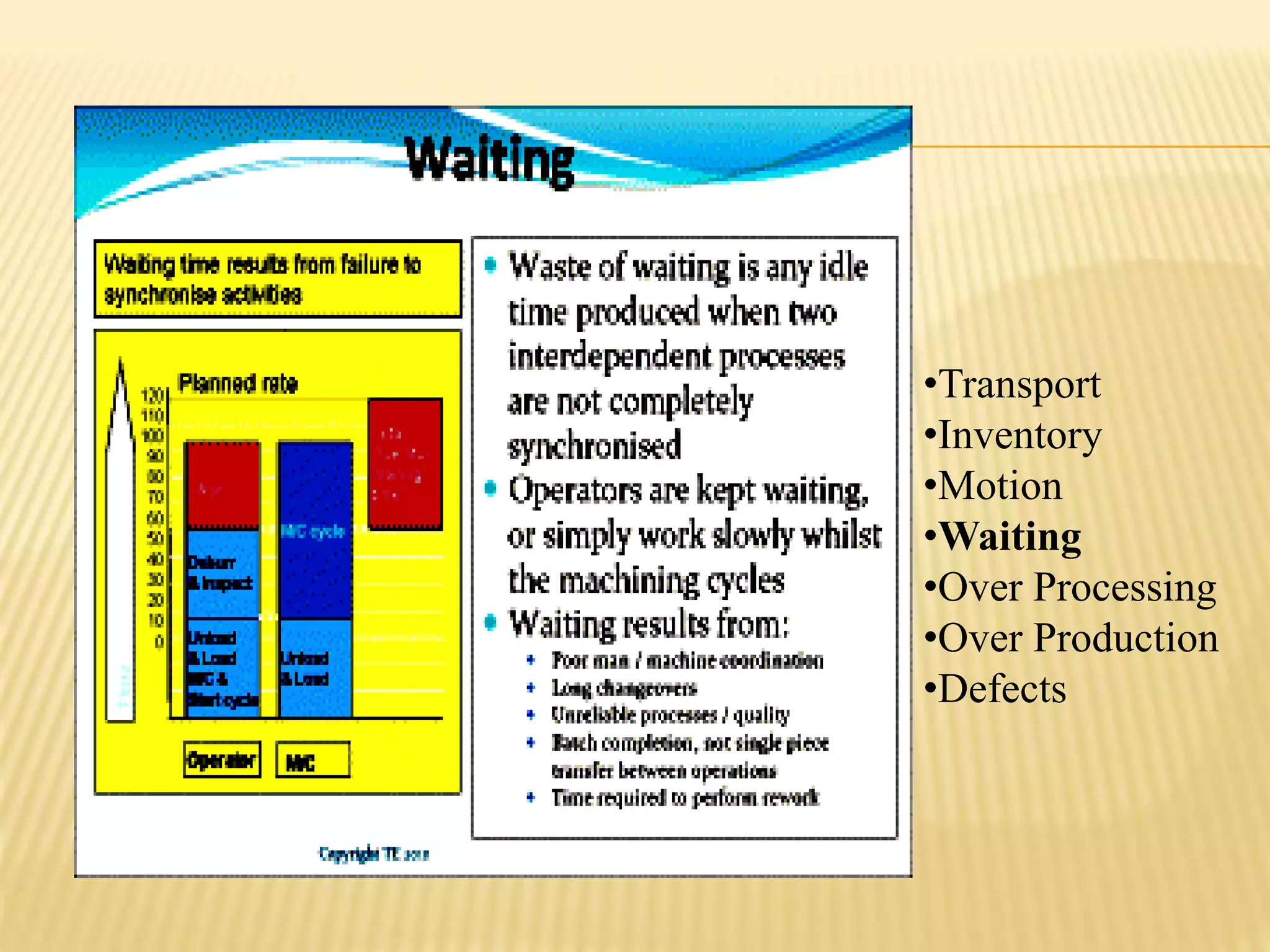

This document discusses lean manufacturing. It defines lean manufacturing as a system aimed at eliminating waste from all activities and operations. The goal is to produce products faster, better, and cheaper than competitors while eliminating as much waste as possible. The seven types of waste are then defined: transport, inventory, motion, waiting, overproduction, overprocessing, and defects. Examples are provided for each type of waste.