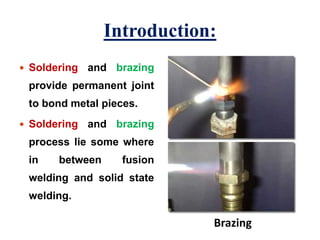

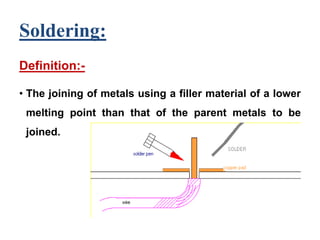

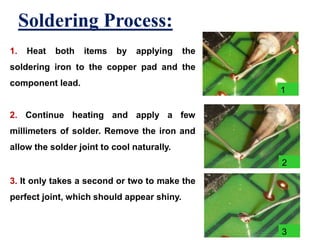

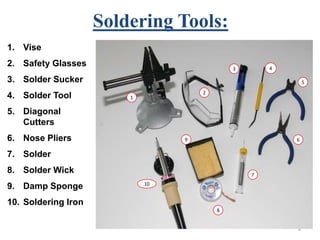

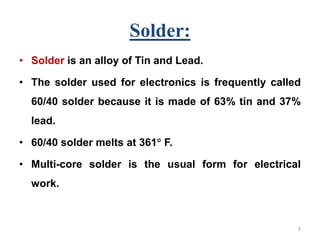

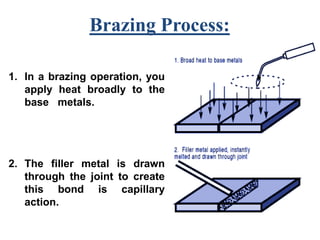

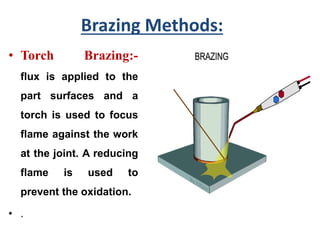

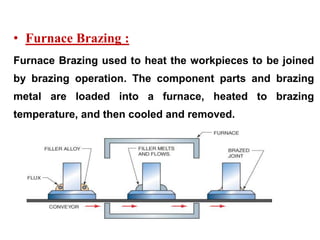

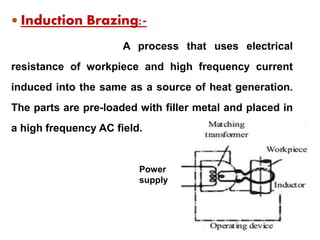

Soldering and brazing are processes used to join metal pieces. Soldering uses a lower melting point filler metal to join parts, while brazing uses higher temperatures above 450°C for the filler metal to melt without melting the parts. Common soldering tools and techniques were discussed, along with advantages like low heat and joining dissimilar metals, and disadvantages like low joint strength. Brazing methods like torch, furnace, and induction brazing were also outlined, along with advantages like joining any metals but disadvantages of potentially weaker joints at high temperatures.