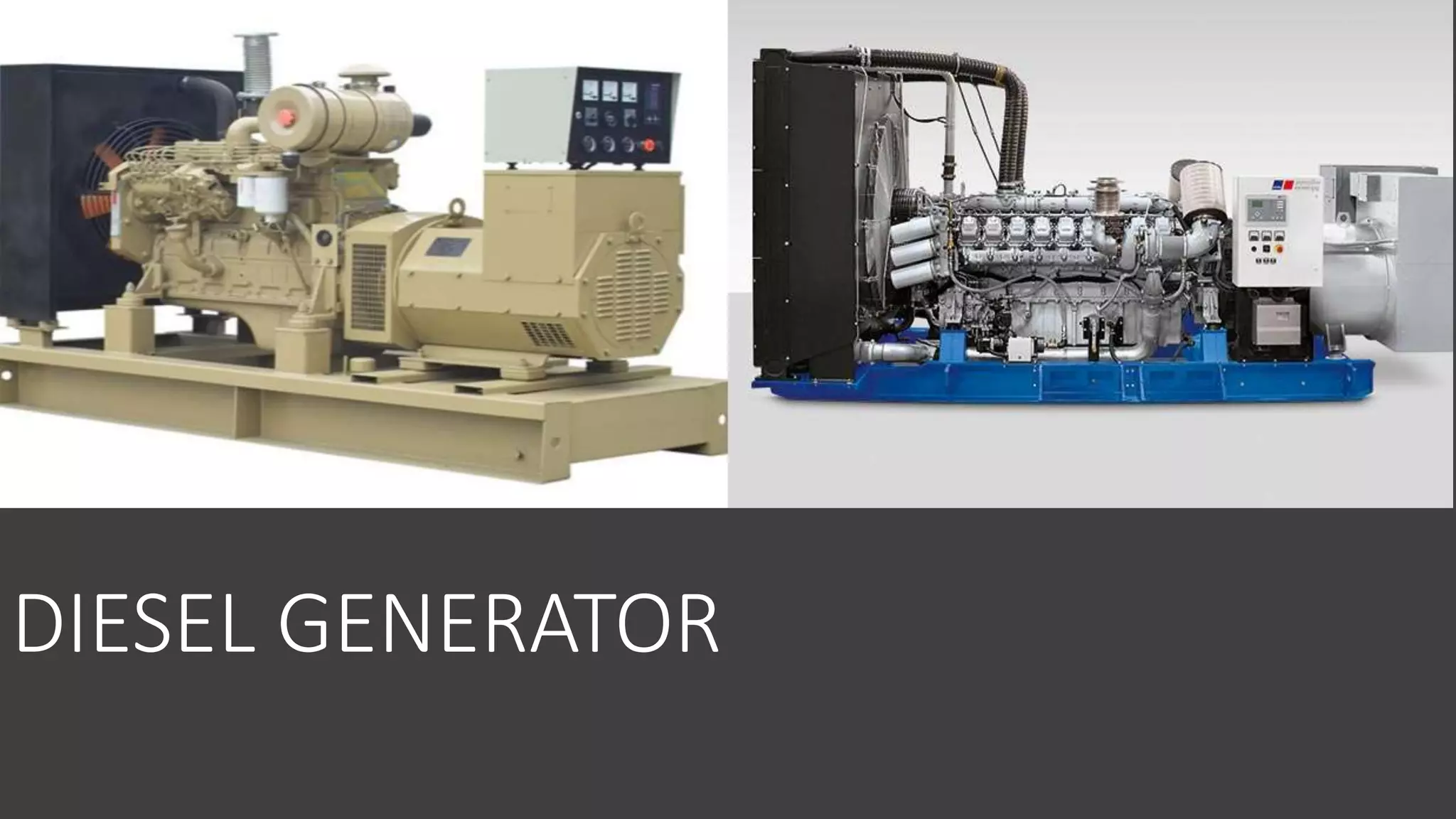

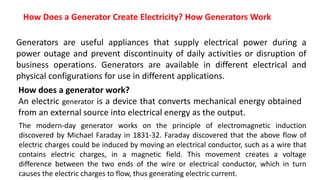

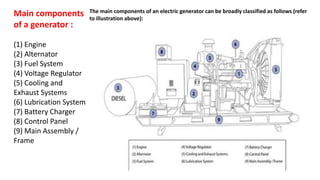

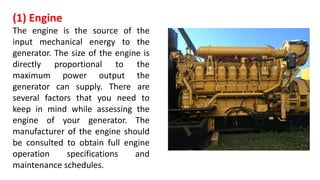

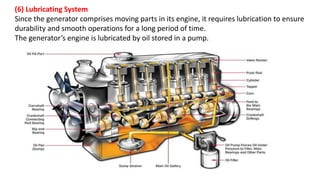

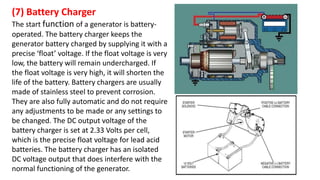

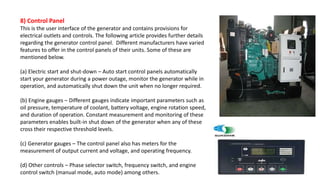

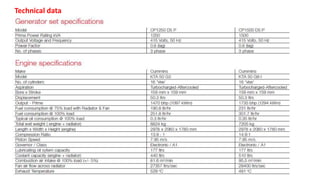

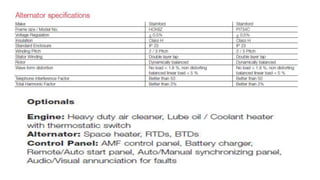

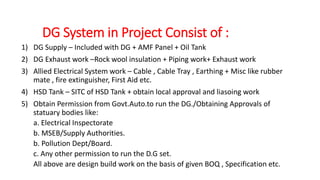

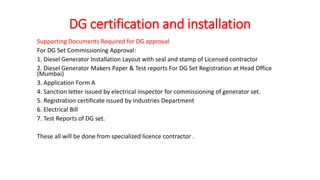

This document provides information about the components and workings of a diesel generator. It describes the main components as the engine, alternator, fuel system, voltage regulator, cooling and exhaust systems, lubrication system, battery charger, control panel, and main assembly/frame. For each component, it explains its function and key sub-components. It also provides technical details about how a generator converts mechanical energy to electrical energy through electromagnetic induction. Overall, the document serves as an overview of the parts and process of how a diesel generator is able to generate and supply electricity.