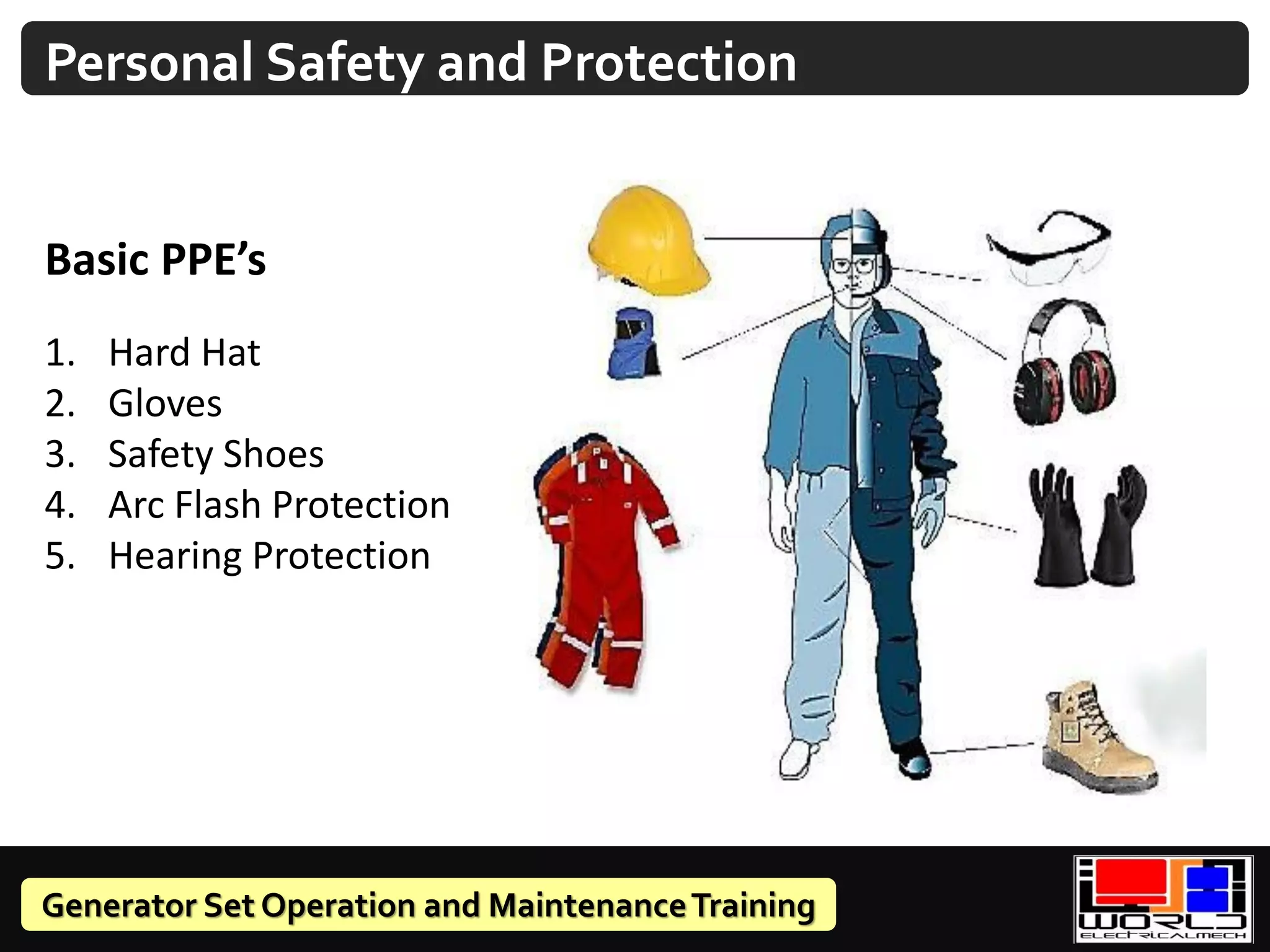

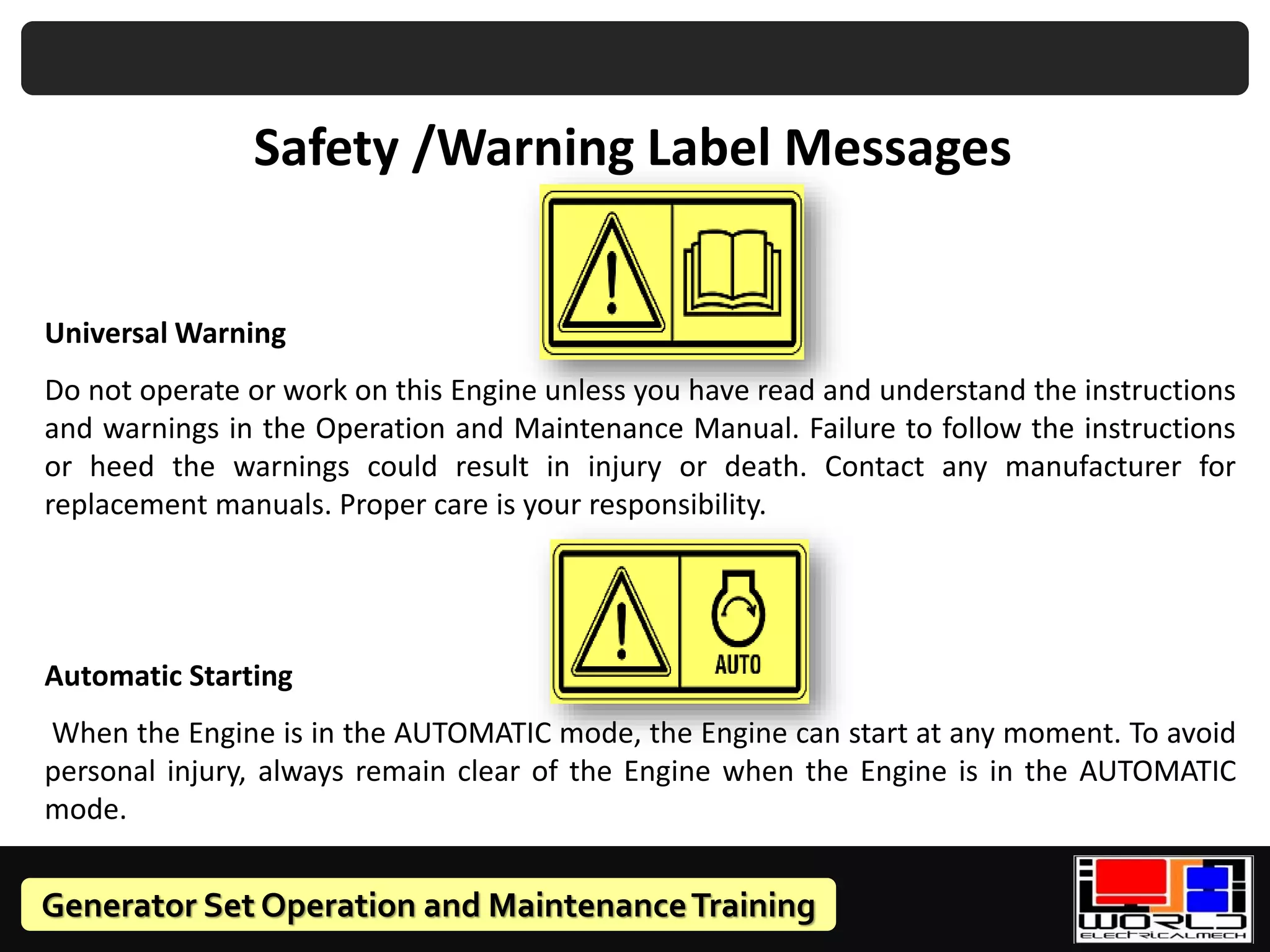

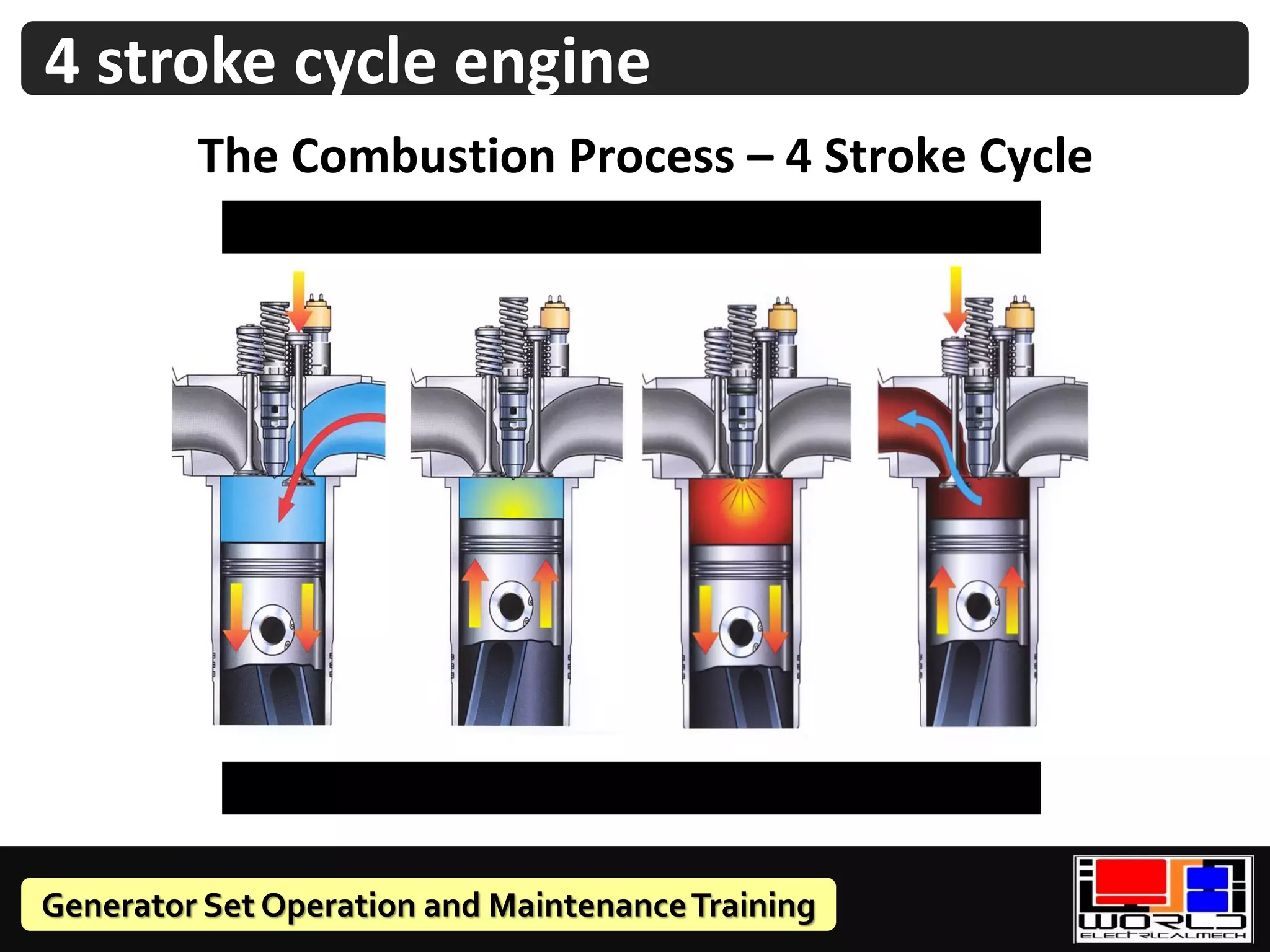

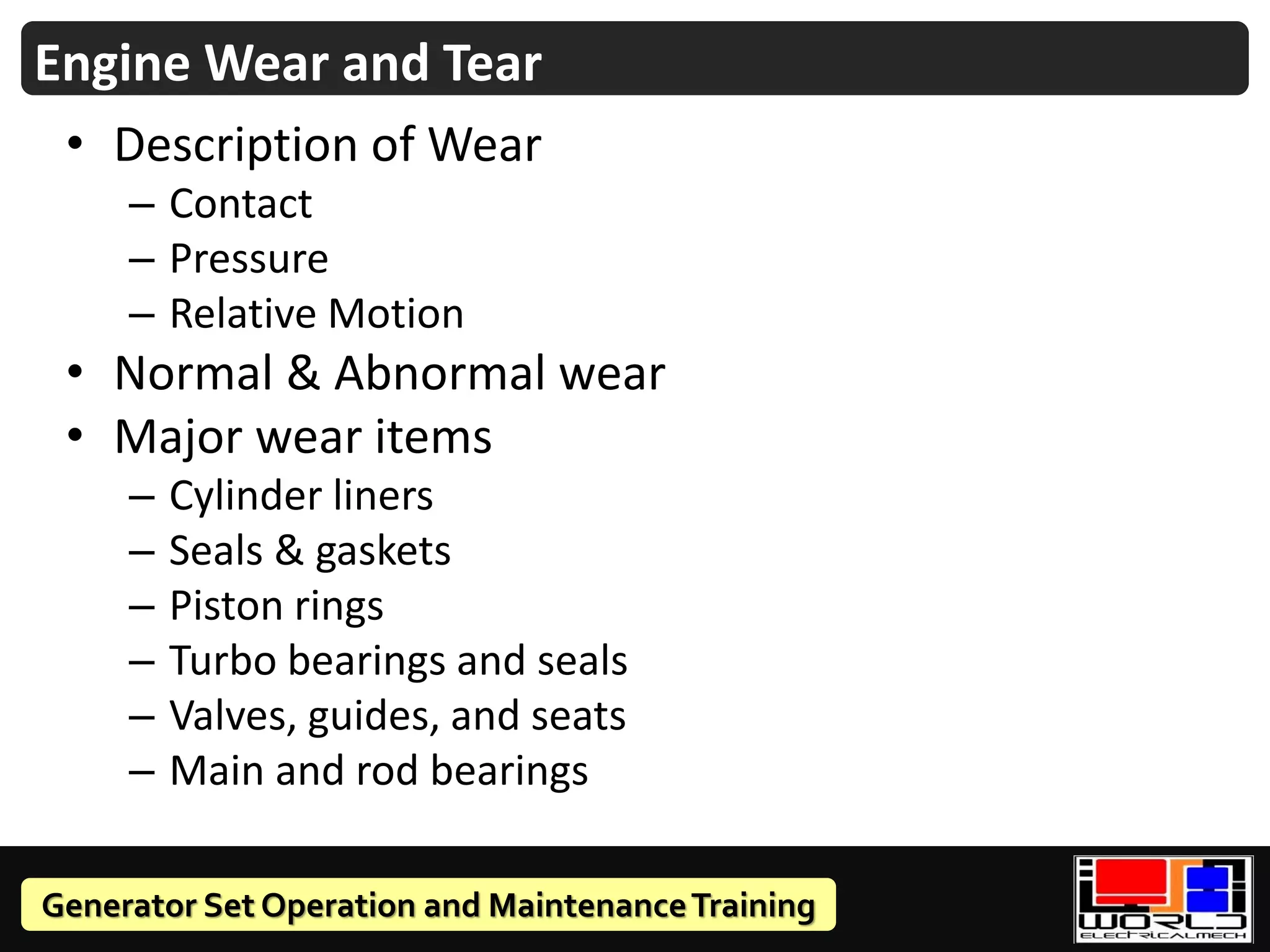

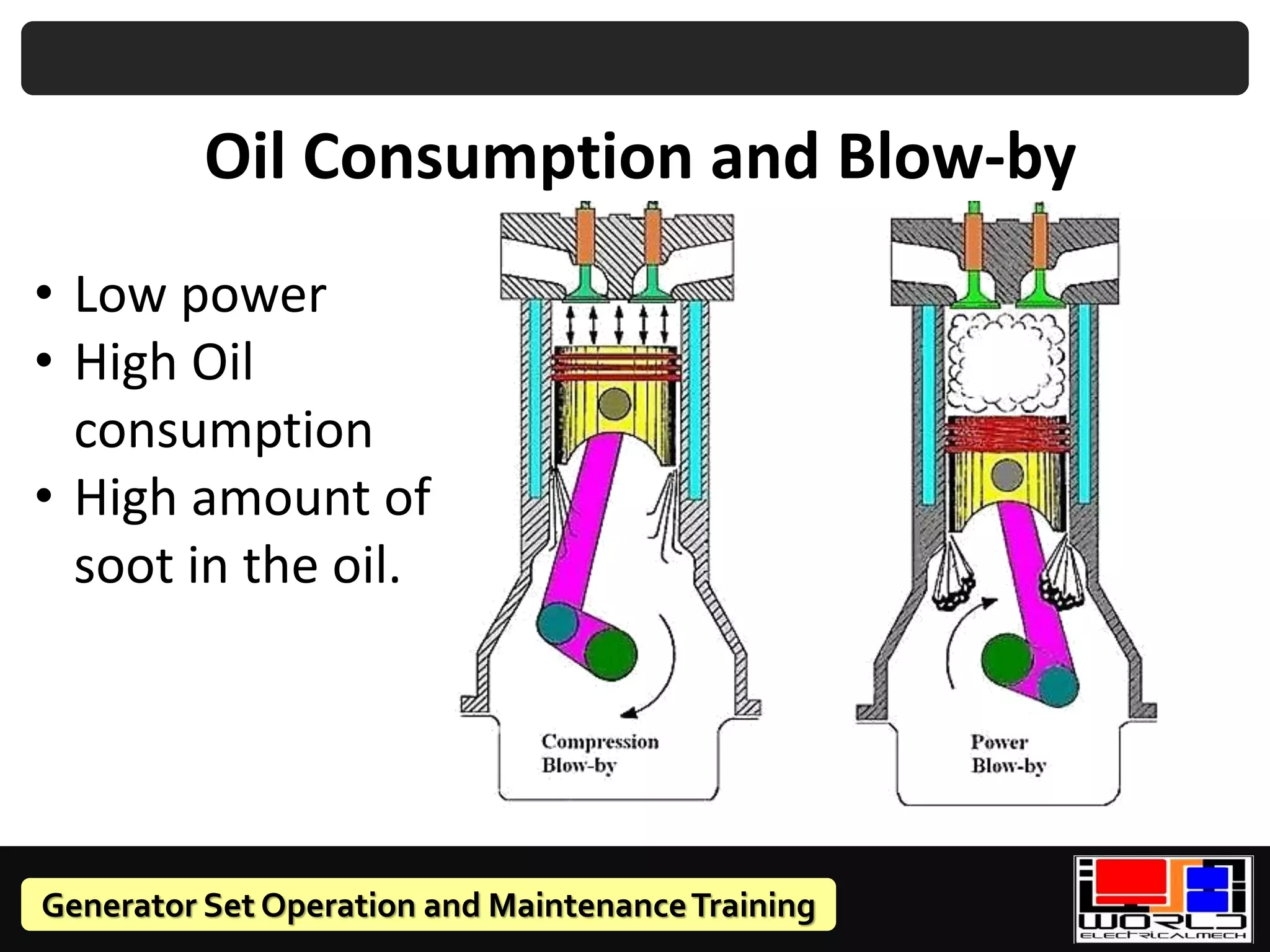

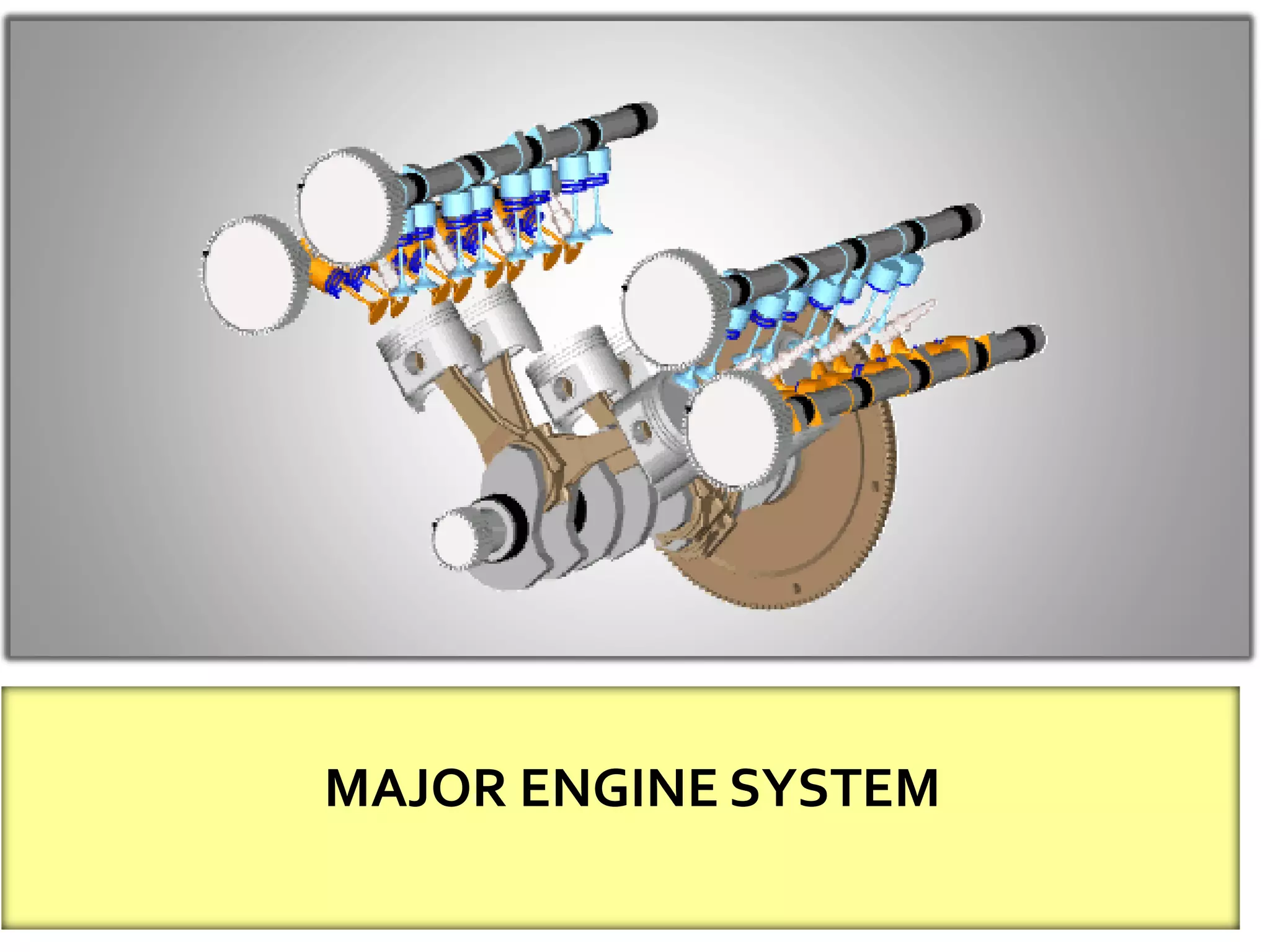

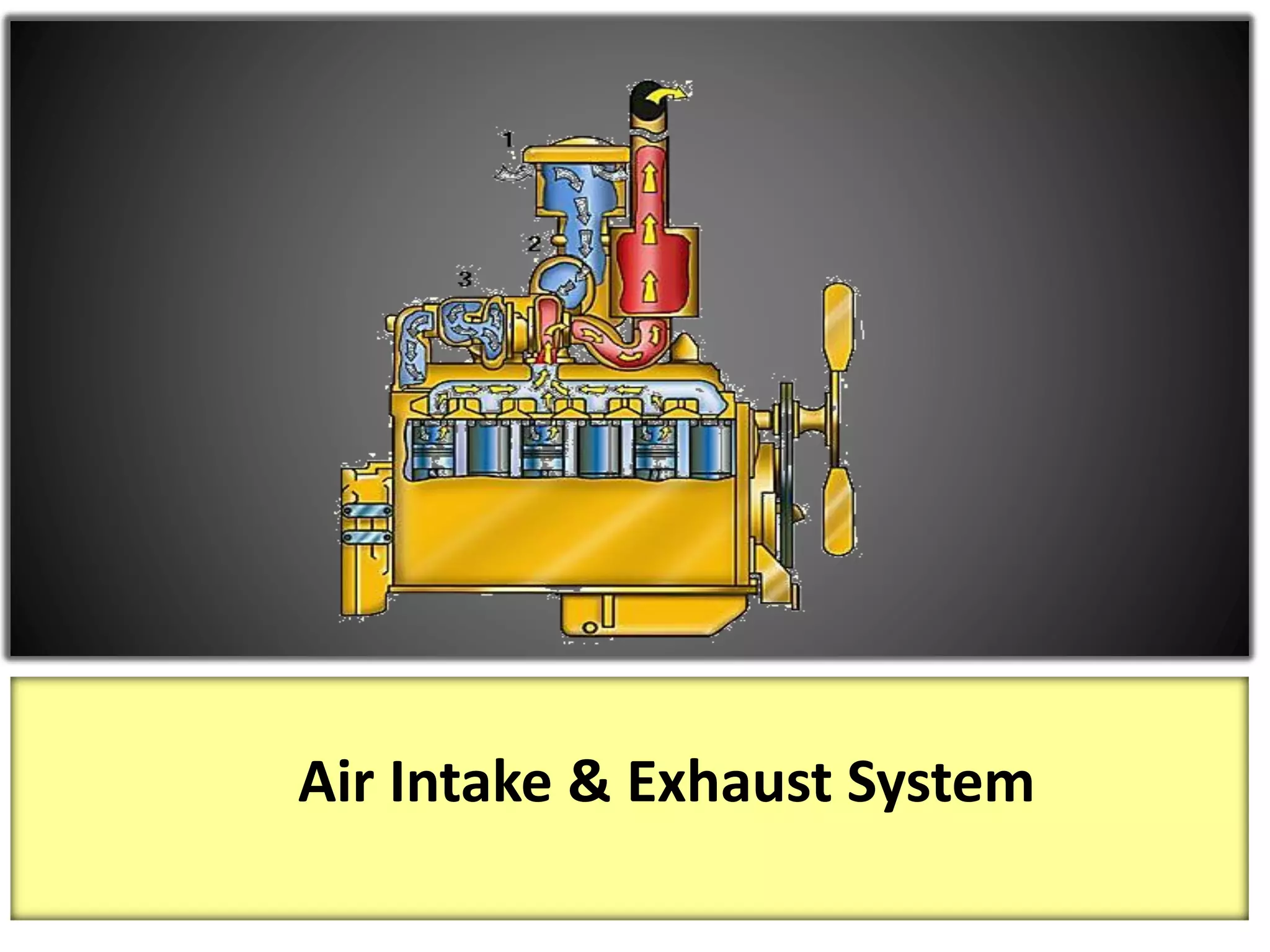

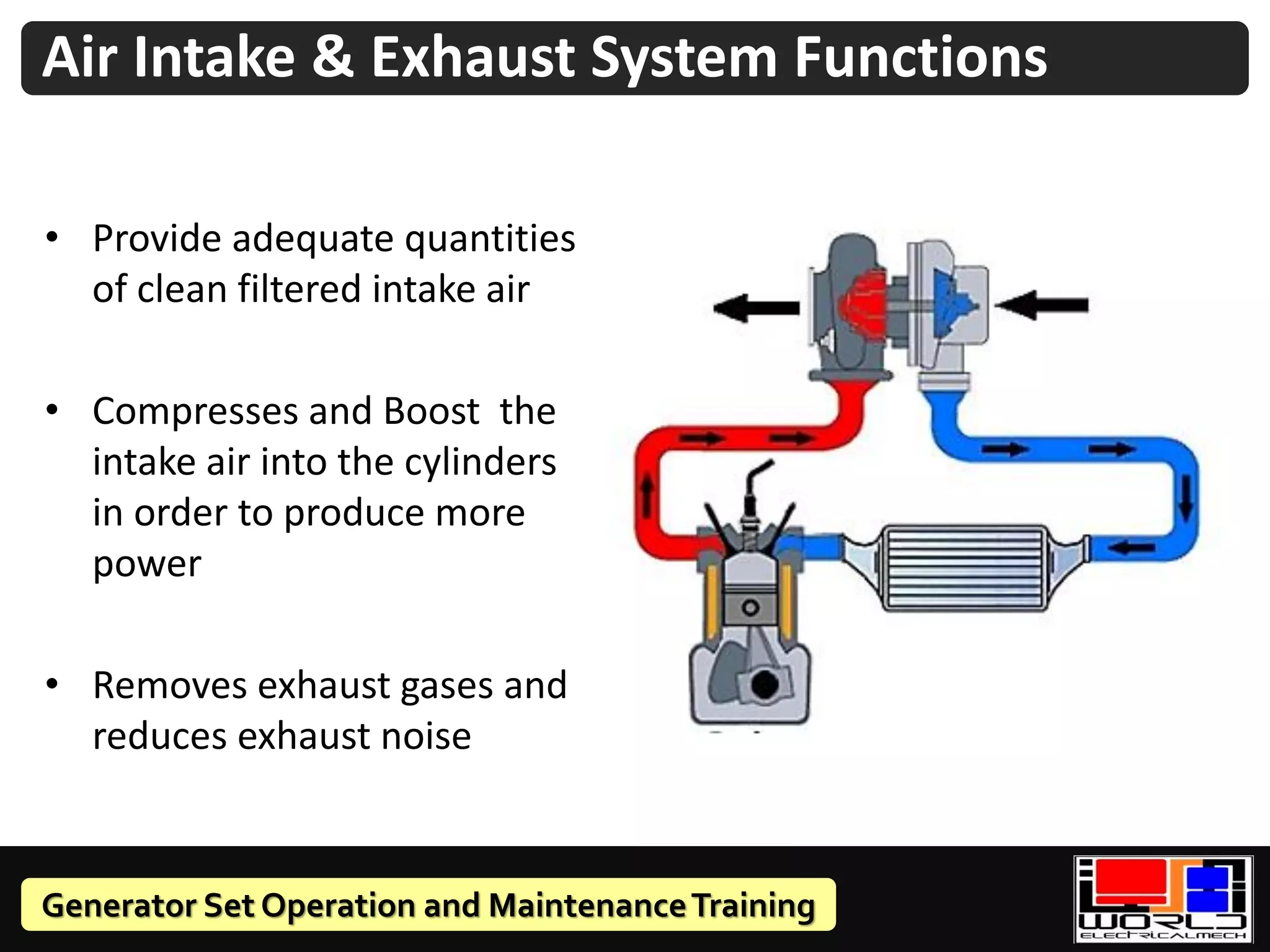

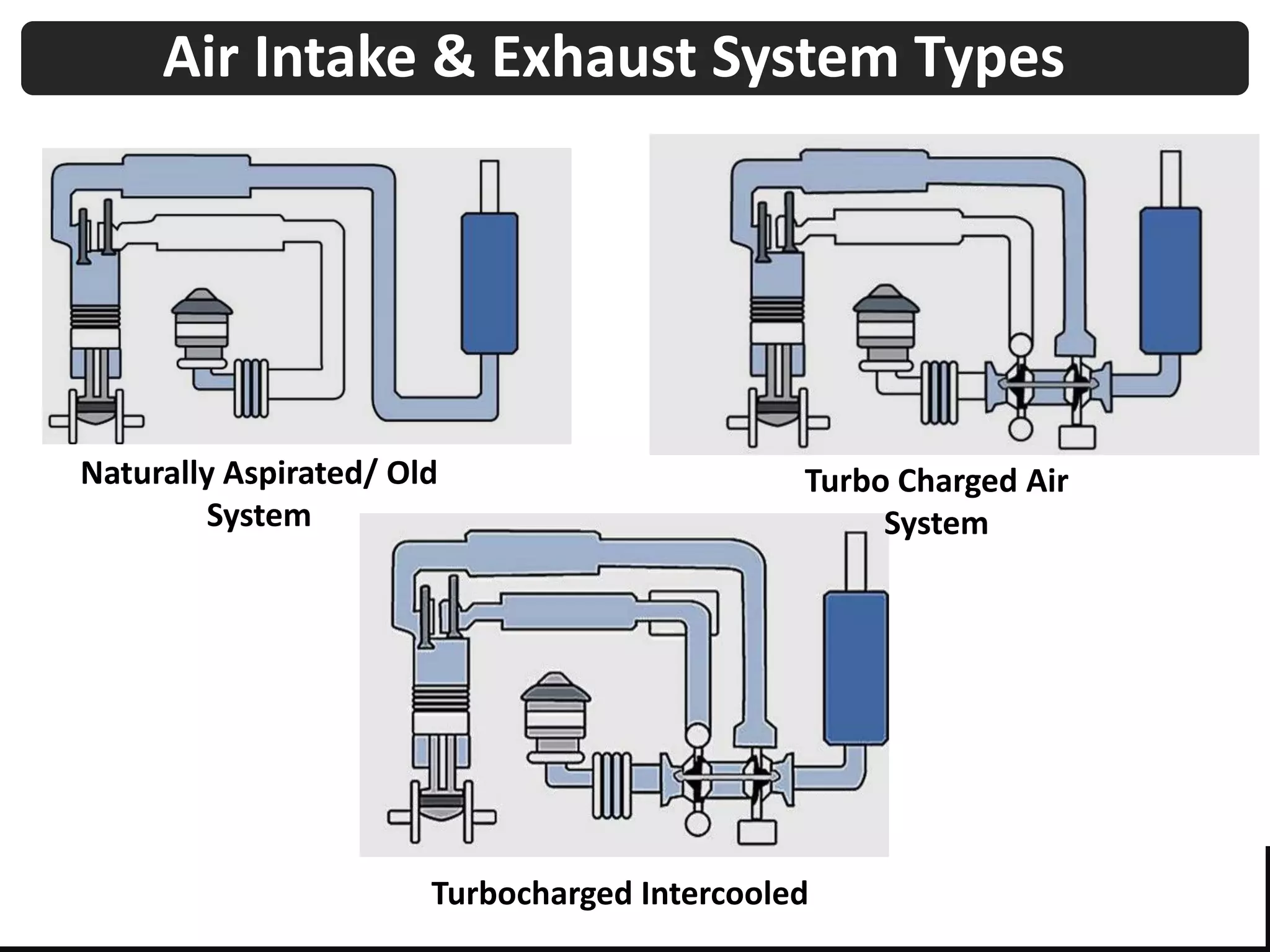

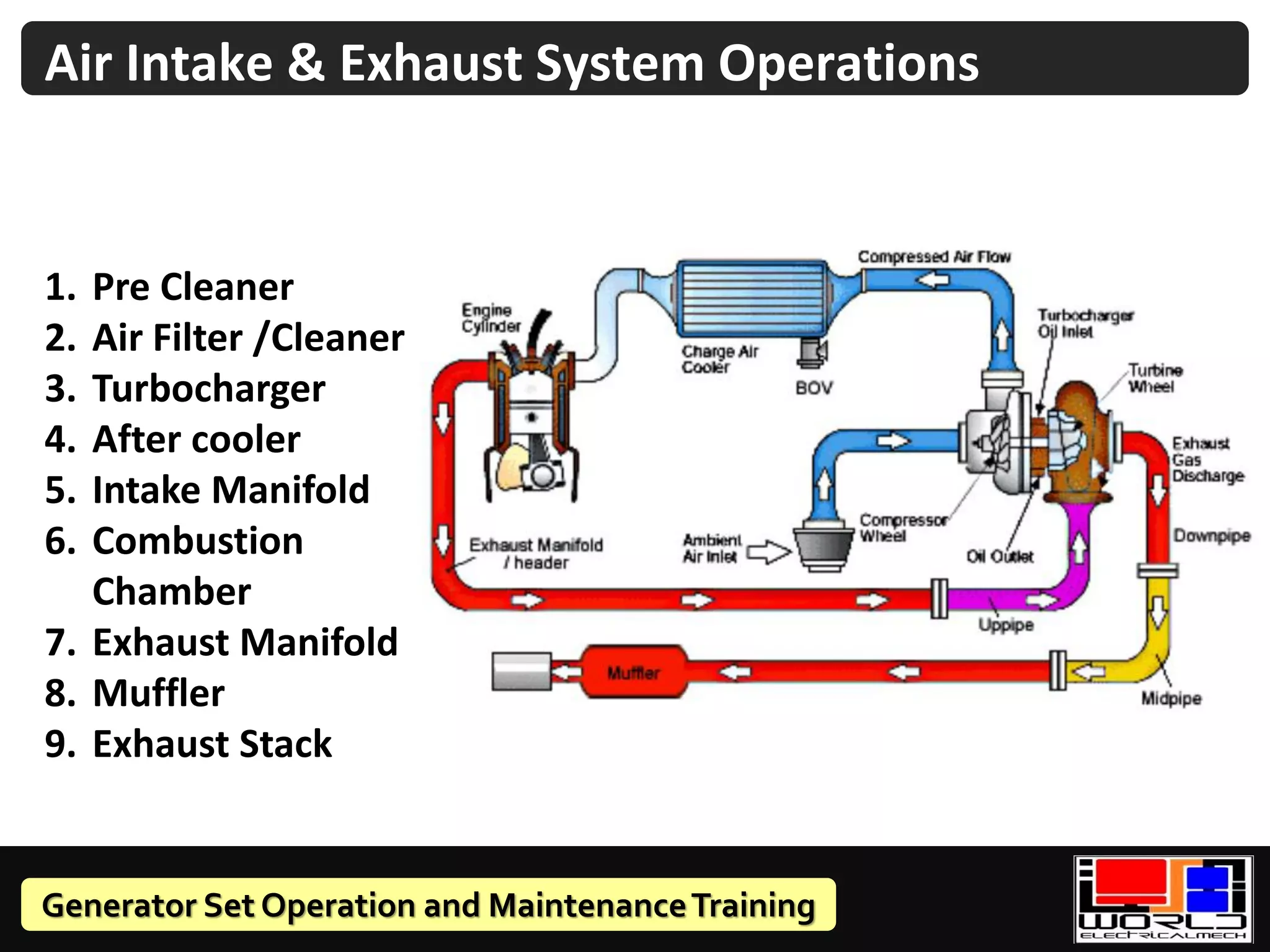

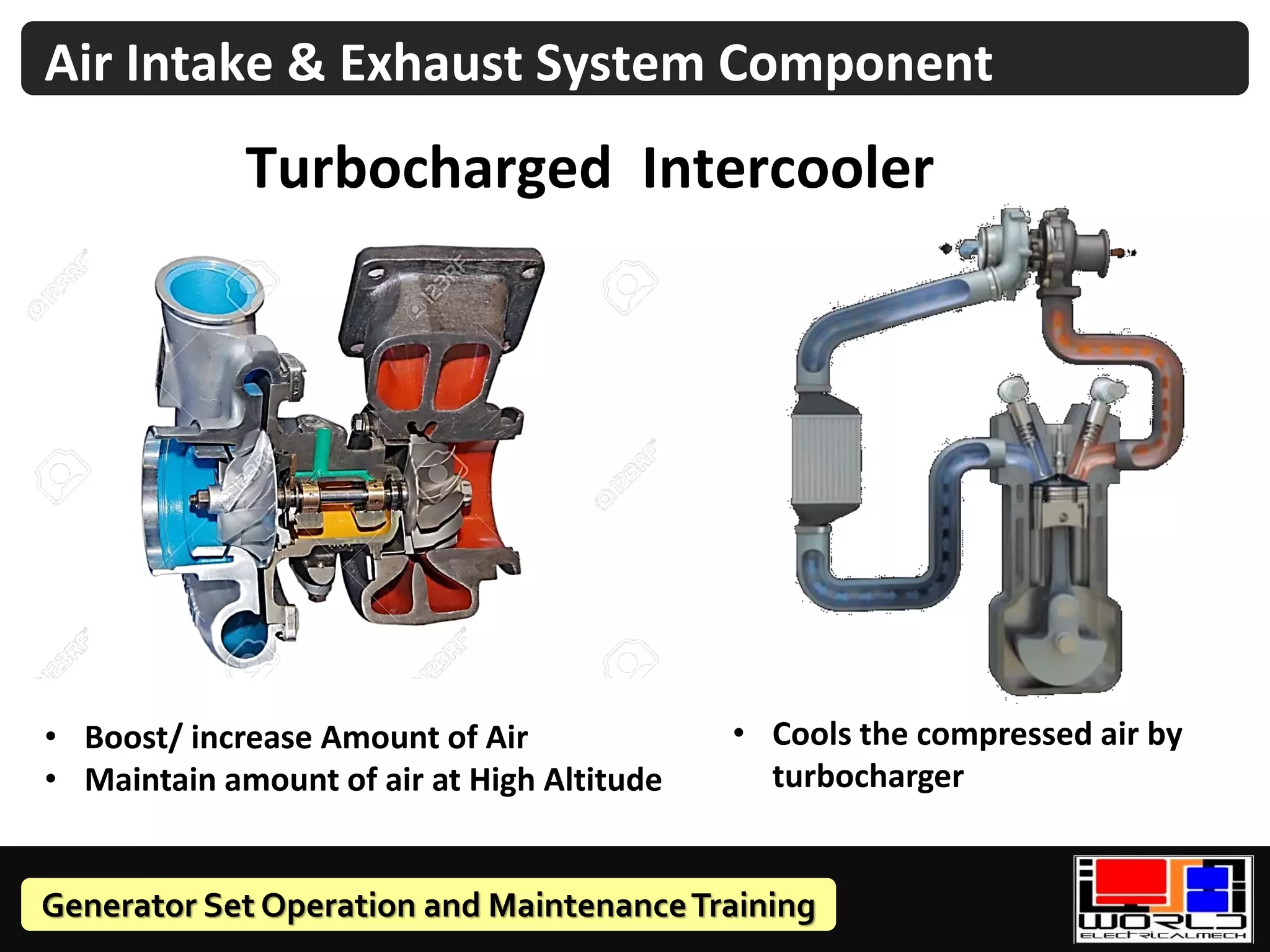

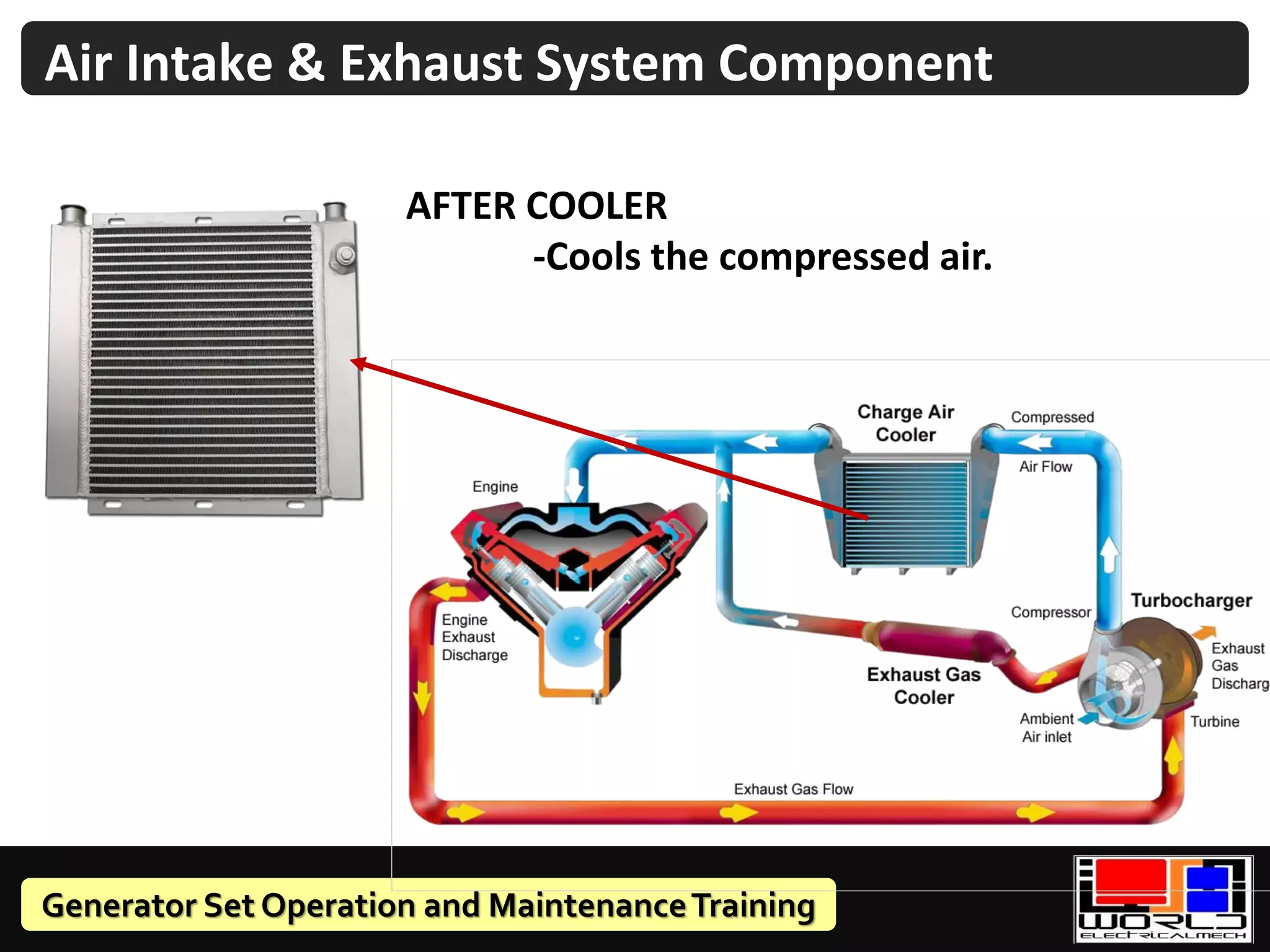

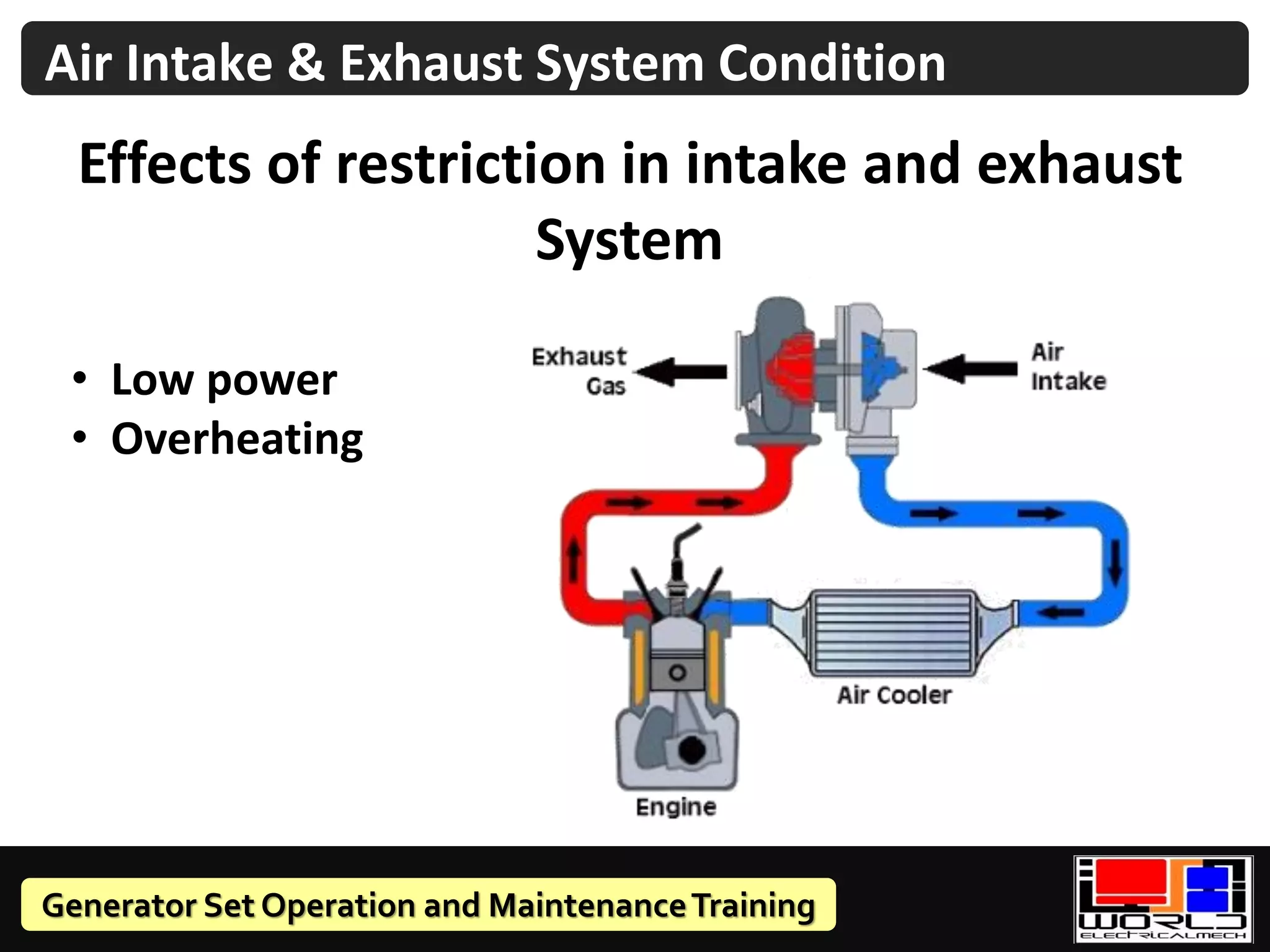

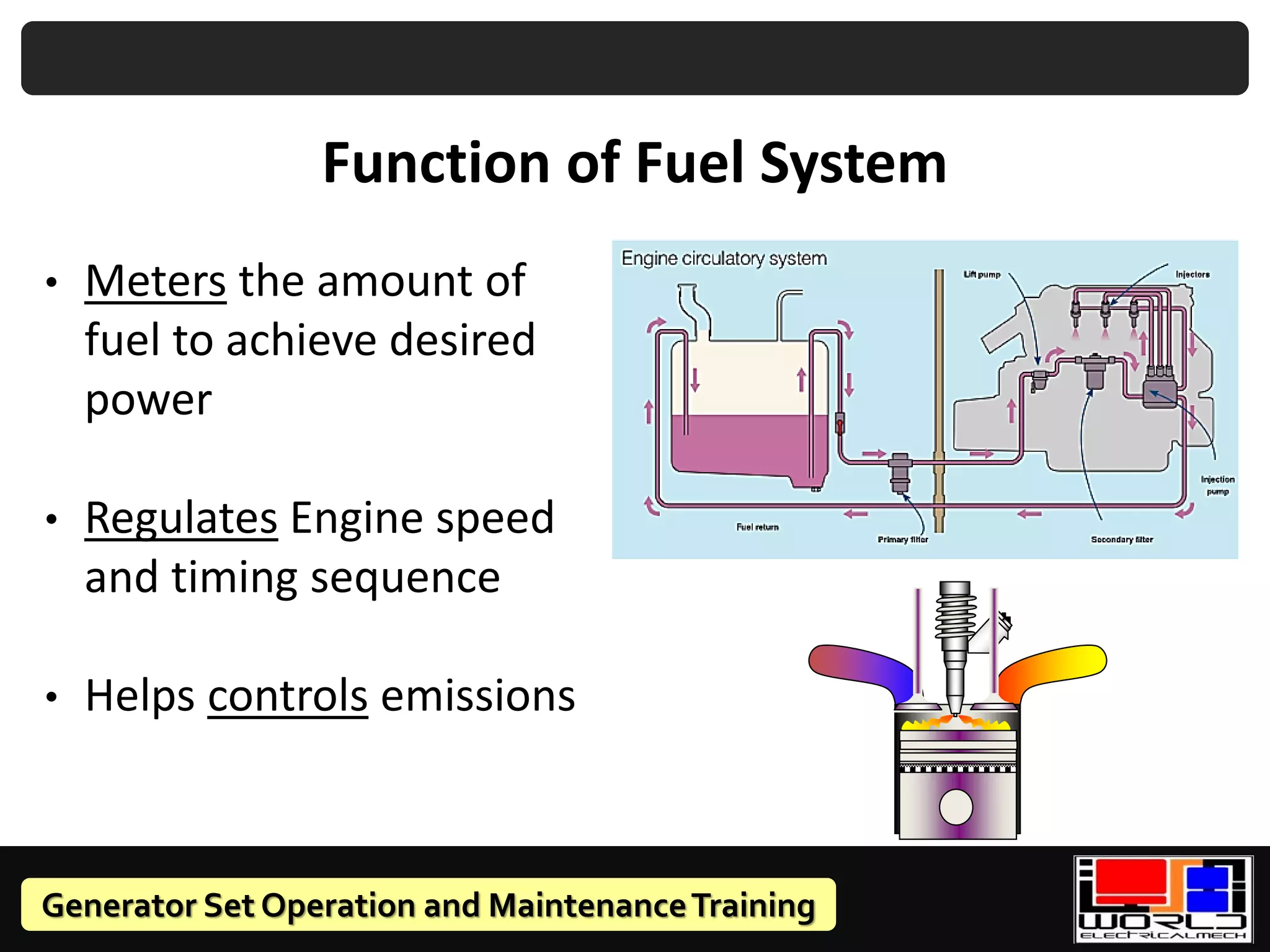

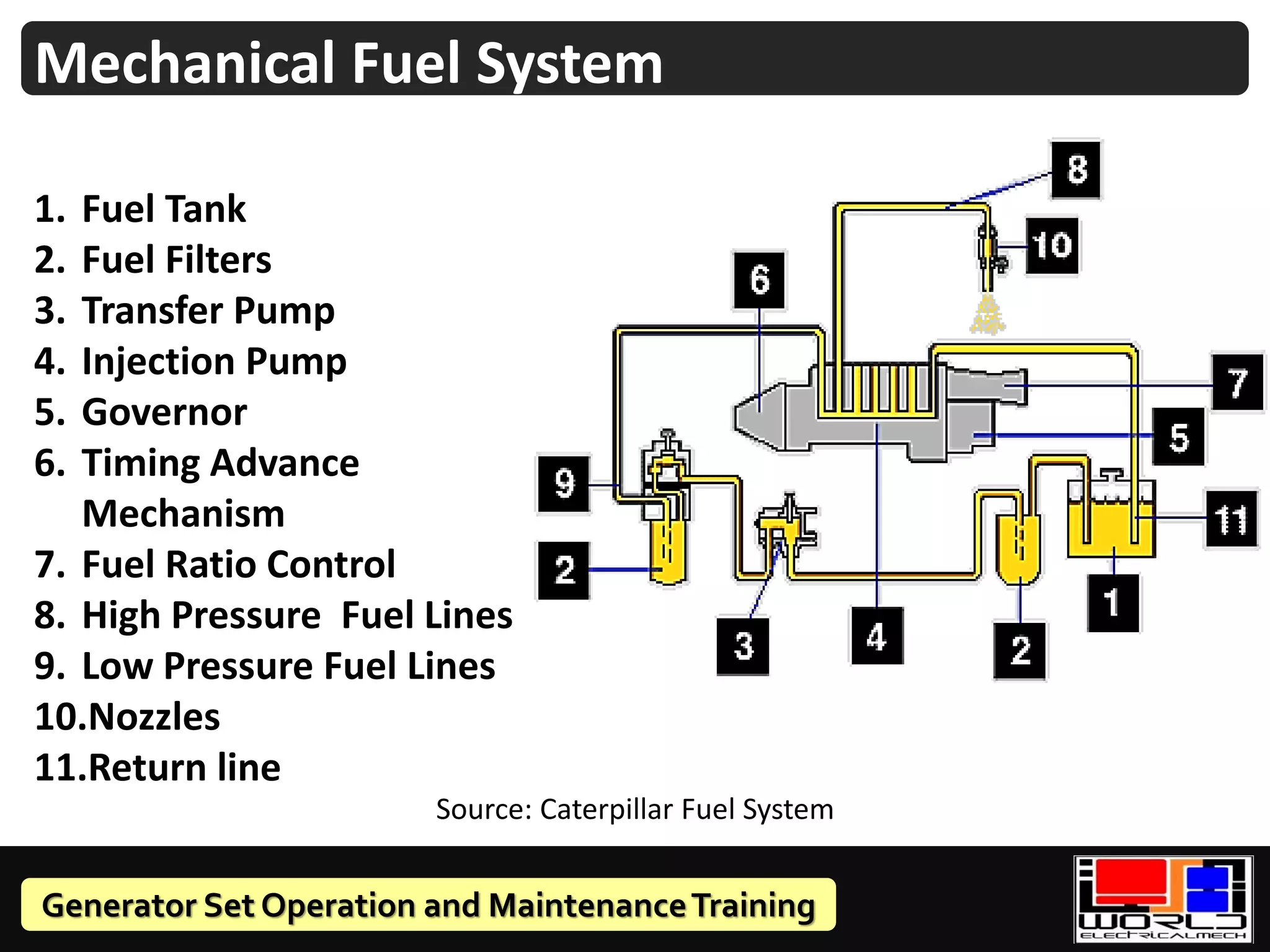

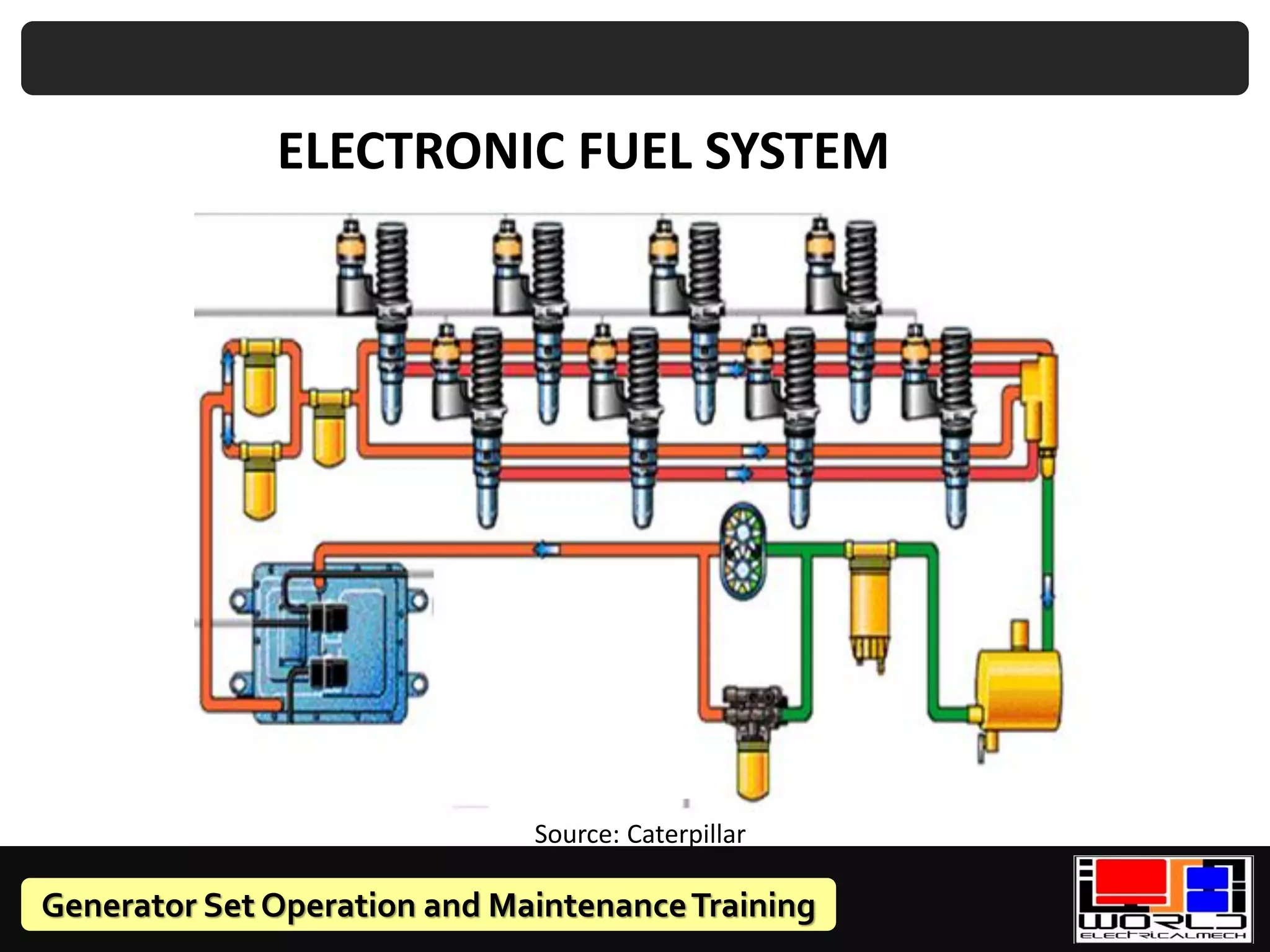

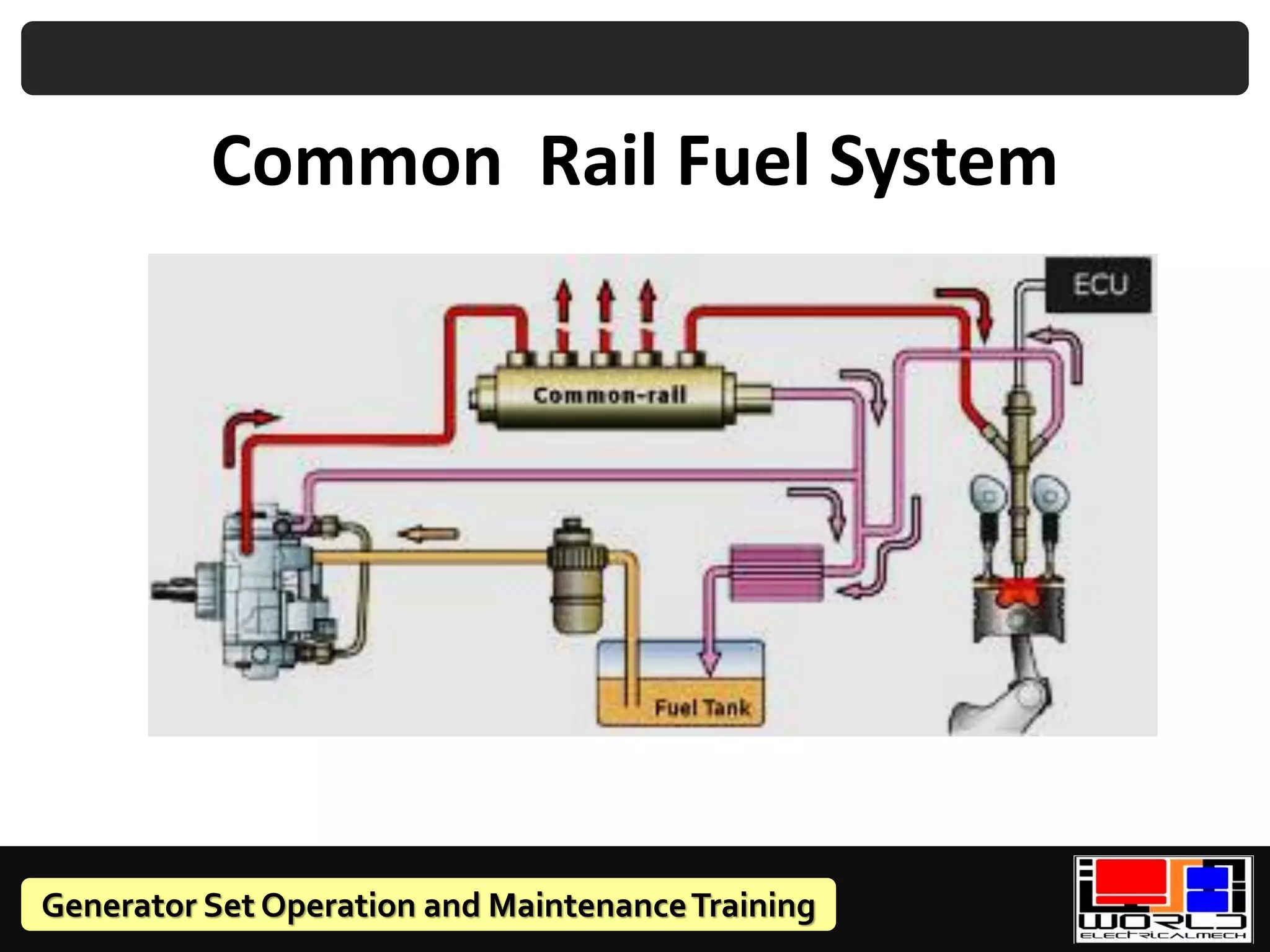

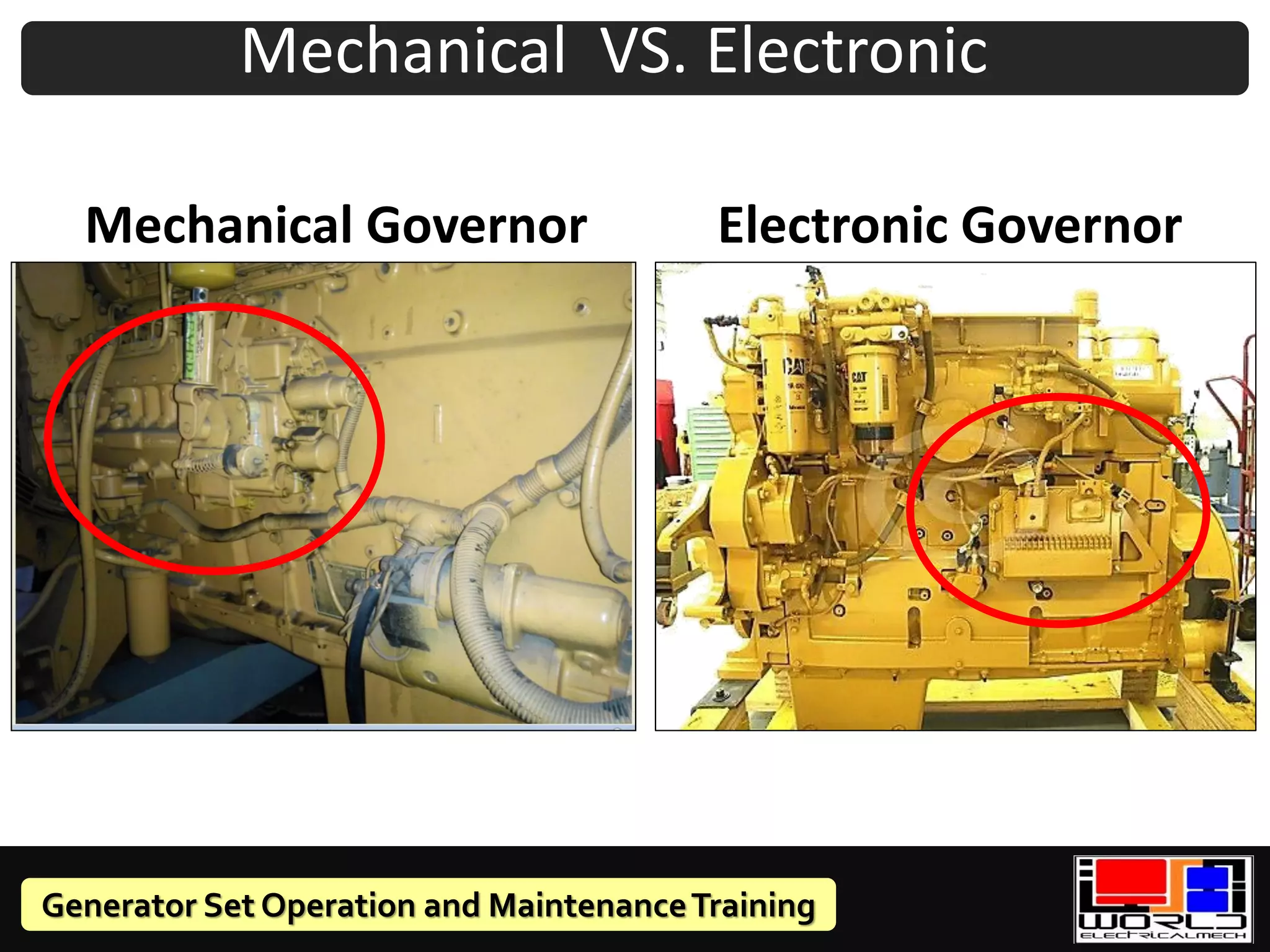

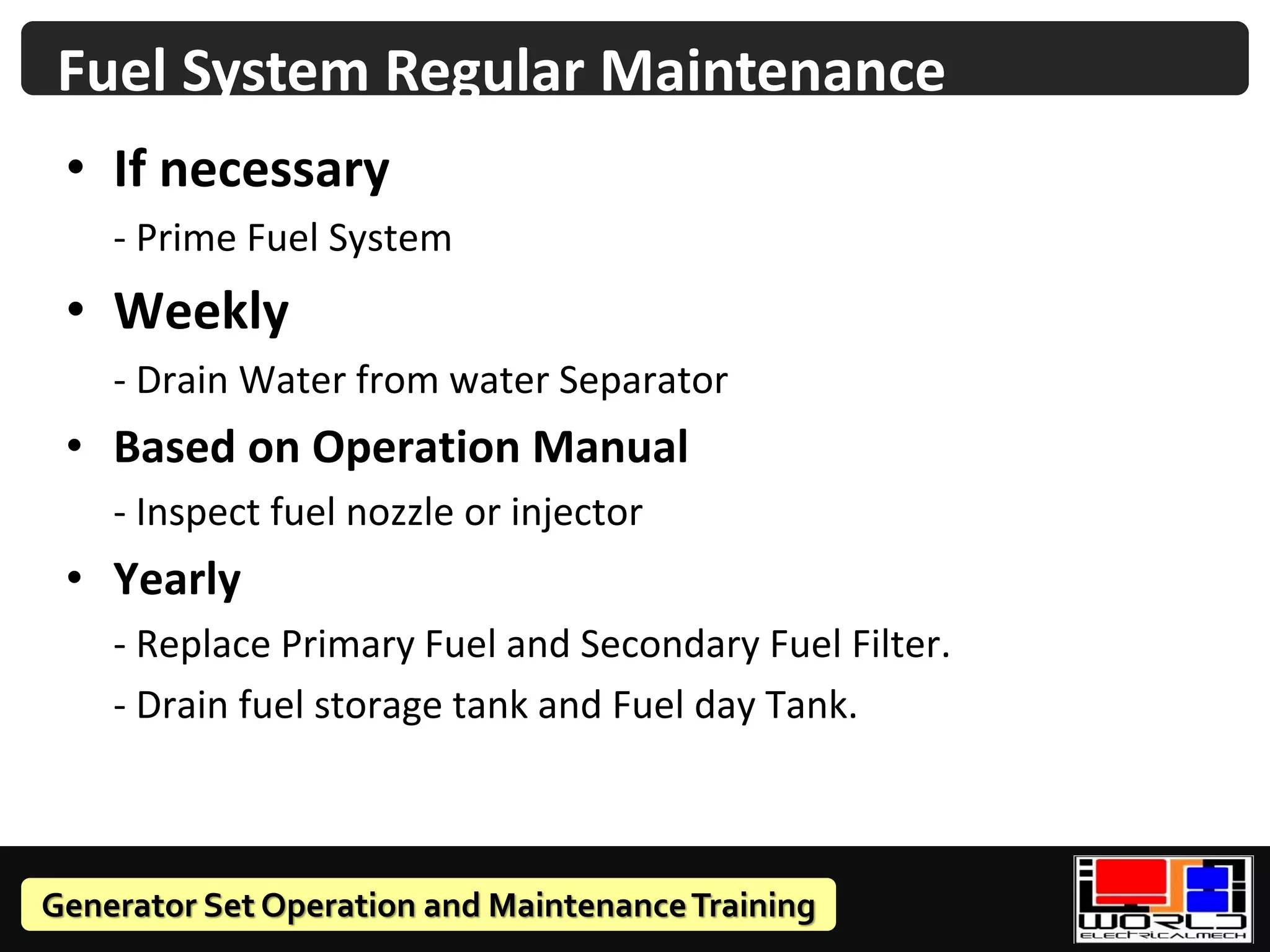

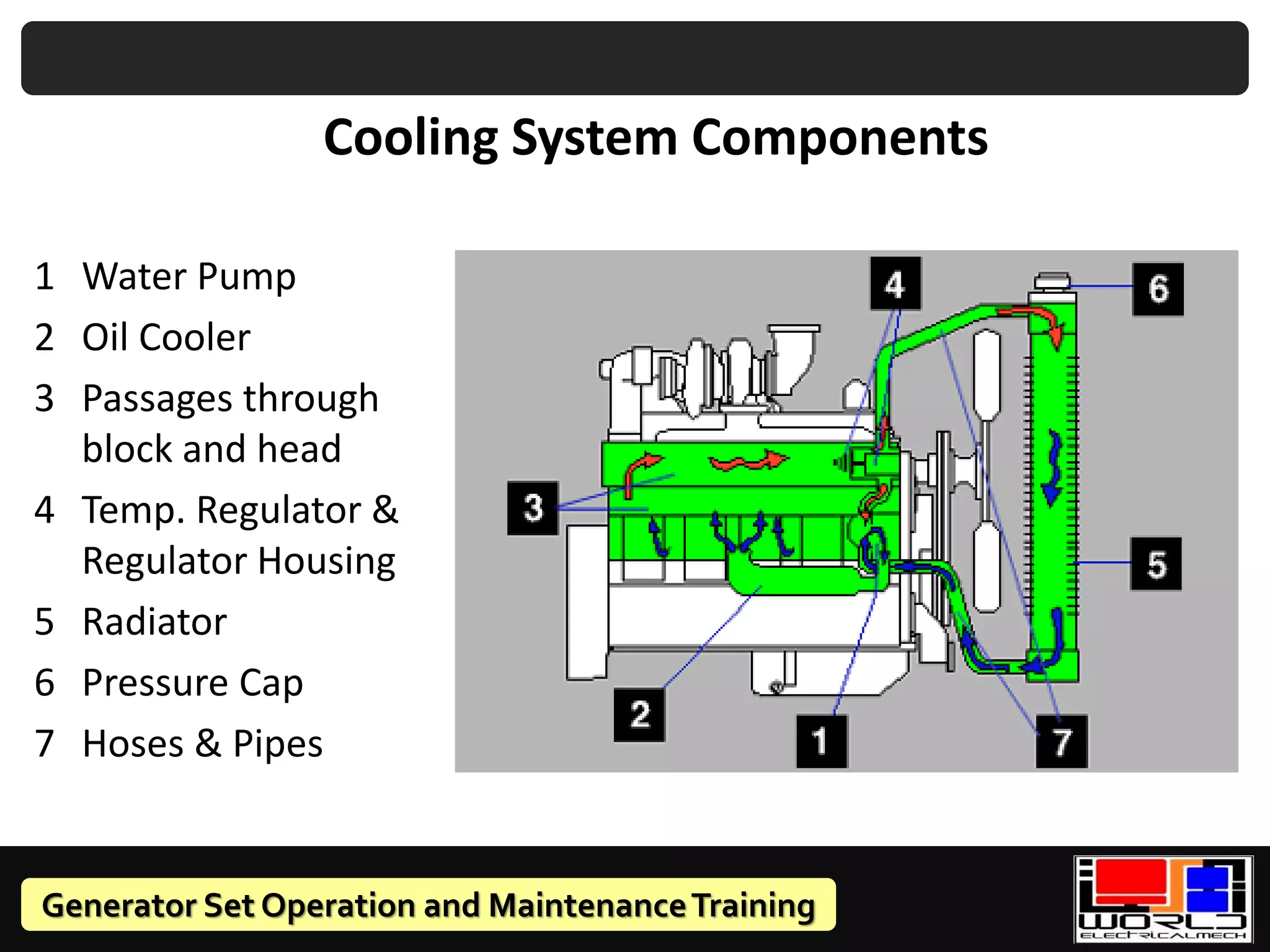

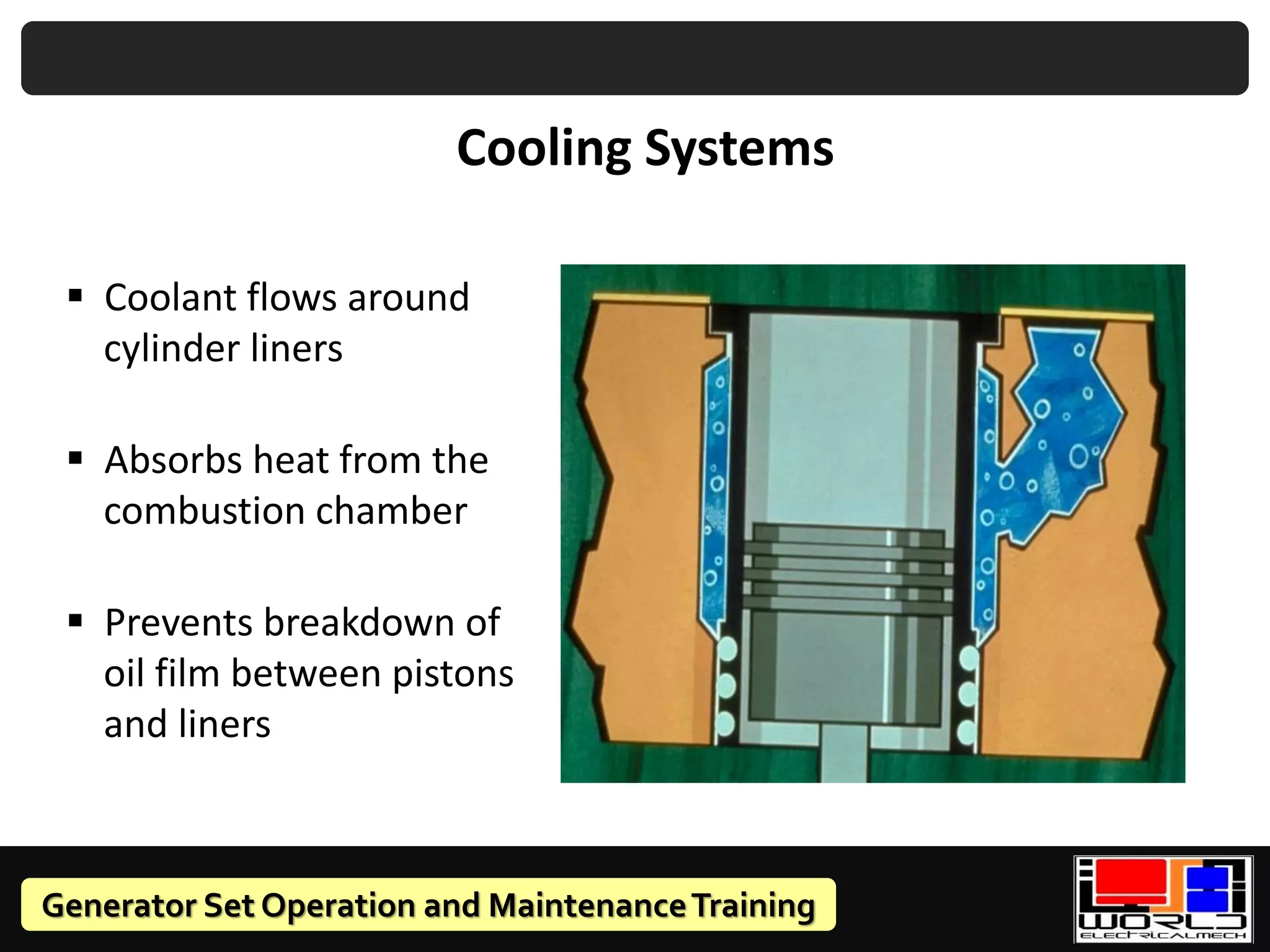

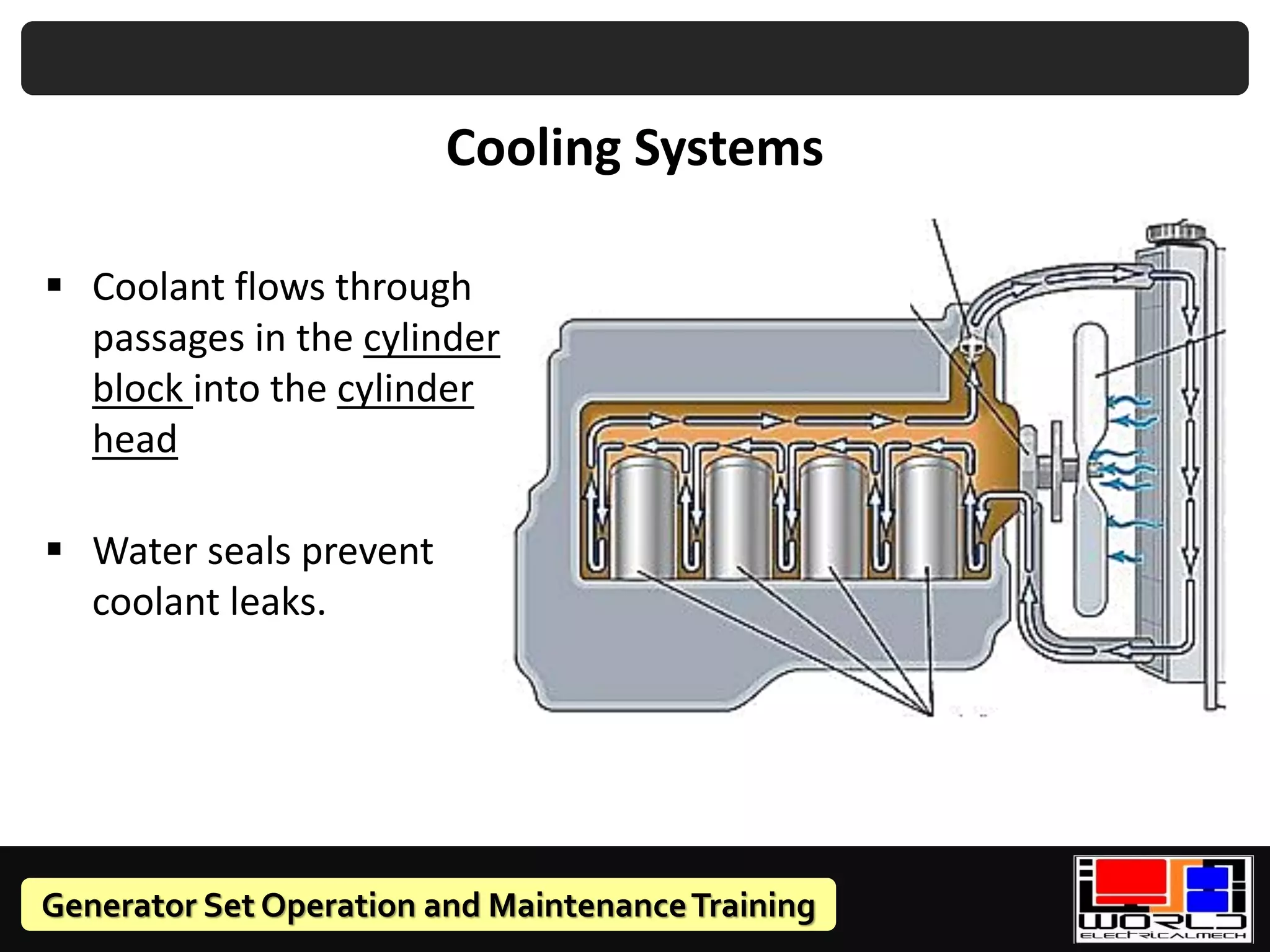

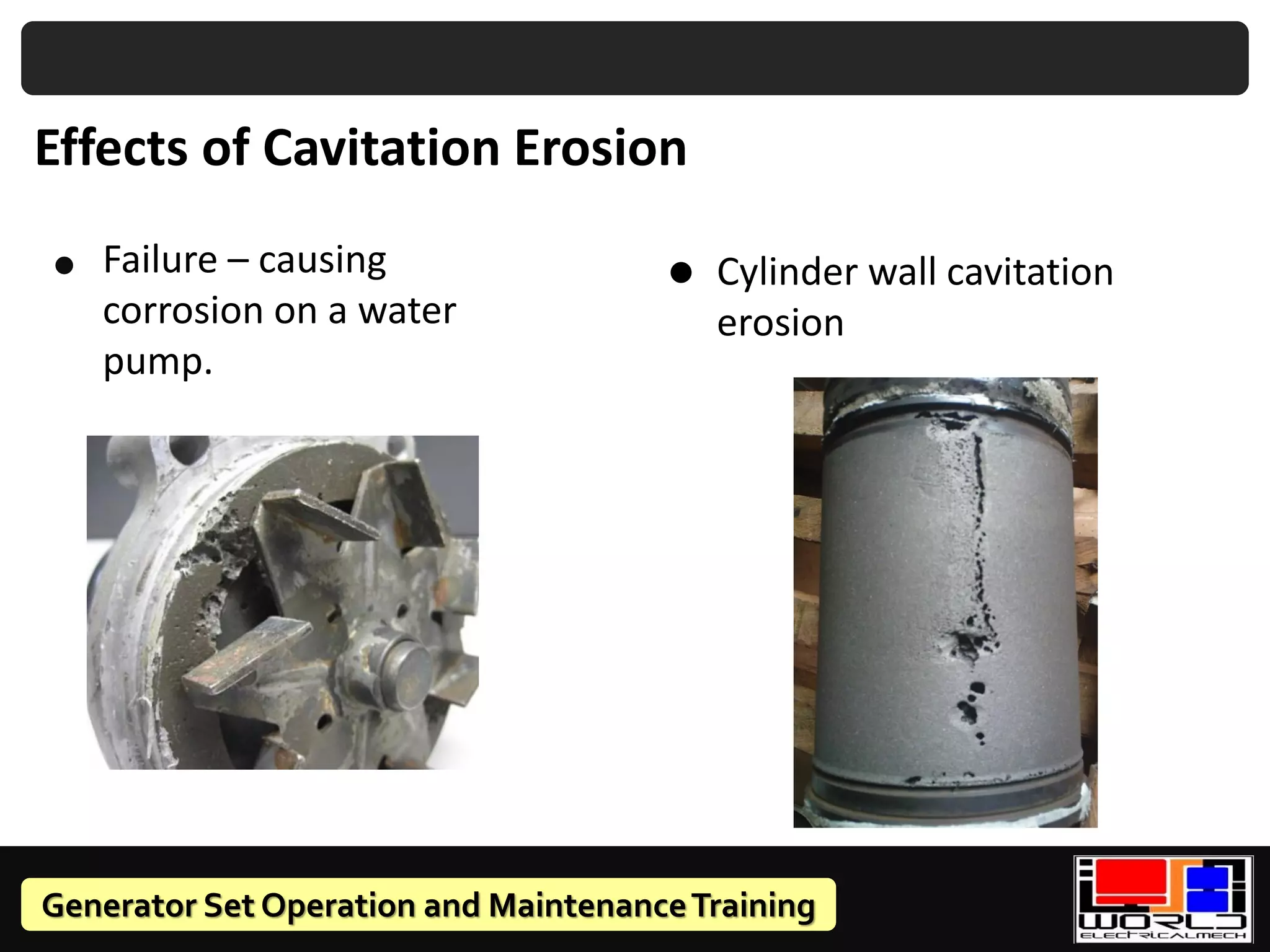

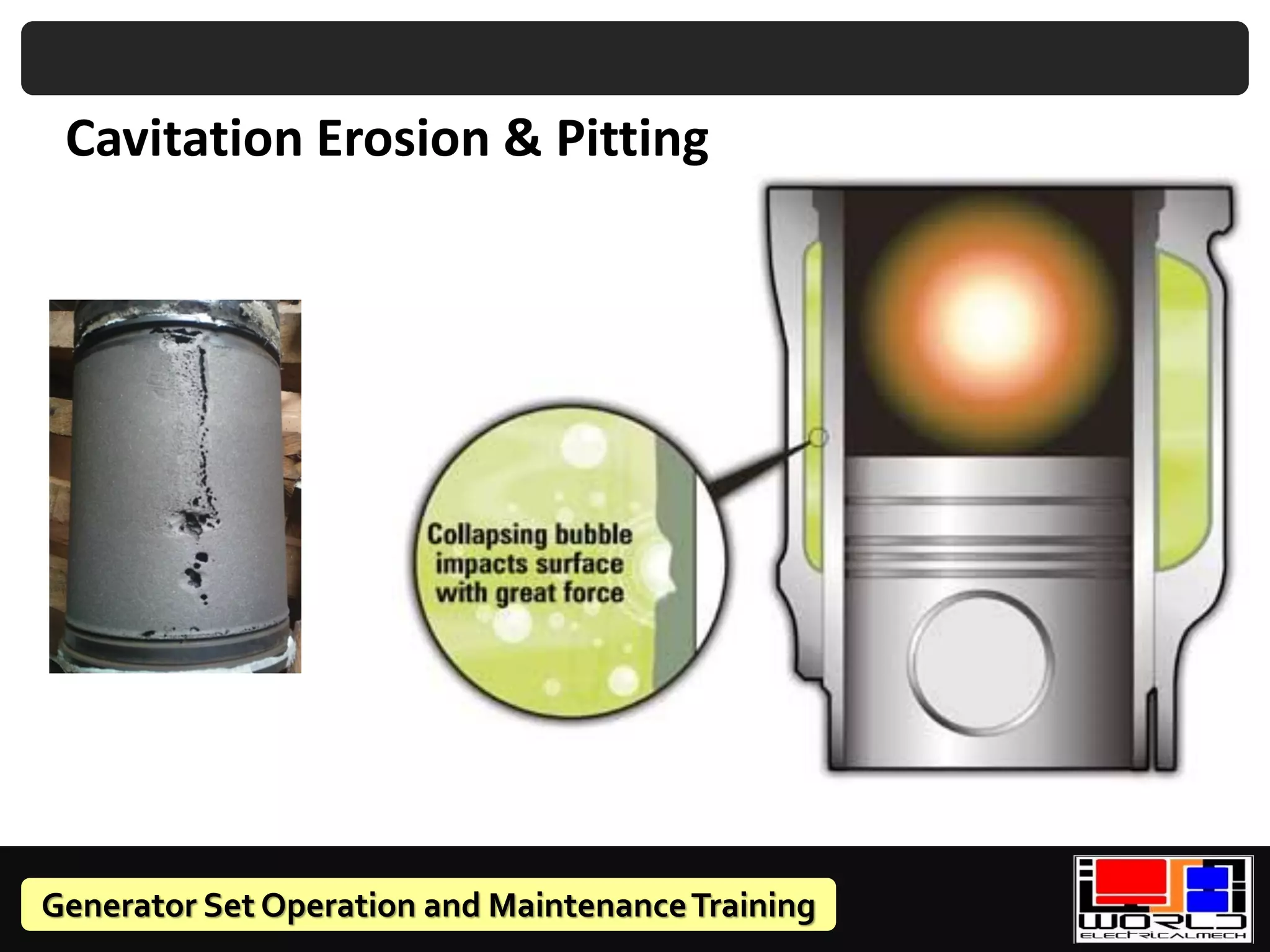

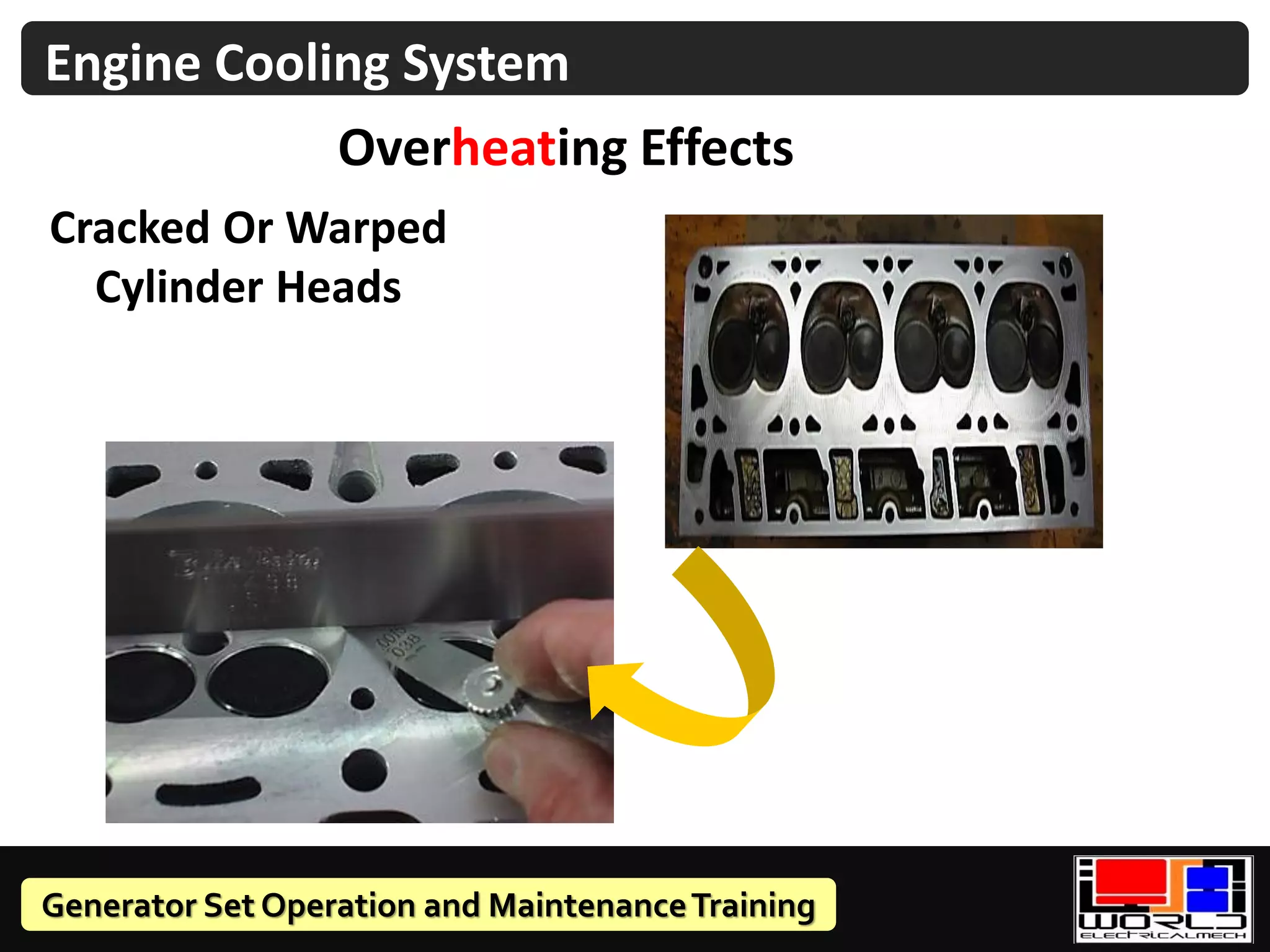

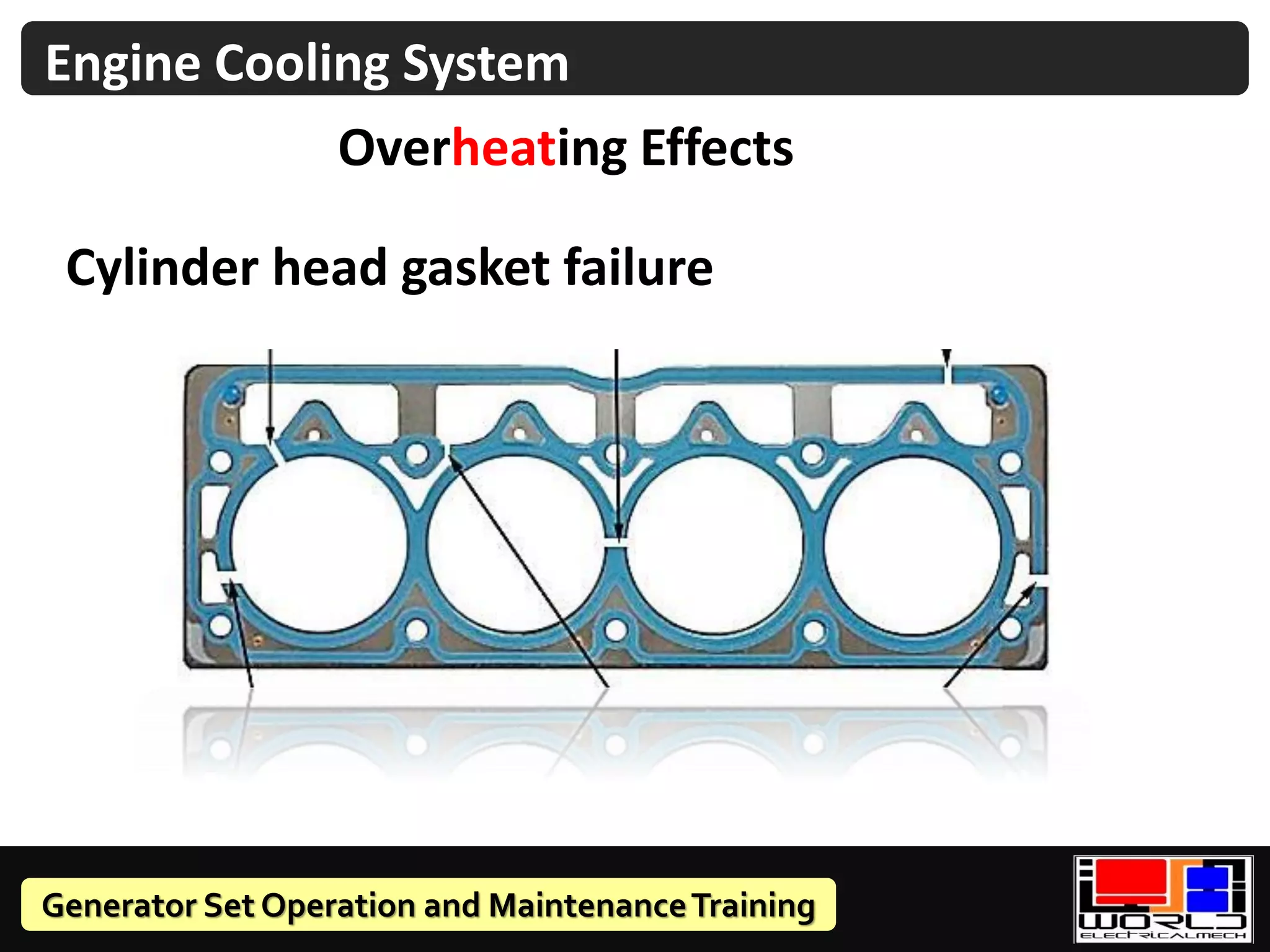

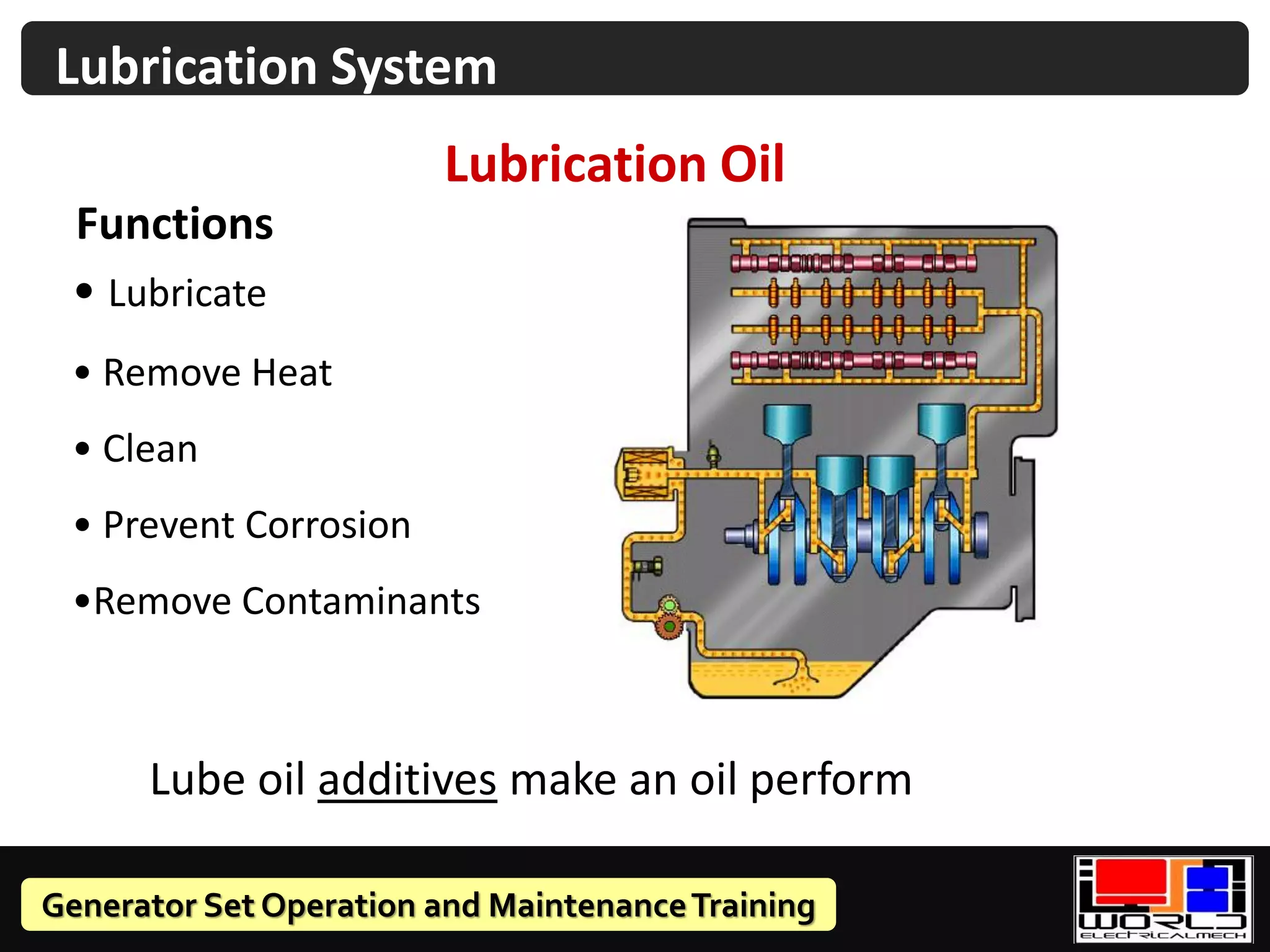

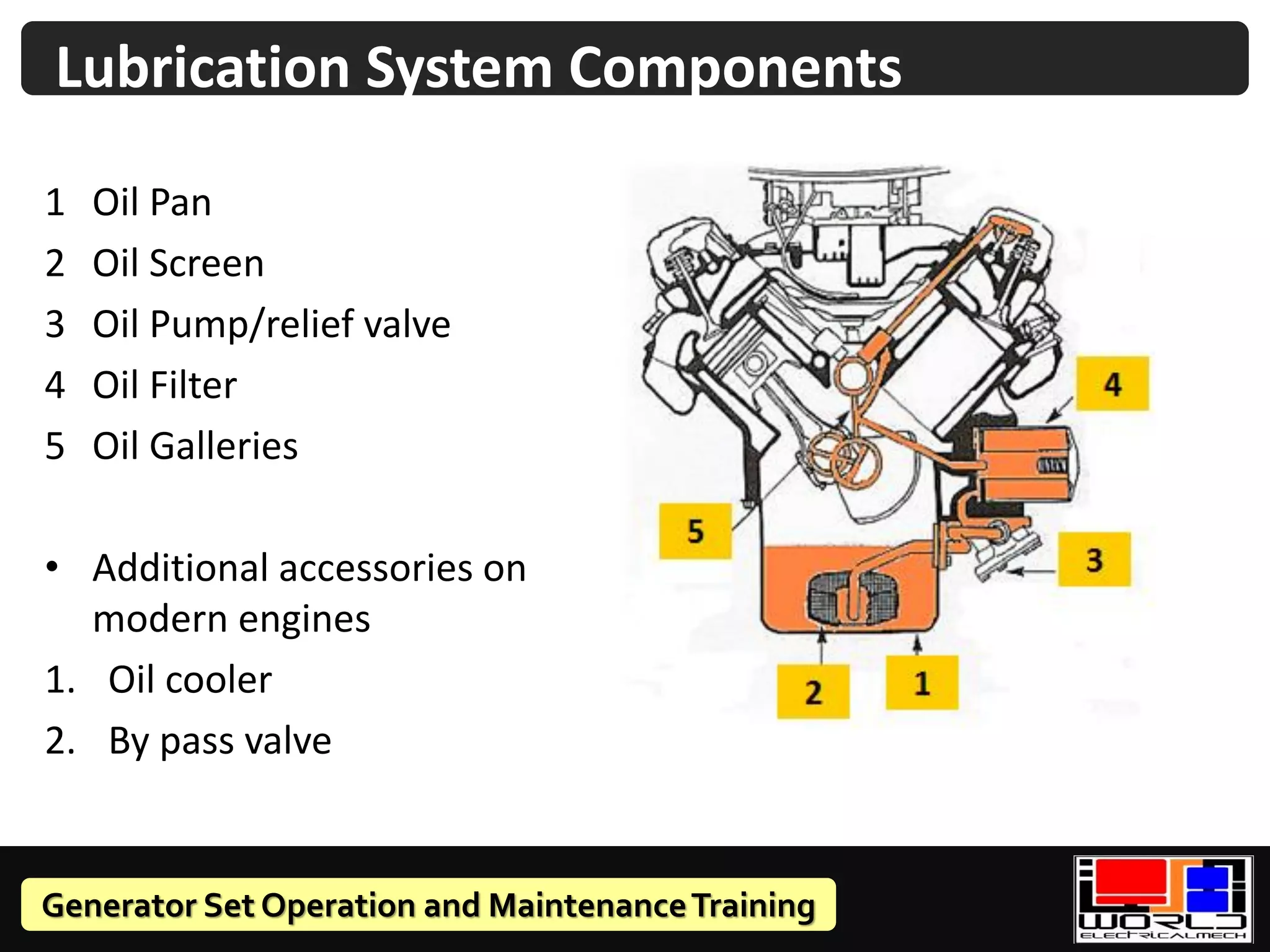

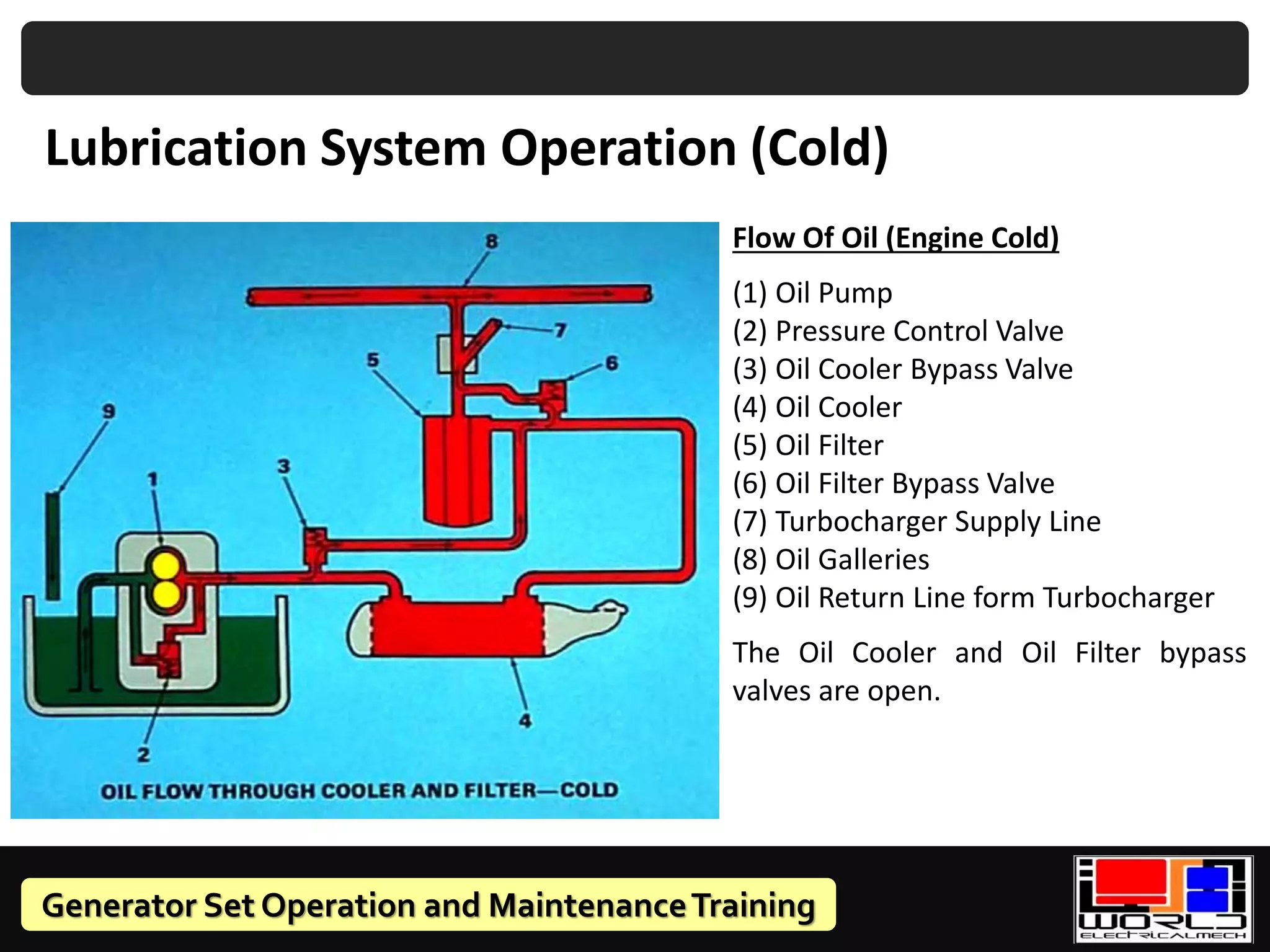

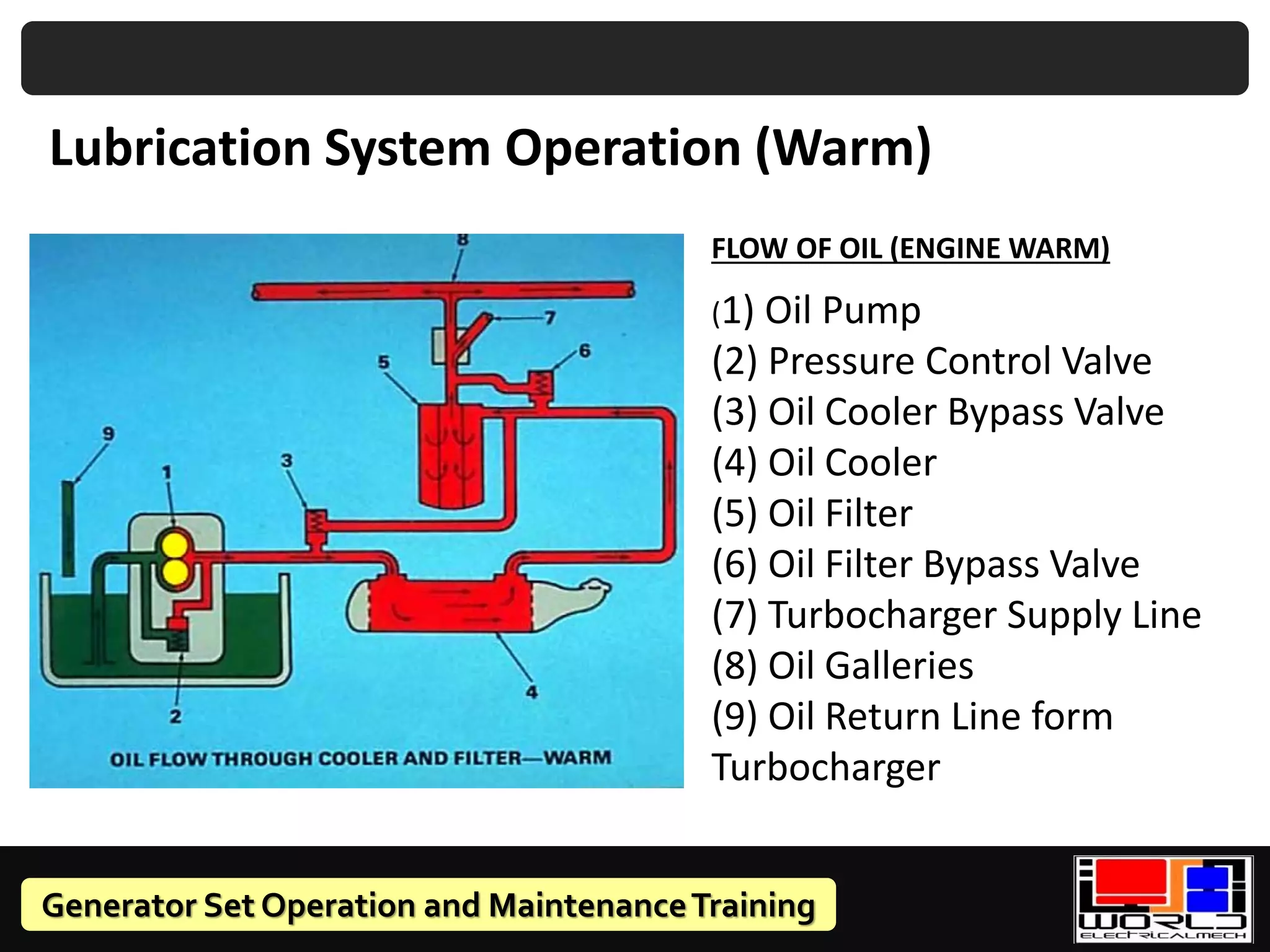

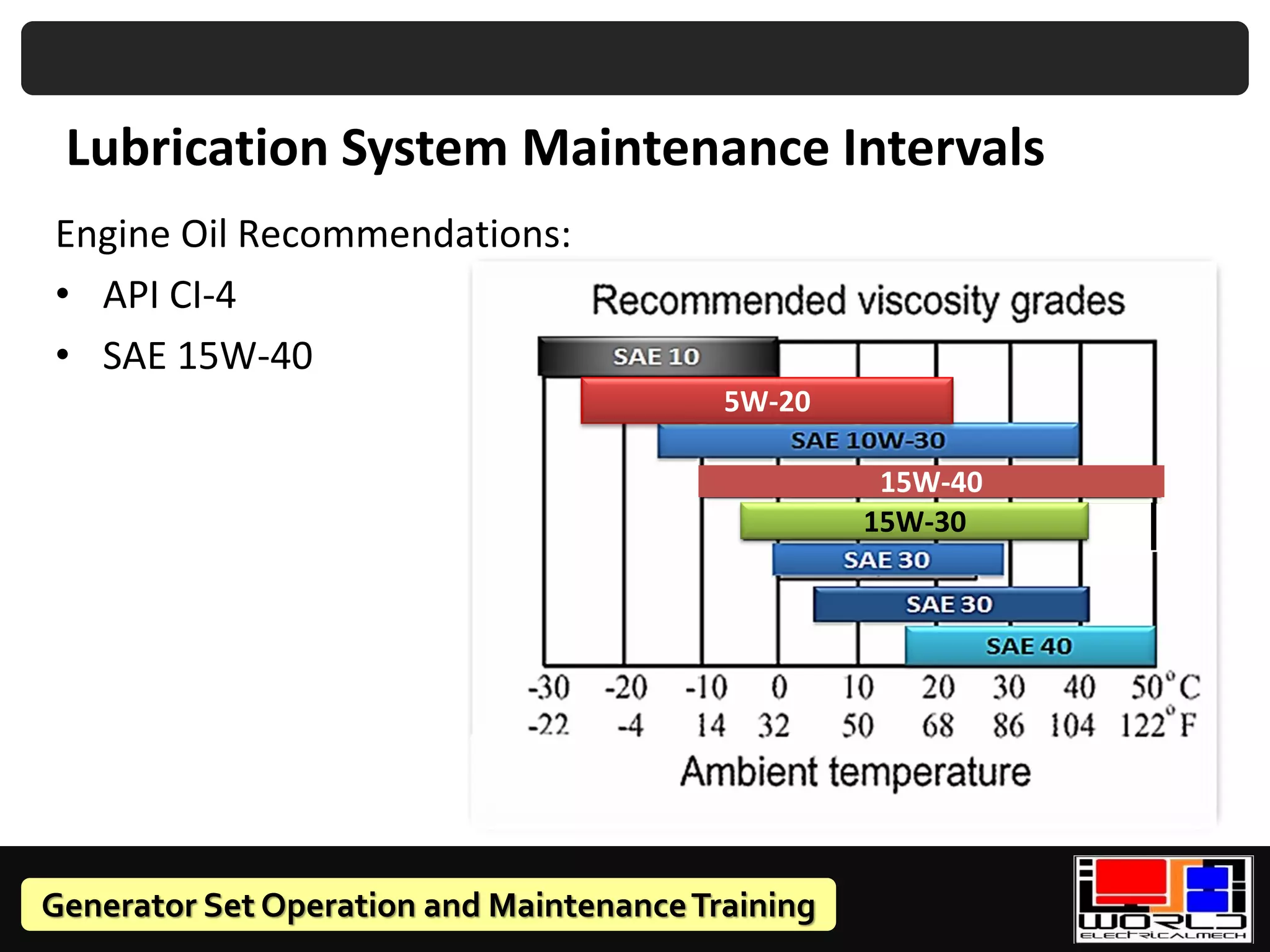

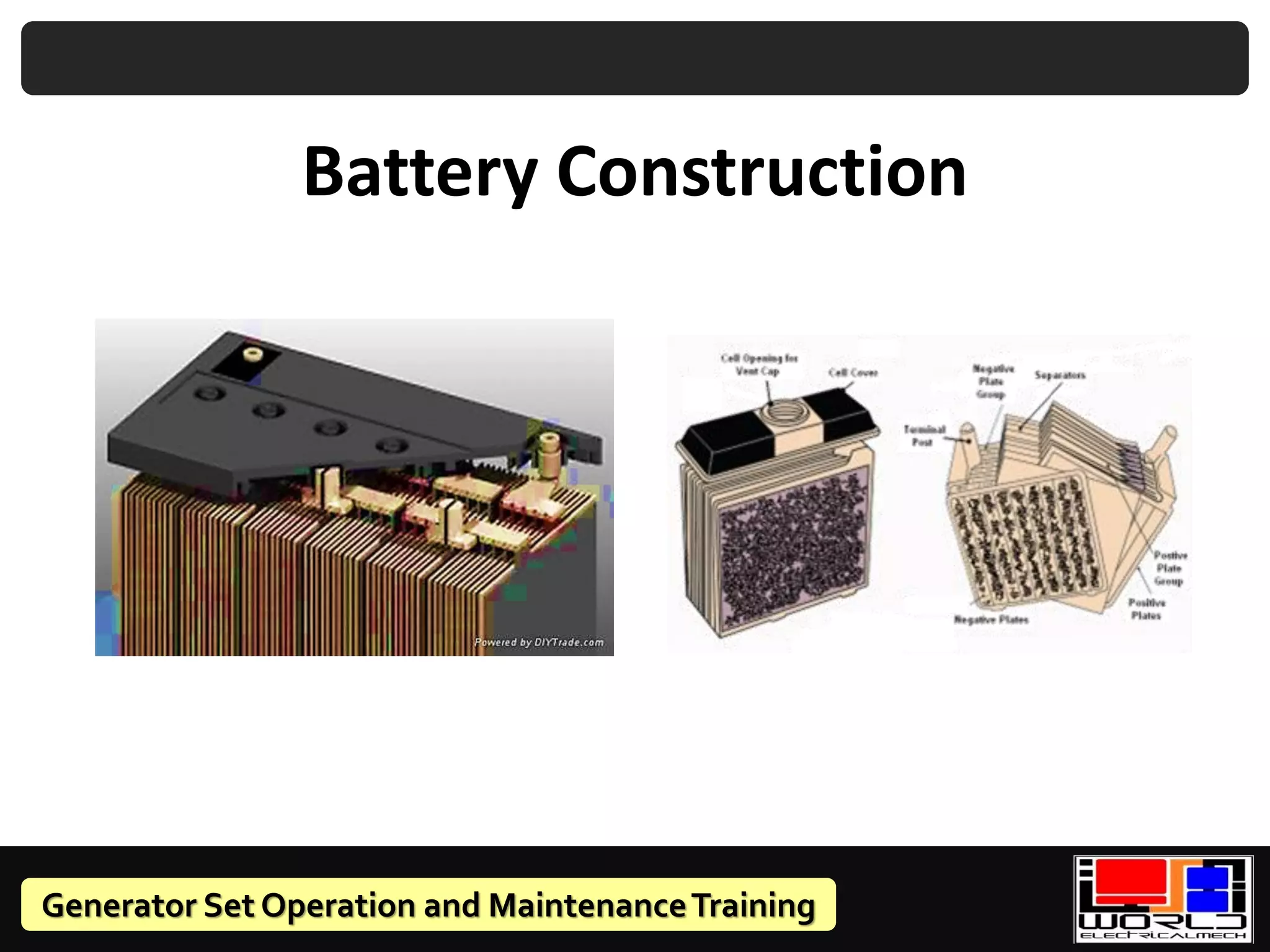

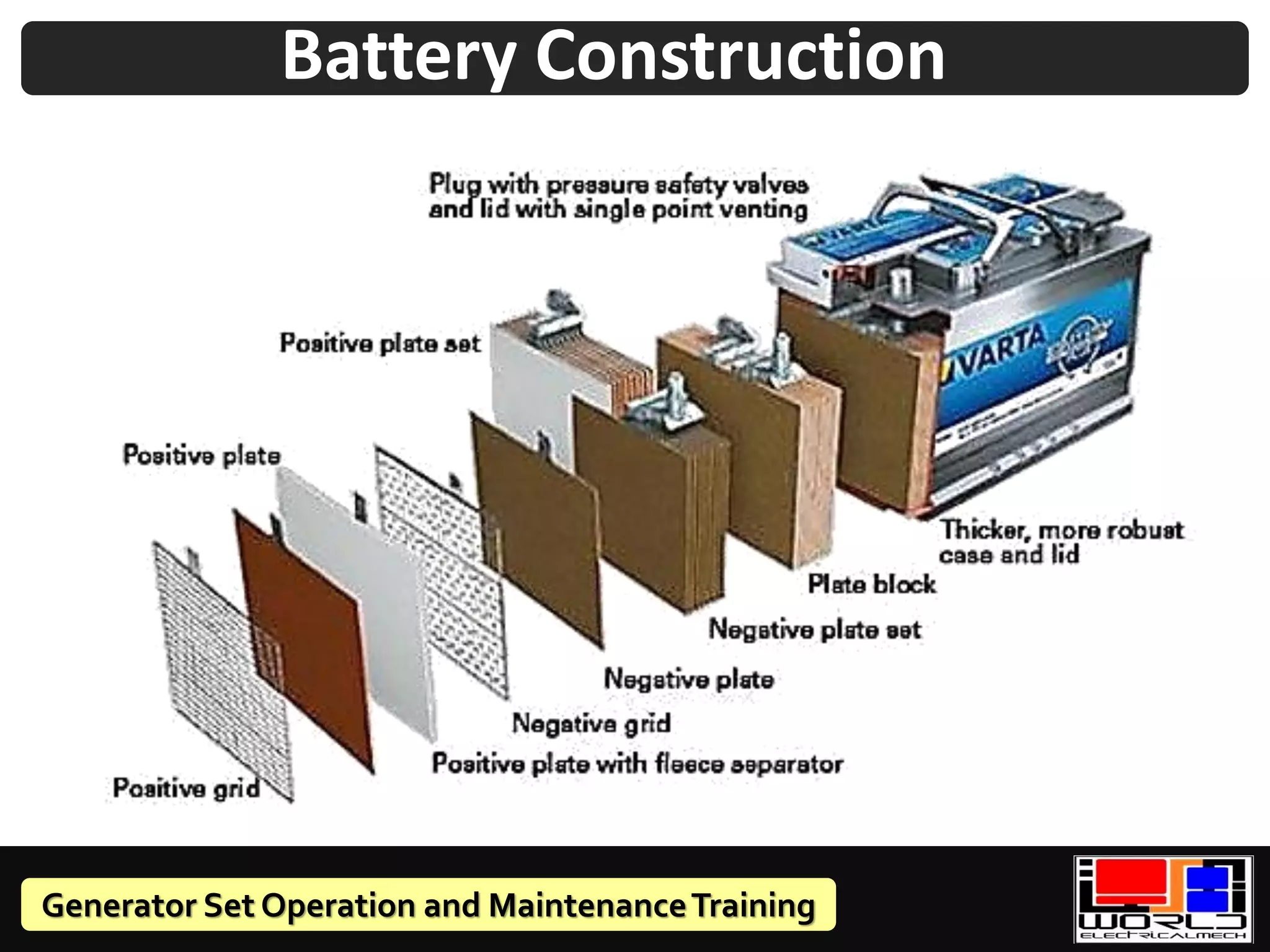

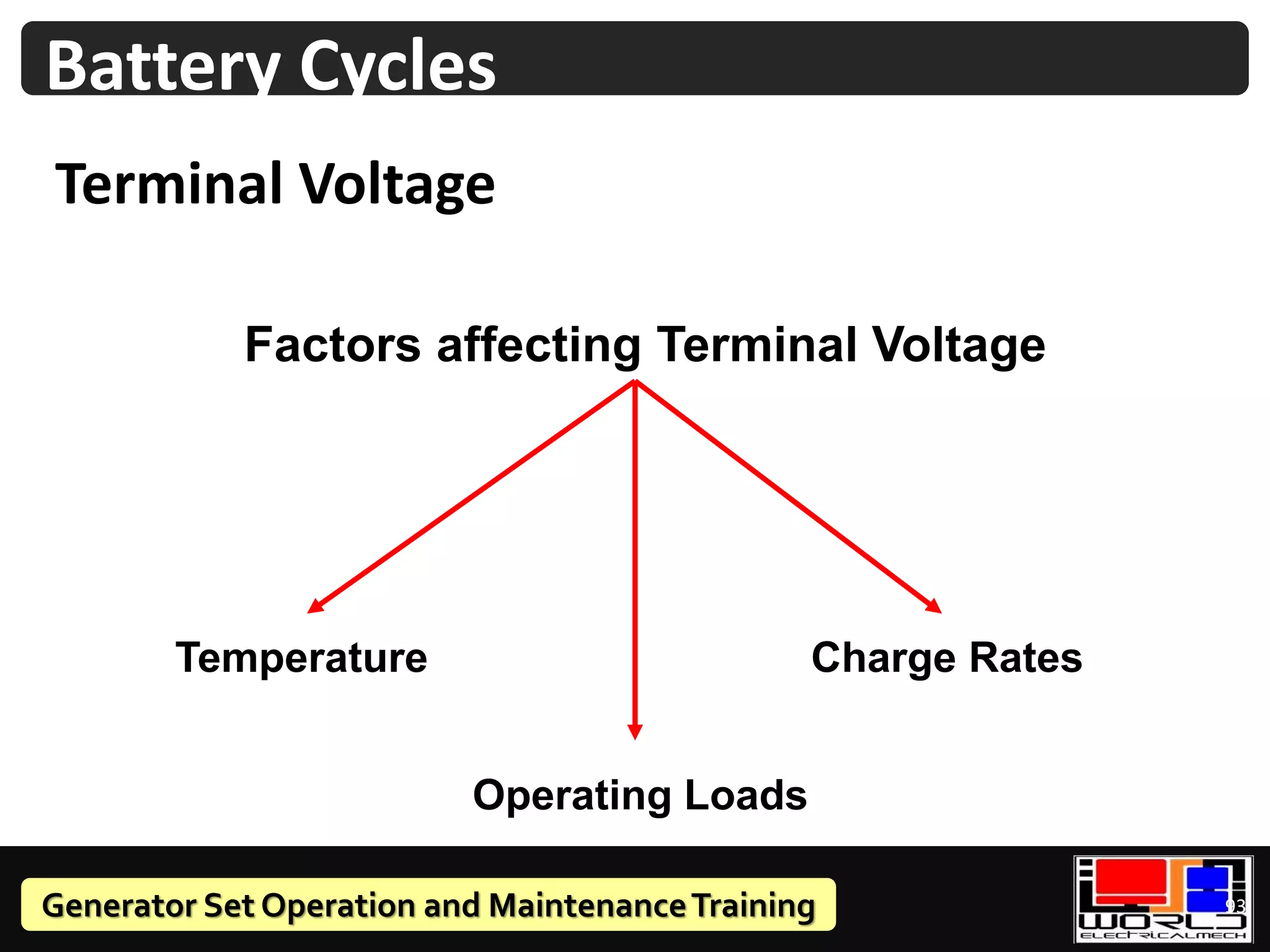

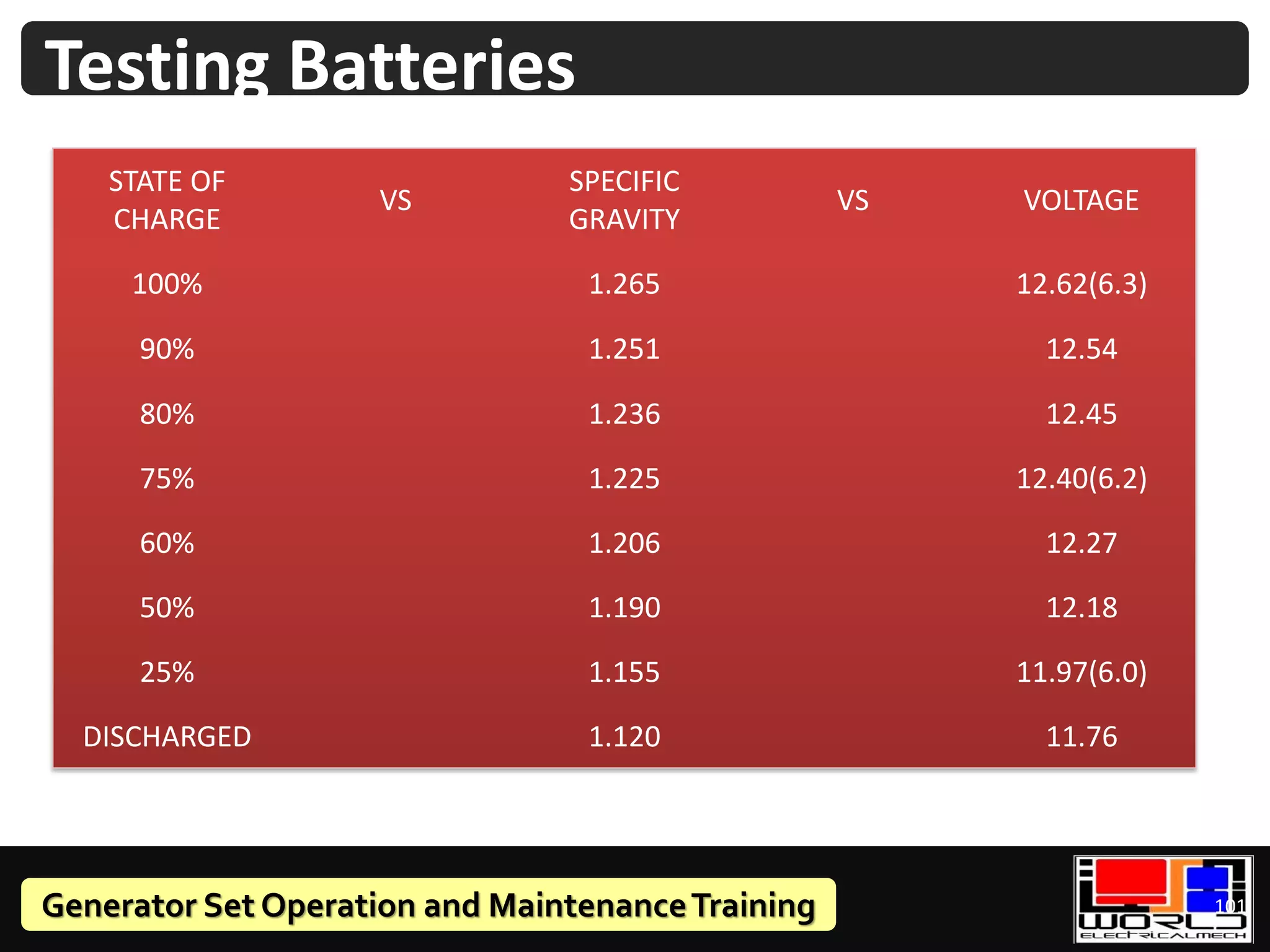

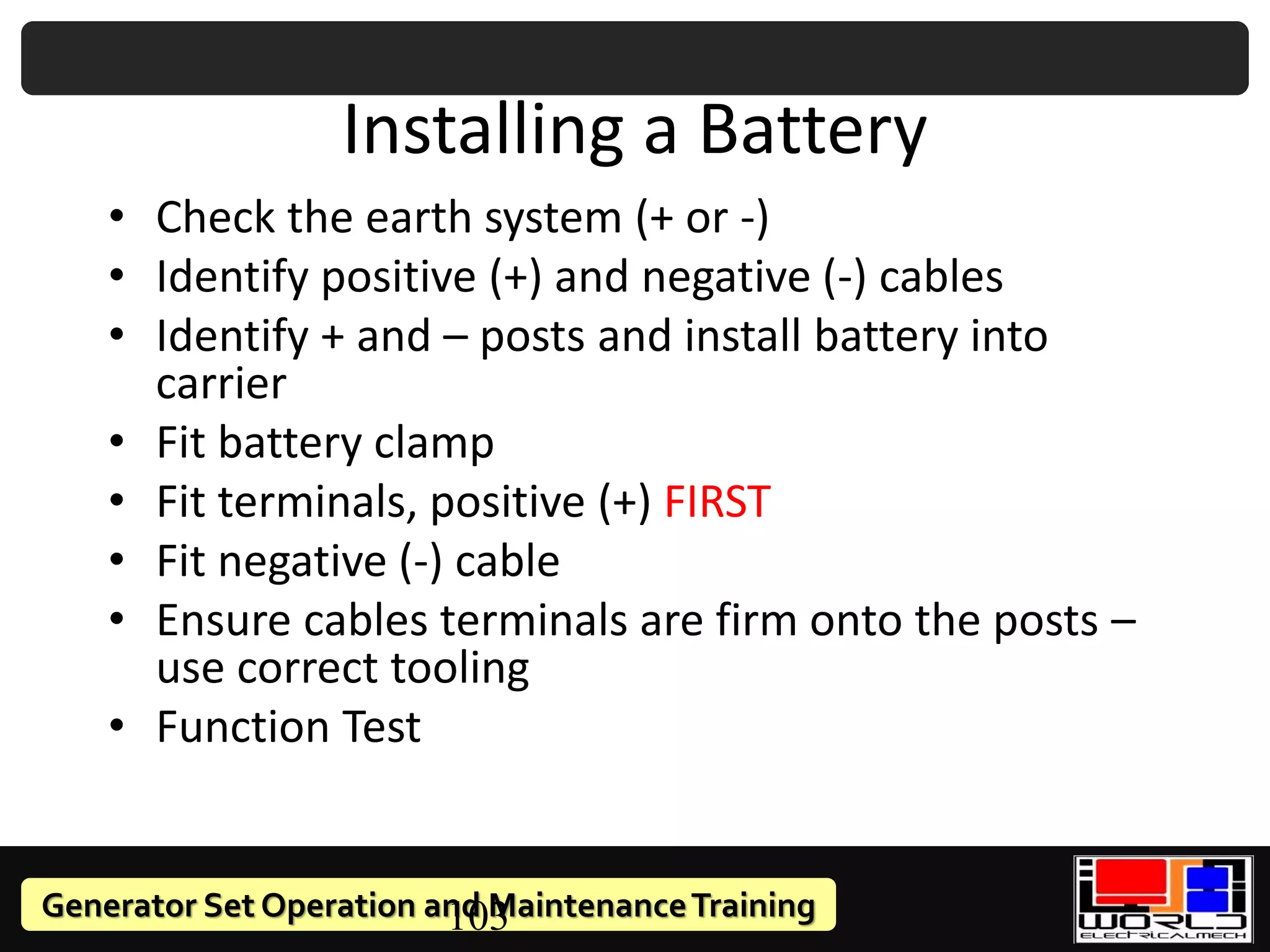

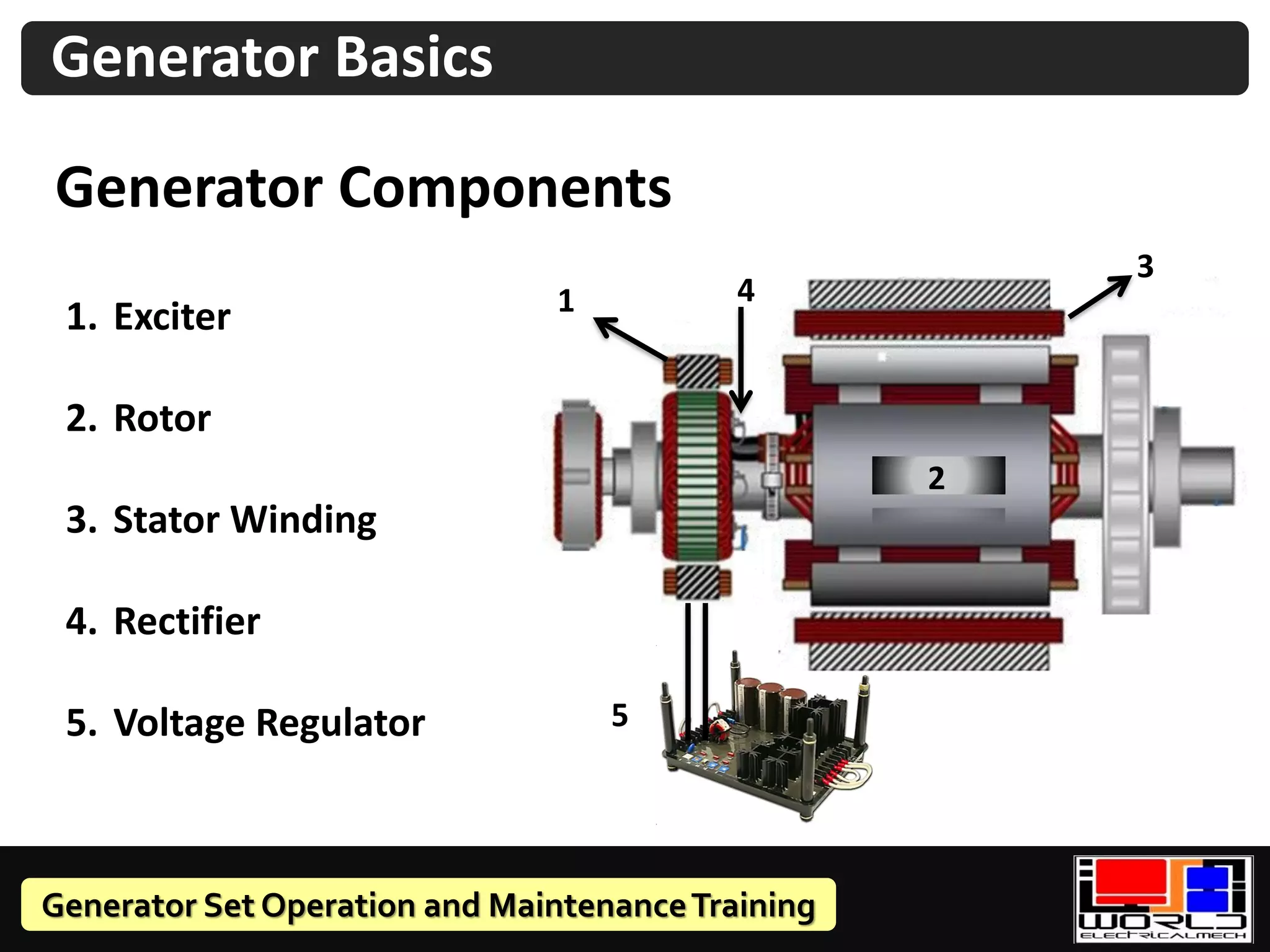

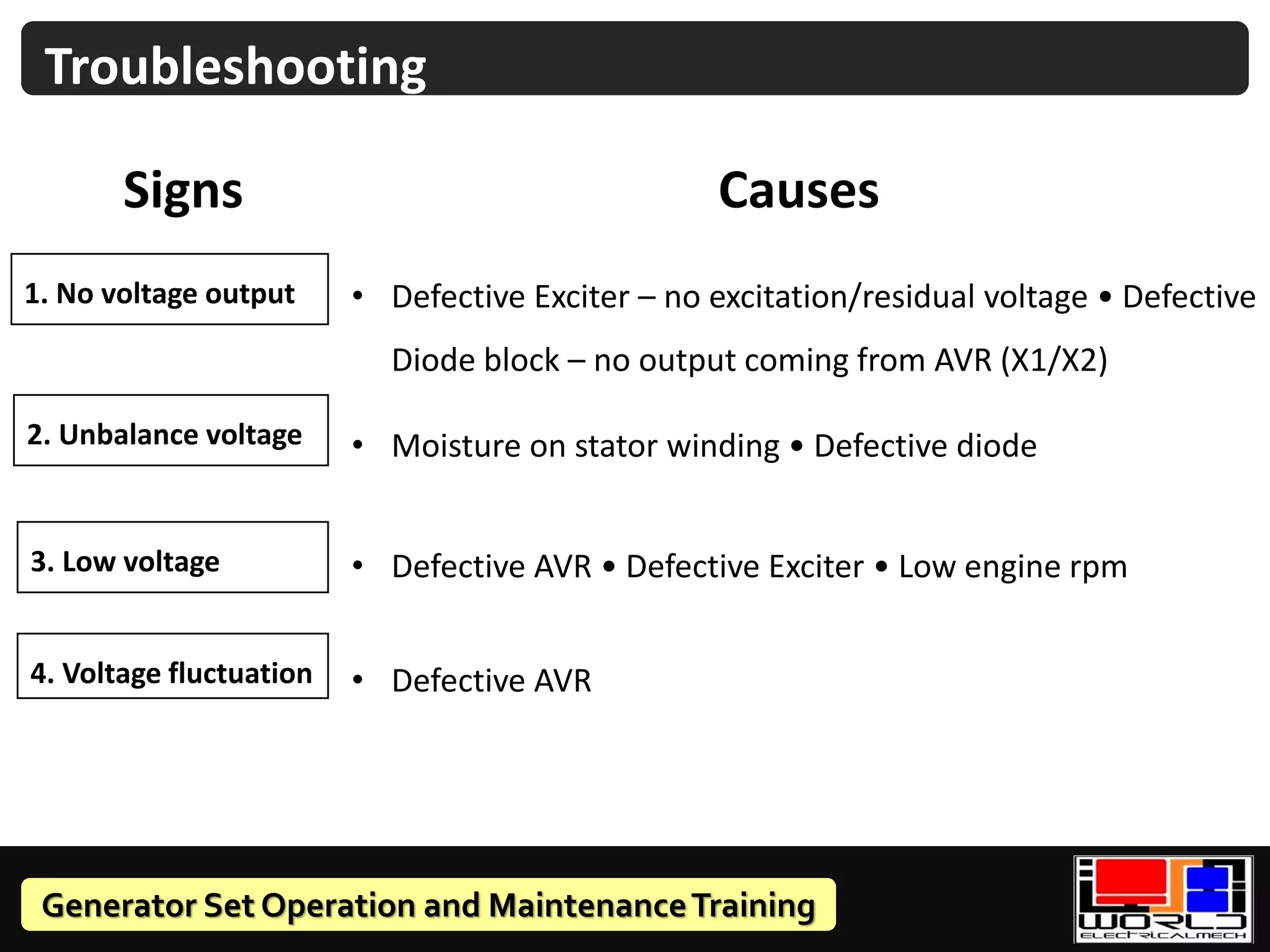

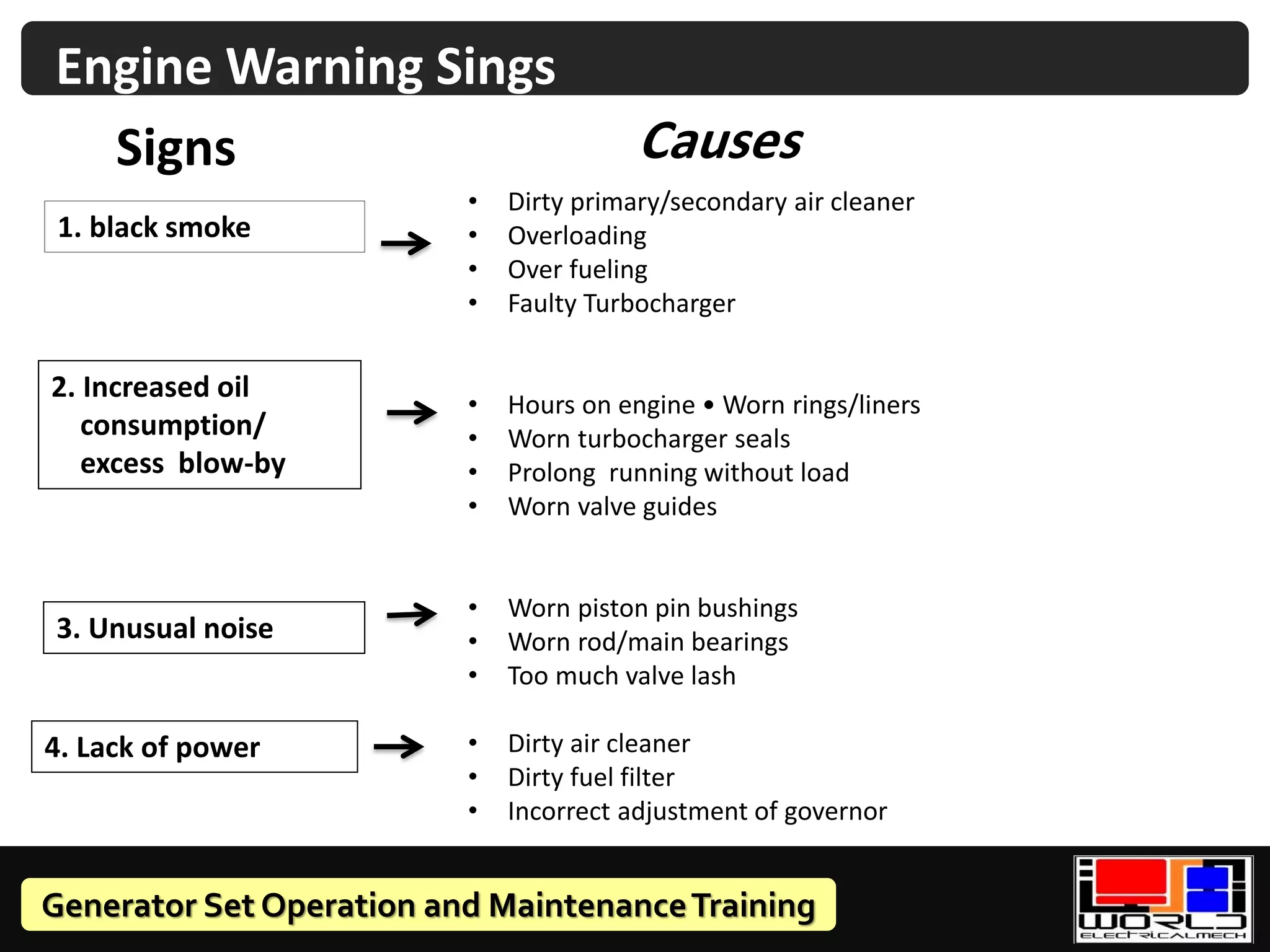

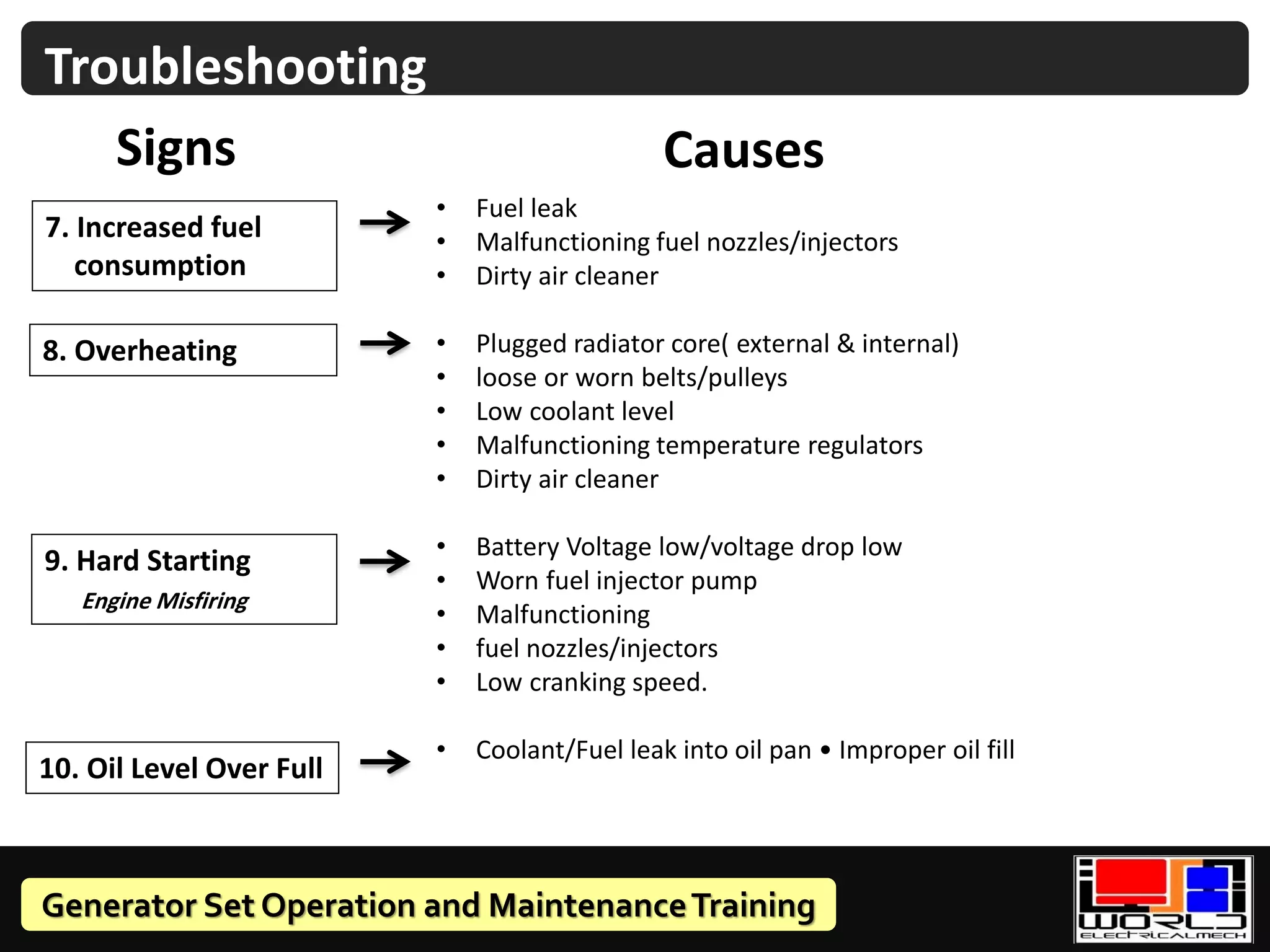

This document outlines an agenda for a training on generator set operation and maintenance. It covers safety, engine systems like air intake/exhaust, fuel, cooling, and lubrication. It discusses component operation, common problems, and maintenance schedules. Day 2 of the training focuses on battery maintenance, alternator/generator system operation, maintenance, and troubleshooting. The goal is to provide knowledge to properly operate, maintain, and diagnose issues with generator set systems.