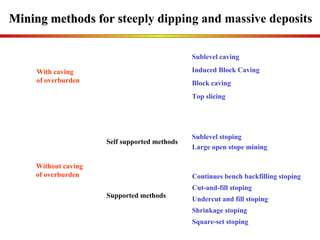

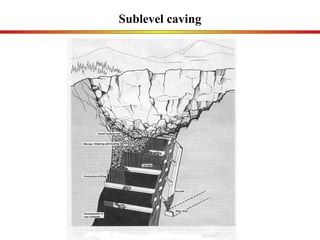

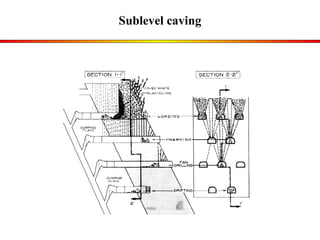

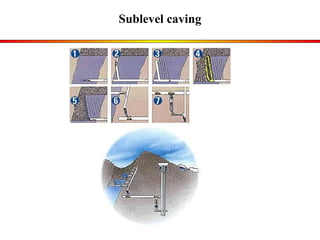

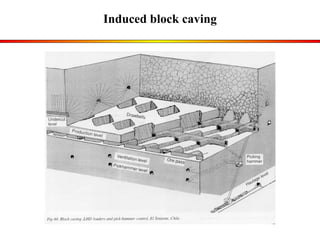

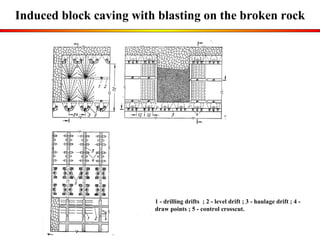

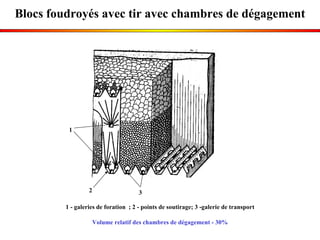

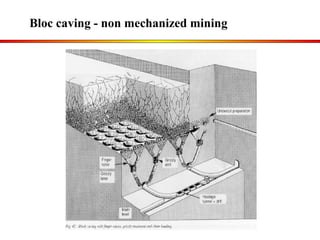

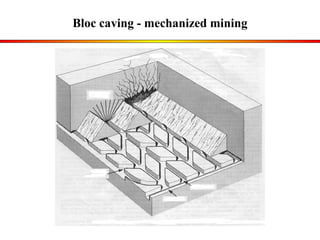

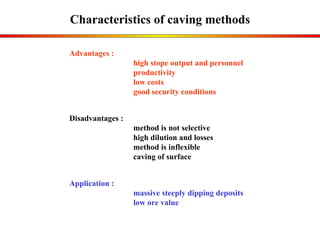

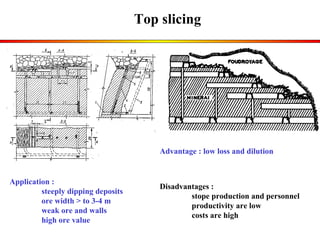

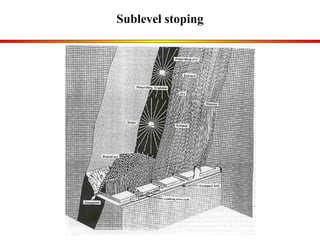

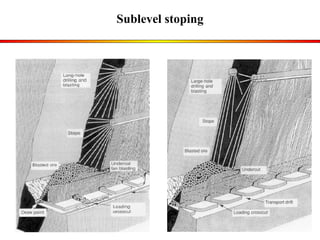

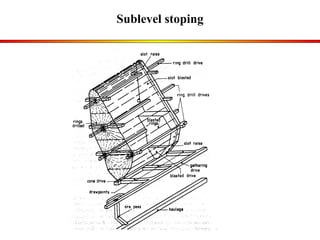

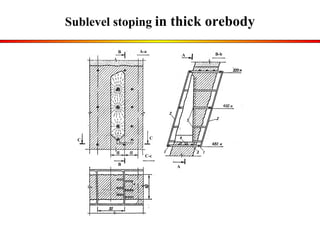

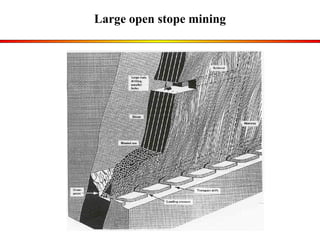

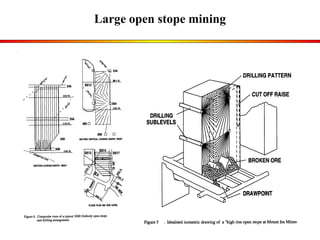

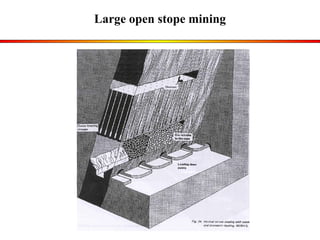

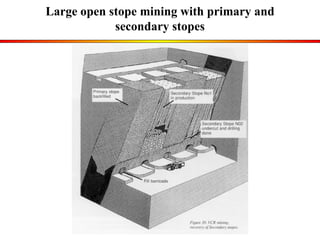

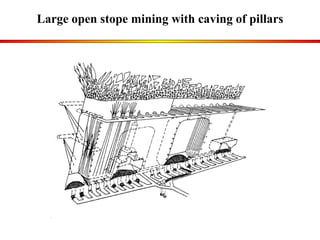

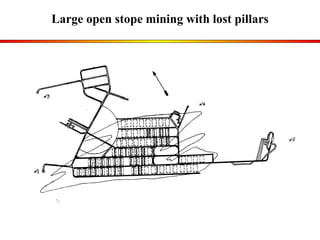

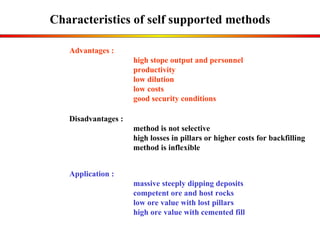

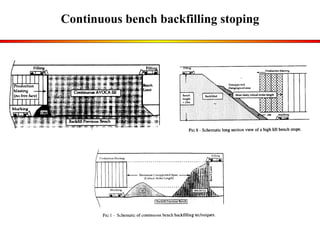

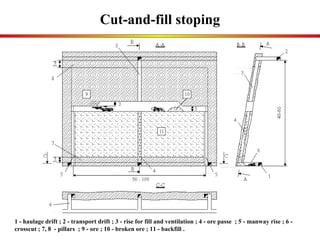

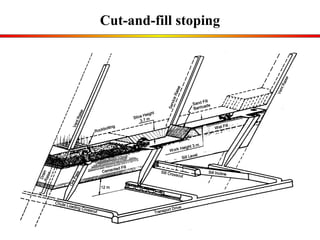

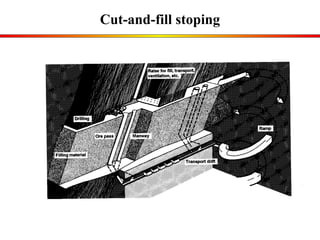

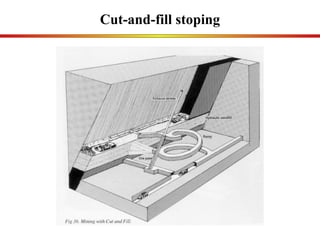

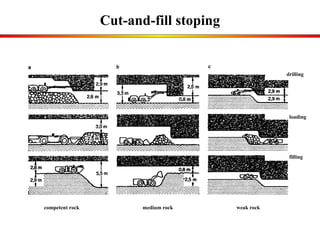

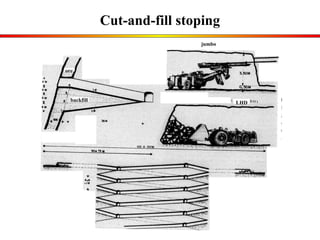

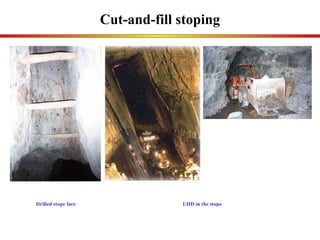

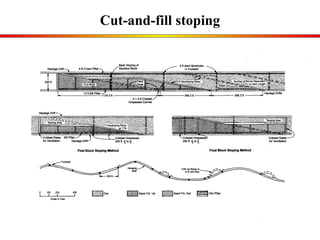

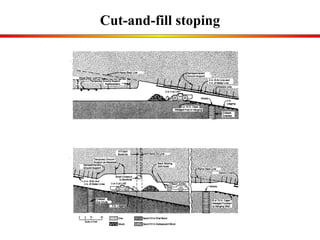

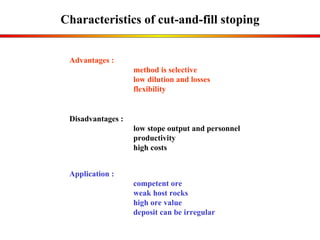

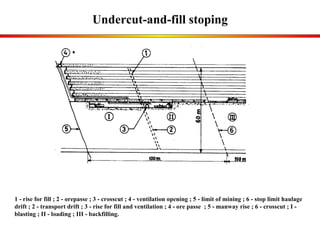

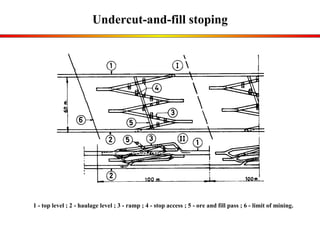

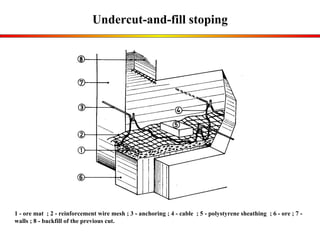

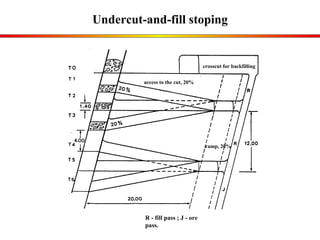

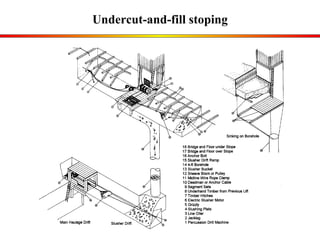

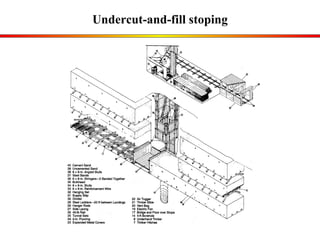

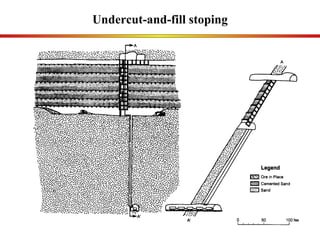

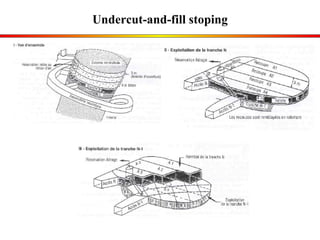

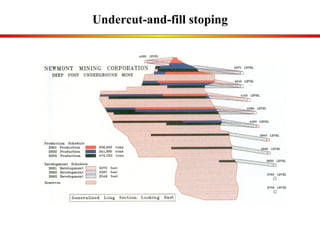

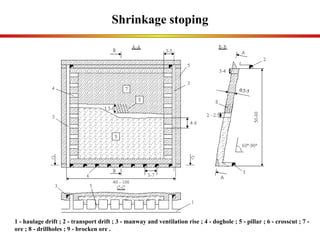

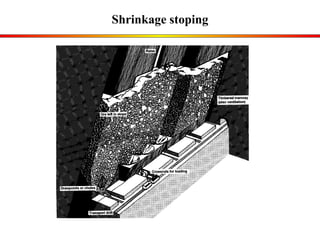

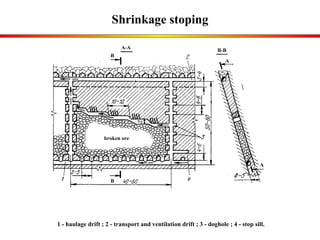

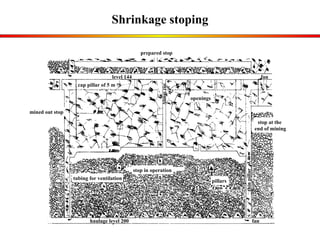

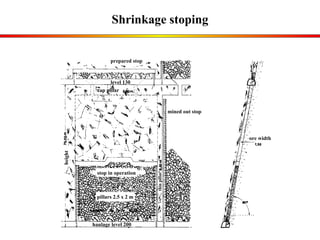

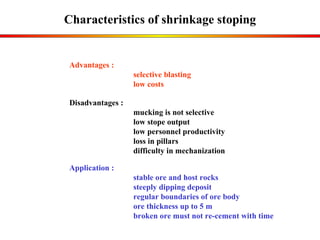

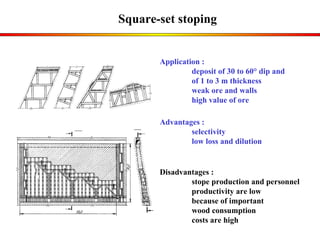

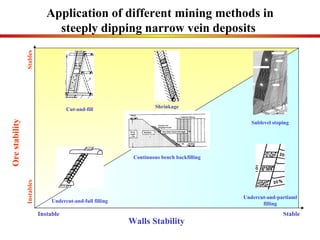

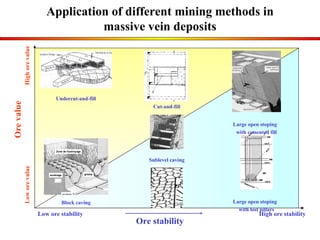

The document discusses various mining methods for steeply dipping and massive ore deposits. It describes caving methods like sublevel caving and induced block caving that are suitable for massive deposits with low ore value. It also outlines self-supported methods including sublevel stoping and large open stope mining. Supported methods such as cut-and-fill stoping and undercut-and-fill stoping are described as well. Each method is examined in terms of its applications, advantages, and disadvantages.