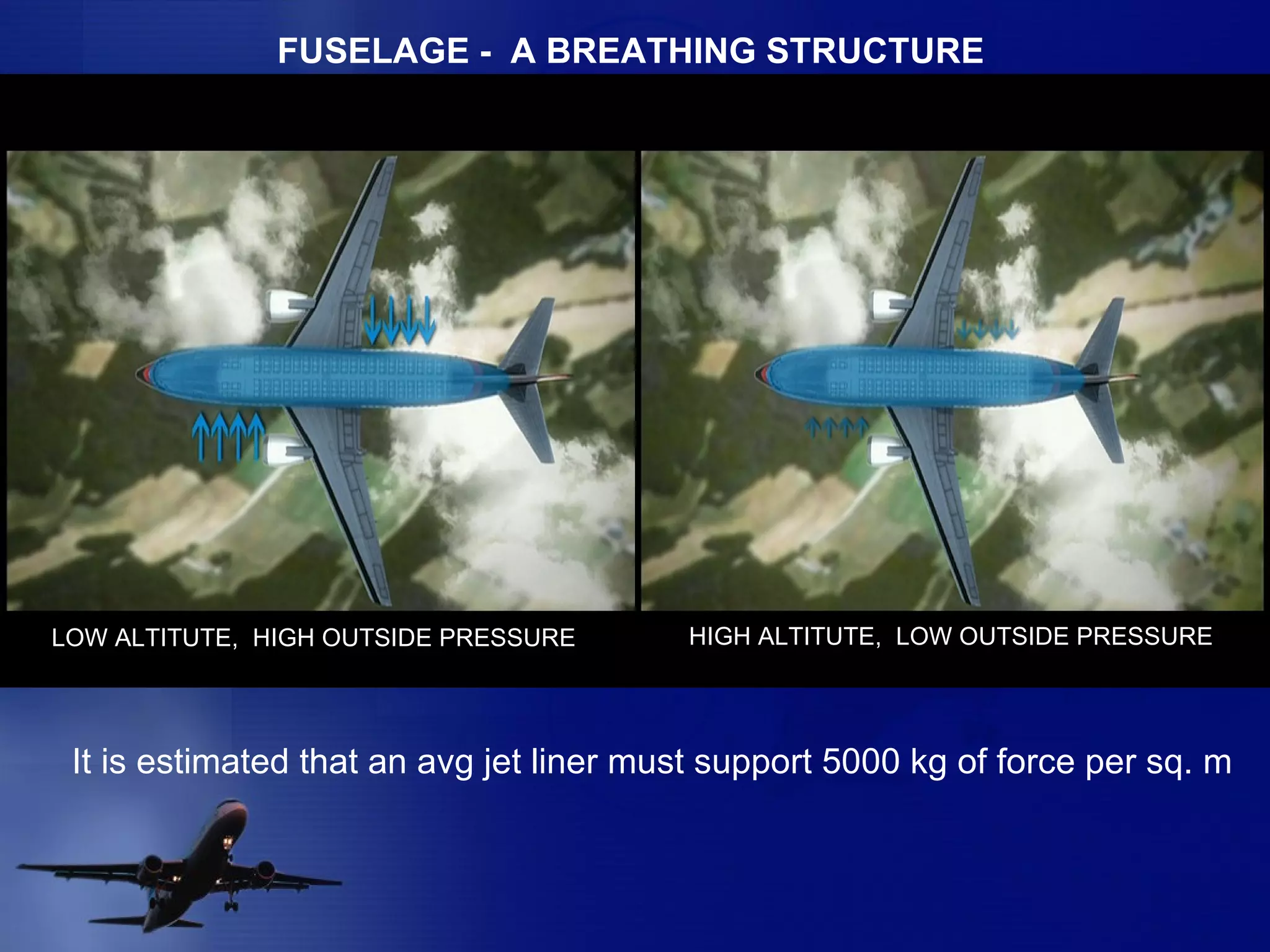

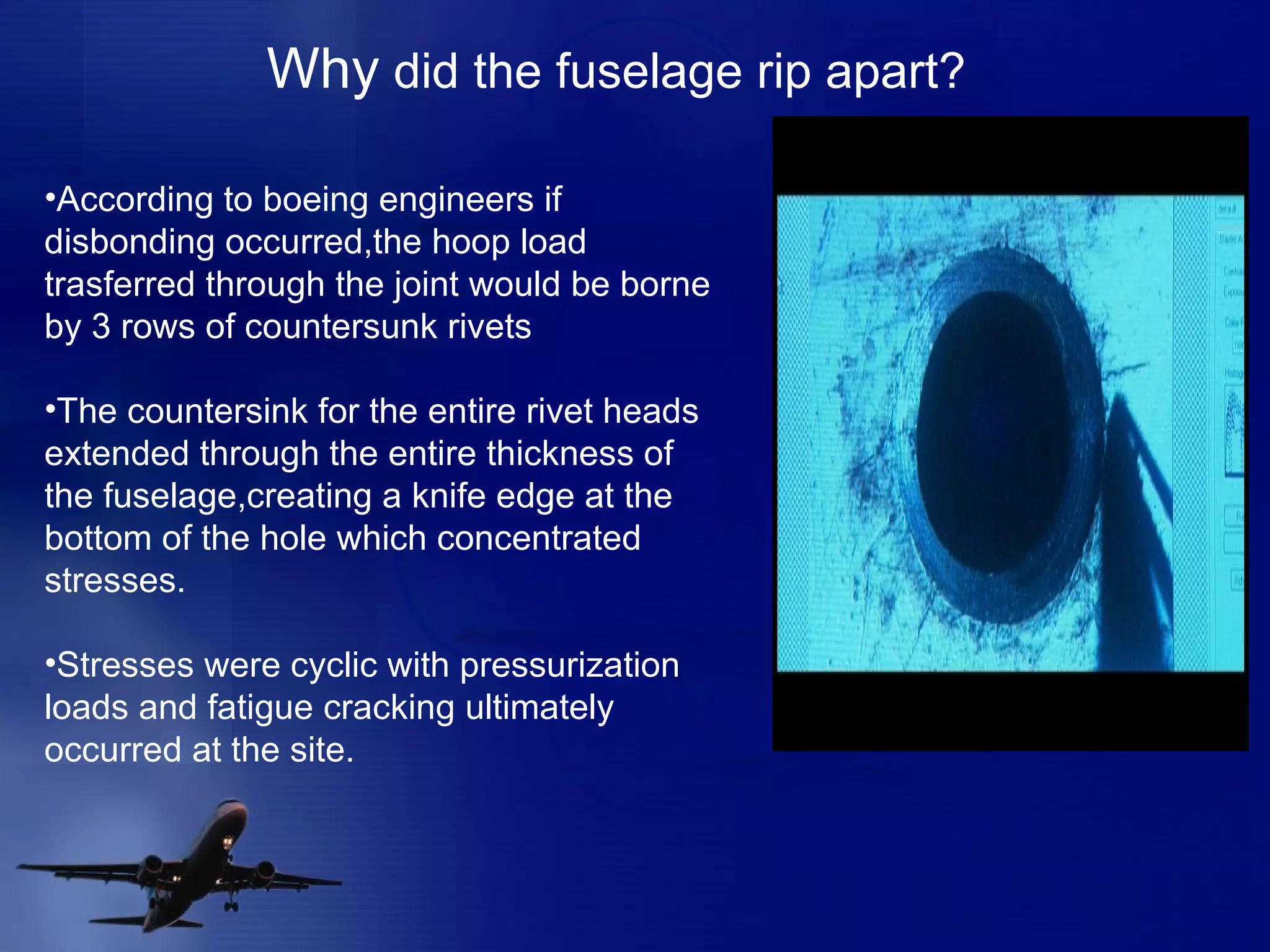

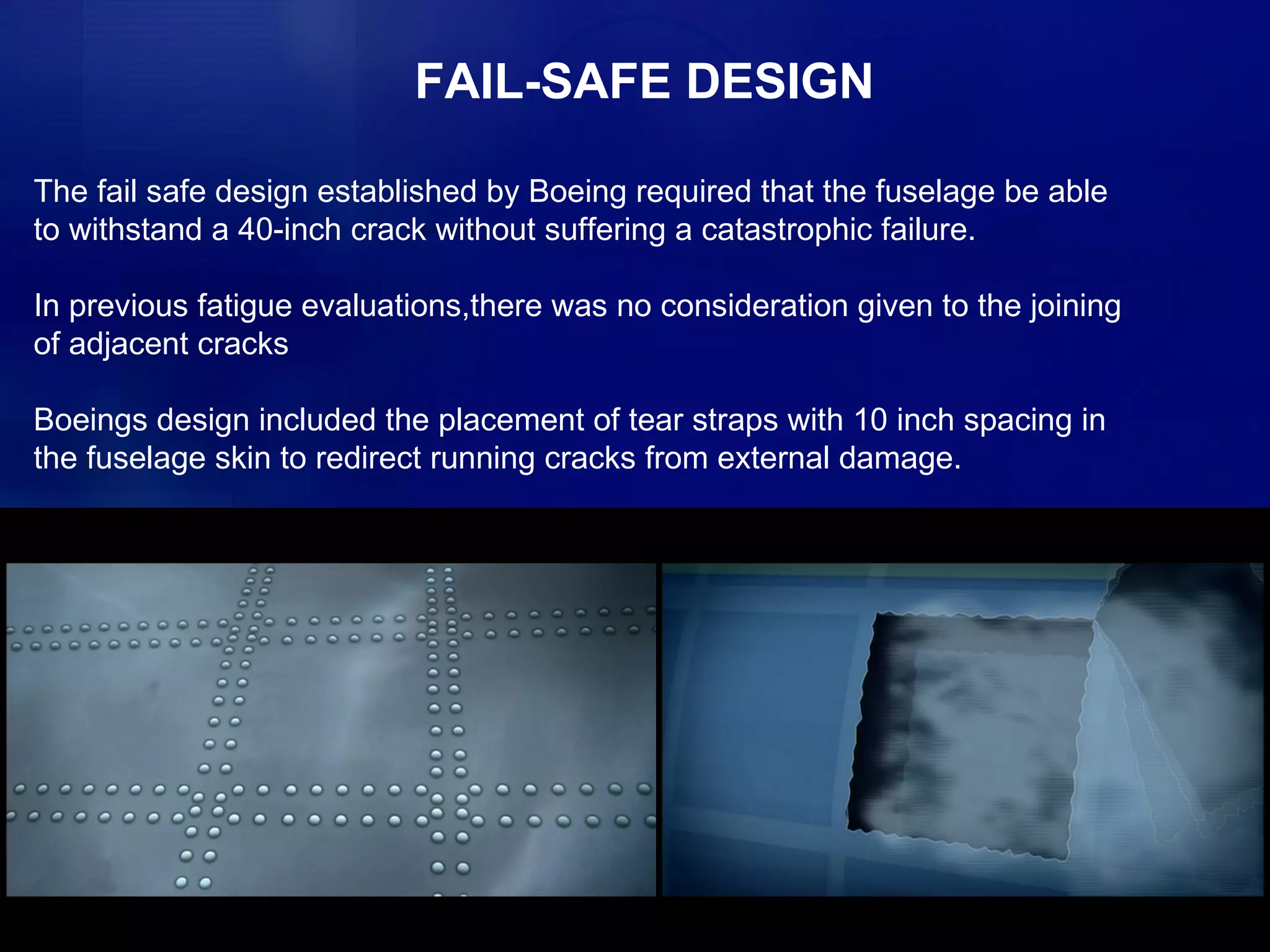

The document summarizes several aviation disasters caused by mechanical failures:

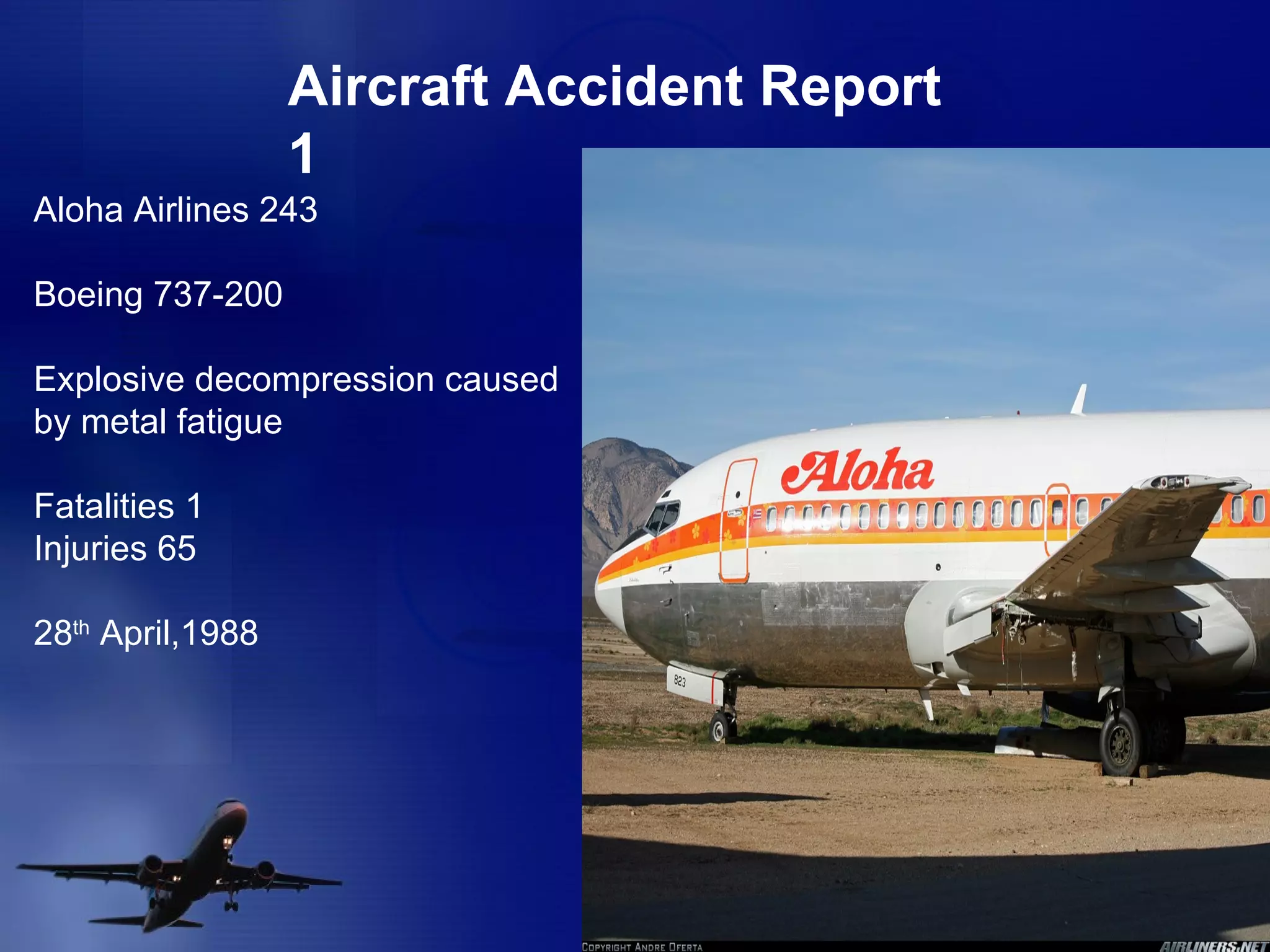

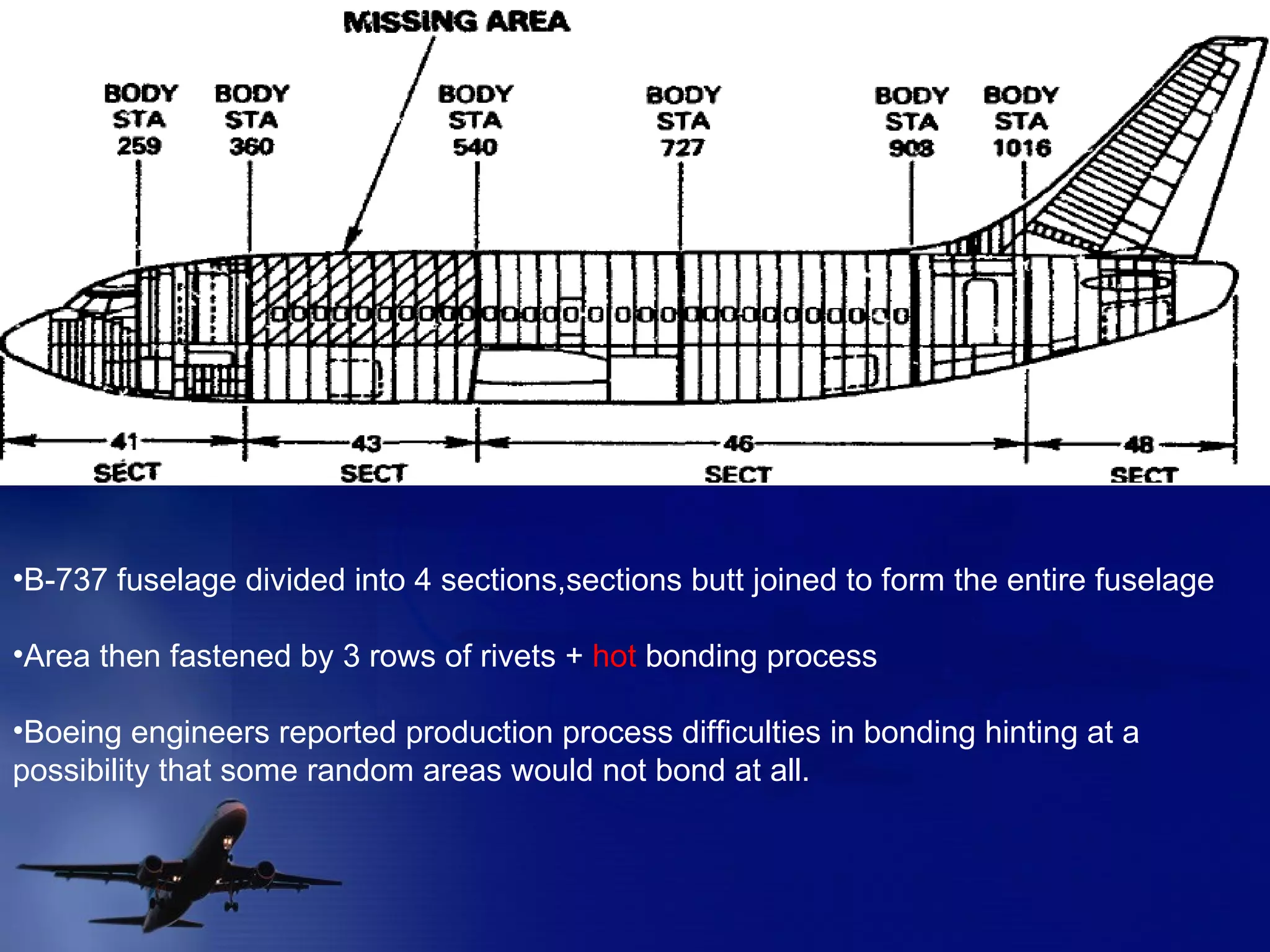

1) Aloha Airlines Flight 243 in 1988 experienced explosive decompression due to metal fatigue in the Boeing 737 fuselage, which had not been properly inspected. One person was killed.

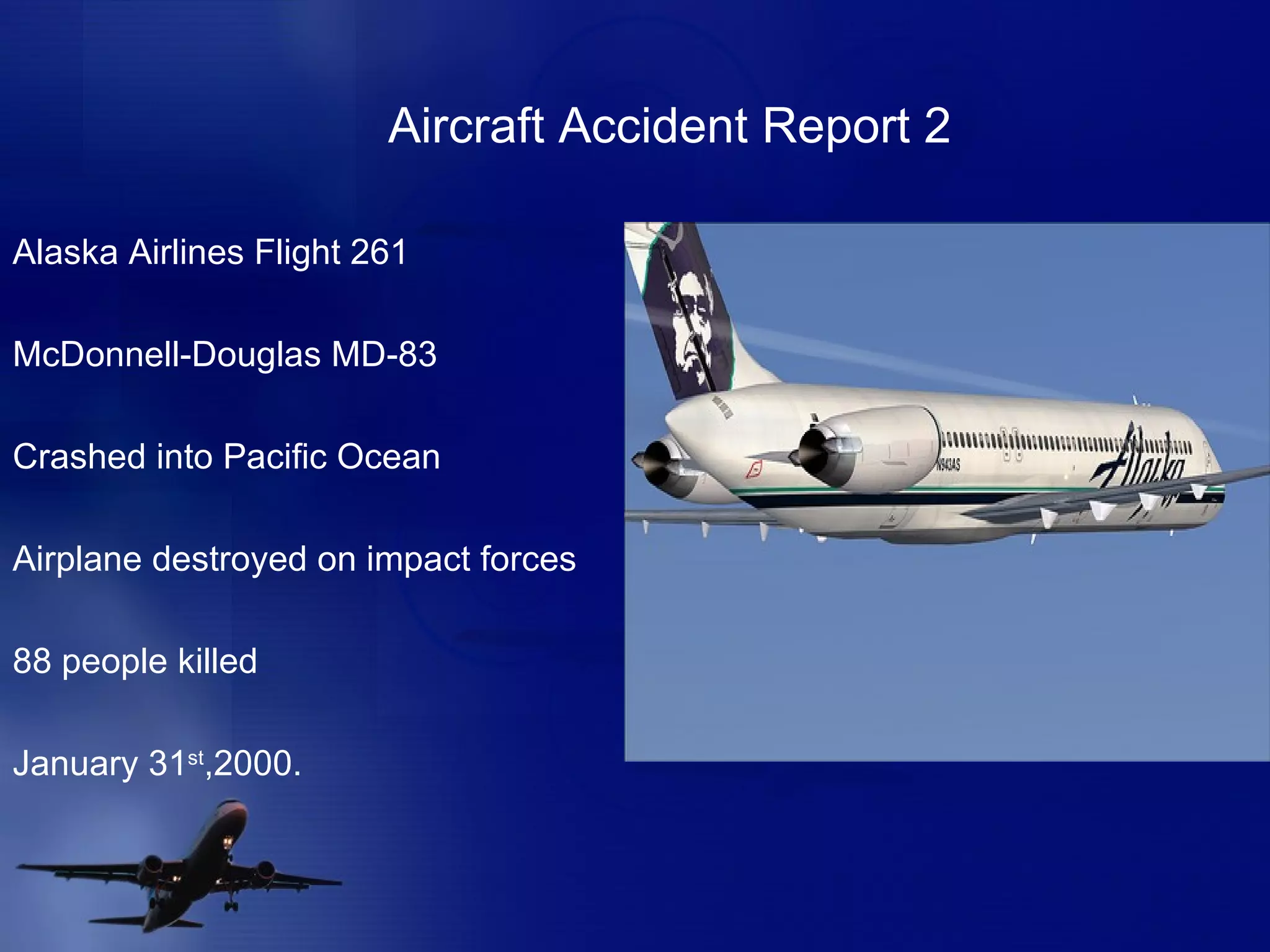

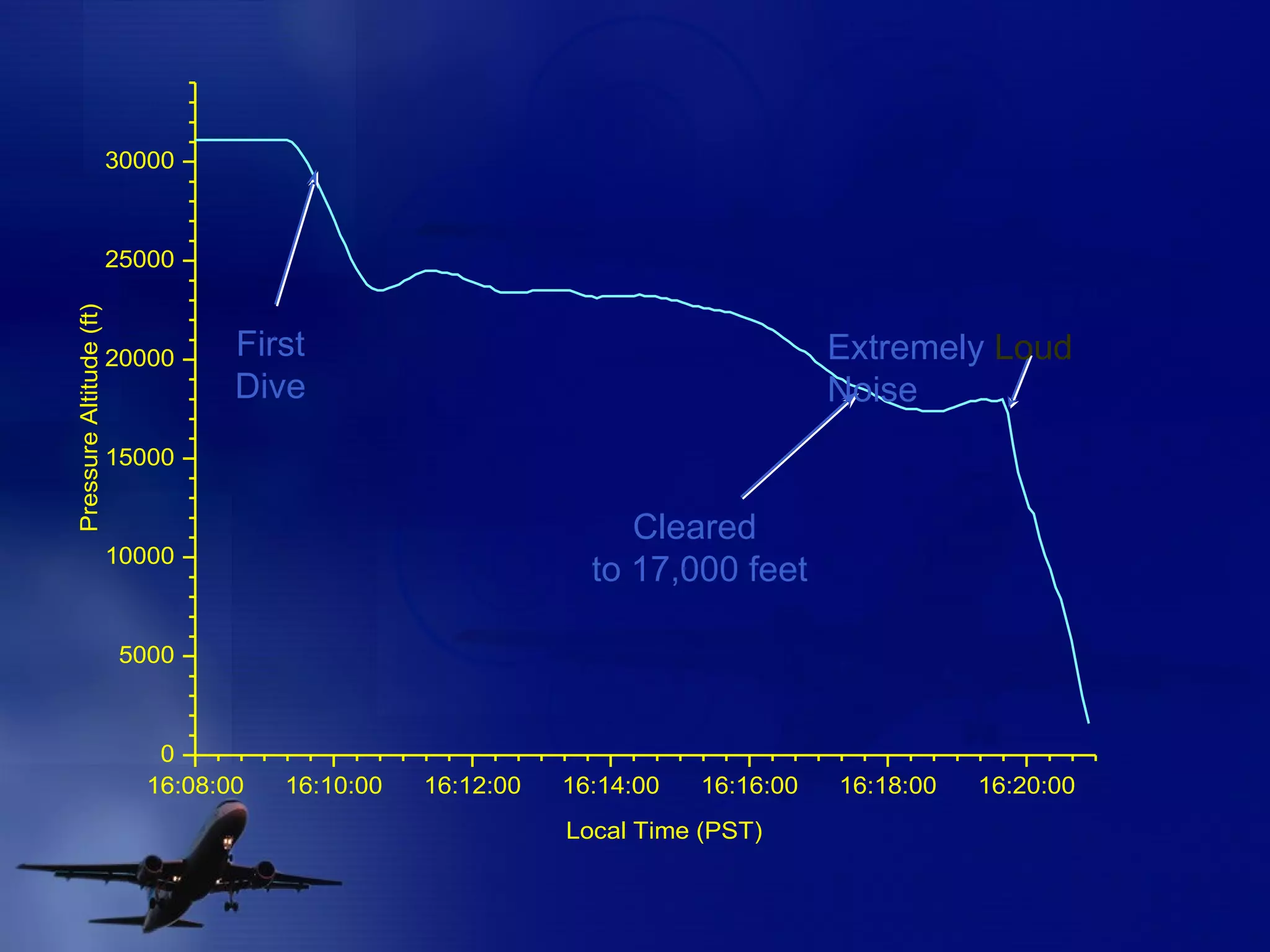

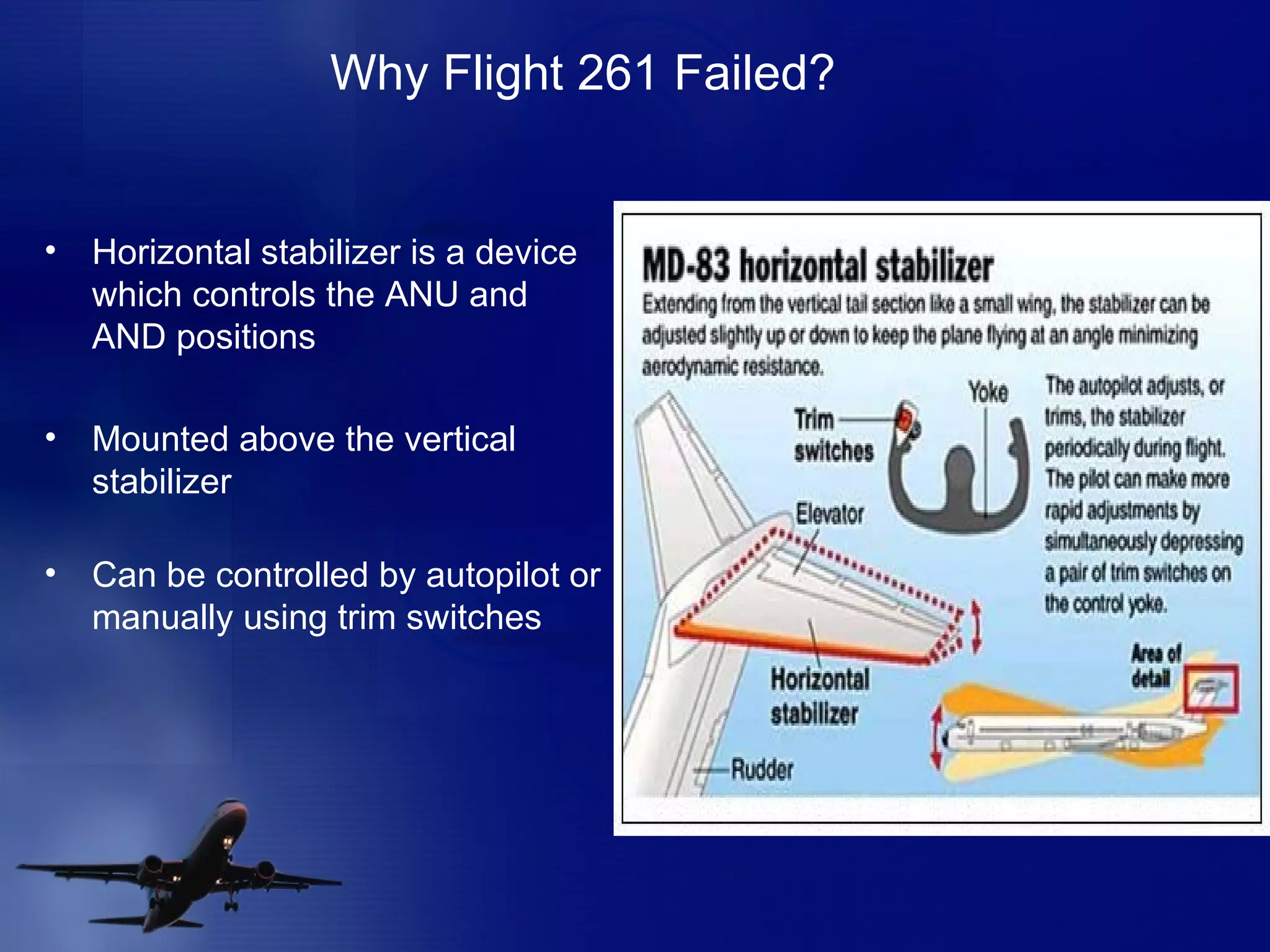

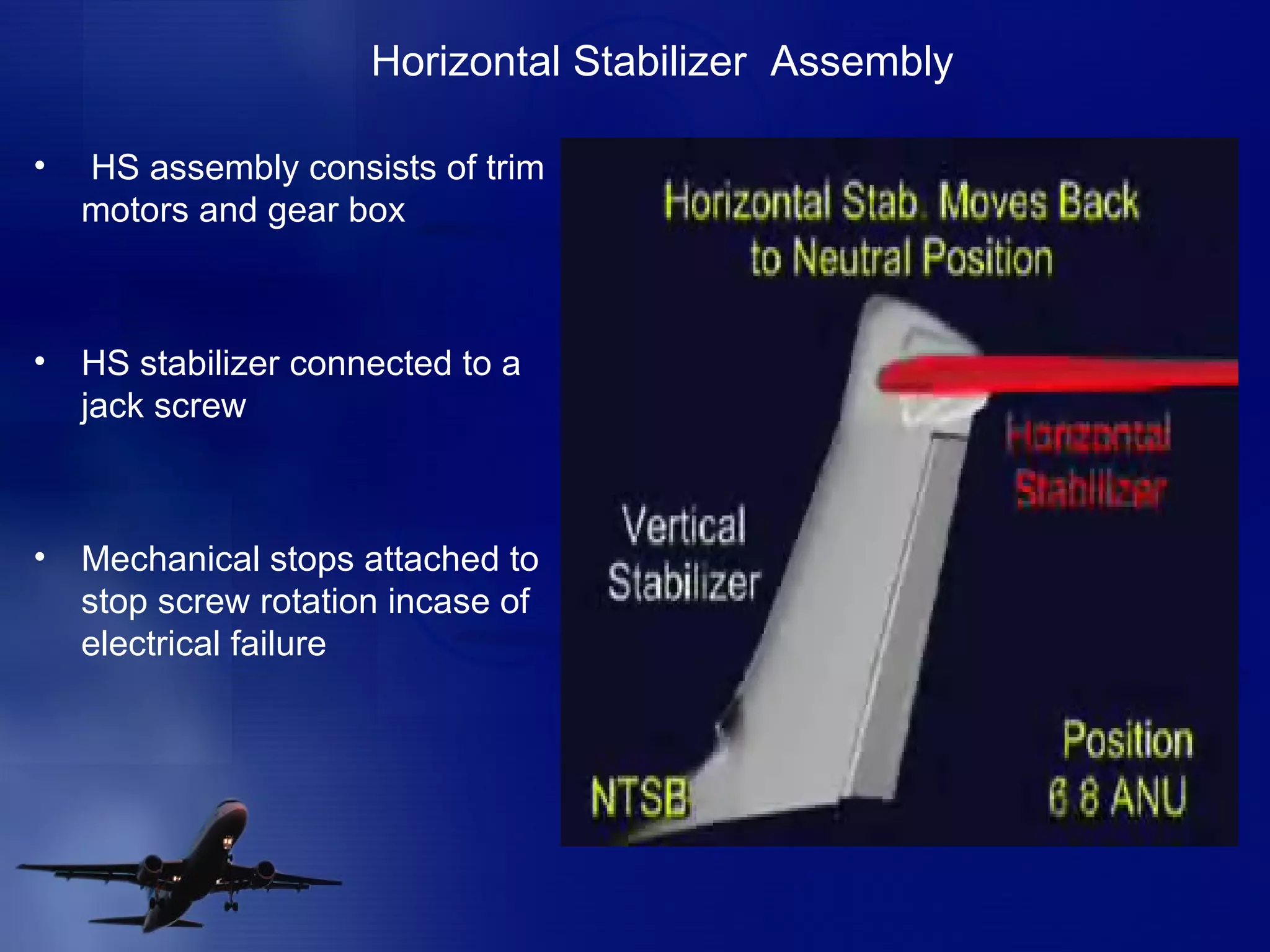

2) Alaska Airlines Flight 261 in 2000 crashed into the ocean after the horizontal stabilizer became jammed due to improper maintenance of the jackscrew assembly. All 88 people on board were killed.

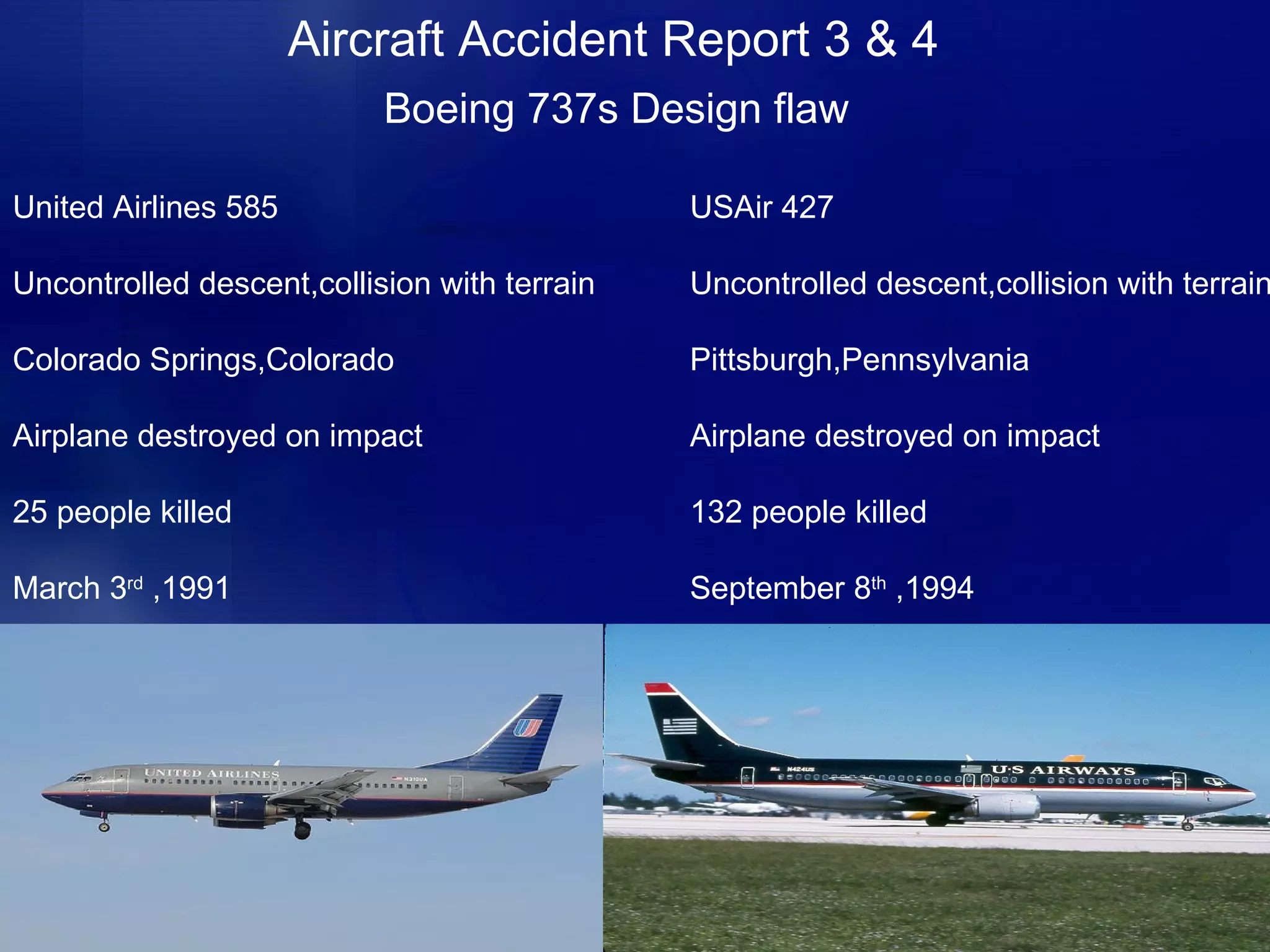

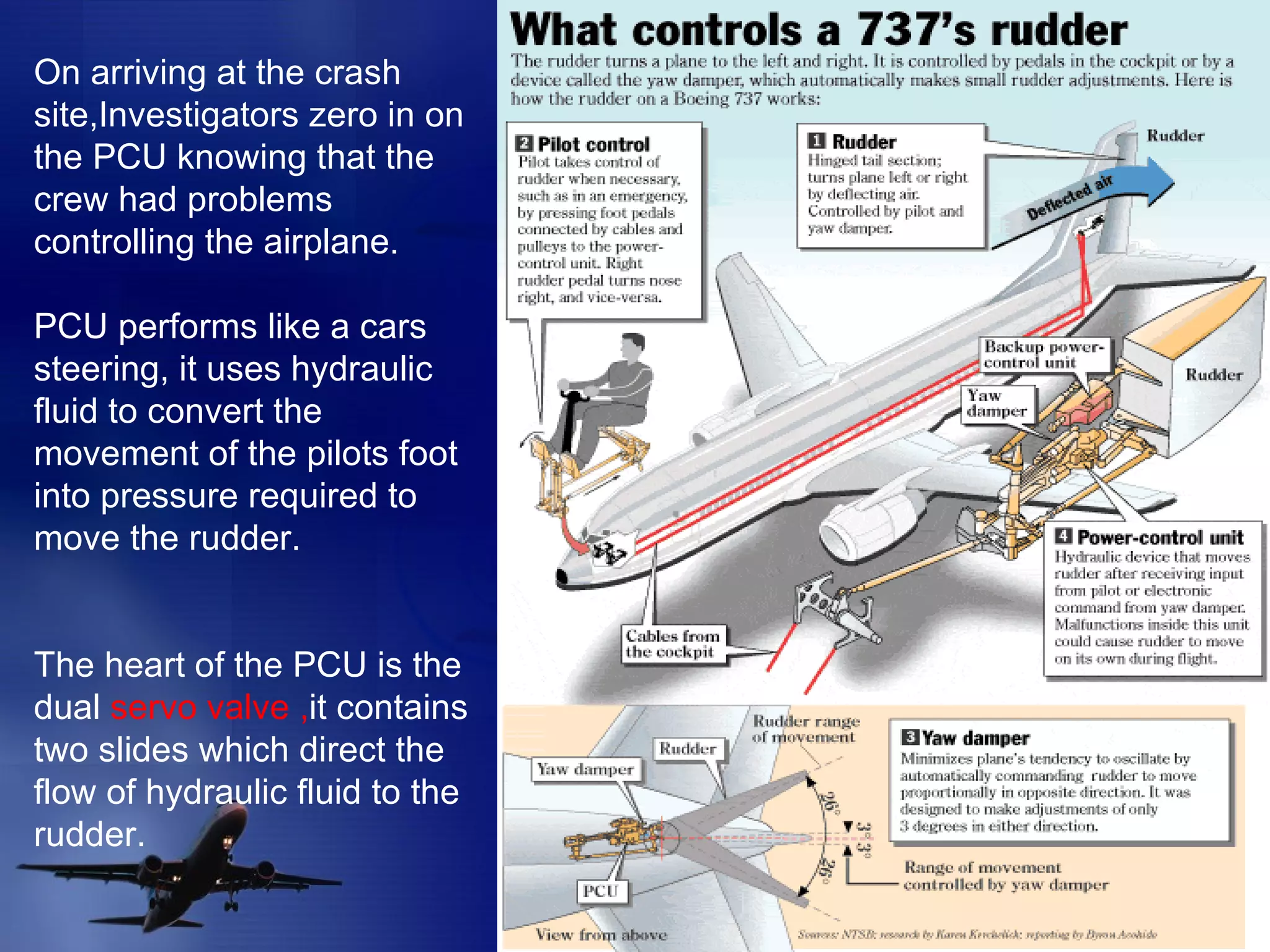

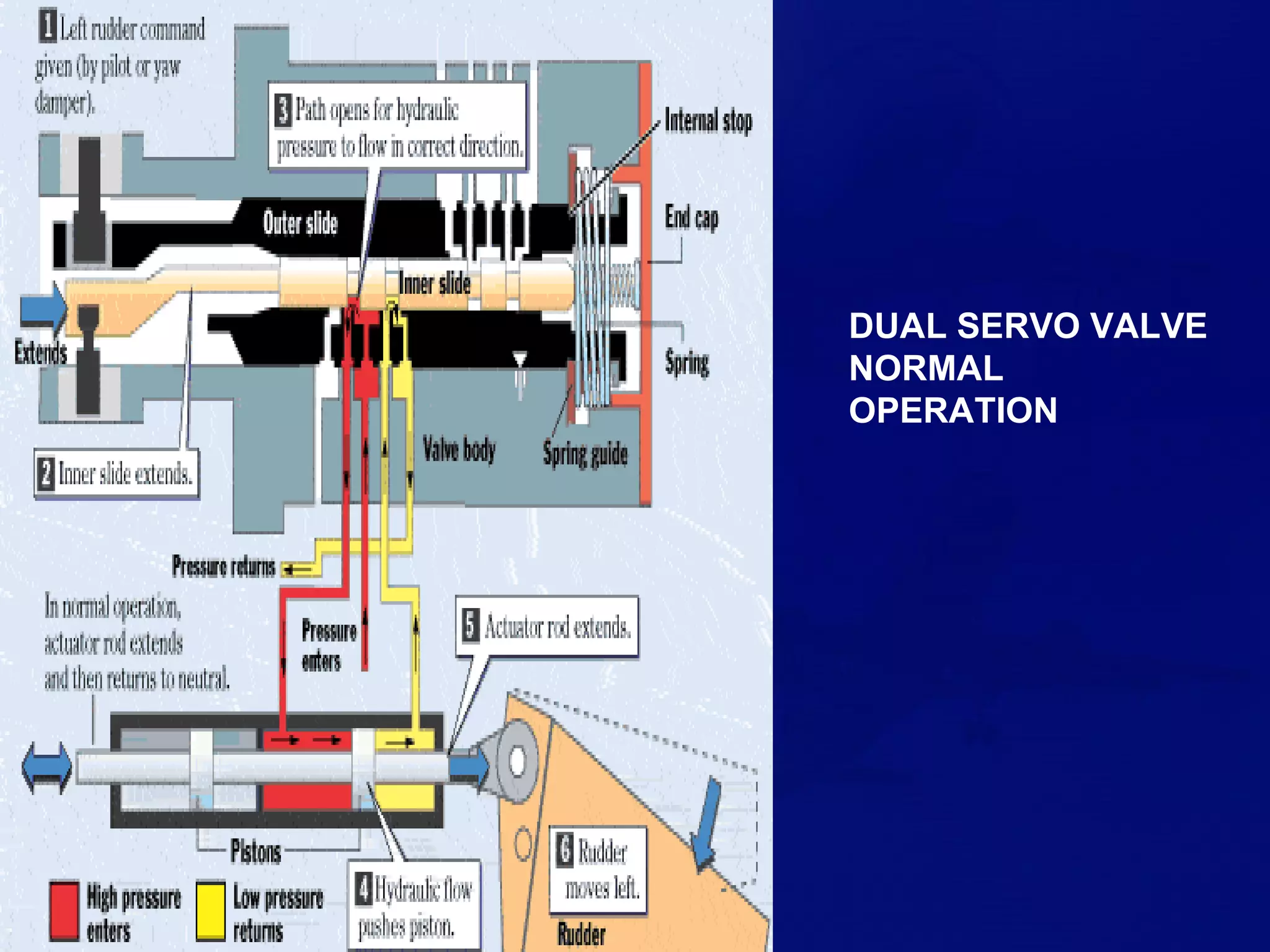

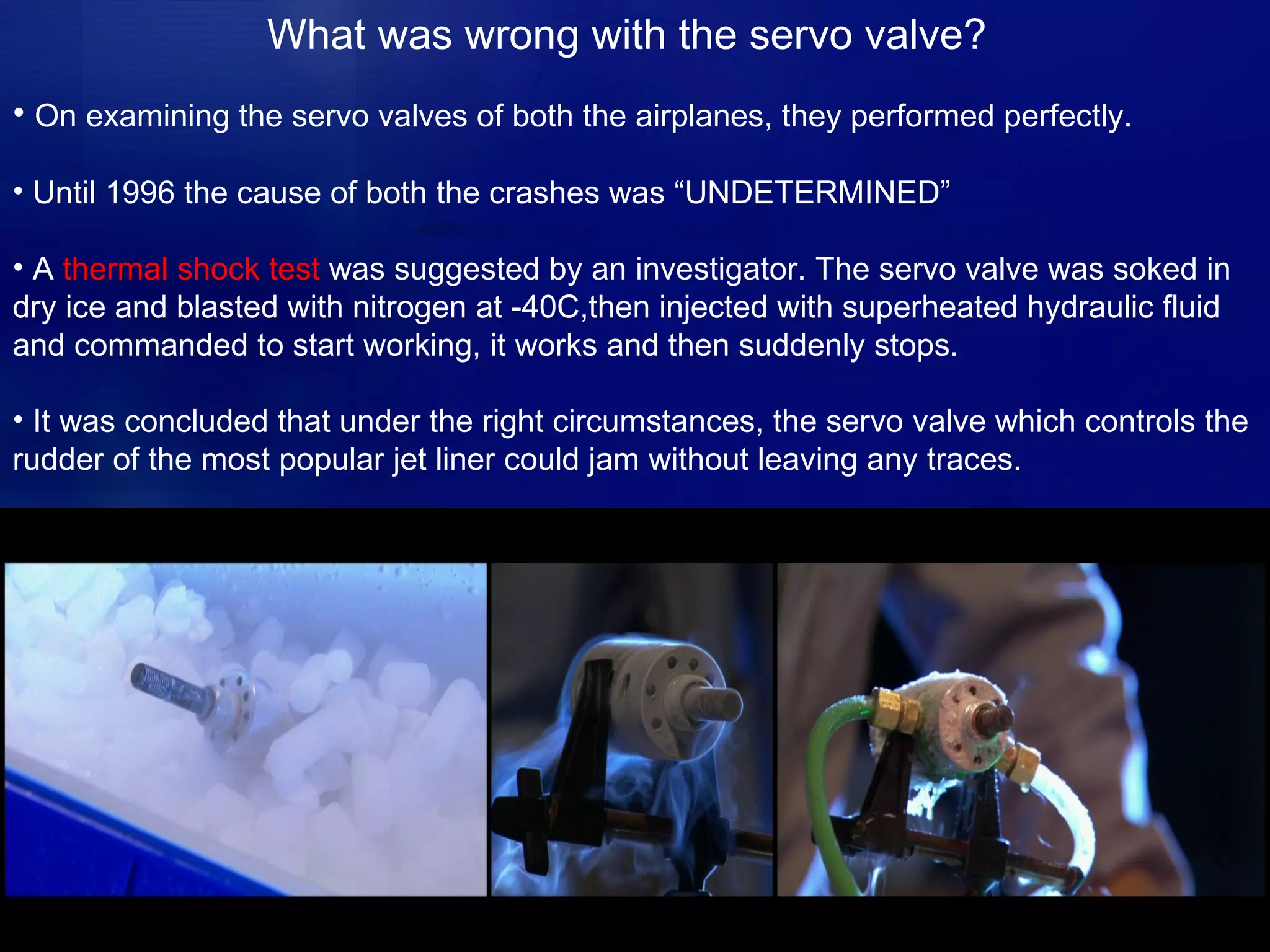

3) Two Boeing 737s, United Airlines Flight 585 in 1991 and USAir Flight 427 in 1994, crashed after the rudder power control unit (PCU) servo valve malfunctioned, causing uncontrolled descents. Testing later revealed the valve