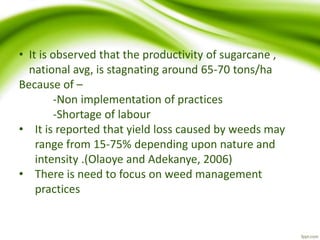

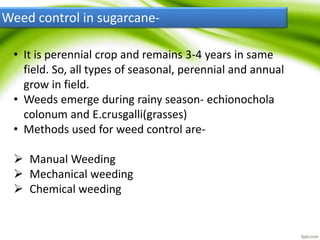

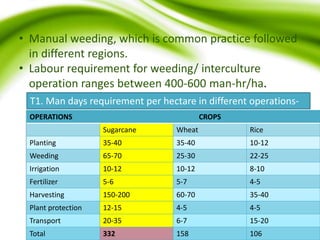

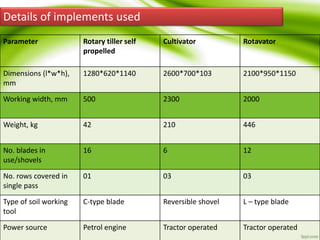

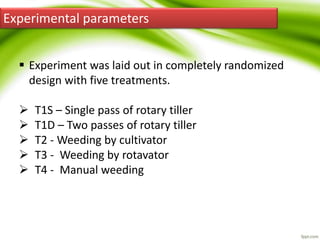

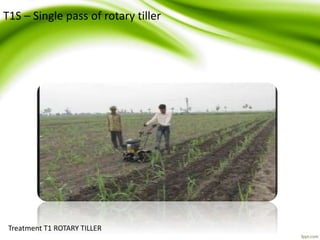

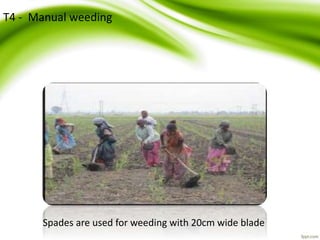

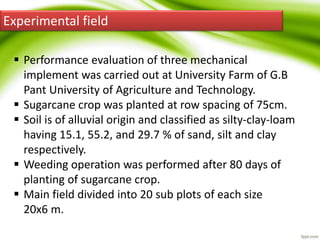

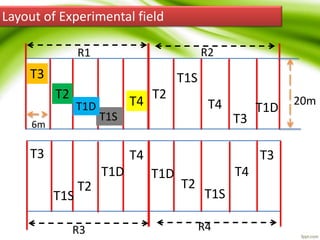

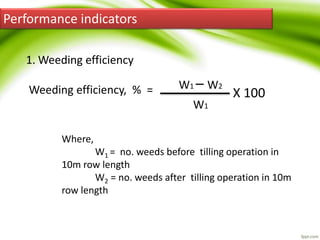

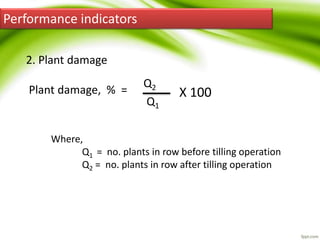

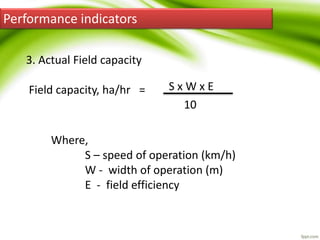

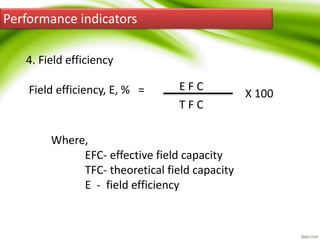

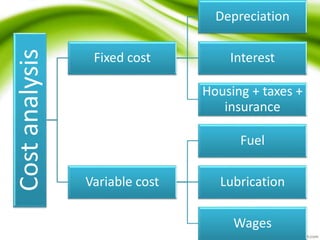

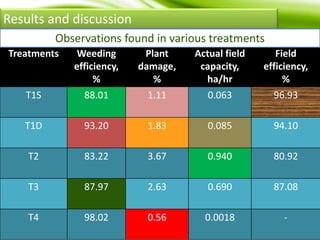

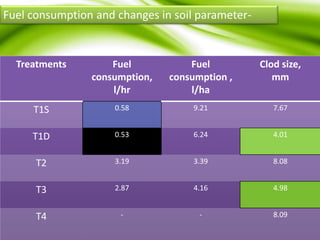

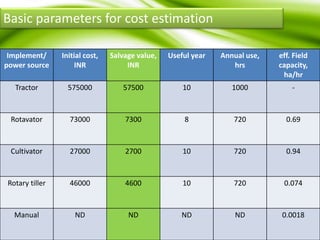

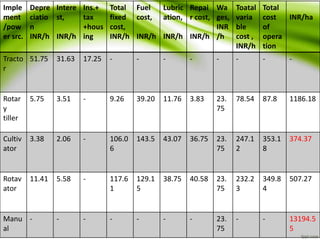

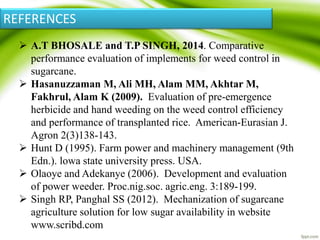

This document summarizes a seminar presentation comparing the performance of different mechanical implements for weed control in sugarcane. It describes experiments evaluating the weeding efficiency, plant damage, fuel consumption, and costs of operations using a rotary tiller, cultivator, rotavator, and manual weeding. The results showed that a single or double pass with the rotary tiller was the most effective mechanical method based on higher weeding efficiency and lower plant damage compared to the cultivator and rotavator. However, manual weeding had the highest weeding efficiency and lowest cost of operation, though it required more labor.