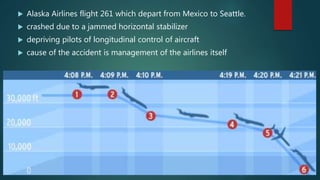

Alaska Airlines Flight 261 crashed into the Pacific Ocean near Anacapa Island, California on January 31, 2000, killing all 88 people onboard. The crash was caused by a jammed horizontal stabilizer that deprived the pilots of control of the aircraft. An investigation found that maintenance issues from extended inspection intervals and improper lubrication of the jackscrew assembly led to the failure of the stabilizer control system. Management decisions to cut costs and increase flight intervals without notifying regulators contributed to the accident.

![Wreckage recovery and analysis

Using side-scan sonar, remotely operated vehicles, and

a commercial fishing trawler,

workers recovered about 85% of the fuselage (including

the tail section) and a majority of the wing components.

In addition, both engines,

as well as the Flight Data Recorder (FDR) and CVR were

retrieved.

All wreckage that was retrieved from the crash site was

unloaded at Port Hueneme, California for examination

and documentation by NTSB investigators.[1]

Recovered jackscrew – The spiral "wire"

wound around the threaded portion is the

remains of the acme nut internal screw

thread that was stripped from the nut.](https://image.slidesharecdn.com/finalalaskaairlinesflight261presentation-180320005121/85/alaska-airlines-flight-261-Crash-6-320.jpg)