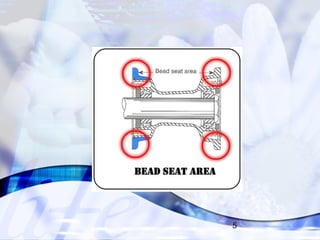

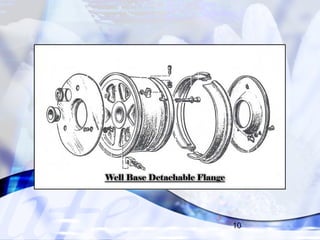

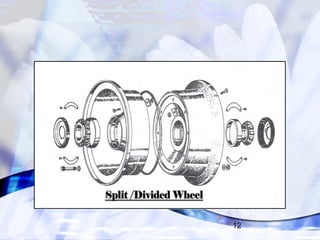

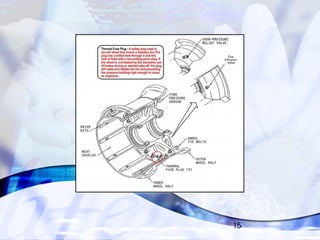

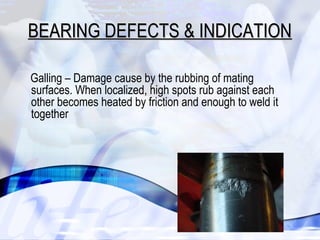

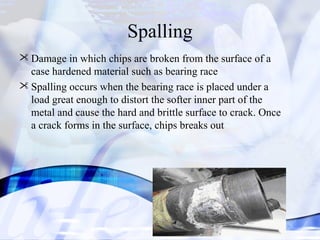

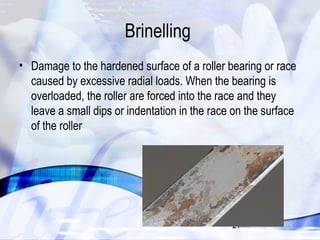

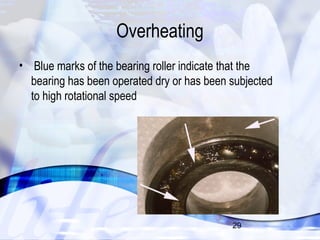

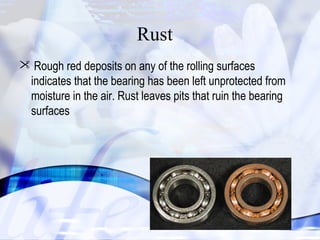

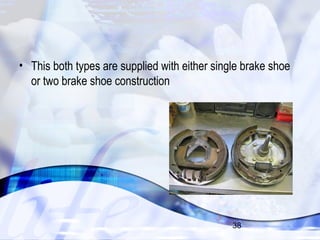

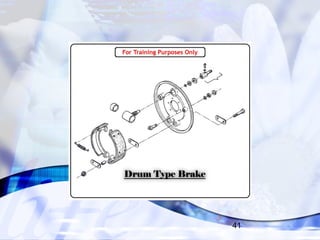

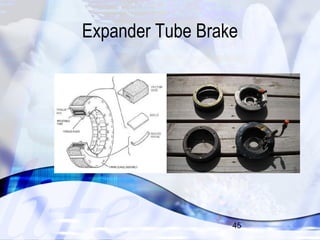

The document discusses aircraft wheel and bearing defects. It describes the different types of aircraft wheel constructions, including wheel base non-detachable flange, wheel base removable flange, and split or divided wheel. It also discusses bearing defects such as galling, spalling, brinelling, water stains, overheating, and rust. Finally, it provides an overview of aircraft brake systems, describing brake actuating units that use servo or non-energizing brakes, as well as types of non-energizing brakes like single disk, dual disk, expander tube, and multiple disc brakes.