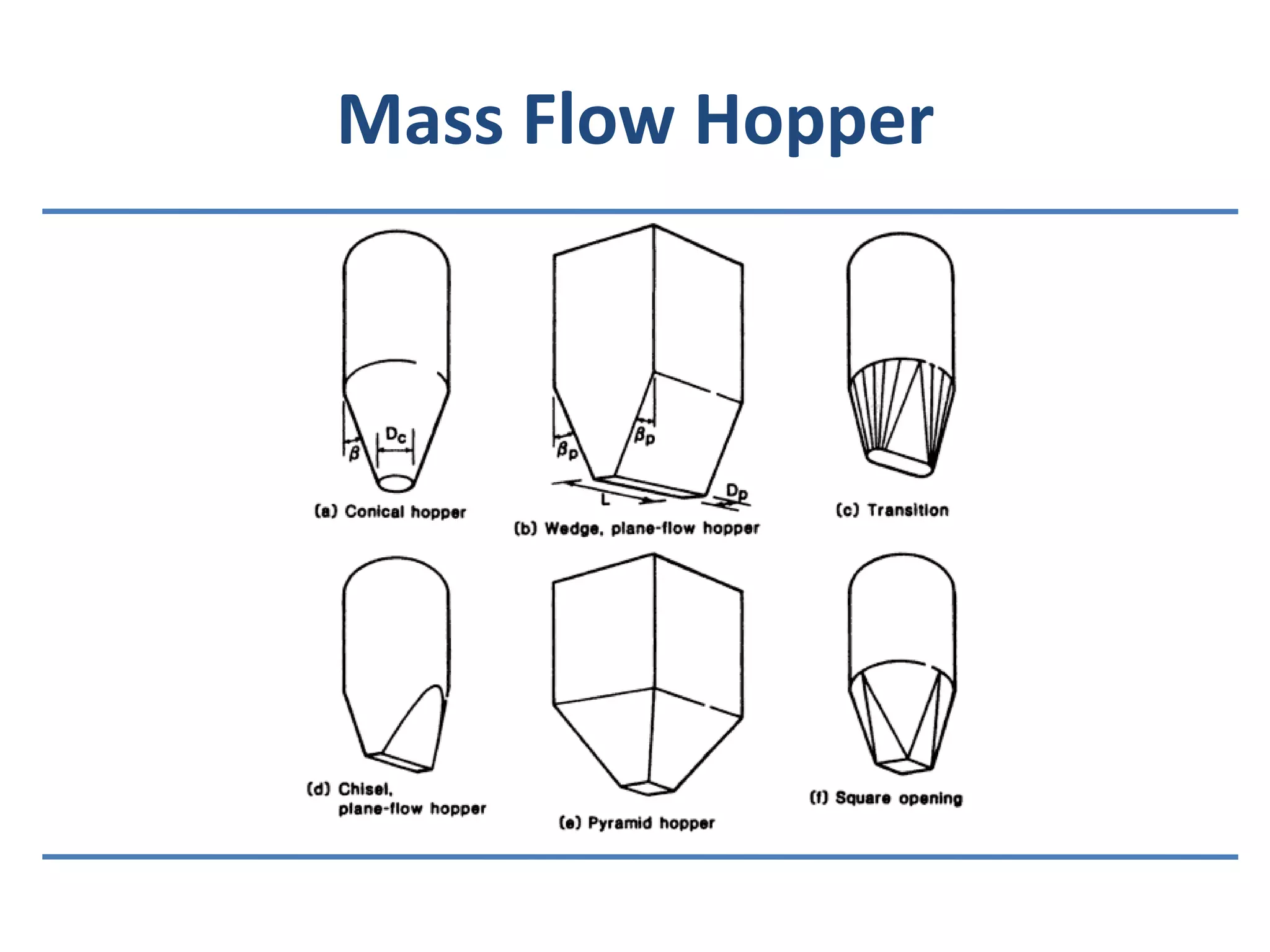

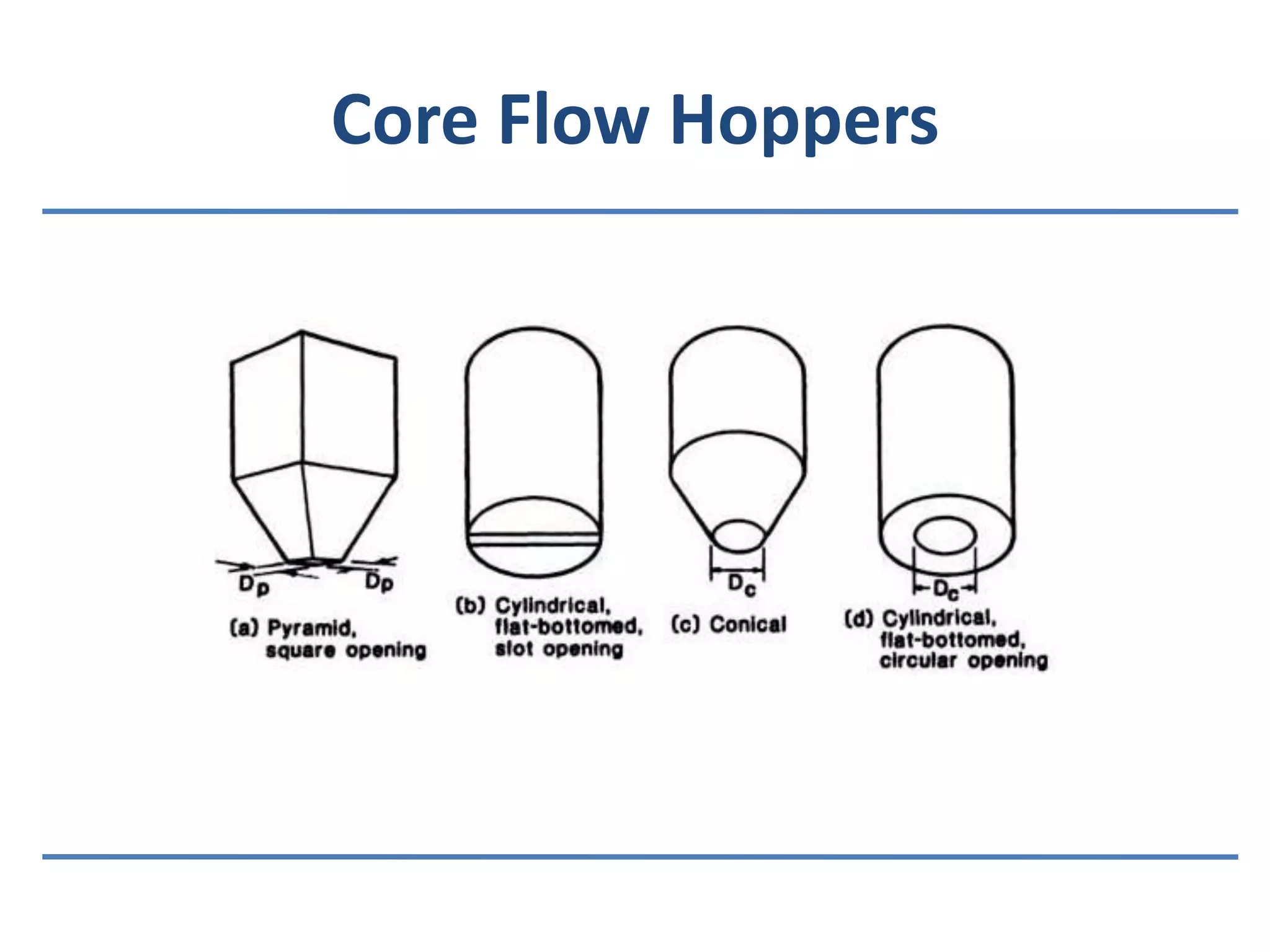

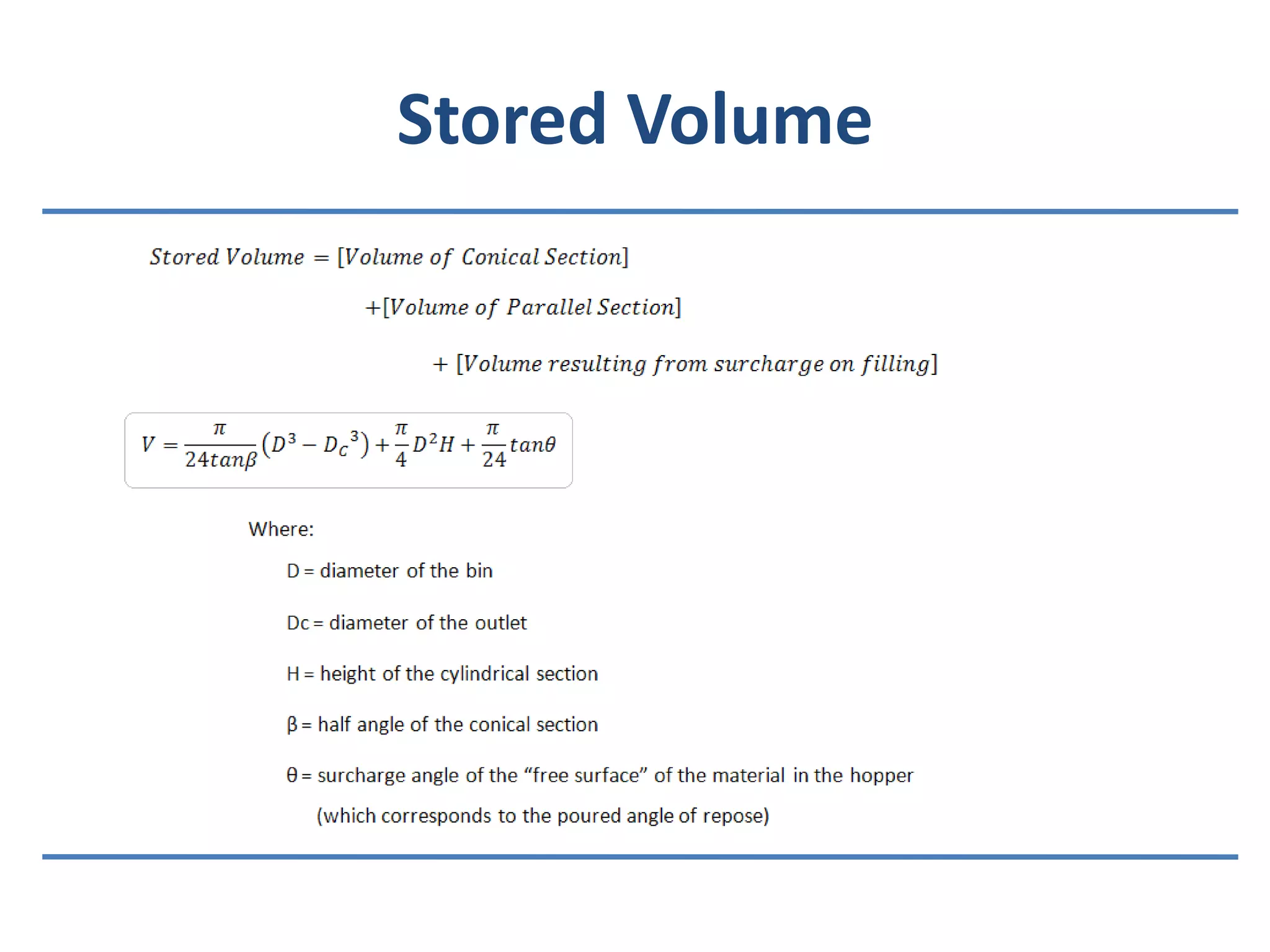

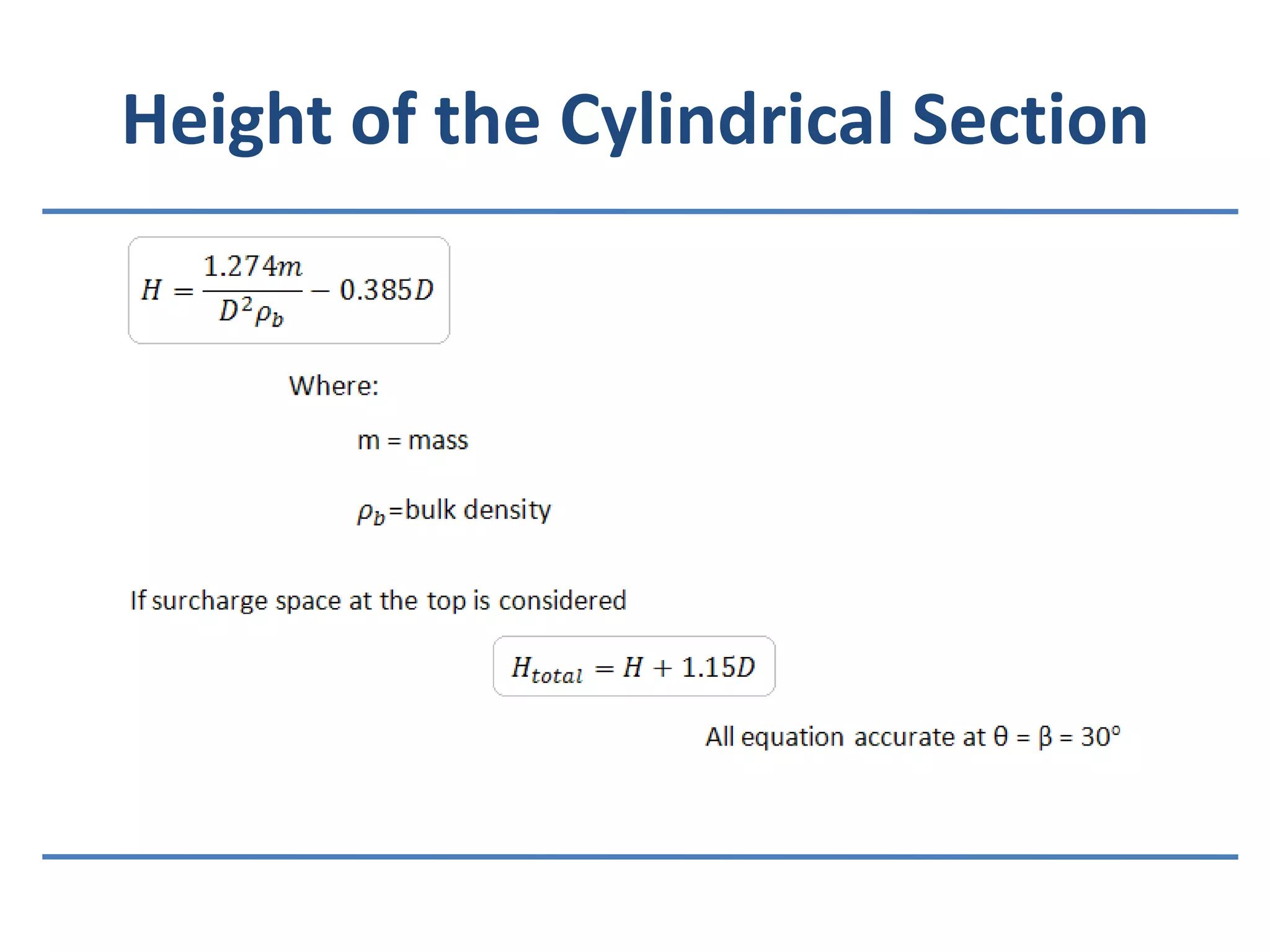

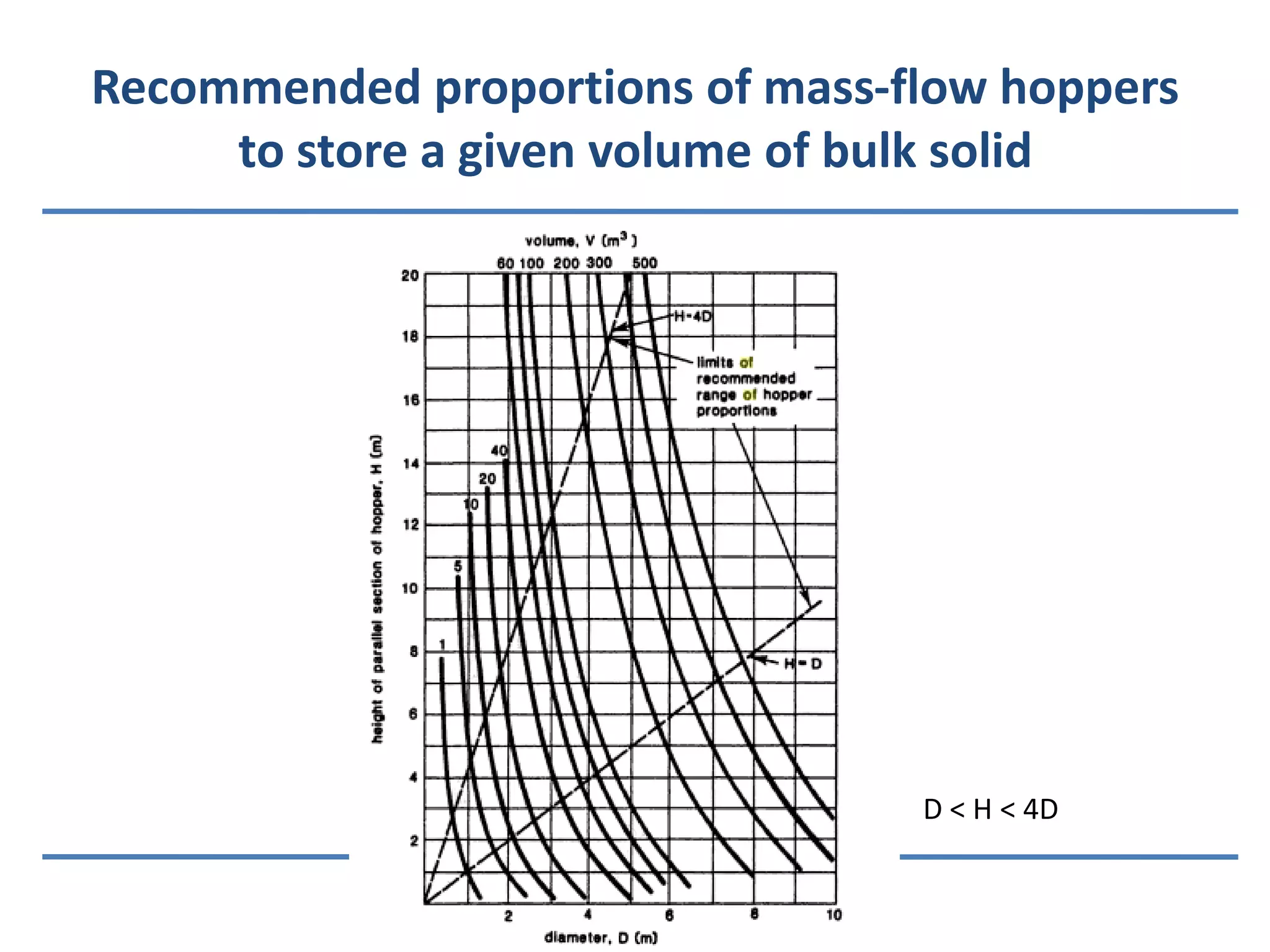

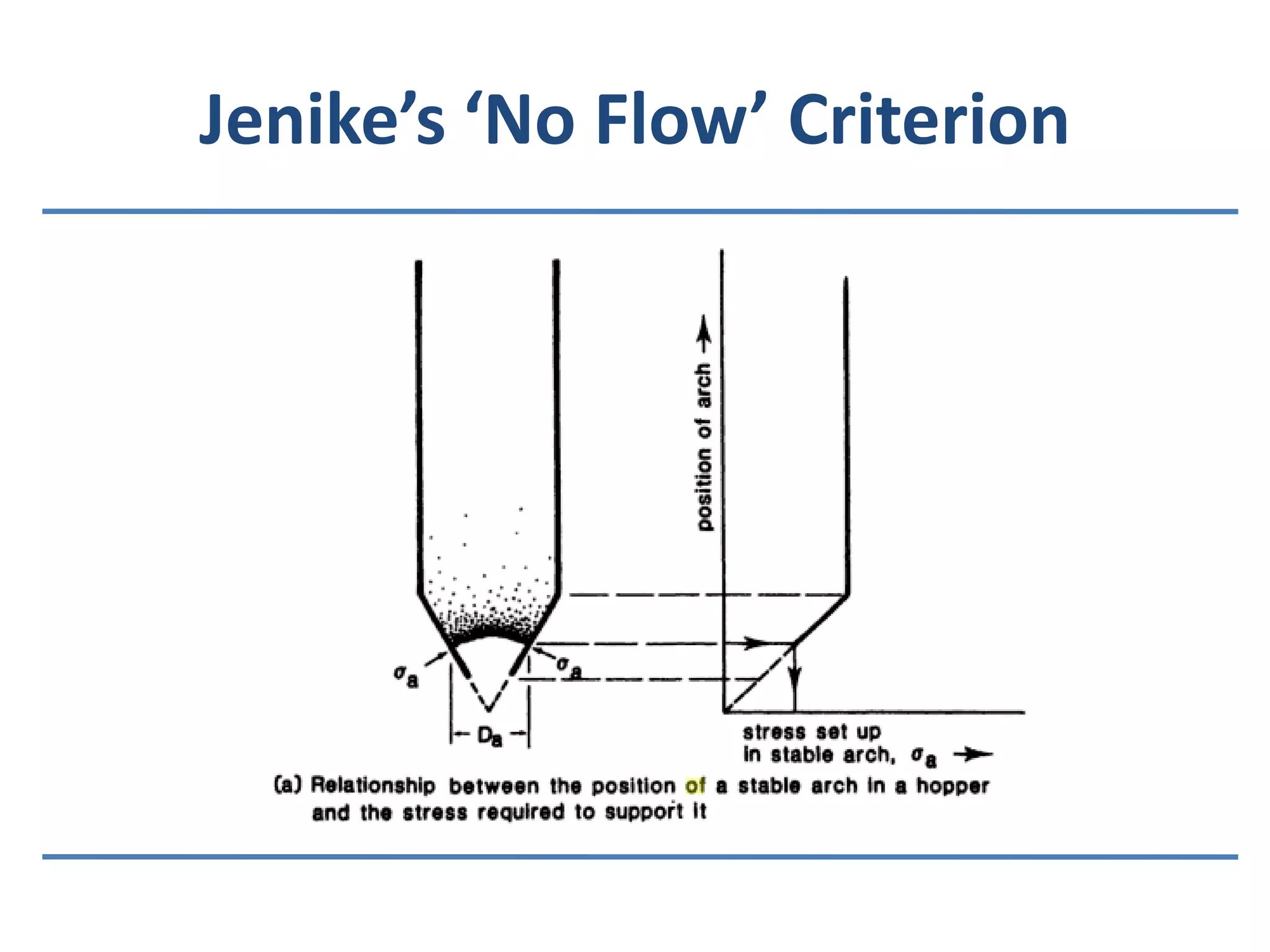

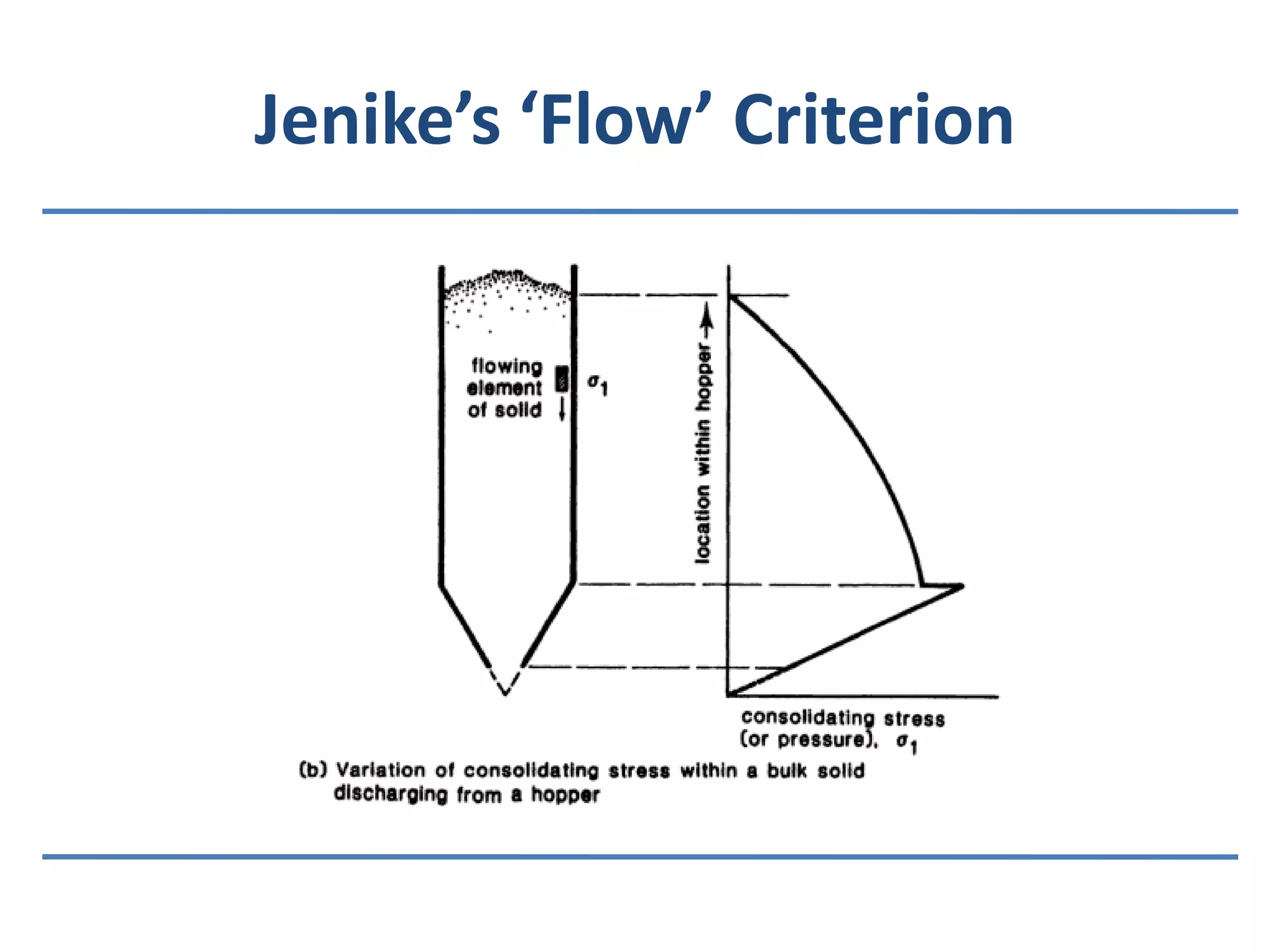

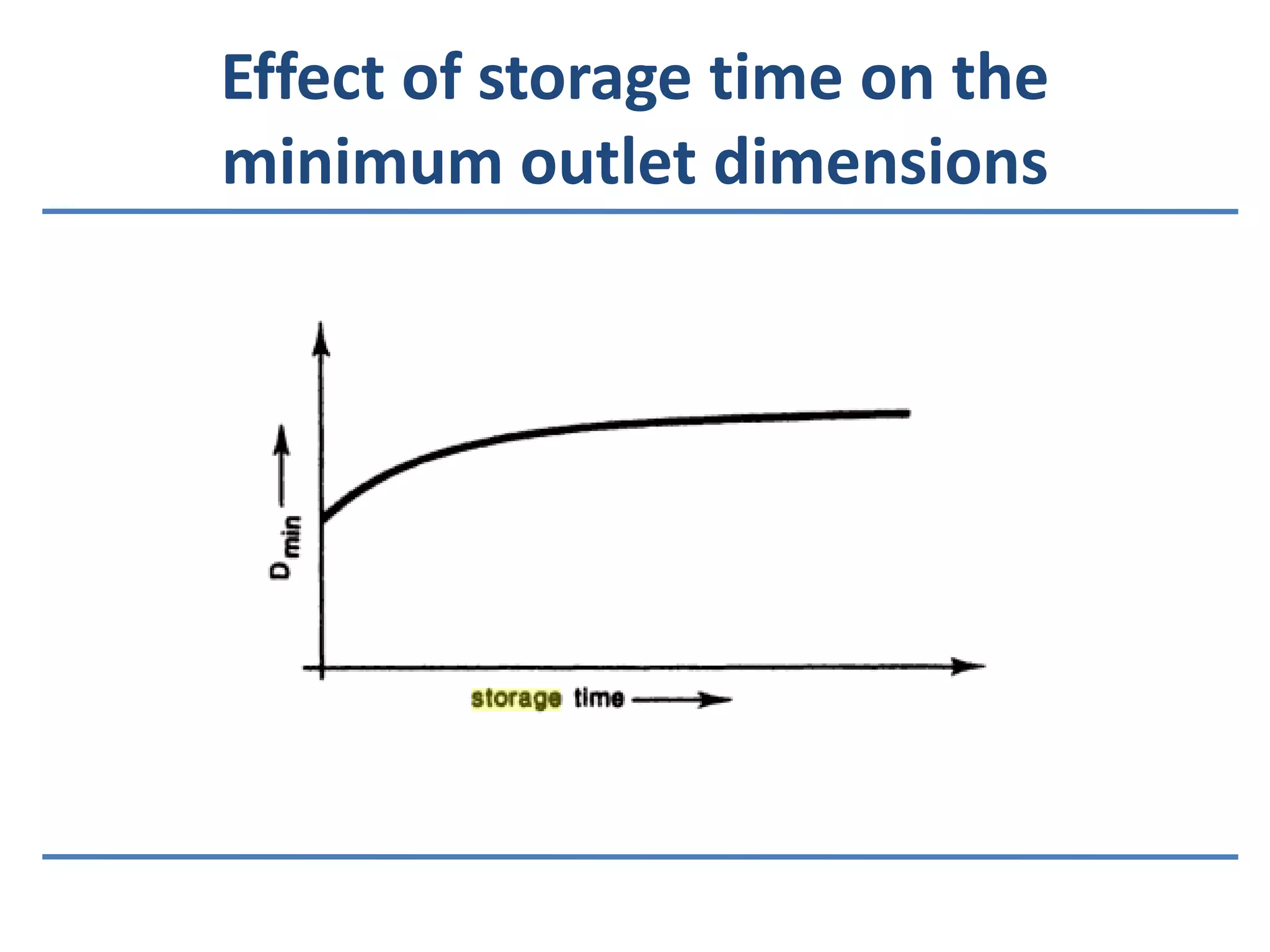

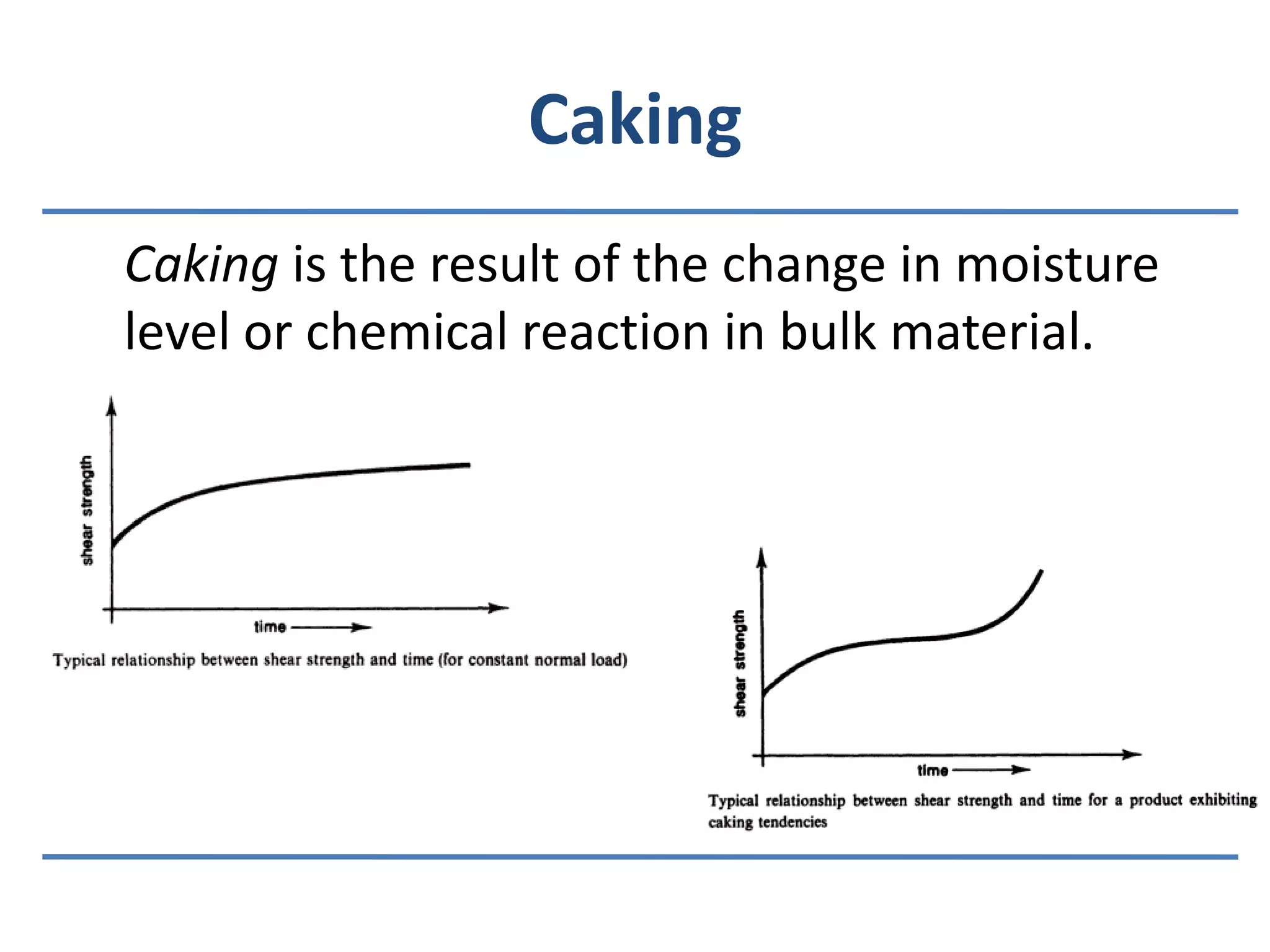

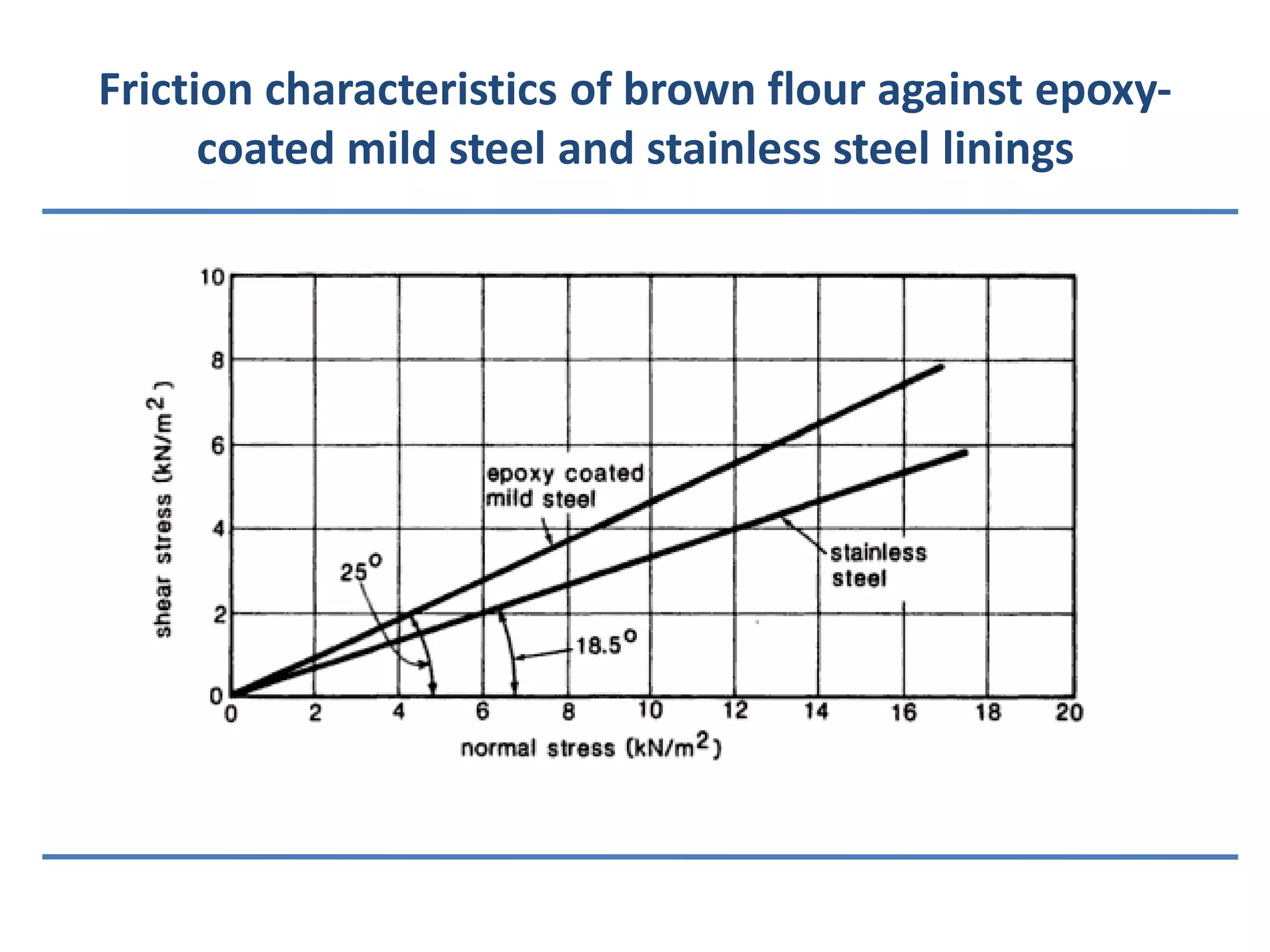

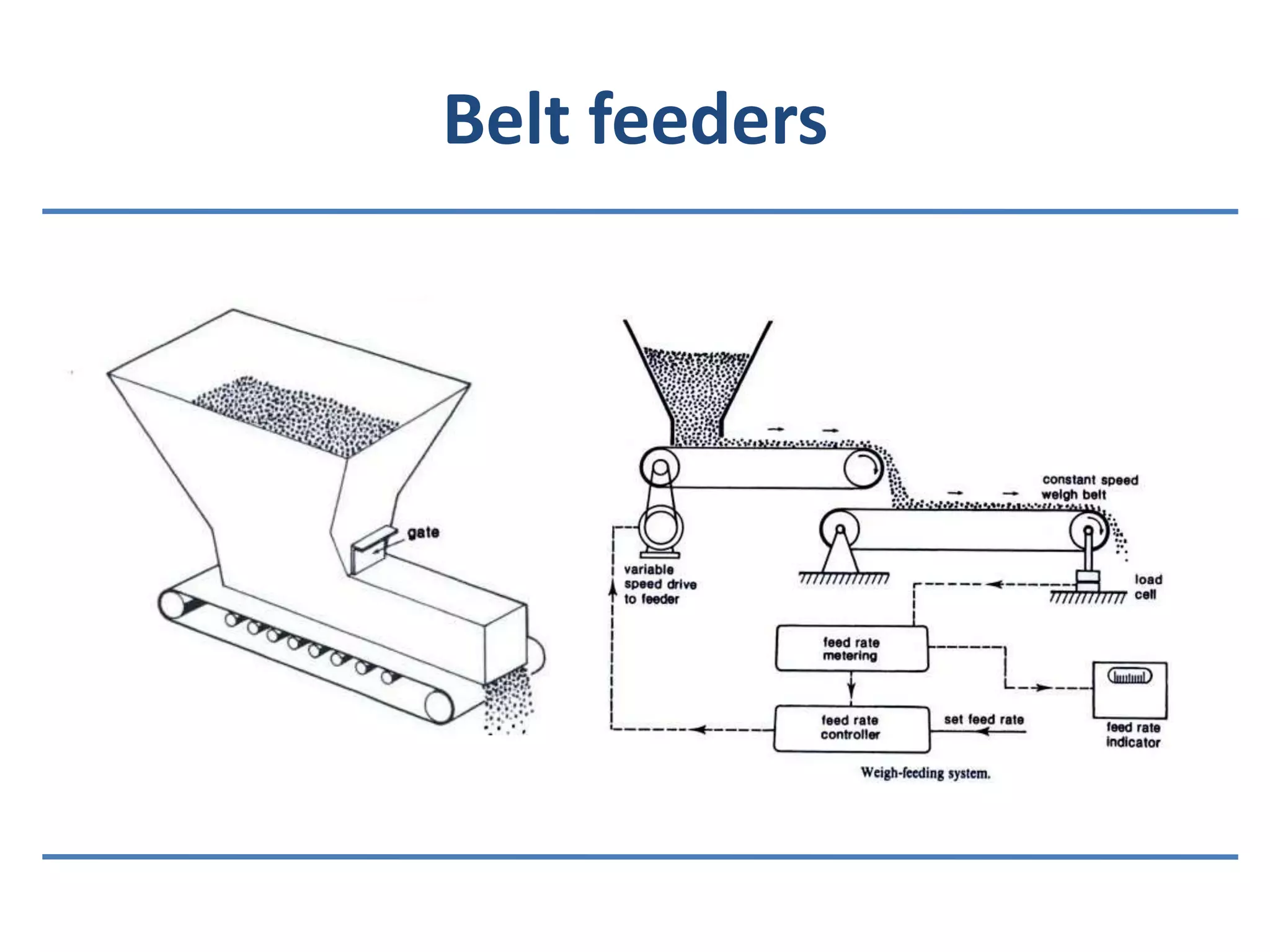

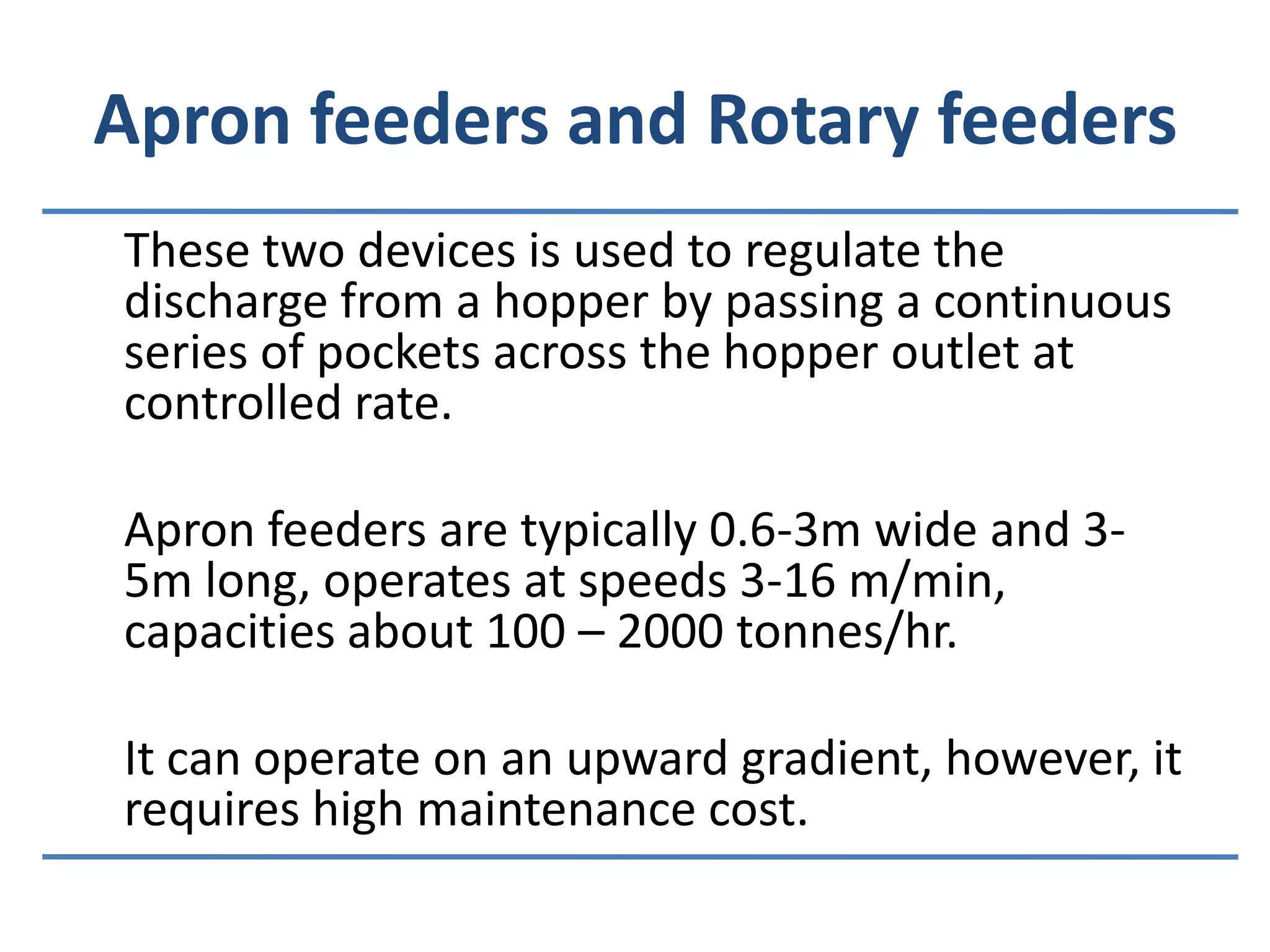

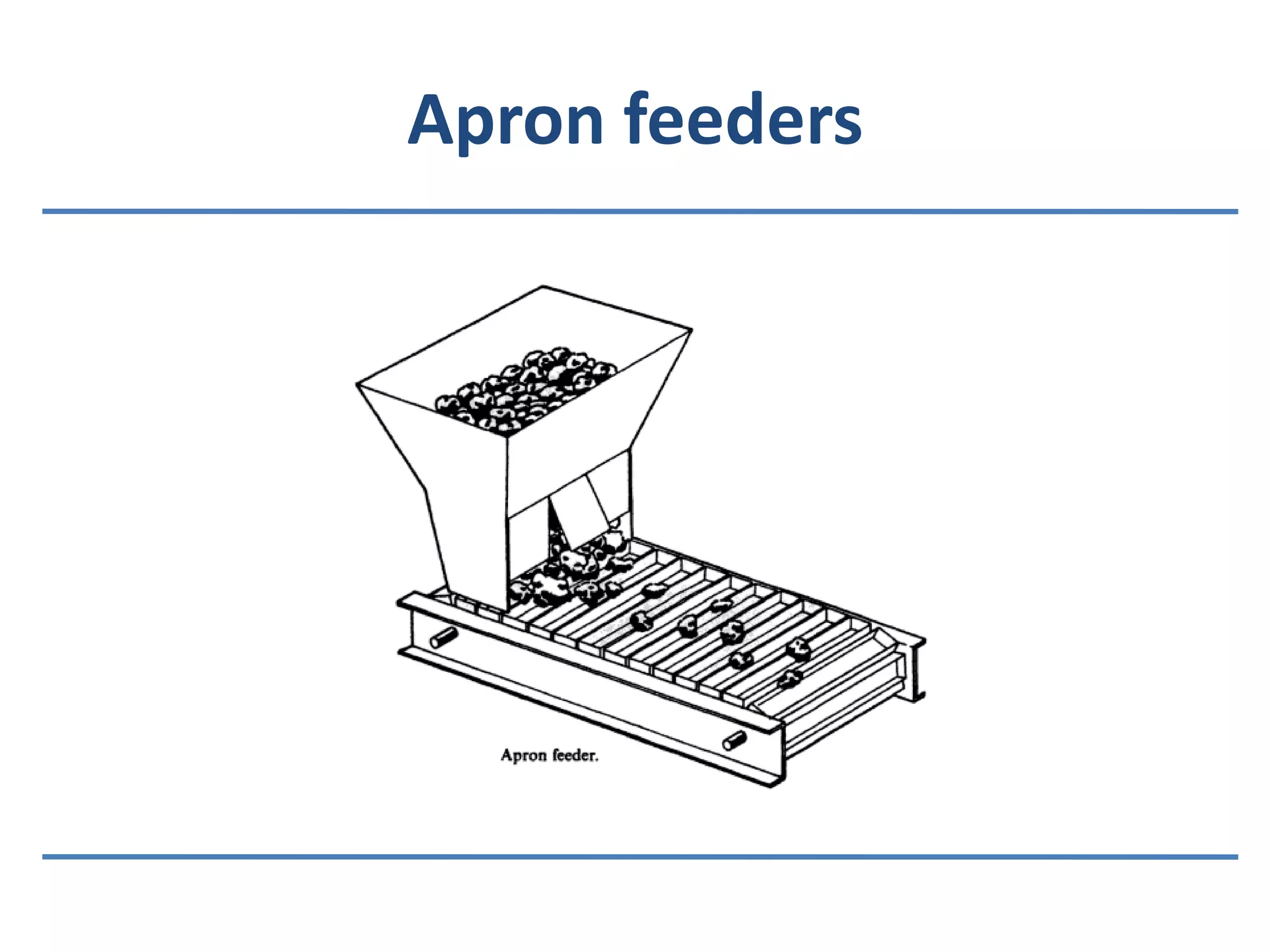

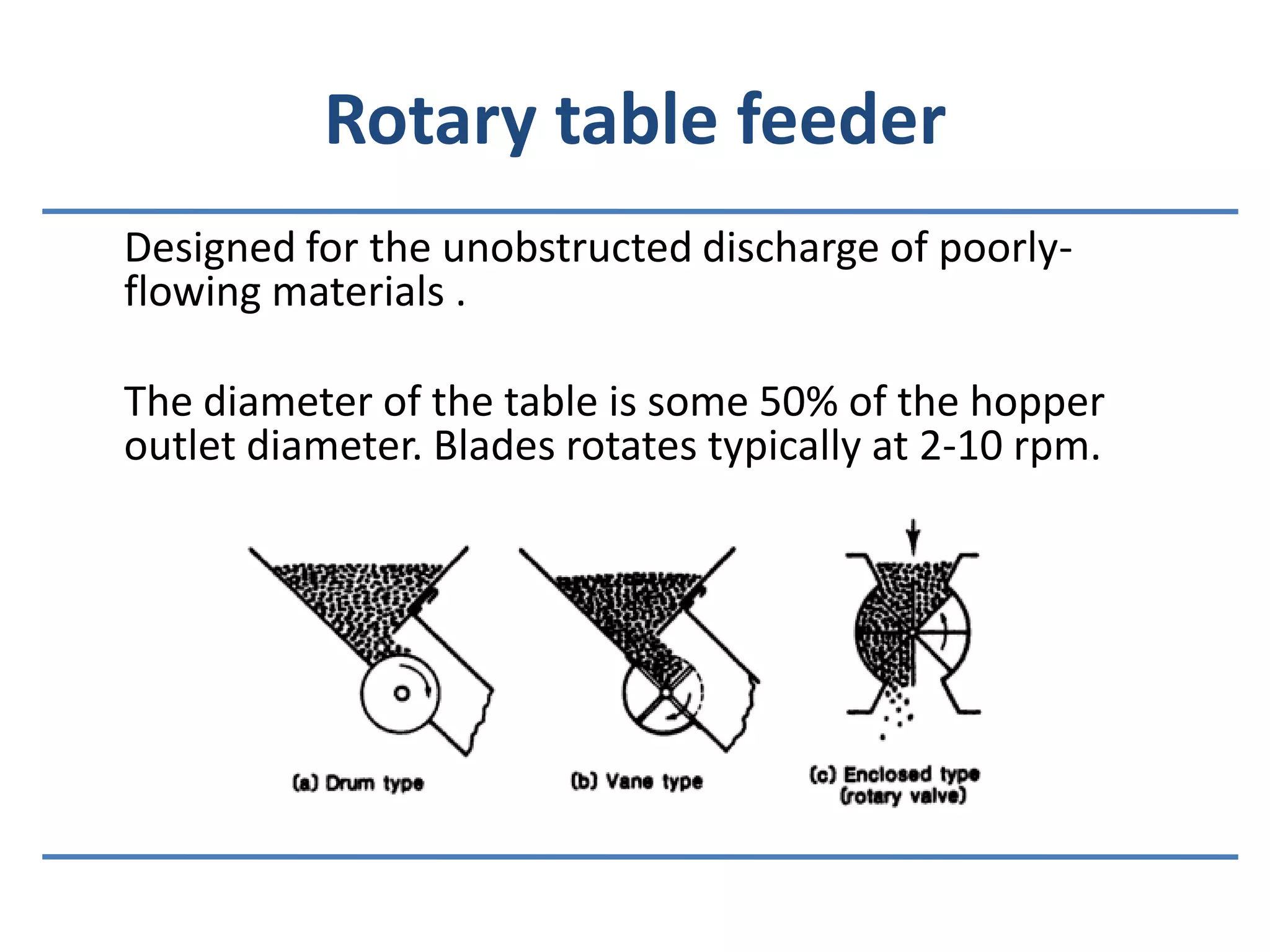

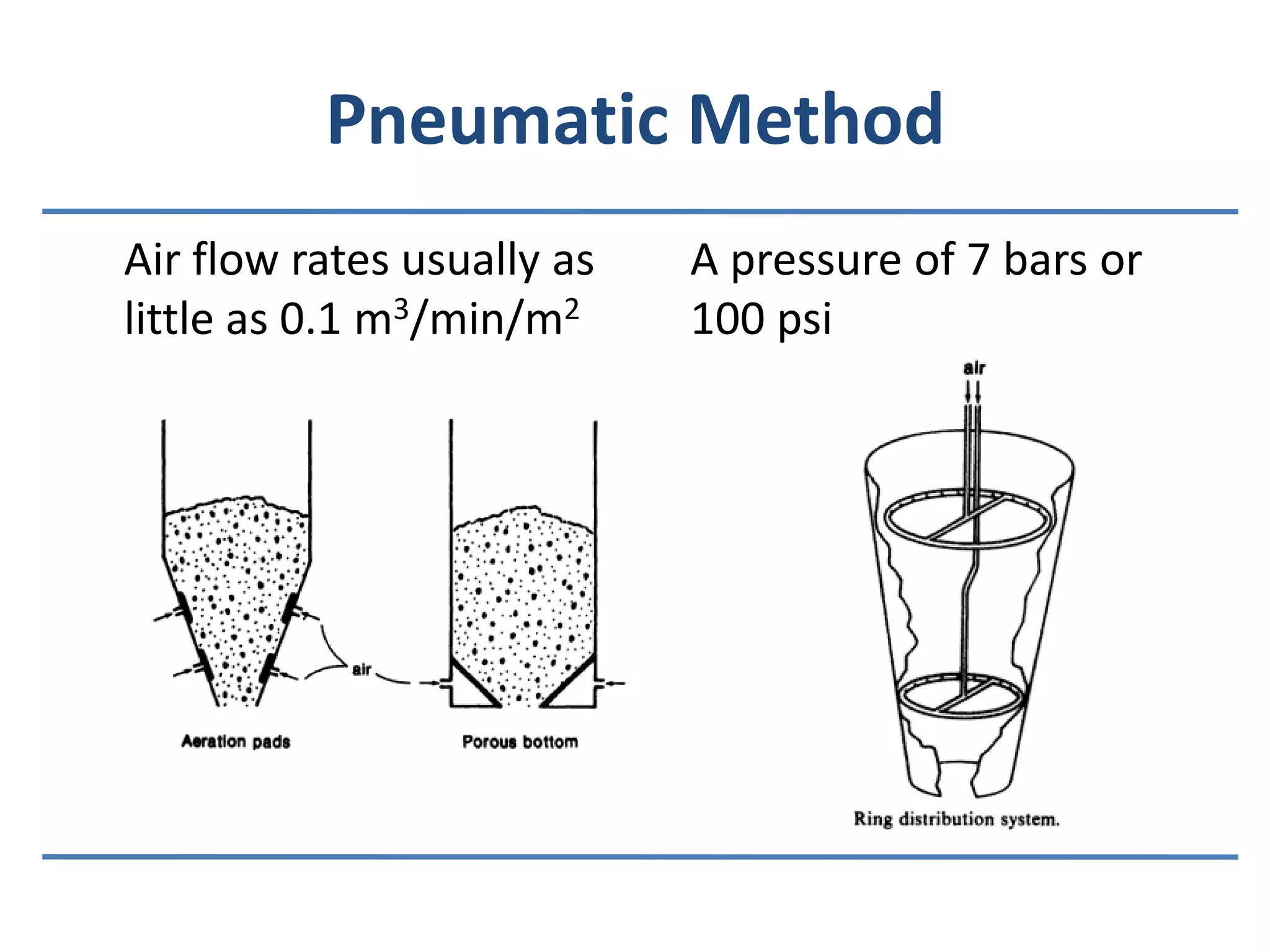

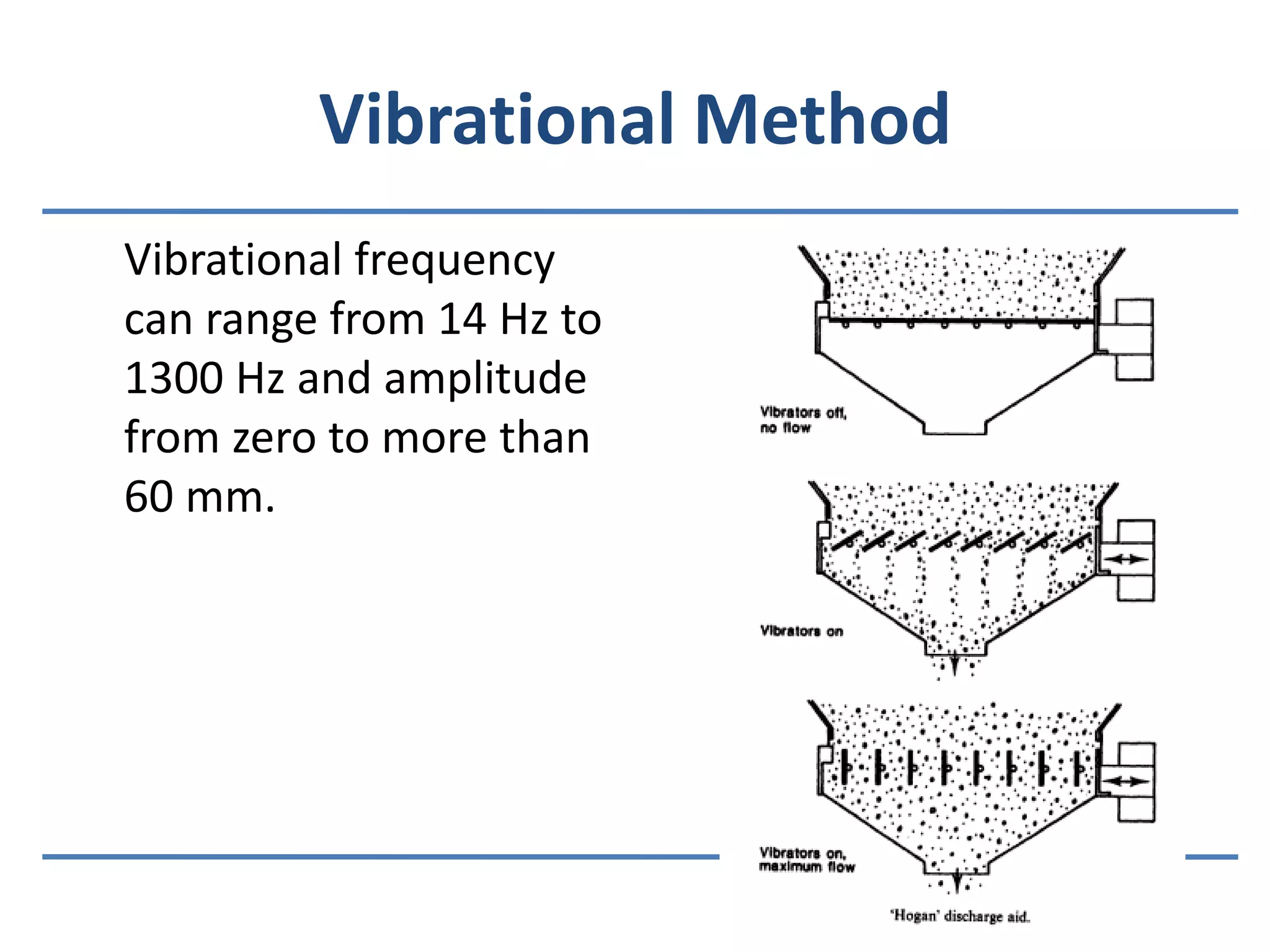

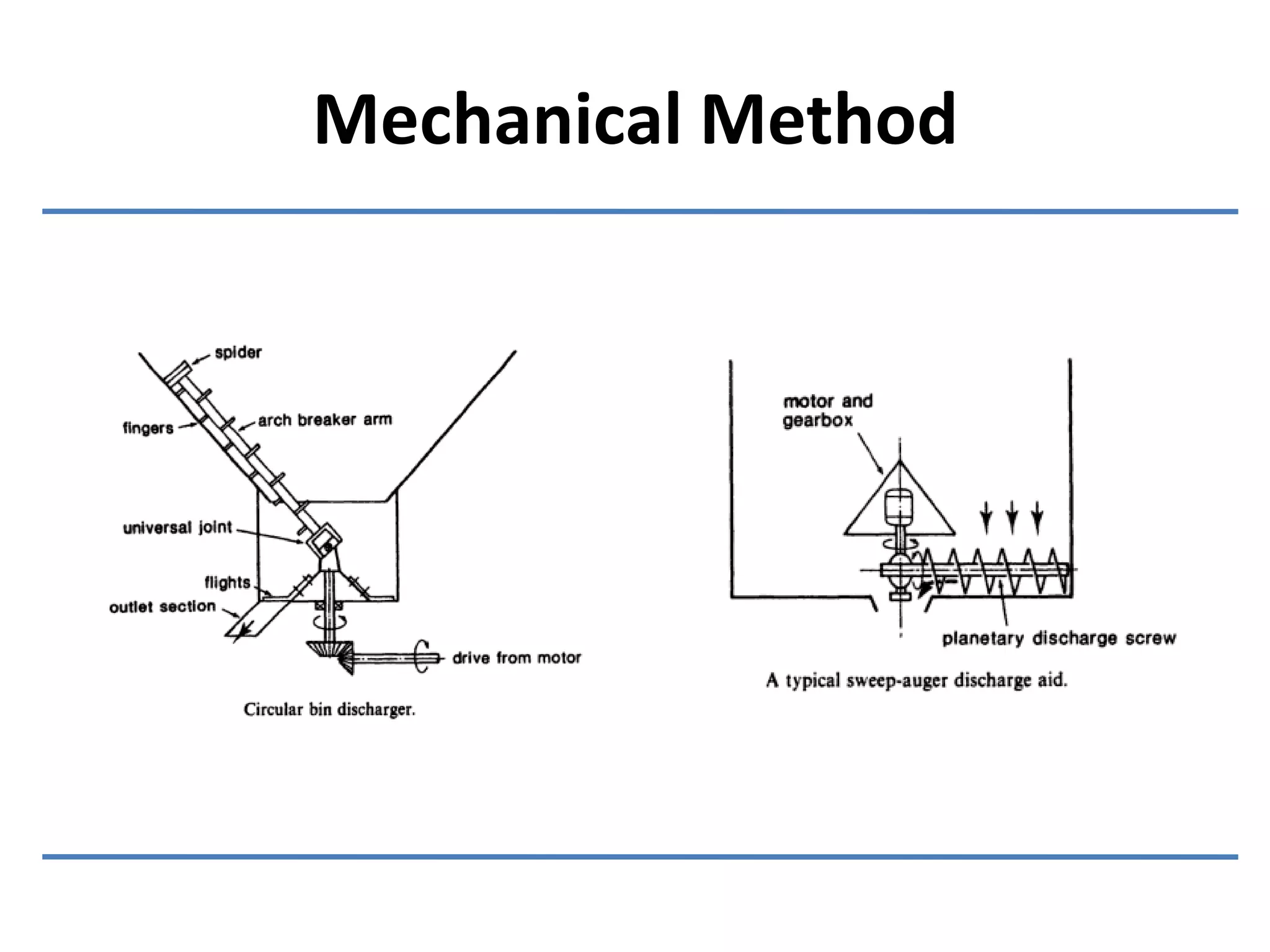

This document discusses storage bins, silos, and hoppers used to store bulk solids. It covers various design considerations for hopper discharge including throttling material flow. Mass flow and core flow hoppers are described. Recommended proportions for hopper dimensions to store a given volume are provided. Caking issues and common causes of silo failure are also summarized. Different types of mechanical feeders used to regulate discharge from hoppers are introduced, including belt, apron, rotary table, and screw feeders. Pneumatic and vibrational methods for discharging material are briefly outlined.